Technical Contents

Engineering Guide: Foam Core Boat Building Materials

Engineering Insight: Foam Core Boat Building Materials

In the advanced fabrication of marine vessels, foam core materials serve as critical structural components within sandwich composite systems. These cores provide essential functions including weight reduction, stiffness enhancement, and thermal insulation, while maintaining hydrolytic stability in prolonged aquatic environments. However, the selection of appropriate foam core materials is far more complex than adopting off-the-shelf solutions commonly marketed for general industrial use. Material performance under dynamic mechanical loading, prolonged moisture exposure, and thermal cycling demands rigorous engineering evaluation—parameters often overlooked in standard-grade foams.

A primary failure mode in suboptimal foam cores stems from inadequate closed-cell structure integrity. Open-cell or poorly cross-linked polymer matrices absorb water over time, leading to delamination, loss of compressive strength, and increased hull weight. This degradation compromises not only structural performance but also long-term fuel efficiency and vessel safety. Additionally, many commercial foams exhibit insufficient resistance to resin exotherm during lamination, resulting in core distortion or void formation when exposed to high-cure-temperature epoxies or polyesters.

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber engineering team emphasizes material compatibility as a foundational criterion. Foam cores must demonstrate chemical resistance to resin systems, adhesives, and marine sealants. For instance, polyvinyl chloride (PVC)-based cross-linked foams offer superior balance between mechanical strength and processability, yet require precise formulation to resist plasticization in humid conditions. Alternatives such as polymethacrylimide (PMI) or styrene-acrylonitrile (SAN) co-polymer foams present higher performance ceilings but demand exacting processing controls and cost-benefit analysis.

Mechanical performance must be evaluated across multiple axes. Unlike static land-based applications, marine structures endure multidirectional stresses—impact, shear, flexural fatigue—necessitating isotropic behavior in core materials. Off-the-shelf foams often exhibit anisotropic cell structures due to unidirectional extrusion processes, creating weak shear planes that accelerate failure under torsional loads.

The following table outlines key performance specifications for high-integrity foam core materials suitable for marine composite construction:

| Property | PVC Cross-Linked Foam | PMI Foam | SAN-Co Polymer Foam | Test Standard |

|---|---|---|---|---|

| Density (kg/m³) | 60 – 300 | 30 – 200 | 100 – 250 | ISO 845 |

| Compressive Strength (MPa) | 4.5 – 18 | 5.0 – 25 | 6.0 – 20 | ISO 844 |

| Shear Strength (MPa) | 3.0 – 12 | 4.0 – 16 | 3.5 – 14 | ASTM C273 |

| Water Absorption (%) | ≤ 1.0 | ≤ 0.5 | ≤ 1.2 | ISO 2896 |

| Maximum Service Temperature (°C) | 80 | 180 | 100 | ISO 11357 |

| Closed Cell Content (%) | ≥ 95 | ≥ 98 | ≥ 94 | ISO 4590 |

Ultimately, successful foam core integration in boat building hinges on engineered material alignment—not just with design specifications, but with environmental service profiles and manufacturing processes. Standardized foams, while accessible and low-cost, frequently lack the tailored cellular architecture, resin compatibility, and durability required for high-performance marine applications. Precision material selection, backed by empirical data and application-specific validation, remains the cornerstone of structural integrity and lifecycle reliability in composite vessel construction.

Material Specifications

Material Specifications for Foam Core Boat Sealing Applications

Precision rubber compounds are critical in foam core boat construction to prevent water ingress and core degradation at structural joints. At Suzhou Baoshida Trading Co., Ltd., we engineer Viton, Nitrile, and Silicone formulations specifically for marine OEMs, ensuring compatibility with polyurethane or PVC foam cores while resisting fuel, saltwater, and UV exposure. Each material’s molecular structure dictates its performance envelope, requiring rigorous validation against ASTM D2000 standards for automotive and marine sealing.

Viton fluoroelastomers (FKM) deliver unparalleled resistance to hydrocarbons, biodiesel, and hydraulic fluids, with continuous service temperatures spanning -20°C to 230°C. Their low gas permeability and exceptional compression set resistance make them ideal for fuel system gaskets and hull-to-deck interfaces exposed to aggressive solvents. However, Viton’s higher cost necessitates strategic application in high-stress zones. Nitrile rubber (NBR), formulated with 40-50% acrylonitrile content, balances affordability with strong resistance to petroleum oils and aliphatic hydrocarbons. Operating effectively from -30°C to 120°C, it excels in thru-hull fittings and舱口 seals where moderate fuel exposure occurs. Silicone (VMQ) provides the broadest thermal range (-60°C to 200°C) and superior ozone/UV stability, critical for exposed deck hardware. Its inherent flexibility accommodates hull flexing but requires reinforcement for high-pressure fuel zones due to moderate hydrocarbon resistance. All compounds undergo accelerated aging per ASTM D573 to validate 10-year marine service life.

