Technical Contents

Engineering Guide: Garlock 3200

Engineering Insight: Garlock 3200 – The Critical Role of Material Selection in Industrial Sealing

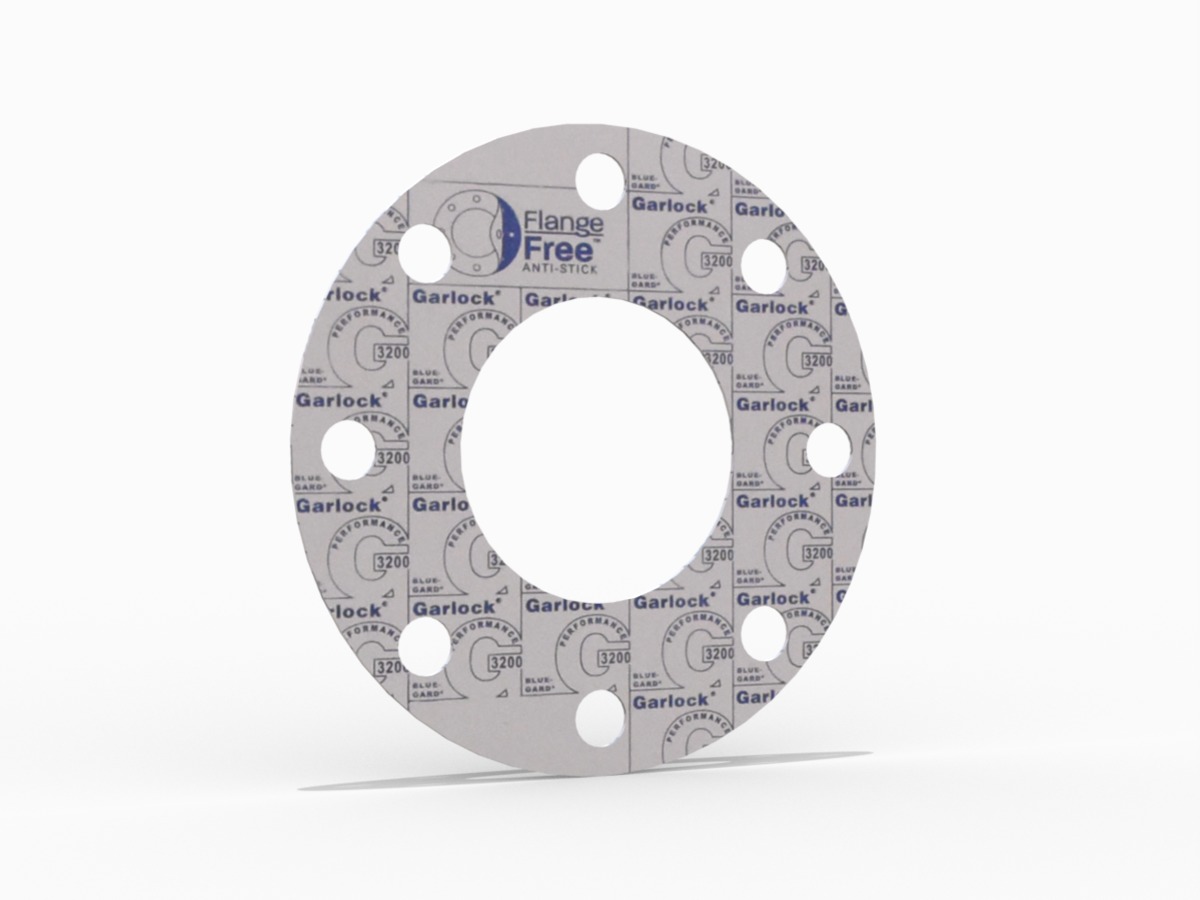

In the demanding environments of chemical processing, pulp and paper, and high-temperature industrial systems, material selection is not a secondary consideration—it is the foundation of sealing integrity and long-term reliability. Garlock 3200, a high-performance expanded PTFE (ePTFE) gasket material, exemplifies how engineered solutions outperform generic alternatives in aggressive service conditions. Unlike standard rubber or low-grade PTFE compounds, Garlock 3200 is formulated to resist chemical attack, maintain dimensional stability under thermal cycling, and conform to flange irregularities without cold flow degradation.

Off-the-shelf sealing materials often fail prematurely because they are designed for broad compatibility rather than specific operational challenges. Conventional elastomers, such as NBR or EPDM, may provide adequate performance in mild environments but degrade rapidly when exposed to strong acids, solvents, or elevated temperatures. Even standard PTFE gaskets, while chemically inert, can suffer from creep relaxation and lack the resilience needed for dynamic flange systems. These failures result in unplanned downtime, safety hazards, and increased total cost of ownership—costs that far exceed any initial savings from selecting a lower-grade material.

