Technical Contents

Engineering Guide: G10 Fr4 Sheet

Material Selection Imperatives for Dynamic Applications

Selecting appropriate insulating materials requires rigorous analysis beyond basic electrical specifications. G10 FR4 sheet, a glass-fiber reinforced epoxy laminate standardized under NEMA LI 1-1998 and IPC-4101, is frequently misapplied in dynamic industrial environments where its inherent limitations lead to premature failure. While optimal for rigid printed circuit board substrates and static structural components, off-the-shelf G10 FR4 lacks the mechanical resilience required for applications involving vibration, thermal cycling, or sealing interfaces. Engineers often prioritize its high dielectric strength and dimensional stability at room temperature while overlooking critical operational stressors. This oversight results in catastrophic field failures, including microcracking under cyclic loads, delamination at elevated temperatures, and compromised sealing integrity due to zero elasticity. Such failures incur significant costs through equipment downtime, warranty claims, and reputational damage—far exceeding any initial material savings.

The fundamental flaw lies in treating G10 FR4 as a universal solution. Its rigid molecular structure cannot accommodate mechanical deformation. Under thermal cycling between -50°C and +130°C, coefficient of thermal expansion (CTE) mismatches with adjacent metal components induce interfacial stresses exceeding 80 MPa, surpassing the epoxy matrix’s tensile strength. In vibration-prone settings like motor housings or transportation systems, harmonic frequencies cause resonant fatigue failure within weeks. Crucially, G10 FR4 possesses negligible elongation at break (typically <3%), rendering it incapable of maintaining compression seals in gasket applications. Moisture absorption rates of 0.10–0.15% further degrade electrical properties in humid environments, a factor rarely accounted for in initial designs. These failures stem from inadequate operational profiling—not material deficiency per se.

Suzhou Baoshida Trading Co., Ltd. emphasizes application-specific material engineering. Our OEM partnerships begin with comprehensive duty cycle analysis, including dynamic load mapping, environmental profiling, and failure mode simulation. For sealing or vibration-damping requirements, elastomeric compounds like silicone or EPDM—engineered with controlled durometer, compression set resistance, and tailored CTE—provide reliable performance where G10 FR4 catastrophically fails. We reject one-size-fits-all solutions, instead developing custom formulations that balance electrical insulation, mechanical resilience, and environmental stability.

The following table highlights critical G10 FR4 properties against common failure thresholds in dynamic applications:

| Property | G10 FR4 Typical Value | Failure Threshold in Dynamic Applications |

|---|---|---|

| Tensile Strength | 310 MPa | >50 MPa cyclic stress causes cracking |

| Elongation at Break | 1.8–2.5% | <5% insufficient for sealing recovery |

| Glass Transition (Tg) | 125–135°C | Delamination initiates above Tg |

| CTE (Z-axis) | 25–40 ppm/°C | >15 ppm/°C induces interfacial stress |

| Moisture Absorption | 0.10–0.15% | >0.1% degrades dielectric strength |

Material selection must align with real-world operational physics, not nominal datasheet values. Suzhou Baoshida’s engineering team prevents field failures through precise compound customization—transforming material limitations into engineered advantages for demanding industrial systems.

