Technical Contents

Engineering Guide: Foam Rubber Mattress

Engineering Insight: Material Selection in Foam Rubber Mattress Manufacturing

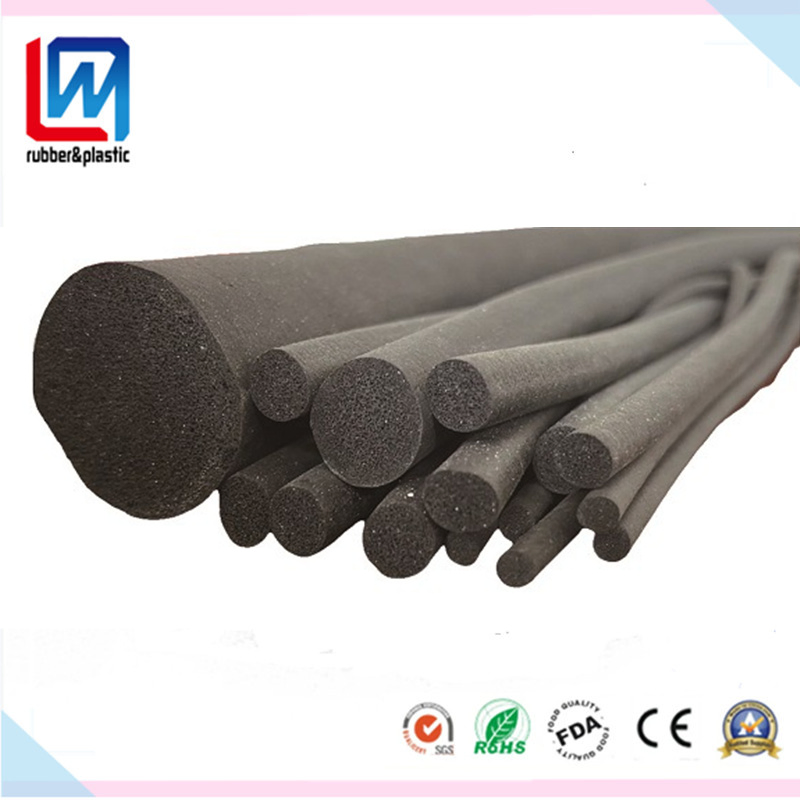

The performance and longevity of a foam rubber mattress are fundamentally determined by the precision of material selection during the design phase. In industrial applications—ranging from medical support surfaces to heavy-duty seating in commercial vehicles—off-the-shelf foam solutions frequently underperform due to their generalized formulation. These standard-grade foams are engineered for broad consumer use, prioritizing cost-efficiency over durability, load distribution, and environmental resistance. As a result, they fail to meet the rigorous demands of specialized applications where consistent mechanical behavior, chemical stability, and long-term compression resistance are non-negotiable.

At Suzhou Baoshida Trading Co., Ltd., we emphasize a science-driven approach to rubber formulation, where each polymer matrix is tailored to the operational environment. Natural rubber latex, for example, offers superior elasticity and resilience but may degrade under prolonged UV or ozone exposure. In contrast, synthetic alternatives such as chloroprene (CR) or ethylene propylene diene monomer (EPDM) provide enhanced resistance to weathering, oils, and thermal cycling—critical in industrial or outdoor installations. The cellular structure of the foam—whether open-cell for breathability or closed-cell for moisture resistance—must also be engineered in tandem with the base polymer to ensure functional integrity.

One of the most common failure points in generic foam rubber mattresses is compression set degradation. Standard foams may retain only 60–70% of their original thickness after 25% compression over 22 hours at 70°C, leading to permanent deformation and loss of support. High-performance formulations, however, can maintain over 90% recovery under identical conditions. This difference is not merely incremental—it defines whether a product remains serviceable in a hospital bed frame or fails prematurely in a logistics vehicle seat.

Additionally, flame retardancy, low off-gassing, and compliance with ISO and REACH standards are not optional in regulated environments. Off-the-shelf foams often lack documentation or consistent batch-to-batch quality, introducing compliance risks. Custom-engineered solutions incorporate additive packages—such as non-halogenated flame retardants and antimicrobial agents—blended at precise concentrations to meet both performance and regulatory benchmarks without compromising material integrity.

