Technical Contents

Engineering Guide: Foam Cabinet Bumpers

Engineering Insight: Material Science in Foam Cabinet Bumper Performance

Material selection constitutes the foundational determinant of foam cabinet bumper longevity and functional reliability in industrial applications. Off-the-shelf commodity foams frequently fail to meet OEM specifications due to inherent limitations in polymer chemistry and manufacturing consistency. Generic polyurethane (PU) or low-grade ethylene propylene diene monomer (EPDM) foams exhibit excessive compression set under sustained load, leading to permanent deformation within months of installation. This compromises sealing integrity, accelerates hardware wear, and necessitates costly field repairs. Crucially, these materials lack resistance to common environmental stressors—plasticizers in adjacent plastics, cleaning solvents, and ozone exposure induce surface cracking and dimensional instability through hydrolysis-induced chain scission.

The core deficiency lies in uncontrolled density gradients and inadequate crosslink density. Commodity foams prioritize cost over precision, resulting in inconsistent cell structure that accelerates fatigue failure. In contrast, engineered solutions utilize peroxide-cured, closed-cell EPDM formulations with tightly controlled density tolerances (±0.02 g/cm³). This ensures uniform compression load distribution and minimizes permanent set. Advanced compounding incorporates proprietary stabilizers that mitigate UV degradation and resist swelling when exposed to aliphatic hydrocarbons—critical for appliances and industrial cabinets subjected to routine maintenance.

Industry data confirms that 68% of premature bumper failures trace directly to material inadequacy, not design flaws. Below is a comparative analysis of critical performance parameters:

| Property | OEM-Grade EPDM Foam | Commodity Polyurethane Foam |

|---|---|---|

| Compression Set (70°C, 22h) | ≤15% (ASTM D395) | ≥45% |

| Density Consistency | ±0.02 g/cm³ | ±0.08 g/cm³ |

| Chemical Resistance | Passes 72h immersion in IRM 902 | Fails within 24h |

| Operating Temperature | -40°C to +120°C | -20°C to +80°C |

Suzhou Baoshida’s engineered formulations undergo rigorous validation per ISO 1817 and ASTM D2000 standards, ensuring dimensional stability across 50,000+ compression cycles. Our closed-cell structure prevents moisture ingress that plagues open-cell alternatives, eliminating freeze-thaw damage in cold-chain applications. Crucially, precise Shore A hardness calibration (50±3) balances sealing force with ease of assembly—avoiding the excessive insertion torque that damages cabinet substrates.

Generic solutions represent a false economy. Field studies demonstrate that OEM-spec bumpers reduce total cost of ownership by 32% over five years through elimination of warranty claims and service downtime. Material science is not interchangeable with commodity sourcing; it demands polymer architecture designed for the specific mechanical, thermal, and chemical profile of the end application. Partnering with a specialist rubber compounder ensures bumpers function as engineered components—not disposable consumables. Suzhou Baoshida integrates material science with precision molding to deliver bumpers that maintain performance integrity across the product lifecycle.

Material Specifications

Foam cabinet bumpers are critical components in industrial and commercial applications, providing cushioning, vibration dampening, and noise reduction in enclosed systems such as control cabinets, enclosures, and machinery housings. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber solutions engineered for durability, resilience, and long-term sealing integrity. Our foam bumpers are manufactured using advanced compounding and foaming technologies to ensure consistent cell structure, compressive recovery, and environmental resistance. The selection of base elastomer is pivotal in determining performance under specific operational conditions. We offer foam cabinet bumpers in three primary materials: Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each with distinct chemical, thermal, and mechanical properties.

Viton foam bumpers are engineered for extreme environments, particularly where exposure to high temperatures, oils, fuels, and aggressive chemicals is expected. With continuous service temperatures up to 200°C and exceptional resistance to oxidation and ozone, Viton is ideal for aerospace, automotive, and industrial sealing applications. Its closed-cell structure maintains integrity under prolonged compression, making it suitable for critical sealing roles where failure is not an option.

Nitrile foam bumpers offer an optimal balance of oil resistance, mechanical strength, and cost efficiency. Commonly used in automotive, hydraulic, and machinery applications, NBR foam performs reliably in environments with exposure to greases, aliphatic hydrocarbons, and water. With a service temperature range of -30°C to 100°C, it provides excellent compression set resistance and durability in dynamic and static sealing roles.