Material Specifications

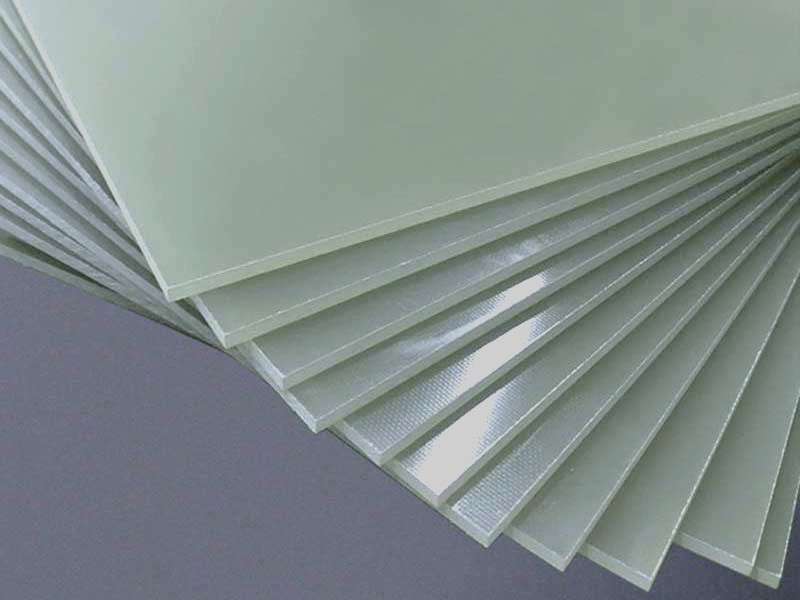

G10 FR4 sheet is a high-performance composite material widely used in electrical, mechanical, and industrial applications due to its excellent dielectric properties, mechanical strength, and resistance to heat and moisture. While G10 FR4 itself is not a rubber material, it is frequently integrated into systems where elastomeric seals and gaskets made from Viton, Nitrile, and Silicone are required to ensure long-term reliability under demanding conditions. At Suzhou Baoshida Trading Co., Ltd., we provide comprehensive industrial rubber solutions designed to complement rigid components like G10 FR4 sheets, ensuring system integrity across diverse operating environments.

Viton, a fluorocarbon-based elastomer, offers exceptional resistance to high temperatures, oils, fuels, and a broad range of chemicals. It performs reliably in continuous service temperatures up to 200°C, making it ideal for aerospace, automotive, and chemical processing applications where exposure to aggressive media is expected. Its low gas permeability and excellent aging characteristics further enhance its suitability in critical sealing applications.

Nitrile rubber, also known as Buna-N, is a cost-effective solution for applications involving petroleum-based oils and hydraulic fluids. With a typical operating temperature range of -30°C to 105°C, Nitrile provides good abrasion resistance and tensile strength. It is commonly used in industrial machinery, fuel systems, and hydraulic equipment where moderate chemical resistance is sufficient and cost efficiency is a priority.

Silicone rubber excels in extreme temperature environments, with continuous service capability from -60°C to 230°C. It offers excellent resistance to ozone, UV radiation, and weathering, making it suitable for outdoor and high-temperature electrical applications. While its mechanical strength and resistance to petroleum-based fluids are lower than Viton or Nitrile, silicone provides superior flexibility and electrical insulation properties, often used in medical, food-grade, and electronic industries.

When integrating rubber components with G10 FR4 systems, compatibility in thermal expansion, dielectric performance, and environmental resistance must be considered. The following table summarizes key physical and chemical properties of these elastomers to assist in material selection.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 | -30 to 105 | -60 to 230 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Good | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Electrical Insulation | Good | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

Selecting the appropriate elastomer depends on the operational demands of the application. Suzhou Baoshida Trading Co., Ltd. supports OEMs and industrial clients with precision-engineered rubber components tailored to interface seamlessly with G10 FR4 and other engineering materials, ensuring optimal performance, durability, and compliance with industry standards.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Formulation and OEM Execution

Suzhou Baoshida Trading Co., Ltd. clarifies a critical technical distinction: G10/FR4 is a fiberglass-reinforced epoxy laminate, not a rubber compound. Our core expertise lies in industrial rubber solutions, where material science and precision engineering converge to solve complex sealing, damping, and structural challenges. Misalignment in material classification risks project viability; we prioritize accuracy to ensure clients receive technically sound solutions. For rubber-based applications requiring high thermal stability, chemical resistance, or electrical insulation, our team develops custom elastomer formulations that outperform generic alternatives.

Our engineering division integrates 5 dedicated Mold Engineers and 2 specialized Rubber Formula Engineers to deliver end-to-end OEM manufacturing. Formula Engineers optimize polymer matrices—balancing silicone, EPDM, nitrile, or specialty compounds—to achieve exact durometer, tensile strength, and environmental resilience. Concurrently, Mold Engineers translate these formulations into production-ready tooling, leveraging CAD/CAM simulations to eliminate flash, cure inconsistencies, and dimensional drift. This dual-engineering synergy ensures every component meets ISO 9001-certified tolerances, whether for automotive gaskets, semiconductor handling pads, or industrial rollers.