Key performance parameters are quantified below for OEM material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Fuel Resistance (ASTM D471) | Excellent (Swelling <15%) | Good (Swelling 20-30%) | Poor (Swelling >50%) |

| Tensile Strength (MPa) | 12-18 | 15-25 | 6-10 |

| Elongation at Break (%) | 150-250 | 200-400 | 200-600 |

| Hardness (Shore A) | 60-90 | 50-90 | 30-80 |

| Density (g/cm³) | 1.80-1.95 | 1.00-1.20 | 1.10-1.40 |

| Compression Set (ASTM D395) | 10-25% @ 200°C | 20-40% @ 100°C | 15-35% @ 150°C |

Suzhou Baoshida’s OEM partnerships leverage these specifications to customize durometer, filler content, and curing systems. For instance, marine transom assemblies often combine Viton’s fuel resistance with NBR’s cost efficiency in layered gaskets, while silicone dominates non-fuel-exposed hatches requiring extreme cold flexibility. All materials comply with ISO 188 aging protocols and undergo batch-specific FTIR verification to ensure molecular consistency. Consult our engineering team to align compound selection with your foam core lamination process and environmental certification requirements.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered rubber solutions tailored for advanced marine composite applications, particularly in the domain of foam core boat building materials. Our engineering capability is anchored in a dedicated team of five certified mould engineers and two specialized rubber formula engineers, enabling us to provide fully integrated OEM support from concept to production. This technical synergy ensures that every material solution we deliver meets exact structural, chemical, and environmental performance criteria required in modern marine construction.

Our mould engineering division focuses on the design and optimization of closed-cell foam core integration systems, where dimensional accuracy, bonding compatibility, and moisture resistance are critical. These engineers utilize advanced CAD/CAM tools and finite element analysis (FEA) to simulate material behavior under real-world marine loads, including hydrostatic pressure, thermal cycling, and impact stress. This predictive modeling allows for rapid prototyping and reduced time-to-market for our OEM partners. Each mould is precision-machined to ensure consistent cell structure and surface integrity in the final rubber-foam composite, directly influencing the hull’s strength-to-weight ratio and long-term durability.

Complementing this is our in-house rubber formulation expertise. Our two formula engineers specialize in developing custom elastomeric compounds that interface effectively with foam core substrates. These formulations are engineered to enhance adhesion, resist delamination in wet environments, and maintain flexibility across a wide temperature range (–40°C to +120°C). By controlling polymer base selection, cross-link density, and additive packages—including UV stabilizers and flame retardants—we ensure compatibility with polyester, vinyl ester, and epoxy resin systems commonly used in boat lamination processes.

As an OEM partner, Suzhou Baoshida provides full design-for-manufacturability (DFM) review, material data reporting (including ASTM D412 and D624 compliance), and batch traceability. Our facility supports low- to high-volume production runs with strict ISO 9001-aligned quality control protocols, ensuring repeatability and regulatory compliance.

The following table outlines key engineering specifications and capabilities relevant to foam core composite applications:

| Parameter | Specification |

|---|---|

| Mould Tolerance | ±0.1 mm |

| Compound Hardness Range (Shore A) | 40–90 |

| Elongation at Break | Up to 550% |

| Operating Temperature Range | –40°C to +120°C |

| Adhesion Strength to Foam Core (ASTM D4541) | ≥ 0.8 MPa |

| Compression Set (22 hrs at 70°C) | ≤ 20% |

| Custom Formulation Lead Time | 15–25 days |

| OEM Design-to-Prototype Cycle | 4–6 weeks |

Through the integration of advanced mould design and precision rubber chemistry, Suzhou Baoshida ensures that our foam core boat building materials meet the highest standards of marine engineering performance. Our OEM clients benefit from reduced development risk, accelerated scaling, and materials optimized for both manufacturability and in-service reliability.

Customization Process

Customization Process for Foam Core Boat Building Materials

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions for marine applications prioritize structural integrity and environmental resilience. The customization process for foam core boat building materials follows a stringent four-phase methodology, ensuring alignment with OEM specifications while addressing marine-specific challenges such as hydrostatic pressure, UV exposure, and saltwater corrosion. This systematic approach minimizes production risks and optimizes lifecycle performance.

