Technical Contents

Engineering Guide: Foam In A Tube

Engineering Insight: The Critical Role of Material Selection in Foam-in-Tube Applications

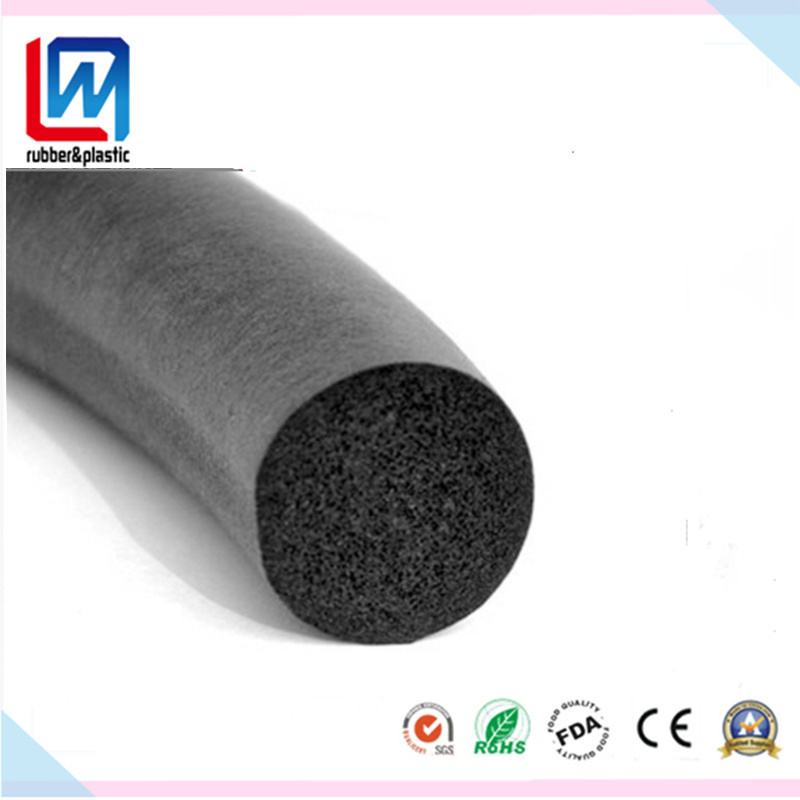

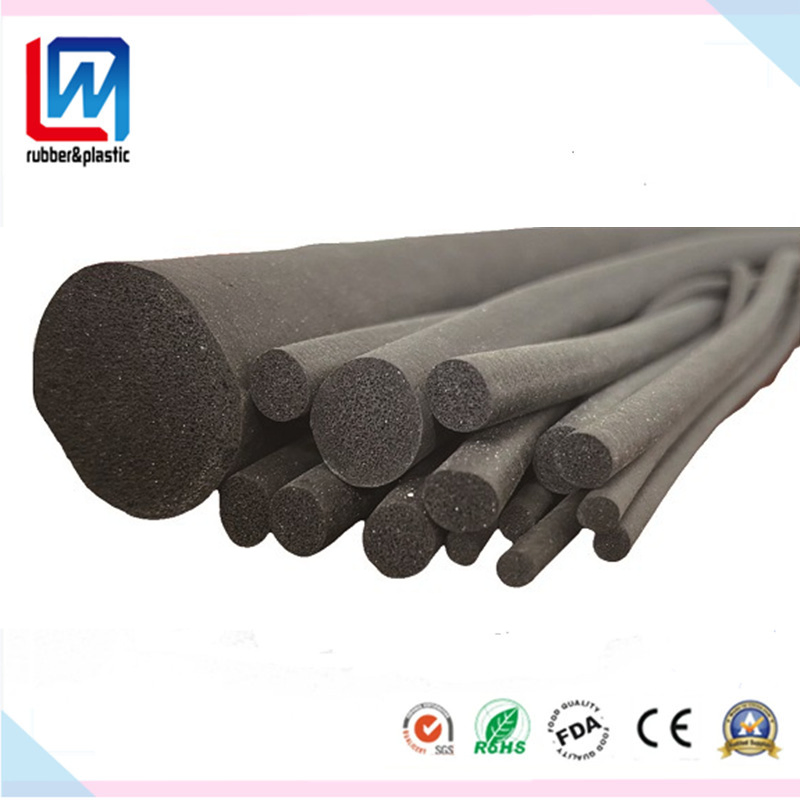

In industrial sealing and cushioning systems, foam-in-tube (FIT) technology represents a sophisticated solution where elastomeric foam is encapsulated within a flexible tubular rubber sheath. While this configuration offers advantages in compression set resistance, environmental sealing, and long-term resilience, its performance is fundamentally contingent upon precise material selection. Off-the-shelf FIT products often fail in demanding applications due to a one-size-fits-all approach that neglects the chemical, thermal, and mechanical realities of the operating environment.