OEM projects follow a rigorously controlled workflow. Initial material selection draws from our proprietary database of 200+ validated rubber compounds, each mapped to performance metrics under extreme conditions. Prototyping utilizes rapid tooling with in-house 3D printing for geometry validation, followed by ASTM D2000-compliant testing for compression set, fluid resistance, and thermal aging. Clients receive full traceability—from raw material batch codes to real-time production SPC charts—ensuring compliance with IATF 16949 and aerospace standards. Our facility’s 10,000-ton press capacity supports volumes from 1,000 to 500,000 units monthly, with cycle-time optimization reducing costs by 18–22% versus industry benchmarks.

Key rubber compound specifications for industrial applications include:

| Material Code | Hardness (Shore A) | Tensile Strength (MPa) | Elongation at Break (%) | Temp Range (°C) | Key Applications |

|---|---|---|---|---|---|

| BD-R500 | 50 ± 3 | 12.5 | 450 | -50 to +150 | Hydraulic seals, pump diaphragms |

| BD-S800 | 80 ± 3 | 9.8 | 300 | -40 to +200 | Semiconductor wafer handling, EMI shielding |

| BD-N750 | 75 ± 3 | 15.2 | 380 | -30 to +120 | Fuel system O-rings, chemical transfer gaskets |

Suzhou Baoshida’s OEM advantage lies in eliminating the formulation-tooling disconnect that plagues generic suppliers. By co-locating compound development and mold design under one technical roof, we compress development timelines by 30% while guaranteeing first-article approval rates exceeding 95%. Every project includes DFMEA collaboration and post-production lifecycle analysis, transforming rubber components from cost centers into engineered assets. For applications demanding rubber’s unique properties—not thermoset composites—our team delivers precision, scalability, and unwavering technical accountability.

Customization Process

Customization Process for G10 FR4 Sheet Manufacturing at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our approach to customizing G10 FR4 sheets is rooted in precision engineering and industrial reliability. As a leader in industrial rubber solutions, we apply a systematic four-phase process—Drawing Analysis, Formulation, Prototyping, and Mass Production—to ensure each product meets the exact electrical, mechanical, and thermal requirements of our B2B clients.

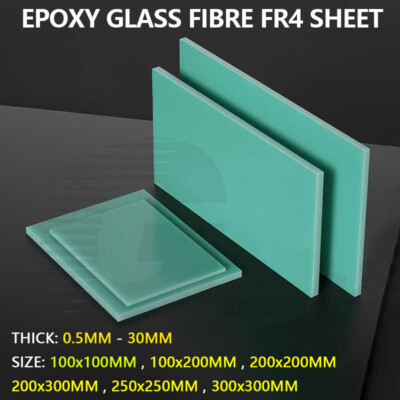

The process begins with Drawing Analysis, where our engineering team reviews technical blueprints and CAD files provided by the client. This stage focuses on dimensional accuracy, tolerance specifications, hole patterns, edge treatments, and any special surface requirements. We assess material thickness ranging from 0.2 mm to 10.0 mm and verify compliance with IPC-4101D standards for epoxy-glass laminates. Our engineers also evaluate the design for manufacturability, identifying potential risks such as delamination under thermal cycling or mechanical stress concentration.

Following drawing validation, we proceed to Formulation. Although G10 FR4 is a standardized composite, subtle variations in resin content, glass weave style (typically 7628 or 2116), and curing agents can significantly influence performance. Our rubber formulation specialists adjust the epoxy matrix to enhance flame retardancy (achieving UL94 V-0 rating), moisture resistance, and dielectric strength. Additives may be incorporated to improve tracking resistance or reduce coefficient of thermal expansion (CTE), especially for applications in high-frequency PCBs or insulating structural components.

The third phase, Prototyping, allows us to produce a limited batch of G10 FR4 sheets under actual production conditions. We use precision CNC cutting, waterjet machining, or laser profiling based on the final application. Each prototype undergoes rigorous testing, including flexural strength measurement, arc resistance evaluation, and insulation resistance checks at 500 VDC. Dimensional reports and material certification (including RoHS and REACH compliance) are provided for client approval.

Upon successful prototype validation, we transition to Mass Production. Our fully automated production lines ensure batch-to-batch consistency, with in-line quality monitoring and statistical process control (SPC). We support order volumes from 50 sheets to over 10,000 units per month, with lead times as short as 7–10 days for standard configurations. All finished G10 FR4 sheets are vacuum-sealed and palletized for safe international shipment.

