Technical Contents

Engineering Guide: Frosted Perspex Tube

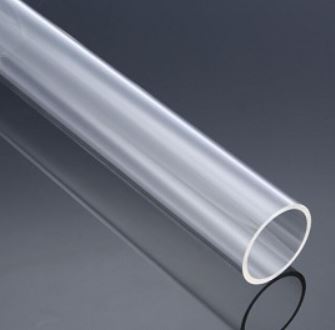

Engineering Insight: Material Selection Imperatives for Frosted Perspex Tubing

As a Rubber Formula Engineer specializing in polymer systems, I must clarify a critical industry misconception upfront: perspex (acrylic) is distinct from rubber elastomers. However, the material science principles governing performance failures in off-the-shelf frosted perspex tubes mirror challenges we solve daily in industrial rubber compounding. Generic acrylic tubes frequently fail in demanding applications due to unaddressed environmental stressors, leading to catastrophic field failures and costly downtime. Standard extrusion-grade polymethyl methacrylate (PMMA) lacks the tailored formulation required for industrial environments, where UV exposure, chemical contact, thermal cycling, and mechanical stress converge.

Frosted surface treatment—achieved via chemical etching or bead blasting—introduces micro-cracks that accelerate photodegradation under UV radiation. Unmodified PMMA undergoes chain scission, causing yellowing, reduced light transmission, and embrittlement. In chemical processing or outdoor signage applications, standard tubes exhibit swelling or crazing when exposed to hydrocarbons or solvents, as their molecular structure lacks cross-linking or stabilizer packages. Thermal expansion coefficients further compound issues; rapid temperature shifts induce stress fractures at mounting points, particularly where the frosted surface disrupts structural homogeneity. These failures are not inherent to acrylic but stem from neglecting application-specific material engineering.

Suzhou Baoshida Trading Co., Ltd. addresses these vulnerabilities through OEM-grade material customization. Our engineered solutions integrate UV absorbers (e.g., benzotriazoles), impact modifiers, and optimized frosting protocols that preserve optical diffusion while minimizing stress concentration. Below is a comparative analysis of critical performance metrics:

| Property | Standard Off-the-Shelf Tube | Baoshida Engineered Solution |

|---|---|---|

| UV Resistance (QUV-B, 1000h) | >30% YI increase, 40% TS loss | <8% YI increase, <10% TS loss |

| Toluene Exposure (24h, 23°C) | Severe swelling, opacity shift | Minimal swelling (<2%), stable diffusion |

| Thermal Shock Tolerance | Fractures at ΔT >40°C | Stable up to ΔT 85°C |

| Surface Crack Initiation | Visible micro-cracks post-frosting | Controlled surface roughness (Ra 1.2–1.8μm) |

The data underscores why commodity tubes fail: they prioritize cost over resilience. Industrial applications demand acrylic formulations with rigorously controlled molecular weight distribution, additive dispersion, and frosting depth calibration. At Baoshida, we collaborate with OEMs to define operational parameters—fluid compatibility, light diffusion requirements, and mechanical loads—then validate prototypes via accelerated aging and finite element analysis. This prevents the hidden costs of premature replacement: production halts, safety hazards, and reputational damage.

Material selection is not a procurement decision but an engineering commitment. Generic frosted perspex tubes sacrifice longevity for immediacy; engineered solutions deliver lifecycle value. Partner with Suzhou Baoshida to transform acrylic from a commodity component into a reliability asset. Our OEM framework ensures every tube specification aligns with your operational reality, eliminating the guesswork that plagues off-the-shelf alternatives.

Material Specifications

Material Specifications for Frosted Perspex Tube Applications

Frosted perspex tubes are widely used in industrial and commercial applications requiring diffused light transmission, chemical resistance, and aesthetic clarity. While the primary structural component is acrylic (polymethyl methacrylate, PMMA), the performance and sealing integrity of these systems in dynamic environments depend heavily on the elastomeric components used in associated gaskets, seals, and connectors. Suzhou Baoshida Trading Co., Ltd. provides precision-engineered rubber solutions compatible with frosted perspex tube installations, focusing on three primary elastomers: Viton, Nitrile (NBR), and Silicone. Each material offers distinct advantages depending on temperature range, chemical exposure, and mechanical stress conditions.