The core failure mechanism in generic FIT solutions stems from mismatched material properties. Standard foam inserts are typically formulated from low-density polyurethane or EVA foams, which degrade rapidly under continuous heat exposure or in the presence of oils, ozone, and UV radiation. When such foams are paired with non-specialized rubber sheaths—often EPDM or SBR with minimal additive optimization—the result is premature compression set, sheath cracking, or foam disintegration. These failures compromise sealing integrity, leading to leakage, contamination ingress, or mechanical misalignment.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material pairing based on application-specific stressors. For high-temperature environments exceeding 100°C, silicone rubber sheaths with closed-cell silicone foam cores provide superior thermal stability and maintain elasticity. In dynamic sealing applications involving repeated compression cycles, microcellular polyurethane foams with tailored hardness (40–60 Shore A) and high recovery rates ensure long-term performance. For outdoor applications, EPDM sheaths with enhanced UV and ozone resistance—formulated with specific anti-degradants—are essential to prevent surface cracking.

Material compatibility with fluids is another critical factor. Standard FIT products often fail when exposed to hydraulic oils, brake fluids, or industrial solvents due to swelling or chemical degradation of the rubber sheath. Our engineered solutions utilize fluorocarbon (FKM) or ACM rubber sheaths in such cases, which offer excellent resistance to a broad spectrum of aggressive media.

The following table outlines key material pairings and their performance characteristics for industrial foam-in-tube applications:

| Core Foam Material | Sheath Material | Temperature Range (°C) | Key Advantages | Typical Applications |

|---|---|---|---|---|

| Silicone Foam | Silicone Rubber | -60 to +200 | High thermal stability, low compression set | Aerospace seals, high-temp gaskets |

| Microcellular PU | EPDM Rubber | -40 to +120 | High resilience, good weather resistance | Automotive door seals, industrial enclosures |

| EVA Foam | SBR Rubber | -20 to +80 | Low cost, moderate flexibility | Light-duty packaging, temporary seals |

| Closed-cell NBR | NBR Rubber | -30 to +100 | Oil and fuel resistance | Hydraulic systems, engine compartments |

| Polyethylene Foam | LDPE Sheath | -40 to +80 | Moisture barrier, low permeability | Insulation, moisture-sensitive packaging |

Material selection is not a secondary consideration—it is the foundation of reliable foam-in-tube performance. Off-the-shelf solutions fail because they prioritize cost and availability over engineering rigor. At Baoshida, we apply a systems-level approach, matching foam density, cell structure, sheath polymer chemistry, and additive packages to the exact service conditions. This precision ensures longevity, reliability, and optimal function in mission-critical industrial environments.

Material Specifications

Material Specifications for Foam-in-Tube Sealing Applications

Material selection is paramount for foam-in-tube (FIT) products in demanding industrial sealing environments. At Suzhou Baoshida Trading Co., Ltd., our OEM engineering protocols prioritize elastomer compatibility with operational stressors including temperature extremes, chemical exposure, and long-term compression stability. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent core solutions within our industrial rubber portfolio, each exhibiting distinct performance boundaries critical for FIT integrity. Viton delivers exceptional resistance to aggressive chemicals, fuels, and high temperatures, making it indispensable for aerospace and chemical processing FIT seals where hydrocarbon exposure is routine. Its fluoropolymer structure ensures minimal swelling in oils and solvents, though cost considerations necessitate precise application targeting. Nitrile remains the workhorse for general industrial FIT applications due to its balanced cost-performance profile, particularly in automotive and hydraulic systems. It provides robust resistance to petroleum-based fluids and moderate heat but exhibits vulnerability to ozone, weathering, and polar solvents like ketones. Silicone excels in extreme temperature flexibility and biocompatibility, dominating medical, food-grade, and high-temperature electrical FIT applications. Its inherent low toxicity and wide thermal range are offset by poor resistance to hydrocarbons and lower tensile strength compared to hydrocarbon-based elastomers.

Compression set resistance is a non-negotiable parameter for FIT longevity, as permanent deformation directly compromises sealing force retention. Viton typically achieves 15-25% compression set after 70 hours at 150°C, critical for static seals in engine compartments. Nitrile ranges from 20-40% under the same conditions, suitable for less severe duty cycles. Silicone performs well at elevated temperatures (25-35% at 200°C) but may degrade rapidly under continuous compression in dynamic applications. Tensile strength and density further dictate extrusion resistance and installation durability during FIT manufacturing and field use.