Garlock 3200 addresses these limitations through a microstructure of interconnected nodes and fibrils, created via a proprietary expansion process. This structure delivers superior compressibility and recovery, enabling the material to maintain sealing force under fluctuating pressure and temperature. Its near-zero cold flow ensures long-term load retention, a critical factor in maintaining joint integrity over extended service cycles. Additionally, the material’s purity—free from fillers or plasticizers—eliminates the risk of contamination in sensitive processes, making it ideal for pharmaceutical and food-grade applications.

Material selection must be driven by application-specific parameters, including media compatibility, operating temperature and pressure, flange type, and regulatory requirements. A one-size-fits-all approach compromises performance and safety. For instance, in a sulfuric acid service at 150°C, a standard rubber gasket would rapidly swell and decompose, whereas Garlock 3200 maintains structural integrity due to its inert fluoropolymer base.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered solutions over commoditized substitutes. Our technical team works with OEMs and maintenance engineers to validate material compatibility and optimize gasket design for mission-critical applications. Selecting Garlock 3200 is not merely a product choice—it is a commitment to reliability, safety, and operational continuity.

| Property | Value | Test Method |

|---|---|---|

| Density | 0.75 g/cm³ | ASTM D7111 |

| Tensile Strength (Longitudinal) | 10 MPa | ASTM D4767 |

| Compressibility @ 138 MPa | 20–30% | ASTM F36 |

| Recovery @ 138 MPa | ≥ 50% | ASTM F36 |

| Temperature Range | -268°C to +260°C | — |

| Fluid Resistance | Excellent against acids, bases, solvents | ASTM D471 |

| Thickness Range | 0.4 mm to 3.0 mm | Customizable |

Material Specifications

Garlock 3200 Material Specifications for Industrial Sealing Applications

Garlock 3200 represents a critical engineered gasket sheet solution within demanding industrial sealing environments. Its performance is intrinsically linked to the base elastomer formulation selected, directly impacting service life, chemical compatibility, and operational safety. Suzhou Baoshida Trading Co., Ltd. provides expert guidance on material selection for Garlock 3200, ensuring optimal fit for specific OEM manufacturing requirements and end-use conditions. Understanding the fundamental properties of the primary elastomer options—Viton fluorocarbon, Nitrile (NBR), and Silicone—is essential for reliable system integrity under pressure, temperature extremes, and chemical exposure. Material choice must align with fluid media, thermal cycling parameters, and mechanical stress profiles inherent to the application.

The comparative analysis below details core technical specifications for Viton, Nitrile, and Silicone formulations within the Garlock 3200 product line. These values represent typical performance ranges under standardized test conditions per ASTM D2000 and ISO 37 protocols. Actual in-service performance may vary based on specific compound variants, compression set requirements, and dynamic loading factors. Precise material qualification against the target operational envelope is mandatory prior to OEM integration.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 12-18 | 15-22 | 5-10 |

| Elongation at Break (%) | 150-250 | 200-400 | 200-600 |

| Hardness (Shore A) | 65-85 | 50-90 | 30-80 |

| Compression Set (%, 22h/150°C) | ≤25 | ≤35 | ≤20 |

| Key Chemical Resistance | Strong acids, fuels, oils, aromatics | Aliphatic hydrocarbons, water, hydraulic fluids | Water, alcohols, ozone, UV |

| Key Limitations | Poor ketone/amine resistance; higher cost | Limited aromatic fuel/oil resistance; poor ozone resistance | Low tear strength; poor steam resistance; limited hydrocarbon resistance |

Viton formulations deliver superior resistance to high-temperature fluids, aggressive chemicals, and oxidative degradation, making them indispensable for aerospace, chemical processing, and critical automotive fuel systems where failure is unacceptable. Nitrile remains the cost-effective standard for general-purpose industrial applications involving petroleum-based oils, water, and moderate temperatures, particularly in hydraulic and pneumatic systems. Silicone excels in extreme low-temperature flexibility, biocompatibility, and resistance to weathering, ozone, and steam, serving vital roles in medical devices, food processing, and outdoor electrical insulation.