Viton, a fluorocarbon-based rubber (FKM), delivers superior performance in high-temperature and chemically aggressive environments. It maintains structural integrity when exposed to oils, fuels, acids, and chlorinated solvents, making it ideal for industrial or automotive applications where perspex tube systems interface with hydraulic or fuel lines. With continuous service temperatures up to 230°C and excellent ozone and UV resistance, Viton ensures long-term reliability in demanding settings.

Nitrile rubber (NBR) is a cost-effective solution for applications involving petroleum-based fluids and moderate mechanical stress. It exhibits excellent abrasion resistance and tensile strength, with good performance in environments with intermittent exposure to oils and greases. While its upper temperature limit is lower than Viton (approximately 120°C), NBR remains a preferred choice for general-purpose sealing in machinery and lighting systems utilizing frosted perspex tubes.

Silicone rubber (VMQ) excels in extreme temperature applications, offering serviceability from -60°C to 200°C. It provides outstanding flexibility at low temperatures and maintains elasticity under thermal cycling. Silicone is highly resistant to UV radiation and ozone, making it suitable for outdoor or architectural lighting installations. However, it has lower mechanical strength and poor resistance to hydrocarbon fuels, limiting its use in high-stress or fuel-exposed environments.

The selection of the appropriate elastomer must consider the operational environment, longevity requirements, and compatibility with adjacent materials. Suzhou Baoshida Trading Co., Ltd. ensures all rubber components are precision-molded and tested for dimensional accuracy and material consistency to support seamless integration with frosted perspex tube systems.

Material Comparison Table

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–400 | 400–600 |

| Hardness (Shore A) | 70–90 | 60–80 | 40–80 |

| Resistance to Oils & Fuels | Excellent | Good to Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Fair to Good |

| Common Applications | Aerospace, Chemical Processing | Automotive, Hydraulics | Lighting, Outdoor Enclosures |

Manufacturing Capabilities

Engineering Capability: Precision Manufacturing of Frosted Perspex Tubing

Suzhou Baoshida Trading Co., Ltd. integrates advanced rubber formulation science with precision tooling expertise to deliver engineered frosted perspex (PMMA) tubing solutions for demanding industrial applications. Our core strength lies in the seamless collaboration between dedicated Mould Engineering and Rubber Formula Engineering teams. While perspex tubing falls under thermoplastic extrusion, our proprietary rubber-derived surface treatment processes and sealing interface solutions require deep material science mastery. This cross-disciplinary approach ensures frosted tubes meet exacting functional requirements beyond standard optical diffusion, including vibration damping, chemical resistance, and thermal stability at critical connection points.

Our team comprises five specialized Mould Engineers and two certified Rubber Formula Engineers, uniquely positioned to optimize the entire production ecosystem. Mould Engineers employ cavity pressure mapping and thermal simulation software (Moldflow) to design extrusion dies that achieve uniform frosting patterns without compromising tube concentricity or wall integrity. Concurrently, Formula Engineers develop custom silicone or EPDM-based surface modifiers applied during post-extrusion processing. These formulations precisely control light diffusion coefficients while enhancing abrasion resistance and adhesion properties for downstream assembly. This synergy eliminates common industry pain points like inconsistent frosting density, micro-cracking under thermal cycling, or poor bonding with rubber seals in hybrid assemblies.

As an OEM partner, we execute end-to-end project ownership from concept to量产. Our engineers conduct rigorous material-rheology analysis to match perspex grades with operational environments, ensuring compatibility with co-extruded rubber components or mounting hardware. Every frosted tube undergoes in-process metrology for dimensional stability and frosting homogeneity, validated against client-specified optical transmission curves. This closed-loop engineering process guarantees batch-to-batch repeatability essential for automotive fluid handling, medical device housings, and industrial lighting systems where light diffusion consistency directly impacts performance.