The following table outlines key performance specifications comparing standard and engineered foam rubber formulations:

| Property | Standard Foam Rubber | Engineered Foam Rubber (Baoshida) |

|---|---|---|

| Density (kg/m³) | 40–60 | 60–120 (customizable) |

| Tensile Strength (MPa) | 0.8–1.2 | 1.8–3.5 |

| Elongation at Break (%) | 150–250 | 300–600 |

| Compression Set (22h @ 70°C, 25%) | 25–40% | 8–15% |

| Hardness (Shore A) | 30–50 | 20–80 (adjustable) |

| Flame Resistance (UL94) | HB | V-0 (achievable) |

| Service Temperature Range | -10°C to +70°C | -40°C to +120°C |

Material selection is not a commodity decision—it is a core engineering imperative. By rejecting generic substitutes and investing in purpose-built foam rubber systems, OEMs ensure reliability, compliance, and total cost of ownership reduction across the product lifecycle.

Material Specifications

Material Specifications for Industrial Foam Rubber Mattresses

Selection of elastomeric compounds directly influences the functional longevity and performance envelope of foam rubber mattresses in demanding industrial applications. At Suzhou Baoshida Trading Co., Ltd., we prioritize material science rigor to ensure optimal resilience against compression set, chemical exposure, and thermal degradation. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent three critical polymer families, each engineered for distinct operational environments. Viton delivers unparalleled resistance to aggressive chemicals and extreme temperatures, making it indispensable for aerospace or chemical processing isolation layers. Nitrile provides cost-effective resilience against oils, fuels, and moderate heat, ideal for automotive or machinery operator seating. Silicone excels in biocompatibility and extreme-temperature stability, serving medical device padding and high-heat industrial zones. Density ranges from 300–800 kg/m³ must align with load-bearing requirements, while tensile strength (per ASTM D412) and elongation at break dictate structural integrity during cyclic compression. Crucially, compression set values (ASTM D395) below 25% after 70 hours at 70°C ensure dimensional recovery, preventing permanent deformation in continuous-use scenarios.

The following comparative analysis details key physical and chemical properties essential for B2B procurement decisions. All data reflects industry-standard test protocols under controlled laboratory conditions.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -30 to +120 | -60 to +230 |

| Tensile Strength (MPa) | 12–18 | 10–20 | 5–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–700 |

| Compression Set (70°C, 70h) (%) | 15–25 | 20–40 | 10–20 |

| Density (kg/m³) | 1700–1900 | 950–1100 | 1100–1300 |

| Key Chemical Resistance | Fuels, Acids, Ozone | Oils, Greases, Water | Steam, Oxygen, UV |

| Typical Foam Application | Chemical isolation layers | Industrial work mats | Medical support surfaces |

Material selection must account for synergistic factors beyond baseline specs. Viton’s superior chemical inertness necessitates specialized compounding for foam cell structure stability, increasing raw material costs by 30–40% versus NBR. Nitrile formulations require plasticizer optimization to prevent migration-induced hardening in solvent-rich environments, directly impacting mattress service life. Silicone’s low surface energy enhances release properties during molding but demands precise catalyst control to avoid scorch in high-density foams. For critical applications, Suzhou Baoshida implements ASTM D1056 supplementary testing, including fatigue resistance (ISO 139) and outgassing analysis (ASTM E595), to validate real-world performance. OEM partners should collaborate with our engineering team to calibrate durometer (40–80 Shore A), cell morphology, and flame retardancy (UL 94 HF-1) to specific operational hazards. This data-driven approach ensures foam rubber mattresses meet ISO 9001-certified durability benchmarks while minimizing total cost of ownership through extended replacement cycles.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering team is the cornerstone of our industrial rubber solutions, particularly in the development and production of foam rubber mattresses for demanding B2B clients. Our in-house engineering department comprises five dedicated mould engineers and two specialized rubber formula engineers, enabling full vertical control from concept to final product. This integrated technical team ensures precision, repeatability, and customization at scale—critical for OEM manufacturing in regulated and performance-sensitive industries.