The comparative analysis below details key specifications governing FIT material suitability. All values reflect standard commercial grades cured per ASTM D2000 M2BA 710; custom formulations are available to address specific OEM requirements.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Continuous Temp Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Short-Term Peak (°C) | 300 | 150 | 230 |

| Compression Set (70h/150°C) | 15-25% | 20-40% | 25-35% (200°C) |

| Tensile Strength (MPa) | 10-15 | 15-25 | 5-8 |

| Density (g/cm³) | 1.80-1.95 | 1.00-1.20 | 1.10-1.30 |

| Fuel Resistance (ASTM #3) | Excellent (Swelling <15%) | Good (Swelling 20-40%) | Poor (Swelling >100%) |

| Ozone Resistance | Excellent | Poor | Excellent |

Suzhou Baoshida’s FIT solutions leverage these material fundamentals through rigorous OEM collaboration. We emphasize that Silicone’s low density and high thermal stability are optimal for lightweight gasketing in electronics cooling, while Nitrile’s superior abrasion resistance suits ruggedized conduit sealing. Viton formulations are mandatory for fuel injector sleeves exposed to biofuels. Understanding the interplay between compression set, chemical swell, and thermal degradation prevents field failures—our technical team provides full material validation data sheets and application-specific compound recommendations to ensure FIT performance aligns with your operational lifecycle requirements. Material choice is not merely specification compliance; it is engineered risk mitigation for critical sealing interfaces.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-performance foam in a tube products. With a dedicated team of five certified mould engineers and two specialized rubber formula engineers, we maintain full in-house control over the entire product development cycle—from concept and material formulation to precision tooling and scalable manufacturing. This integrated approach ensures rapid prototyping, consistent quality, and optimal performance tailored to the exacting demands of industrial applications.

Our mould engineering team brings over 60 combined years of experience in designing and optimizing closed-cell foam extrusion tooling. Each engineer specializes in thermoset rubber processing, with deep expertise in EPDM, silicone, and neoprene foam systems. They utilize advanced CAD/CAM software and finite element analysis (FEA) to simulate flow dynamics, thermal distribution, and die swell behavior, ensuring dimensional accuracy and uniform cell structure in every extruded profile. This precision engineering reduces material waste, accelerates time-to-market, and enhances long-term product reliability.

Complementing the mould team, our two rubber formula engineers focus exclusively on custom elastomer formulation for foam in a tube applications. They develop proprietary compound recipes that balance critical parameters such as compression set, thermal stability, UV resistance, and flame retardancy. By controlling raw material selection at the molecular level—including blowing agents, crosslink density, and cell nucleation modifiers—we achieve consistent foam density (ranging from 0.40 to 0.85 g/cm³) and tailored mechanical properties. This level of formulation control is essential for meeting OEM specifications in automotive sealing, HVAC insulation, and industrial gasketing.

Our OEM capabilities are built on a foundation of technical agility and confidentiality. We support co-engineering partnerships, providing full documentation including material data sheets, process validation reports, and PPAP submissions. Clients benefit from dedicated project management, IP protection, and scalable production runs—from pilot batches to high-volume continuous extrusion. All formulations and tooling are developed to comply with international standards, including ISO 9001, RoHS, and UL 94.

The following table outlines key technical specifications achievable through our engineering platform:

| Parameter | Range / Value |

|---|---|

| Foam Density | 0.40 – 0.85 g/cm³ |

| Durometer Hardness (Shore A) | 20 – 70 |

| Linear Length Tolerance | ±0.5 mm/m |

| Operating Temperature Range | -50°C to +150°C (material-dependent) |

| Cell Structure | Closed-cell, uniform morphology |

| Standard Materials | EPDM, Silicone, Neoprene, NBR/PVC |

| Custom Additives | Flame retardants, anti-oxidants, colorants |

Through the synergy of advanced tooling design and scientific material engineering, Suzhou Baoshida delivers foam in a tube solutions that meet the highest standards of performance and reliability in industrial environments.

Customization Process

Customization Process for Foam-in-Tube Industrial Sealing Solutions

At Suzhou Baoshida Trading Co., Ltd., our foam-in-tube customization follows a rigorously controlled sequence to ensure dimensional accuracy, material performance, and production scalability. This process begins with comprehensive drawing analysis, where engineering teams dissect client CAD files and technical specifications. Critical parameters including cross-sectional tolerances (±0.05 mm for critical seals), durometer range (40–80 Shore A), and environmental exposure requirements are validated against ISO 3302-1:2014 standards. We identify potential manufacturability risks such as undercuts or excessive wall thinning, providing actionable feedback within 72 hours to prevent downstream delays.

Material formulation constitutes the core technical phase, leveraging our 15-year expertise in closed-cell elastomeric foams. Based on the validated drawing and application data—such as fluid resistance (e.g., ASTM D471 oil immersion), temperature range (-50°C to +150°C), and compression set targets—we engineer proprietary rubber compounds. EPDM, NBR, or silicone base polymers are compounded with precision-blended blowing agents, activators, and stabilizers to achieve uniform cell structure and density. Each formulation undergoes computational simulation for flow behavior during extrusion, ensuring minimal post-cure shrinkage (<1.5%).

