Technical Contents

Engineering Guide: Foam Laser Cutting Service

Engineering Insight: Material Selection in Foam Laser Cutting Services

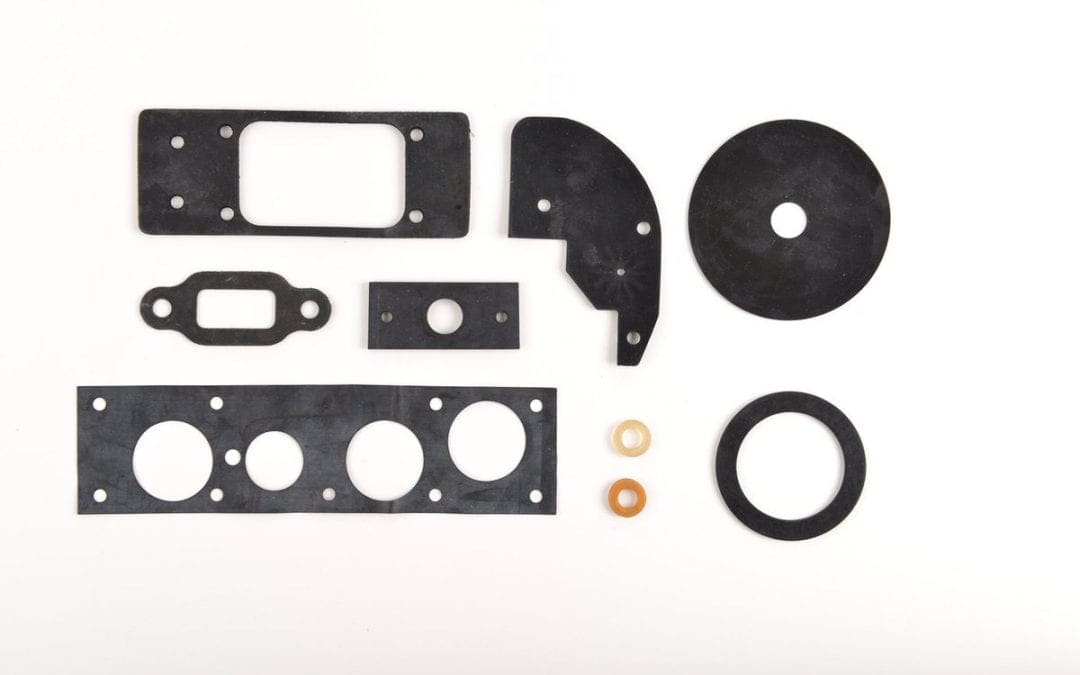

In industrial rubber applications, precision foam components are increasingly demanded across automotive, medical, and electronics sectors. While foam laser cutting services offer unmatched accuracy and repeatability, the success of such processes hinges critically on proper material selection. A common misconception is that any foam can be effectively laser-cut to specification. However, off-the-shelf foam materials—often designed for cushioning or packaging—are structurally and chemically unsuited for high-precision laser processing, leading to inconsistent edge quality, thermal degradation, and part failure in end-use environments.

Foam behavior during laser cutting is governed by thermal conductivity, melt viscosity, and chemical composition. Open-cell foams like polyurethane (PU) or melamine react differently under CO₂ laser energy than closed-cell elastomeric foams such as EPDM or silicone rubber. For instance, standard flexible PU foam tends to char and melt at the cut edge due to low thermal resistance, producing particulate contamination and dimensional inaccuracy. In contrast, engineered closed-cell nitrile rubber (NBR) or chloroprene foams maintain structural integrity under laser exposure, enabling clean, sealed edges with minimal post-processing.

The failure of generic foam solutions stems from their lack of formulation control. Industrial-grade foams used in laser cutting are compounded with flame retardants, stabilizers, and cross-linking agents that enhance laser compatibility. Off-the-shelf foams lack these modifications, resulting in unpredictable ablation rates and poor edge sealing—especially critical in gasketing or sealing applications where fluid resistance and compression set are performance determinants.

At Suzhou Baoshida Trading Co., Ltd., we prioritize material-performance alignment. Our foam laser cutting service integrates material science with process engineering, ensuring that only laser-optimized elastomeric foams enter production. This approach eliminates the trial-and-error often seen when standard foams are retrofitted into precision roles.