Our mould engineers bring over 15 combined years of experience in designing, prototyping, and refining compression and injection moulds tailored for foam rubber applications. Utilizing advanced CAD/CAM software and CNC machining partnerships, they develop robust tooling that ensures dimensional accuracy, consistent cell structure, and minimal flash in the final product. Each mould is optimized for thermal efficiency, cycle time reduction, and long-term durability—key factors in high-volume OEM production. The team also conducts finite element analysis (FEA) to simulate material flow and predict compression set, significantly reducing time-to-market for new designs.

Complementing our mould expertise are two senior rubber formula engineers who specialize in closed-cell and open-cell foam compounding. Their work focuses on tailoring elastomer formulations to meet exact physical, thermal, and chemical performance criteria. Whether the application demands enhanced resilience, flame retardancy, low compression set, or resistance to ozone and UV degradation, our formula engineers develop proprietary blends using EPDM, CR, SBR, or silicone-based systems. These formulations are rigorously tested for density, tensile strength, elongation, and compression deflection (ILD) to ensure compliance with international standards such as ISO 2440 and ASTM D3574.

Our OEM capabilities are built on this dual engineering advantage—mould precision and material science. Clients benefit from a seamless development pipeline that includes prototype sampling, design for manufacturability (DFM) reviews, and small-batch validation before full-scale production. We support custom branding, packaging, and technical documentation, including material test reports and RoHS/REACH compliance certificates.

The following table outlines key technical parameters we routinely engineer for foam rubber mattress applications:

| Property | Typical Range | Test Standard |

|---|---|---|

| Density | 40–120 kg/m³ | ISO 845 |

| Tensile Strength | 0.8–2.5 MPa | ISO 37 |

| Elongation at Break | 100–300% | ISO 37 |

| Compression Deflection (ILD) | 10–50 N | ASTM D3574 |

| Compression Set (25%, 22h, 70°C) | ≤ 20% | ISO 1856 |

| Hardness (Shore A) | 20–60 | ISO 7619-1 |

| Operating Temperature | -40°C to +120°C | Custom formulation dependent |

This technical foundation allows us to deliver engineered foam rubber solutions that meet exact OEM specifications while maintaining cost efficiency and production scalability.

Customization Process

Customization Process for Foam Rubber Mattress Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our foam rubber mattress customization integrates rigorous scientific methodology with industrial scalability. This four-phase process ensures precise alignment with OEM performance requirements while maintaining production efficiency. Each stage undergoes strict validation to eliminate design-to-manufacturing discrepancies.

Drawing Analysis

Initial engagement begins with comprehensive technical drawing review. We analyze CAD files for dimensional tolerances, material thickness gradients, and structural integrity under load conditions. Critical attention is given to geometric complexity affecting mold flow dynamics and demolding feasibility. Our engineering team cross-references ISO 2439 foam testing standards to identify potential stress concentration zones. This phase culminates in a feasibility report detailing material constraints, draft angle adjustments, and mold design recommendations to prevent sink marks or void formation during curing.

Formulation Development

Based on performance targets, our rubber formula engineers develop bespoke thermoset polyurethane or latex formulations. Key variables include polymer backbone selection, blowing agent ratios, and crosslink density modifiers to achieve target resilience and hysteresis. We prioritize VOC compliance per GB/T 24441-2009 while optimizing for compression set resistance. Each formulation undergoes accelerated aging simulations to predict 10-year performance decay rates. Critical parameters are validated through dynamic mechanical analysis (DMA) to ensure viscoelastic properties meet client specifications across -20°C to 60°C operational ranges.

Prototyping and Validation

Three iterative prototype batches are produced using production-intent tooling. Physical testing adheres to ASTM D3574 protocols for indentation force deflection (IFD), air flow permeability, and tensile strength. We conduct 72-hour continuous load testing to measure permanent deformation at 50% compression. Prototypes undergo third-party certification for flammability (CAL 117), odor emissions (VDA 270), and microbial resistance. Client feedback triggers micro-adjustments to cell structure morphology before final sign-off.