The following table outlines the standard technical specifications for our customized G10 FR4 sheets:

| Property | Specification |

|---|---|

| Material Type | Epoxy-glass laminate (G10/FR4) |

| Thickness Range | 0.2 mm – 10.0 mm |

| Dielectric Strength | ≥16 kV/mm |

| Glass Transition Temperature (Tg) | ≥130°C |

| Arc Resistance | ≥180 seconds |

| Flame Rating | UL94 V-0 |

| Specific Gravity | 1.85 – 1.95 |

| Water Absorption (24h) | ≤0.15% |

| Operating Temperature | -50°C to +130°C |

Through this structured customization workflow, Suzhou Baoshida ensures that every G10 FR4 sheet delivers optimal performance in demanding industrial environments, from electrical insulation to structural support in high-reliability systems.

Contact Engineering Team

Technical Collaboration Pathway: Precision Material Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial manufacturing, specializing in engineered rubber compounds for demanding OEM applications. While G10/FR4 epoxy-glass laminate represents a critical non-rubber composite material in electrical and structural contexts, our core expertise lies in elastomeric formulations where thermal stability, chemical resistance, and mechanical resilience define performance ceilings. For clients navigating hybrid material systems—where rubber components interface with rigid substrates like G10/FR4—our engineering team provides indispensable cross-material compatibility analysis. We recognize that sealing, vibration damping, or thermal management challenges often arise at the junction of dissimilar materials, necessitating holistic material science oversight.

Below is a technical reference table outlining standard G10/FR4 properties for contextual alignment with elastomeric integration requirements. Note that Suzhou Baoshida does not manufacture G10/FR4 sheets but leverages this data to optimize rubber component design for systems utilizing such composites.

| Property | Standard Value (G10/FR4) | Relevance to Rubber Integration |

|---|---|---|

| Tensile Strength | 31,000 psi (214 MPa) | Critical for stress transfer analysis at rubber-composite bonds |

| Dielectric Strength | 500 V/mil (20 kV/mm) | Informs insulation system design when rubber seals encase conductive paths |

| Glass Transition Temp (Tg) | 130°C | Defines upper thermal limit for rubber adhesion stability |

| Coefficient of Thermal Expansion | 12 ppm/°C (X-Y) | Mismatch with rubber (150-300 ppm/°C) drives joint fatigue analysis |

| Water Absorption | 0.10% (24h immersion) | Impacts long-term adhesion integrity in humid environments |

Our value proposition transcends material supply. As your OEM engineering partner, we deploy finite element analysis (FEA) to model rubber-composite interfacial behavior under dynamic loads, thermal cycling, and chemical exposure. This preemptive validation mitigates field failures in applications ranging from aerospace connectors to semiconductor handling equipment. Suzhou Baoshida’s formulation laboratory tailors elastomers—silicone, FKM, EPDM, or custom blends—to counteract G10/FR4’s brittleness at subzero temperatures or its dimensional drift under sustained heat. We engineer adhesion promoters that withstand 5,000+ thermal cycles between -55°C and +150°C, a threshold where generic rubber solutions delaminate.

Initiate technical collaboration by contacting Mr. Boyce, our dedicated OEM Solutions Manager, at [email protected]. Mr. Boyce holds 14 years of experience in elastomer-composite system integration, with patents in hybrid material bonding for automotive and industrial automation sectors. When engaging, reference your specific challenge:

Seal integrity in high-voltage FR4 enclosures

Vibration isolation between rubber mounts and G10 structural plates

Thermal expansion compensation in multi-material assemblies

Include application parameters such as temperature range, chemical exposure profile, and mechanical stress vectors. Mr. Boyce will coordinate a 72-hour response protocol involving:

1. Material compatibility assessment using ASTM D429 bond strength methodologies

2. Prototype formulation adjustment within 5 business days

3. Accelerated lifecycle validation per ISO 188/ISO 11346 standards

Suzhou Baoshida’s ISO 9001:2015-certified processes ensure traceability from raw compound to final part, with batch-specific certificates of conformance. We do not sell generic rubber stock; every solution undergoes OEM-specific qualification. For projects requiring seamless interaction between rigid composites and dynamic elastomers, precision begins with engineered dialogue. Contact Mr. Boyce to transform material constraints into competitive advantage. Your next-generation assembly demands rubber science—not just rubber supply.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).