Below is a comparison of common foam materials and their suitability for laser cutting:

| Material | Cell Structure | Laser Compatibility | Edge Quality | Typical Use Case |

|---|---|---|---|---|

| Flexible PU Foam | Open-cell | Low | Charring, irregular | Packaging, cushioning |

| Rigid Melamine | Open-cell | Moderate | Brittle, dusty | Acoustic insulation |

| NBR Rubber Foam | Closed-cell | High | Smooth, sealed | Industrial gaskets |

| EPDM Foam | Closed-cell | High | Clean, precise | Automotive weather sealing |

| Silicone Sponge | Open/closed | Moderate to High | Uniform, non-toxic | Medical, food-grade seals |

| Neoprene Foam | Closed-cell | High | Sealed, flexible | Marine and outdoor applications |

Selecting the correct foam is not merely a material choice—it is a systems-level engineering decision. At Baoshida, we collaborate with OEMs to evaluate operational stressors—temperature, chemical exposure, compression load—before recommending a foam substrate for laser fabrication. This ensures that every laser-cut component performs reliably in its intended application, avoiding the costly failures associated with inappropriate material substitution.

Material Specifications

Material Specifications for Foam Laser Cutting Services

Precise material selection is critical for achieving optimal results in foam laser cutting applications. At Suzhou Baoshida Trading Co., Ltd., we engineer solutions for industrial rubber components where dimensional accuracy, edge quality, and material integrity directly impact performance in demanding environments. Our expertise spans fluorocarbon, nitrile, and silicone foam formulations, each requiring tailored laser parameters due to distinct chemical structures and thermal behaviors. Understanding these specifications ensures minimal thermal degradation, clean kerf edges, and adherence to OEM tolerances.

Viton® (FKM) foam delivers exceptional resistance to extreme temperatures, fuels, and aggressive chemicals, making it ideal for aerospace and automotive sealing systems. Its high fluorine content necessitates stringent fume extraction during laser processing to mitigate hydrofluoric acid formation. Nitrile (NBR) foam provides cost-effective resistance to oils and hydraulic fluids, commonly used in gaskets for industrial machinery. However, its lower thermal stability requires reduced laser power to prevent edge charring. Silicone foam excels in biocompatibility and extreme temperature flexibility, widely adopted in medical and food-grade applications. Its low density and high silica content demand precise wavelength calibration to avoid incomplete vaporization and soot residue.

Material properties directly influence laser absorbance, vaporization thresholds, and post-cut surface characteristics. Density variations affect beam penetration depth, while hardness correlates with dimensional stability during cutting. Continuous operating temperature ranges dictate allowable thermal exposure during processing. Below is a comparative analysis of key technical parameters for laser-cuttable foam variants:

| Material | Density Range (g/cm³) | Hardness Range (Shore A) | Continuous Temp Range (°C) | Key Laser Considerations |

|---|---|---|---|---|

| Viton (FKM) | 1.80–2.05 | 40–90 | -20 to +230 | Requires high-power CO₂ lasers; toxic fume generation mandates Class IV extraction; slow cutting speeds to minimize carbonization |

| Nitrile (NBR) | 0.45–0.65 | 30–80 | -30 to +120 | Moderate laser power; prone to edge melting above 15W; nitrogen assist gas reduces oxidation |

| Silicone | 0.30–0.80 | 10–80 | -60 to +200 | Low-density variants need pulse modulation; infrared lasers preferred; post-cut cleaning required for silica residue |

All materials must meet ASTM D2000 classification standards for cellular rubber. Viton formulations require minimum 66% fluorine content for critical fluid resistance, while NBR foams are optimized with 34–45% acrylonitrile for balanced oil/temperature performance. Silicone foams utilize platinum-cured systems to eliminate peroxide residues that compromise laser cut quality. Pre-processing conditioning to 23°C and 50% RH is mandatory to stabilize dimensional tolerances within ±0.1mm.

Suzhou Baoshida implements material-specific protocols validated through ISO 9001-certified process controls. We conduct pre-production laser parameter trials using client-supplied samples to establish power, speed, and assist gas profiles. This ensures cut edges meet OEM surface roughness requirements (Ra ≤ 6.3 μm) without micro-cracking or thermal halo effects. Material certifications, including RoHS and REACH compliance documentation, are provided with all production batches to support traceability in regulated industries.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Foam Laser Cutting for Industrial Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability in foam laser cutting is built on a foundation of material science expertise and advanced manufacturing integration. With a dedicated team of five mould engineers and two specialized rubber formula engineers, we deliver OEM solutions that meet the exacting demands of industrial clients across automotive, electronics, medical devices, and sealing technology sectors. Our integrated approach ensures that both material formulation and cutting precision are optimized in tandem, eliminating performance gaps often seen in outsourced manufacturing.