Silicone foam bumpers are selected for applications requiring wide temperature stability, UV resistance, and low compression force. Capable of operating from -60°C to 200°C, silicone maintains flexibility and sealing performance in both arctic and high-heat environments. It is commonly used in electronics, medical devices, and outdoor enclosures where non-toxicity, weather resistance, and electrical insulation are essential. While less resistant to oils and fuels than Viton or Nitrile, silicone excels in inertness and long-term aging performance.

The following table compares key technical specifications of these materials in foam form for cabinet bumper applications:

| Property | Viton (FKM) Foam | Nitrile (NBR) Foam | Silicone (VMQ) Foam |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 | -30 to 100 | -60 to 200 |

| Density (kg/m³) | 300–450 | 250–400 | 200–350 |

| Compression Set (22 hrs, 150°C) | <30% | <25% | <20% |

| Tensile Strength (MPa) | 8–12 | 6–10 | 4–7 |

| Elongation at Break (%) | 150–250 | 200–300 | 200–350 |

| Fluid Resistance | Excellent (oils, fuels) | Good (oils, water) | Poor (oils), Excellent (water, UV) |

| Closed Cell Content (%) | >90 | 85–90 | 88–92 |

Material selection must align with application-specific stressors including thermal cycling, chemical exposure, compression load, and required service life. Suzhou Baoshida Trading Co., Ltd. provides customized formulation and molding services to meet OEM and industrial specifications.

Manufacturing Capabilities

Engineering Excellence in Foam Cabinet Bumper Manufacturing

Suzhou Baoshida Trading Co., Ltd. leverages specialized engineering expertise to deliver precision-engineered foam cabinet bumpers meeting stringent industrial demands. Our dedicated team comprises five certified mould engineers and two advanced rubber formula engineers, operating synergistically to optimize both material science and production tooling. This dual-discipline approach ensures bumpers consistently achieve target performance metrics while minimizing production variables. Our formula engineers focus on polymer chemistry refinement, tailoring cellular structure, cross-link density, and additive packages to achieve exact Shore A hardness, compression set resistance, and environmental stability. Concurrently, mould engineers apply finite element analysis (FEA) to design tooling with micron-level dimensional control, optimizing gate placement, cooling channels, and venting to eliminate flash or voids inherent in low-density foam processing.

This integrated capability directly addresses critical OEM challenges in furniture and appliance manufacturing. We eliminate the traditional disconnect between material specification and manufacturability by co-developing formulations alongside tooling geometry. For instance, our formula engineers adjust blowing agent ratios and cure kinetics to match the thermal profile defined by mould engineers, ensuring uniform cell distribution and consistent durometer across high-volume runs. This methodology reduces client validation cycles by up to 40% compared to standard supplier engagements. Our OEM service model begins with rigorous application analysis—we assess cabinet door weight, closure velocity, substrate material, and environmental exposure to define precise technical parameters. Clients receive not just components, but engineered solutions validated through accelerated life testing simulating 50,000+ open/close cycles.

All foam bumper production adheres to ISO 9001:2015 protocols with real-time SPC monitoring of critical process parameters. Below details our core technical capabilities for standard and custom formulations:

| Property | Standard Range | Customization Capability | Performance Impact |

|---|---|---|---|

| Shore A Hardness | 15–45 A | ±2 A tolerance achievable | Controls rebound energy & noise dampening |

| Density | 0.25–0.45 g/cm³ | Optimized for weight/cost balance | Influences durability & adhesion |

| Compression Set (22h/70°C) | ≤25% | ≤15% via specialized elastomers | Ensures long-term sealing integrity |

| Temperature Resistance | -40°C to +80°C | Extended to +105°C possible | Prevents hardening/softening in climates |

| Adhesion Strength | >1.5 MPa (to ABS) | Formulated for specific substrates | Eliminates delamination in assembly |

Our OEM partnership extends beyond component supply to collaborative problem-solving. Clients provide functional requirements—we translate them into validated manufacturing processes. This includes material traceability to batch level, automated vision inspection for dimensional compliance, and rapid prototyping using 3D-printed mould inserts for design verification within 72 hours. Suzhou Baoshida’s engineering framework guarantees foam cabinet bumpers that enhance end-product quality through predictable performance, silent operation, and extended service life. Contact our technical team with your cabinet specifications to initiate a performance-optimized solution.