Critical performance parameters for our frosted perspex tubing are maintained within stringent industrial tolerances as shown below:

| Parameter | Standard Specification | Precision Grade Specification | Test Method |

|---|---|---|---|

| Outer Diameter Tolerance | ±0.15 mm | ±0.05 mm | ISO 3037 |

| Wall Thickness Variation | ≤ 0.10 mm | ≤ 0.03 mm | ASTM D2122 |

| Light Transmission | 45% ±5% | 45% ±2% | ASTM D1003 |

| Haze Value | 85% min | 92% min | ASTM D1003 |

| Thermal Deflection (°C) | 90°C @ 1.82 MPa | 95°C @ 1.82 MPa | ISO 75-2 |

| Surface Roughness (Ra) | 1.2 – 2.0 μm | 1.5 ± 0.2 μm | ISO 4287 |

OEM clients benefit from our engineered material interfaces, where rubber-derived surface treatments prevent delamination in multi-material assemblies. We provide full documentation including material compatibility matrices, process capability indices (Cpk ≥1.67), and accelerated aging data per SAE AMS standards. This technical rigor, combined with scalable production capacity, positions Suzhou Baoshida as the partner of choice for mission-critical frosted perspex components requiring uncompromised optical and mechanical performance. Our engineering team remains embedded throughout the product lifecycle to refine specifications against real-world field data.

Customization Process

Customization Process for Frosted Perspex Tube Integration in Industrial Rubber Systems

At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber solutions tailored to complex industrial applications. When integrating components such as frosted perspex tubes into rubber-based systems—typically for visual monitoring, light diffusion, or aesthetic differentiation—we follow a rigorous four-phase customization process: Drawing Analysis, Formulation Development, Prototyping, and Mass Production. This ensures compatibility, durability, and performance under operational stress.

The process begins with Drawing Analysis, where our engineering team reviews technical schematics provided by the client. Critical parameters include outer and inner diameters, wall thickness, axial length, tolerance ranges (±0.1 mm standard), and interface geometry between the rubber housing and the frosted perspex tube. We assess environmental exposure factors such as UV radiation, temperature cycling, and chemical contact to determine sealing requirements and structural support needs. Dimensional accuracy is verified using CAD cross-referencing and GD&T validation to prevent misalignment during assembly.

Following design validation, we proceed to Formulation Development. Our rubber chemists select base polymers—typically silicone, EPDM, or fluorocarbon (FKM)—based on thermal stability, optical clarity requirements, and resistance to aging. Since frosted perspex (polymethyl methacrylate) has a coefficient of thermal expansion higher than most rubbers, we engineer the compound to accommodate differential expansion, minimizing stress at the rubber-perspex interface. Additives such as UV stabilizers, anti-yellowing agents, and reinforcing fillers are incorporated to preserve the visual quality of the frosted finish over time. Hardness is adjusted within the 50–80 Shore A range to balance flexibility and structural support.

Prototyping is conducted using precision injection molding or compression molding, depending on part complexity. Each prototype undergoes dimensional inspection, compression set testing, and thermal cycling from -40°C to +150°C. Optical performance is evaluated to ensure the frosted tube remains unobstructed by flash or overmolding. Functional tests include pressure integrity checks and adhesion strength measurements at the rubber-perspex bond line, achieved through surface plasma treatment and primer application prior to molding.

Upon client approval, we transition to Mass Production, leveraging automated molding lines with real-time process monitoring. In-line vision systems verify part consistency, while batch traceability is maintained through QR-coded lot tracking. All final units are subjected to 100% visual inspection and抽样 physical testing per ISO 3302 and ISO 2768 standards.