Our formula engineers possess deep expertise in compounding closed-cell and open-cell rubber foams, including EPDM, silicone, neoprene, and NBR/PVC blends. They customize material properties such as compression set resistance, thermal stability, flame retardancy (UL94 HF-1, FMVSS 302), and environmental sealing performance. This in-house formulation control allows us to tailor foam substrates specifically for laser processability—ensuring clean, sealed edges without fraying or carbonization, even at intricate geometries.

Complementing this material proficiency, our five mould engineers apply DFM (Design for Manufacturing) principles to every laser cutting project. They collaborate directly with clients to refine gasket, spacer, cushioning, and insulation designs, translating prototypes into high-yield production workflows. Utilizing CAD/CAM integration with our laser systems, we achieve dimensional accuracy down to ±0.1 mm, critical for automated assembly lines and tight-tolerance sealing applications.

Our CO₂ laser cutting platform is optimized for non-contact processing of soft, compressible foam materials. This eliminates tool wear and deformation risks associated with die cutting, while enabling rapid prototyping and low-volume production without tooling investment. The laser’s focused beam provides hermetic edge sealing in a single pass, enhancing the foam’s resistance to moisture ingress and particulate penetration—key for IP-rated enclosures and cleanroom environments.

We support full OEM service integration, from concept validation and material selection to batch production and QC documentation. Our traceability system includes lot-specific material certifications, first-article inspection reports (FAIR), and PPAP level 2–3 submission support. Clients benefit from shortened development cycles and seamless scale-up from prototype to mass production.

The following table outlines key technical specifications of our foam laser cutting service:

| Parameter | Specification |

|---|---|

| Laser Type | CO₂, 60 W – 100 W, 10.6 μm wavelength |

| Cutting Accuracy | ±0.1 mm |

| Minimum Feature Size | 0.3 mm (holes), 0.5 mm (slots) |

| Max Work Area | 1200 mm × 900 mm |

| Material Thickness Range | 0.5 mm – 25 mm |

| Supported Foam Types | EPDM, Silicone, Neoprene, NBR/PVC, EVA, PE |

| Edge Quality | Sealed, no fraying, minimal char (Ra < 12 μm) |

| Lead Time (Prototype) | 3–5 working days |

| Production Capacity | Up to 50,000 pcs/week (depending on complexity) |

| Compliance Standards | RoHS, REACH, UL94, ISO 9001:2015 |

By combining formula-level material control with precision engineering, Suzhou Baoshida delivers laser-cut foam components that perform reliably in mission-critical applications. Our OEM framework ensures scalability, consistency, and technical partnership at every stage of production.

Customization Process

Customization Process for Precision Foam Laser Cutting Services

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions leverage advanced foam laser cutting technology to deliver components meeting exacting OEM specifications. The customization process is a rigorously controlled sequence ensuring material integrity, dimensional accuracy, and production efficiency from concept to volume output. This systematic approach minimizes iteration and maximizes first-pass yield for complex rubber foam parts.

Drawing Analysis and Material Compatibility Assessment

Initial engagement requires detailed CAD files (DXF, DWG, or STEP formats) specifying geometries, tolerances, and critical features. Our engineering team conducts a comprehensive review focusing on kerf width implications, thermal management during cutting, and structural feasibility. Crucially, we analyze the drawing against the proposed rubber foam compound’s properties. Factors such as cell structure uniformity, thermal degradation temperature, and coefficient of thermal expansion are evaluated to prevent melt distortion, charring, or dimensional instability. Material compatibility with the laser wavelength and power profile is non-negotiable for clean edge quality.

Tailored Rubber Formulation Development

Based on the analysis, our rubber formula engineers design or select the optimal compound. Standard materials include EPT, EPDM, and specialized TPE foams, but customization is routine. Key formulation parameters adjusted include polymer base saturation, blowing agent type/concentration, and thermal stabilizer packages to enhance laser cut performance. The goal is to achieve a balance between low thermal conductivity (minimizing heat-affected zones) and sufficient structural integrity post-cutting. Formulations are validated against flammability standards (e.g., UL 94 HF-1) and environmental resistance requirements specified by the client.