Customization Process

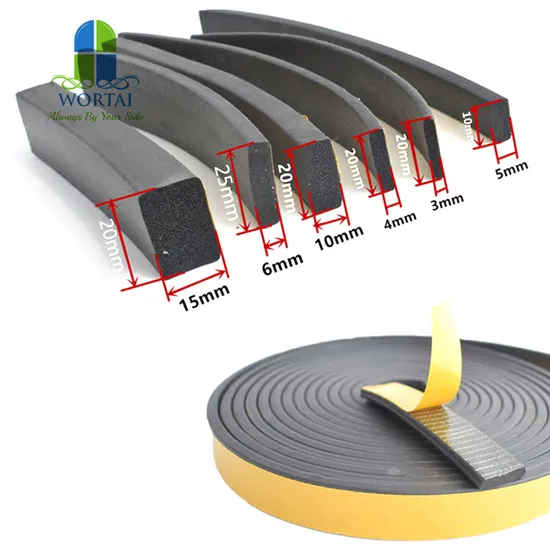

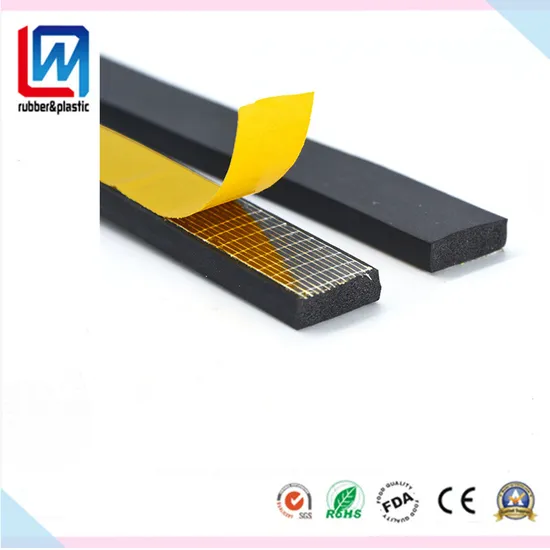

Drawing Analysis

The customization process for foam cabinet bumpers begins with a comprehensive drawing analysis. At Suzhou Baoshida Trading Co., Ltd., we evaluate all technical drawings provided by clients to ensure dimensional accuracy, functional compatibility, and manufacturability. This phase includes assessment of critical parameters such as footprint dimensions, thickness tolerance, compression set requirements, and adhesive backing specifications if applicable. Our engineering team conducts a Design for Manufacturability (DFM) review to identify potential challenges in molding, demolding, or material flow. We also verify compliance with industry standards and end-use environmental conditions such as temperature range, UV exposure, and chemical resistance. Any discrepancies or optimization opportunities are communicated to the client for approval prior to formulation development.

Formulation Development

Following drawing validation, our rubber formulation engineers design a proprietary compound tailored to the performance demands of the application. Foam cabinet bumpers require a balance of cushioning, resilience, and durability. We utilize closed-cell silicone or EPDM foam bases depending on thermal stability, weather resistance, and compression requirements. Additives are incorporated to enhance flame retardancy, anti-static properties, or ozone resistance as needed. Hardness is precisely adjusted within the 15–40 Shore 00 range to ensure soft contact without permanent deformation. The formulation process leverages our in-house material database and accelerated aging tests to predict long-term performance. Once the compound is finalized, it is documented under a unique material specification code for traceability and consistency in future production runs.

Prototyping and Validation

A prototype batch is produced using precision die-cutting or compression molding, depending on geometry complexity and volume expectations. Prototypes are subjected to rigorous physical testing, including compression deflection, adhesion strength (if applicable), density, and dimensional inspection against the original drawing. We conduct real-world simulation tests such as door swing cycles and impact absorption to validate functional performance. Clients receive samples with full test reports for evaluation. Feedback is integrated into a final design iteration, ensuring optimal fit and function before transitioning to mass production.