Below are typical technical specifications for rubber components interfaced with frosted perspex tubes:

| Parameter | Standard Value |

|---|---|

| Material Options | Silicone, EPDM, FKM |

| Hardness Range | 50–80 Shore A |

| Tolerance (±) | 0.1 mm (precision grade) |

| Operating Temperature | -40°C to +150°C (material-dependent) |

| UV Resistance | Enhanced via stabilizer package |

| Interface Bond Strength | ≥ 6 kN/m (peel test, ASTM D6862) |

| Surface Finish (Rubber) | Matte, semi-gloss, or custom texture |

| Production Lead Time | 4–6 weeks post-approval |

This systematic approach ensures that every frosted perspex-integrated rubber component meets exact functional and aesthetic requirements in demanding industrial environments.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Integration with Frosted Perspex Systems

Suzhou Baoshida Trading Co., Ltd. specializes in advanced rubber formulation and OEM manufacturing solutions designed to interface seamlessly with engineered thermoplastics like frosted perspex (PMMA) tubing. While perspex tubes provide critical optical diffusion and structural properties in fluid handling, lighting, and display systems, their performance hinges on compatible sealing, damping, and mounting components. Our expertise lies in developing custom rubber compounds that address thermal expansion differentials, chemical exposure, and mechanical stress points where rubber meets acrylic. This ensures leak-free operation, vibration isolation, and extended service life in demanding industrial environments.

Critical compatibility parameters must be rigorously evaluated when integrating rubber components with frosted perspex systems. The table below outlines key specifications where our engineered elastomers outperform standard materials:

| Parameter | Standard NBR Seal | Baoshida Custom EPDM-X Seal | Perspex (PMMA) Tube Limit |

|---|---|---|---|

| Continuous Temp. Range | -30°C to +100°C | -55°C to +150°C | -40°C to +80°C |

| Toluene Resistance (72h) | Swelling >25% | Swelling <8% | N/A |

| Compression Set (22h/100°C) | 35% | <15% | N/A |

| Shore A Hardness Range | 60-80 | 50-90 (Customizable) | N/A |

| UV Stability (ISO 4892) | Poor | Excellent | Good (Frosted surface) |

These specifications reflect our commitment to solving real-world interface challenges. For instance, standard nitrile rubber seals often fail prematurely in solvent-handling systems due to excessive swelling, directly compromising perspex tube integrity. Our EPDM-X formulations maintain dimensional stability under aggressive chemical exposure while accommodating the 0.06 mm/mm/°C thermal expansion coefficient of PMMA—critical for maintaining seal integrity across temperature cycles.

As your OEM partner, we provide end-to-end engineering support from material selection through production validation. Our laboratory conducts ASTM D2000-compliant testing on every compound batch, including perspex-specific compatibility assessments per ISO 11439. We optimize durometer, filler content, and crosslink density to match your tube’s wall thickness, pressure rating, and operational environment. This precision prevents stress cracking in acrylic substrates and eliminates premature seal extrusion—a common failure mode in high-vibration applications.

Initiate your project with Suzhou Baoshida’s technical team to secure rubber solutions engineered for frosted perspex integration. Mr. Boyce, our Lead Rubber Formulation Engineer and OEM Manager, will conduct a comprehensive application review to define material specifications, tolerance protocols, and validation criteria. With 14 years of experience in thermoplastic-elastomer interface engineering, he ensures your sealing system meets ISO 13485 or AS9100 requirements where applicable.

Contact Mr. Boyce directly at [email protected] to submit your perspex tube specifications, operating conditions, and performance targets. Include details on fluid media, pressure cycles, temperature profiles, and regulatory certifications required. Our team will respond within 4 business hours with a preliminary compound recommendation and DFM analysis. Do not compromise system reliability with generic rubber components—leverage Suzhou Baoshida’s material science expertise for engineered solutions that protect your acrylic assemblies. All inquiries receive confidential technical consultation and prototype support for qualified industrial partners.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).