Suzhou Baoshida Trading Co., Ltd. emphasizes rigorous validation of Garlock 3200 material selection against the specific OEM application matrix. Our engineering team collaborates directly with manufacturers to analyze fluid compatibility charts, conduct thermal aging studies per ASTM D573, and evaluate dynamic sealing performance under simulated service conditions. This precision-driven approach mitigates field failures and ensures compliance with ISO 9001 quality standards for industrial rubber solutions. Consult our technical datasheets for compound-specific ASTM D2000 callouts and OEM qualification protocols.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Solutions for Demanding Industrial Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, enabling us to deliver high-performance, application-specific products such as Garlock 3200 equivalents with consistent reliability. Our technical team comprises five dedicated mould engineers and two specialized rubber formula engineers, integrating material science with precision manufacturing to meet the exacting demands of global OEMs and industrial partners.

Our formula engineers possess deep expertise in elastomer chemistry, with a focus on optimizing compound formulations for thermal stability, chemical resistance, and mechanical performance. With extensive experience in nitrile (NBR), hydrogenated nitrile (HNBR), ethylene propylene diene monomer (EPDM), and fluorocarbon (FKM) systems, they are capable of reverse-engineering or enhancing legacy materials such as Garlock 3200 to meet or exceed original equipment specifications. This capability ensures compatibility with aggressive media including oils, fuels, steam, and industrial chemicals, while maintaining resilience under dynamic sealing conditions.

Complementing our formulation expertise, our five mould engineers bring advanced design and process optimization capabilities to every project. Utilizing CAD/CAM software and precision CNC machining, they develop robust tooling solutions that ensure dimensional accuracy, repeatable part geometry, and minimal flash—critical factors in high-integrity sealing applications. Our in-house tooling development shortens lead times and enables rapid prototyping, allowing for accelerated validation and time-to-market for OEM clients.

We operate under strict quality control protocols, with full traceability from raw material sourcing to final product testing. Our facility supports small-batch customization as well as high-volume production, making us a flexible partner for tier-1 manufacturers seeking reliable, scalable supply chains. All formulations and processes are documented and validated per ISO 9001 standards, ensuring consistency across production runs.

Our OEM capabilities extend beyond replication to value-added engineering support. We collaborate closely with clients to optimize seal design for manufacturability, cost-efficiency, and performance in real-world operating environments. Whether upgrading existing components or developing new sealing solutions for challenging applications, our engineering team delivers technically sound, economically viable outcomes.

The following table outlines key technical properties of our Garlock 3200-equivalent rubber compound, formulated to match the performance profile of the original material while ensuring supply chain resilience and cost optimization.

| Property | Test Method | Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 75 ± 5 |

| Tensile Strength | ASTM D412 | ≥18 MPa |

| Elongation at Break | ASTM D412 | ≥300% |

| Compression Set (22 hrs, 150°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | — | -30°C to +200°C |

| Fluid Resistance (Oil, Fuel, Steam) | ASTM D471 | Excellent |

| Specific Gravity | ASTM D297 | 1.48 ± 0.02 |

Through the synergy of advanced material formulation and precision tooling engineering, Suzhou Baoshida Trading Co., Ltd. delivers industrial rubber solutions that meet the highest standards of performance and reliability. Our technical team is committed to innovation, quality, and partnership—ensuring that every component we produce supports the operational integrity of our clients’ equipment.

Customization Process

Garlock 3200 Customization Process: Precision Engineering from Concept to Volume

Suzhou Baoshida Trading Co., Ltd. executes a rigorously defined customization pathway for Garlock 3200 industrial rubber components, ensuring absolute alignment with client engineering requirements and operational environments. Our OEM-managed process eliminates guesswork through sequential, data-driven phases, beginning with comprehensive drawing analysis. Engineering teams conduct granular GD&T verification against ISO 1122-1 standards, identifying critical tolerances, surface finish specifications, and potential material-flow conflicts in complex geometries. This phase includes thermal expansion coefficient modeling and stress-point simulation using ANSYS software, resolving ambiguities before material formulation commences. Client-supplied drawings undergo cross-functional review to validate feasibility against Garlock 3200’s inherent material constraints, preventing downstream prototyping failures.

Formulation engineering follows, where our rubber chemists translate geometric and environmental requirements into precise molecular architecture. Garlock 3200’s base EPDM polymer is systematically modified through controlled peroxide curing systems and specialized filler matrices to achieve target properties. Key adjustments address compression set resistance for dynamic seals, fluid compatibility with aggressive media (e.g., glycols, weak acids), and thermal stability within client-specified ranges. Each formulation variant undergoes ASTM D2000 classification validation, with critical parameters documented for traceability.