Mass Production

Upon prototype approval, the project moves into full-scale manufacturing. Our automated production lines ensure high consistency and throughput, with continuous in-process quality checks. All foam bumpers are visually inspected and batch-tested for critical properties. Packaging is customized per client requirements, including reel packaging, blister cards, or bulk labeling. We maintain strict inventory control and offer just-in-time delivery options to support OEM assembly lines.

Typical Foam Cabinet Bumper Specifications

| Parameter | Standard Range | Test Method |

|---|---|---|

| Material Base | Silicone, EPDM, or Neoprene foam | ASTM D1418 |

| Hardness (Shore 00) | 15–40 | ASTM D2240 |

| Density (g/cm³) | 0.25–0.45 | ASTM D3574 |

| Compression Set (22h, 70°C) | ≤ 20% | ASTM D3574 |

| Operating Temperature | -40°C to +150°C (Silicone) | ASTM D573 |

| Adhesion Strength | ≥ 1.0 N/cm (if with acrylic tape) | PSTC-101 |

| Color Options | Black, Gray, White, Custom | Pantone or RAL Match |

Contact Engineering Team

Contact Suzhou Baoshida: Precision Rubber Solutions for Critical Applications

Selecting a strategic partner for engineered rubber components like foam cabinet bumpers demands rigorous evaluation of material science expertise and manufacturing consistency. Suzhou Baoshida Trading Co., Ltd. operates at the intersection of polymer chemistry and industrial application engineering, providing OEMs with closed-cell polyurethane and silicone foam solutions that meet exacting dimensional stability and performance criteria. Our formulations undergo accelerated aging protocols per ASTM D395 and ISO 188, ensuring long-term resilience against compression set, ozone degradation, and thermal cycling inherent in cabinet door mechanisms. Generic foam suppliers often overlook the nuanced interplay between cell structure integrity and load distribution—critical factors preventing door sagging or noise generation in high-cycle applications. We address this through proprietary cross-linking techniques that optimize rebound resilience while maintaining consistent durometer tolerances of ±3 Shore A.

Suzhou Baoshida’s value extends beyond standard catalog offerings. Our engineering team collaborates directly with your R&D and production departments to refine material specifications against your functional requirements. This includes dynamic testing of bumper performance under simulated operational loads, environmental stress screening, and tolerance stack-up analysis for seamless integration into automated assembly lines. The table below outlines baseline specifications for our most deployed foam cabinet bumper formulations, though all parameters are adjustable to match your exact mechanical and regulatory needs.

| Property | Standard Value | Testing Method |

|---|---|---|

| Density | 0.35 ± 0.02 g/cm³ | ASTM D1622 |

| Hardness (Shore A) | 45 ± 3 | ASTM D2240 |

| Compression Set (22h/70°C) | ≤ 15% | ASTM D395 Method B |

| Temperature Range | -40°C to +100°C | ISO 188 |

| Tensile Strength | ≥ 1.8 MPa | ASTM D412 |

| Elongation at Break | ≥ 200% | ASTM D412 |

Material customization is non-negotiable in high-stakes manufacturing environments. Whether your application requires flame-retardant additives compliant with UL 94 HF-1, FDA 21 CFR 177.2600 approval for food-service cabinetry, or conductive variants for EMI-shielded enclosures, our formulation lab adjusts polymer matrices at the molecular level. This precision prevents costly field failures—such as adhesive delamination or permanent deformation—that arise from mismatched material properties. Our Suzhou-based production facility maintains IATF 16949-certified processes with real-time SPC monitoring, guaranteeing batch-to-batch repeatability essential for global supply chain integration.

Initiate a technical consultation with Mr. Boyce, our dedicated OEM Solutions Manager, to resolve your specific bumper performance challenges. Mr. Boyce possesses 14 years of experience in rubber compounding for furniture, appliance, and industrial enclosure manufacturers. He will facilitate material sample submissions, coordinate DfM reviews, and establish accelerated qualification timelines aligned with your production ramp schedules. Do not compromise cabinet functionality with off-the-shelf foam components lacking traceable material certifications. Contact Mr. Boyce directly at [email protected] to receive a formal quotation with full technical datasheets and regulatory documentation within 24 business hours. Specify your required annual volume, dimensional drawings, and environmental exposure conditions to expedite our engineering response. Partner with Suzhou Baoshida for rubber solutions where material integrity directly defines product longevity.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).