Mass Production Execution

Upon prototype approval, we transition to high-volume manufacturing with real-time process control. Our automated mixing systems maintain ±0.5% batch consistency in resin-isocyanate ratios. Continuous inline monitoring tracks cure exotherm profiles via embedded thermocouples, while X-ray densitometry verifies uniform cell distribution. Every 500th unit undergoes destructive testing against baseline specs. Suzhou Baoshida implements traceability down to raw material lot numbers, ensuring full compliance with ISO 9001:2015 documentation protocols.

Critical Foam Performance Parameters

| Parameter | Standard Range | Customization Range | Test Method |

|---|---|---|---|

| Density | 30-80 kg/m³ | 25-120 kg/m³ | ISO 845 |

| Hardness (IFD 25%) | 100-300 N | 70-450 N | ASTM D3574 Section 8 |

| Compression Set | ≤15% (22h, 50%) | ≤8% achievable | ISO 1856 |

| Tensile Strength | 80-200 kPa | 60-250 kPa | ASTM D3574 Section 4 |

| Air Flow | 15-60 L/min | 10-100 L/min | ISO 9073-15 |

Suzhou Baoshida’s OEM management framework guarantees seamless transition from concept to volume production. Our closed-loop quality system reduces time-to-market by 30% compared to industry benchmarks while maintaining ≤0.25% defect rates in finished goods. All formulations are protected under strict NDA protocols, with material safety data sheets provided for global regulatory compliance.

Contact Engineering Team

For industrial manufacturers and OEM partners seeking high-performance foam rubber mattress solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted leader in precision rubber engineering. Our expertise in closed-cell and open-cell foam formulations ensures consistent product quality, durability, and compliance with international performance standards. Whether you require customized density profiles, flame-retardant variants, or specialized compression resistance, our technical team is equipped to deliver engineered rubber solutions tailored to your production requirements.

Our foam rubber mattresses are designed for demanding applications across medical, automotive, industrial seating, and marine sectors. Utilizing advanced compounding techniques and quality-controlled vulcanization processes, we produce materials with superior resilience, thermal stability, and long-term structural integrity. Every batch undergoes rigorous testing for compression set, tensile strength, and aging resistance, ensuring reliability under continuous load and variable environmental conditions.

Partnering with Suzhou Baoshida means gaining access to end-to-end technical support, from material selection and prototype development to large-scale manufacturing and logistics coordination. We specialize in scalable production models that maintain consistency across volumes, enabling seamless integration into your supply chain.

Below are representative technical specifications for our standard foam rubber mattress formulations:

| Property | Test Method | Closed-Cell EPDM Foam | Open-Cell Polyurethane Foam | Nitrile-Butadiene (NBR) Foam |

|---|---|---|---|---|

| Density (kg/m³) | ISO 845 | 80 – 120 | 30 – 60 | 90 – 130 |

| Hardness (Shore A) | ISO 7619-1 | 35 – 55 | 20 – 40 | 40 – 60 |

| Tensile Strength (MPa) | ISO 37 | ≥ 0.8 | ≥ 0.5 | ≥ 1.0 |

| Elongation at Break (%) | ISO 37 | ≥ 150 | ≥ 120 | ≥ 180 |

| Compression Set (25%, 24h) | ISO 815 | ≤ 15% | ≤ 20% | ≤ 12% |

| Operating Temperature Range | — | -40°C to +120°C | -30°C to +90°C | -40°C to +100°C |

| Flame Resistance (UL94) | UL 94 | HB / V-0 available | HB | HB / V-0 available |

| Water Absorption (24h) | ISO 2896 | < 3% | < 8% | < 2% |

All materials can be customized in thickness (5 mm to 100 mm), sheet size (up to 2000 mm × 3000 mm), and with optional lamination, adhesive backing, or die-cutting services. We also support RoHS, REACH, and FDA-compliant formulations upon request.

To initiate a technical consultation or request a sample batch for evaluation, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. Direct correspondence to [email protected] ensures immediate access to material data sheets, pricing models, and engineering support. Our team responds to all inquiries within 12 business hours and offers virtual or on-site technical reviews for high-volume partnerships.

For precision-engineered foam rubber mattress solutions backed by industrial-grade data and reliable manufacturing scalability, Suzhou Baoshida delivers performance you can specify with confidence. Reach out today to align your project with advanced rubber technology.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).