Prototyping and Validation

A physical prototype is produced using the finalized material and optimized laser parameters. This stage employs our CO2 or fiber laser systems with precise control over power density, pulse frequency, and assist gas (typically nitrogen). Prototypes undergo rigorous metrology: CMM verification against CAD tolerances (±0.1mm typical), visual inspection for edge carbonization or melt defects, and functional testing per client specifications. Destructive testing assesses tensile strength and compression set at cut edges. Client approval of the prototype, including signed-off first-article inspection reports, is mandatory before progression.

Controlled Mass Production

Upon prototype validation, production commences under strict statistical process control. Laser parameters are locked into the manufacturing execution system, with real-time monitoring of beam power, focal position, and gas pressure. In-line vision systems perform 100% dimensional checks on critical features. Batch traceability is maintained from raw material lot to finished part, adhering to ISO 9001 protocols. Production throughput is optimized while maintaining the ±0.15mm dimensional tolerance standard, with continuous monitoring ensuring consistency across runs from hundreds to millions of units.

Critical Laser Cutting Parameters for Rubber Foam

| Parameter | Specification Range | Critical Factor for Quality |

|---|---|---|

| Foam Density | 30 – 150 kg/m³ | Affects kerf width and edge stability |

| Laser Power | 30 – 150 W | Must prevent carbonization |

| Cutting Speed | 5 – 50 mm/s | Balances throughput and edge quality |

| Assist Gas Pressure | 0.2 – 0.8 MPa (N₂) | Suppresses oxidation and melt |

| Dimensional Tolerance | ±0.10 mm (prototyping) | Validated against client CAD |

| ±0.15 mm (mass production) |

This integrated process, grounded in polymer science and precision engineering, ensures Suzhou Baoshida delivers laser-cut rubber foam components that meet the highest industrial performance and reliability standards demanded by global OEMs.

Contact Engineering Team

For precision-engineered foam laser cutting services tailored to industrial rubber applications, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of advanced material processing in China. As a trusted OEM partner specializing in industrial rubber solutions, we integrate state-of-the-art CO₂ laser systems with deep material science expertise to deliver clean, burr-free cuts across a wide spectrum of foam types, including EPDM, Neoprene, Silicone, NBR, and custom closed-cell formulations. Our laser processing technology ensures dimensional accuracy down to ±0.1 mm, making it ideal for gaskets, seals, insulation components, and complex multi-layer assemblies used in automotive, electronics, medical devices, and industrial equipment sectors.

Our foam laser cutting service eliminates the mechanical stress associated with traditional die-cutting methods, preserving the cellular integrity and compression set performance of sensitive foam materials. Each job is supported by CAD/CAM programming, enabling rapid prototyping and seamless transition to high-volume production. We maintain strict environmental controls in our workshop to prevent material deformation and ensure consistent beam focus, critical for achieving repeatable edge quality and tight tolerances.

Below are key technical specifications for our foam laser cutting capabilities:

| Parameter | Specification |

|---|---|

| Laser Type | Sealed CO₂ RF Excited |

| Maximum Cutting Area | 1200 mm × 900 mm |

| Minimum Feature Size | 0.5 mm (holes), 1.0 mm (slots) |

| Positioning Accuracy | ±0.05 mm |

| Repeatability | ±0.03 mm |

| Cutting Speed Range | 10 mm/s to 1000 mm/s (material dependent) |

| Material Thickness Range | 0.5 mm to 50 mm |

| Supported Foam Types | EPDM, Neoprene, Silicone, NBR, EVA, Polyurethane, Poron®, and custom closed-cell rubbers |

| Edge Quality | Smooth, sealed edges; no fraying or charring |

| File Formats Accepted | DXF, DWG, AI, PDF (vector-based) |

All production runs undergo rigorous first-article inspection and in-process quality checks, with optional certification per ISO 9001 standards. We support low-volume prototyping, mid-range batches, and full-scale serial production with optimized cycle times and lean inventory management.

To discuss your specific foam laser cutting requirements, contact Mr. Boyce, OEM Project Manager at Suzhou Baoshida Trading Co., Ltd. With over 15 years of experience in rubber material processing and international project coordination, Mr. Boyce provides technical consultation on material selection, design for manufacturability, and cost-effective production strategies. He ensures seamless communication between engineering, quality assurance, and client teams to deliver solutions aligned with your performance and timeline demands.

Reach out today via email at [email protected] to submit your design files, request a quote, or schedule a technical consultation. Response time is typically within 4 business hours during China Standard Time (CST). For urgent project inquiries, please include “Laser Cut – Priority” in the subject line to ensure expedited handling. Partner with Suzhou Baoshida for precision, reliability, and innovation in every laser-cut rubber foam component.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).