Prototyping transitions theoretical design into physical validation. Using client-approved materials, we produce 3–5 meter tube samples via precision extrusion at our Suzhou facility. These prototypes undergo accelerated aging (ASTM D573), compression deflection testing (ASTM D575), and dimensional recheck per ASME Y14.5. Clients receive full material test reports (MTRs) including tensile strength, elongation, and ozone resistance data. Iterations are completed within 10 business days, with formal sign-off required before tooling release.

Mass production commences only after prototype validation, utilizing automated extrusion lines with real-time laser micrometry for diameter control (±0.1 mm). Every production lot undergoes 100% visual inspection and statistical process control (SPC) charting of critical dimensions. Traceability is maintained via unique lot coding linked to raw material certificates and cure profiles. Final shipment includes PPAP Level 3 documentation, ensuring compliance with IATF 16949 and client-specific quality protocols.

Key Foam-in-Tube Performance Specifications

| Parameter | Standard Range | Test Method | Acceptance Criteria |

|---|---|---|---|

| Density | 0.35–0.65 g/cm³ | ASTM D3574 | ±0.03 g/cm³ |

| Compression Set (22h/70°C) | 10–25% | ASTM D395 | ≤25% |

| Tensile Strength | 0.8–2.5 MPa | ASTM D412 | Min. 0.8 MPa |

| Temperature Resistance | -50°C to +150°C | ISO 188 | No cracking |

| Fluid Resistance (IRM 903) | Volume Swell ≤25% | ASTM D471 | ≤25% swell |

This end-to-end workflow—anchored in material science and statistical quality control—guarantees foam-in-tube products meeting exact functional demands while minimizing time-to-market. Suzhou Baoshida’s integration of formulation agility and process discipline delivers OEMs reliable, high-performance sealing solutions at scale.

Contact Engineering Team

For industrial manufacturers seeking precision-engineered rubber solutions, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of innovation and reliability. Specializing in high-performance elastomeric materials and custom-formulated compounds, we deliver tailored solutions for demanding applications across automotive, aerospace, construction, and industrial equipment sectors. Our expertise extends to advanced products such as foam in a tube — a versatile sealing and cushioning technology designed for consistent extrusion, environmental resistance, and long-term durability.

Foam in a tube technology represents a significant advancement in on-demand sealing and gap-filling applications. Unlike pre-molded or die-cut foams, this material is dispensed directly into place, conforming precisely to complex geometries and irregular surfaces. This ensures superior adhesion, reduced waste, and enhanced performance in dynamic sealing environments. At Suzhou Baoshida, we formulate our foam in a tube compounds using premium-grade synthetic rubbers, including EPDM, silicone, and polyurethane, each selected for specific thermal, chemical, and mechanical properties.

Our engineering team works closely with OEMs and Tier suppliers to optimize material performance based on operational requirements. Whether the need is for high-temperature resistance, UV stability, low compression set, or flame retardancy, we develop custom formulations that meet exact technical specifications. Every batch is manufactured under strict quality control protocols, ensuring batch-to-batch consistency, full traceability, and compliance with international standards such as ISO 9001 and RoHS.

The following table outlines key technical specifications for our standard foam in a tube product lines:

| Property | EPDM-Based | Silicone-Based | Polyurethane-Based |

|---|---|---|---|

| Density (g/cm³) | 0.45–0.60 | 0.35–0.50 | 0.50–0.65 |

| Hardness (Shore A) | 20–40 | 15–35 | 30–50 |

| Temperature Range (°C) | -40 to +150 | -60 to +200 | -30 to +100 |

| Tensile Strength (MPa) | ≥1.8 | ≥1.5 | ≥2.0 |

| Elongation at Break (%) | ≥250 | ≥200 | ≥300 |

| Compression Set (22h @ 100°C) | ≤30% | ≤20% | ≤35% |

| Curing Mechanism | Moisture-cure | Moisture-cure | Dual-component |

| Substrate Adhesion | Metals, plastics, glass | Metals, ceramics | Metals, primed plastics |

For project integration, technical validation, or material sampling, we invite you to contact Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer. With over 15 years of experience in elastomer development and industrial application support, Mr. Boyce provides direct technical engagement to ensure seamless adoption of our foam in a tube solutions into your manufacturing processes. He is available to discuss formulation customization, dispensing equipment compatibility, curing profiles, and long-term performance validation under real-world conditions.

To initiate a technical consultation or request a sample kit for evaluation, please reach out directly via email at [email protected]. We respond to all inquiries within 24 business hours and offer virtual or on-site support for qualifying partners. At Suzhou Baoshida, we are committed to engineering excellence, supply chain reliability, and long-term collaboration. Partner with us to elevate your sealing performance with intelligent rubber solutions.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).