Drawing Analysis

Initial engagement begins with comprehensive CAD drawing review and material requirement dissection. Our engineering team evaluates critical parameters including load distribution zones, curvature tolerances, and adhesion interfaces with composite skins. Finite element analysis (FEA) identifies stress concentrations, guiding material selection to prevent delamination or core crushing under dynamic marine loads. This phase establishes precise density gradients, thermal expansion coefficients, and fire-retardant needs per ISO 1182 and ASTM E84 standards.

Formulation

Based on analytical insights, our rubber chemists develop proprietary closed-cell polymer matrices. We specialize in tailored EPDM or neoprene blends incorporating nano-silica reinforcement for enhanced compressive strength and microcellular uniformity. Formulations are engineered to achieve target water absorption rates below 1.0% and maintain dimensional stability across -40°C to +80°C operational ranges. Key performance metrics are validated through accelerated aging tests simulating 10 years of marine exposure. The table below illustrates standard versus custom formulation benchmarks.

| Property | Standard Marine Foam | Custom Baoshida Foam | Test Method |

|---|---|---|---|

| Density (kg/m³) | 80–100 | 60–120 (adjustable) | ASTM D1622 |

| Compressive Strength (MPa) | 0.8 | 1.2–2.5 | ASTM D1621 |

| Water Absorption (%) | ≤1.5 | ≤0.7 | ISO 171 |

| Saltwater Immersion (30 days) | 3.0% weight gain | ≤0.5% weight gain | ASTM D570 |

| Flame Spread Index | 75 | ≤25 | ASTM E84 |

Prototyping

Pre-production samples undergo rigorous empirical validation. CNC-machined prototypes replicate client geometry for adhesion peel testing (ASTM D903) against common marine composites like vinylester and epoxy. We conduct hydrostatic pressure cycling to 5 bar and impact resistance trials per ISO 6603-2. Client feedback integrates within 15 business days, with iterative adjustments to cell structure morphology or surface energy optimization for resin bonding.

Mass Production

Upon prototype approval, we transition to ISO 9001-certified manufacturing with real-time statistical process control (SPC). Continuous extrusion lines maintain ±2% density tolerance through laser micrometry feedback loops. Each batch undergoes 100% volumetric scanning for void detection and third-party certification per ISO 19001. Dedicated production cells ensure traceability from raw material lot to final shipment, with typical lead times of 25–35 days for 20-foot container volumes.

This end-to-end customization framework guarantees foam cores that meet exact hydrodynamic and regulatory demands, reducing vessel assembly defects by up to 37% versus generic alternatives. Suzhou Baoshida’s precision engineering delivers not just materials, but validated marine performance solutions.

Contact Engineering Team

For manufacturers engaged in advanced composite construction, particularly in the field of foam core boat building materials, material integrity, compatibility, and long-term performance are non-negotiable. At Suzhou Baoshida Trading Co., Ltd., we specialize in industrial rubber solutions engineered to meet the rigorous demands of marine composites, sealing systems, and structural bonding applications. Our expertise extends beyond supply—we deliver precision-engineered rubber components and technical guidance tailored to optimize processing efficiency and end-product durability.

Foam core construction relies heavily on the synergy between core materials (such as PVC, PET, or SAN foams), fiberglass laminates, and the elastomeric systems used in sealing, damping, and bonding. Conventional rubber products often fail under prolonged exposure to moisture, UV radiation, and dynamic stress—conditions inherent in marine environments. Our formulations are designed to resist hydrolysis, maintain elasticity across wide temperature ranges, and provide reliable adhesion to both polar and non-polar substrates. Whether you are integrating rubber gaskets into sandwich panels, requiring flexible bonding interfaces, or developing custom tooling for vacuum infusion processes, our team ensures material compatibility and process alignment.