Prototyping leverages Suzhou Baoshida’s in-house tooling capabilities for rapid physical validation. CNC-machined or molded prototypes undergo accelerated life testing per ASTM D395 (compression set), ASTM D2240 (hardness), and fluid immersion protocols matching client operational conditions. Torque retention, extrusion resistance, and dimensional stability under thermal cycling are quantitatively measured. Client engineering sign-off requires ≤5% deviation from predicted performance metrics, with reformulation loops completed within 72 hours if thresholds are unmet.

Mass production initiates only after formal prototype approval, utilizing Suzhou Baoshida’s ISO 9001-certified manufacturing cells. Automated mixing ensures batch-to-batch consistency with ±0.5 phr (parts per hundred rubber) accuracy for critical additives. In-process controls monitor cure state via moving die rheometry (MDR) and dimensional conformity via CMM inspection at defined lot intervals. Full material traceability—from raw polymer batch to finished component—is maintained through blockchain-verified logs, satisfying stringent OEM audit requirements.

Garlock 3200 Key Customization Parameters

| Customization Parameter | Standard Range | Precision Adjustment Capability | Critical Test Standard |

|---|---|---|---|

| Hardness (Shore A) | 60–90 | ±2 points | ASTM D2240 |

| Compression Set (22h/150°C) | ≤25% | ≤18% achievable | ASTM D395 Method B |

| Fluid Resistance (ASTM No. 3) | ΔVolume ≤25% | ΔVolume ≤15% achievable | ASTM D471 |

| Operating Temperature | -54°C to +150°C | Extended to +175°C (short-term) | ASTM D573 |

| Tensile Strength (MPa) | ≥10.3 | ≥14.5 achievable | ASTM D412 |

This structured methodology guarantees that every Garlock 3200 component delivers engineered reliability, minimizing client validation cycles and accelerating time-to-installation. Suzhou Baoshida’s integration of material science rigor with industrial-scale manufacturing control establishes a benchmark for mission-critical sealing solutions.

Contact Engineering Team

For industrial manufacturers and engineering teams seeking high-performance sealing solutions, Garlock 3200 represents a benchmark in non-asbestos, die-formed gasket material technology. At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering premium industrial rubber solutions tailored to the rigorous demands of petrochemical, power generation, pulp and paper, and heavy manufacturing sectors. As a trusted supplier of engineered elastomeric products, we provide direct access to authentic Garlock 3200 material, ensuring compliance with international standards and consistent batch-to-batch reliability.

Garlock 3200 is engineered for applications requiring resistance to a broad range of industrial fluids, including steam, acids, caustics, and hydrocarbons. Its reinforced synthetic rubber composition offers excellent resilience under thermal cycling and mechanical stress, making it ideal for use in flanged joints operating under moderate to high pressure. The material’s low creep relaxation characteristics ensure long-term sealing integrity, reducing maintenance frequency and unplanned downtime.

Below are the technical specifications for Garlock 3200, as verified through standardized industrial testing protocols:

| Property | Test Method | Value |

|---|---|---|

| Density | ASTM D2240 | 1.4 g/cm³ |

| Compressive Strength | ASTM F36 | 24 MPa @ 10% compression |

| Temperature Range | — | -54°C to +260°C (-65°F to +500°F) |

| Thickness Range | — | 0.4 mm to 3.0 mm (0.015″ to 0.125″) |

| pH Resistance | ASTM D471 | 2–13 |

| Fluid Resistance | ASTM D471 | Excellent in steam, oils, solvents, mild acids and alkalis |

| Fiber Content | — | Aramid and cellulose reinforcement |

| Binder System | — | Nitrile rubber |

All material supplied by Suzhou Baoshida undergoes rigorous incoming quality inspection, including dimensional verification, hardness testing, and visual defect screening. We maintain strategic inventory levels to support just-in-time delivery schedules and offer custom die-cutting services to meet OEM flange specifications.

For technical inquiries, material data sheets, or volume pricing on Garlock 3200, contact Mr. Boyce, Rubber Formula Engineer and OEM Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce leads our industrial rubber formulation and application support team, providing expert guidance on material selection, compatibility analysis, and sealing performance optimization. With over 15 years of experience in elastomer engineering and OEM collaboration, he ensures clients receive not only high-quality materials but also scientifically grounded technical support.

To request a quotation, schedule a technical consultation, or obtain sample kits for evaluation, please reach out directly via email at [email protected]. Our team responds to all inquiries within 4 business hours and supports communication in English, Mandarin, and technical German for EU-based partners. Suzhou Baoshida is committed to advancing industrial sealing performance through precision materials and engineering partnership. Contact us today to integrate Garlock 3200 into your next production or maintenance cycle with confidence.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).