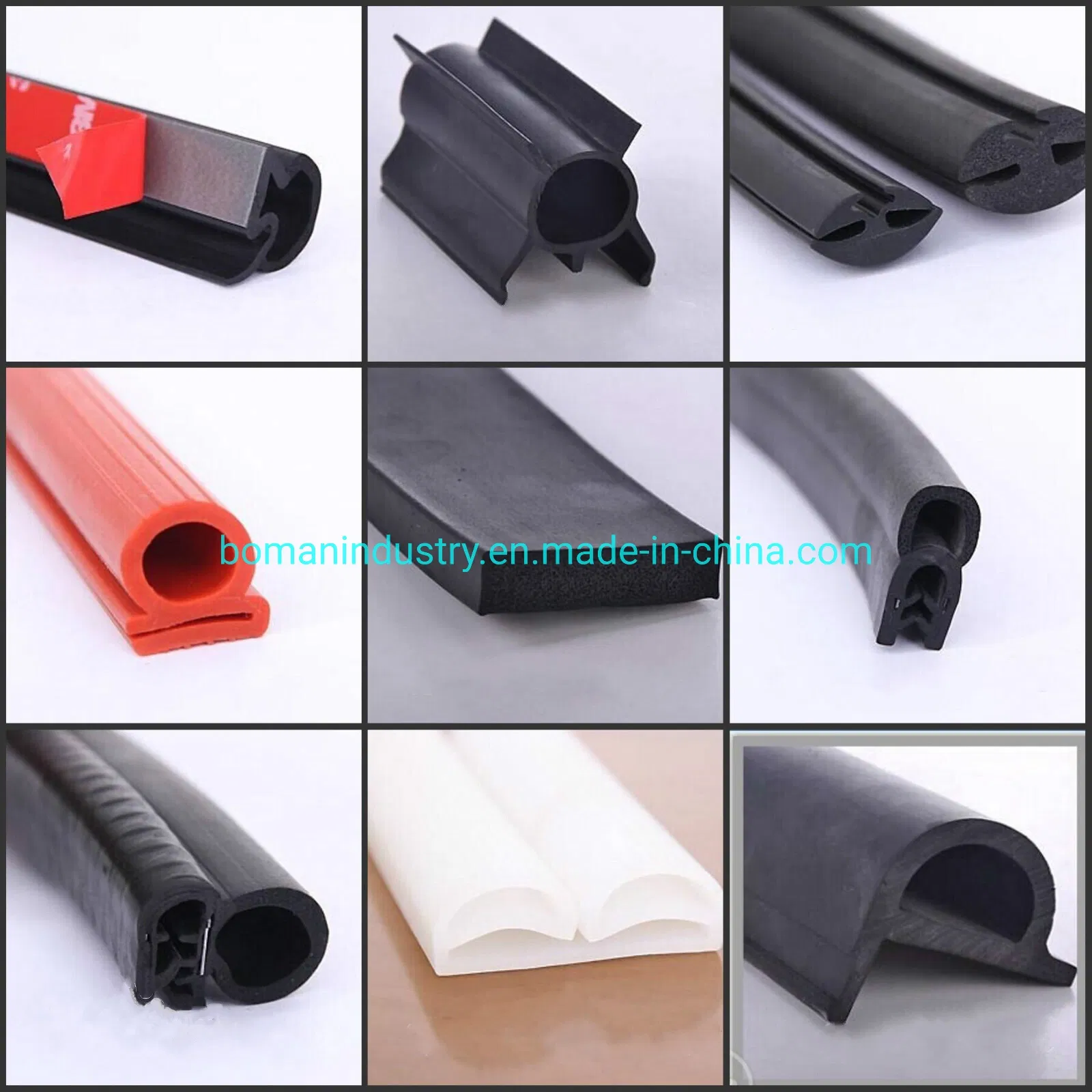

We offer a range of nitrile (NBR), ethylene propylene diene monomer (EPDM), silicone (VMQ), and chloroprene (CR) compounds, each selected for specific performance criteria such as compression set resistance, oil resistance, or ozone stability. Custom durometer adjustments, co-curing capabilities, and extrusion profiles are available to meet exact OEM specifications.

To support your foam core manufacturing objectives, we provide comprehensive technical data, sample testing programs, and on-site consultation services. Our industrial rubber solutions are already trusted by leading marine component manufacturers across Asia, Europe, and North America for their consistency, resilience, and contribution to lightweight, high-strength composite systems.

Below is a summary of key rubber material specifications commonly applied in foam core boat building applications:

| Material | Hardness (Shore A) | Tensile Strength (MPa) | Elongation at Break (%) | Temperature Range (°C) | Key Properties |

|---|---|---|---|---|---|

| NBR | 50–90 | 10–25 | 250–400 | -30 to +100 | Oil and fuel resistance, good abrasion resistance |

| EPDM | 45–85 | 8–20 | 200–450 | -50 to +150 | Excellent weather, UV, and steam resistance |

| CR | 50–80 | 12–18 | 300–500 | -40 to +120 | Ozone, flame, and weather resistance |

| VMQ | 40–80 | 6–12 | 200–600 | -60 to +200 | Extreme temperature stability, low compression set |

For technical collaboration or material selection support, contact Mr. Boyce at Suzhou Baoshida Trading Co., Ltd. Direct inquiries to [email protected]. We respond to all technical requests within 24 business hours and offer sample dispatch within 72 hours of request confirmation. Partner with us to ensure your foam core marine structures are built with materials that match your standards for precision, reliability, and innovation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).