Technical Contents

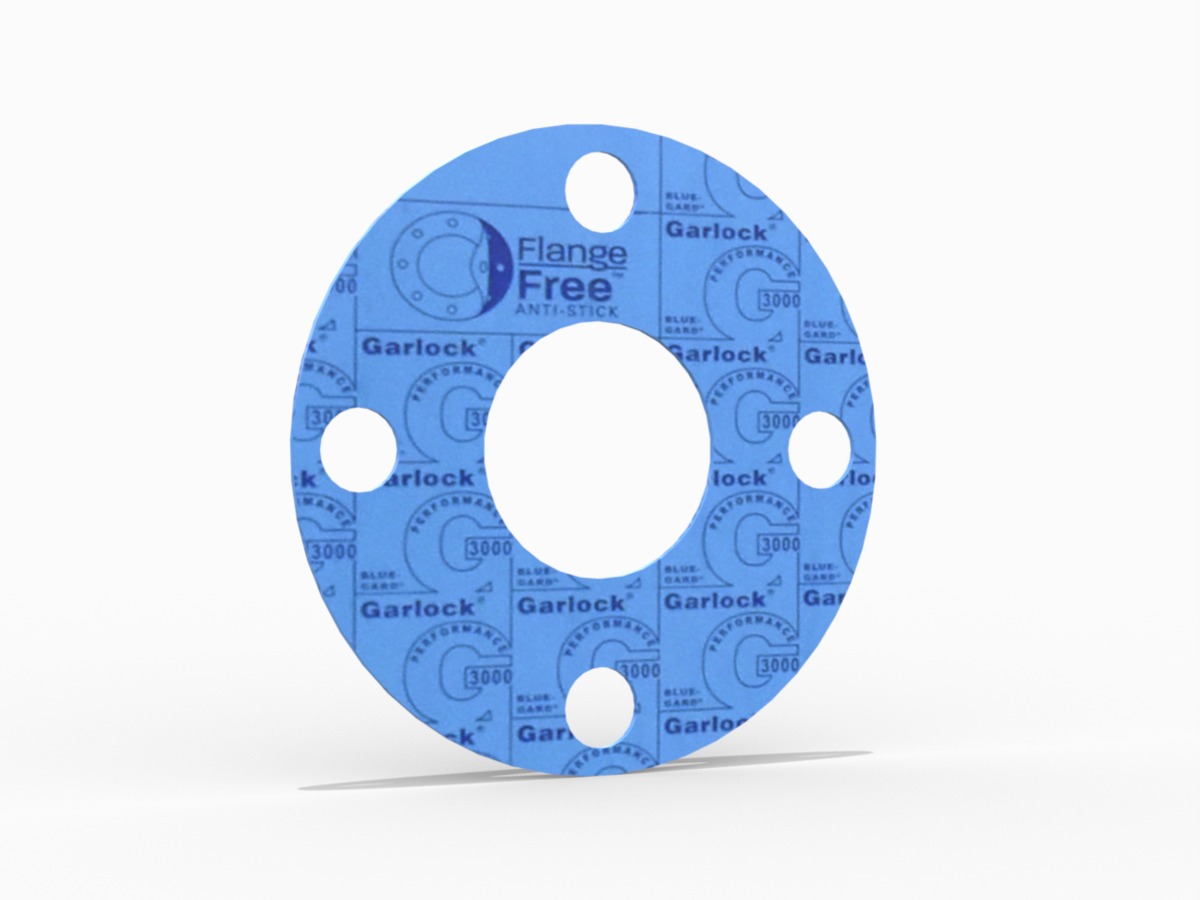

Engineering Guide: Garlock Blue Gard 3000

Engineering Insight: Garlock Blue Gard 3000 – The Critical Imperative of Precision Material Selection

In industrial sealing applications, the catastrophic failure of generic elastomeric gaskets represents a significant, often underestimated operational risk. Off-the-shelf rubber solutions, typically formulated with standard nitrile butadiene rubber (NBR), frequently succumb under demanding service conditions prevalent in chemical processing, power generation, and pulp & paper industries. These failures manifest as premature extrusion, chemical degradation, excessive compression set, or thermal decomposition, leading to unplanned downtime, environmental incidents, and substantial financial losses. The root cause lies in the fundamental mismatch between the generalized formulation of commodity rubbers and the specific, often extreme, chemical, thermal, and mechanical stresses encountered in critical flange joints. Generic compounds prioritize low cost and broad applicability over engineered resilience, lacking the targeted molecular architecture required for sustained performance in aggressive media like hot acids, caustics, solvents, or high-temperature steam.

Garlock Blue Gard 3000 exemplifies the necessity of application-specific material engineering. This advanced sheet gasketing material utilizes a proprietary PTFE-reinforced nitrile formulation. The strategic incorporation of polytetrafluoroethylene (PTFE) fibrils within the NBR matrix creates a synergistic composite structure. This design fundamentally alters the material’s response to stress. The PTFE fibrils provide exceptional resistance to chemical attack and thermal degradation, while the optimized NBR base ensures necessary elasticity, conformability, and resilience during bolt-up and operational cycling. Crucially, Blue Gard 3000 undergoes rigorous compounding to achieve superior resistance to compression set – a primary failure mode for standard NBR gaskets under sustained heat and load. This engineered resistance maintains sealing force integrity over extended service life, preventing the creep relaxation that causes leaks in inferior materials.

The performance delta between generic NBR and Blue Gard 3000 is quantifiable and operationally decisive. Consider the following critical parameters under typical severe service conditions:

| Property | Generic NBR Gasket Material | Garlock Blue Gard 3000 | Operational Significance |

|---|---|---|---|

| Continuous Temp Range | -20°C to +100°C | -30°C to +150°C | Enables reliable service in high-temp steam |

| Compression Set (100°C, 22h) | 40-60% | < 25% | Maintains sealing force, prevents bolt load loss |

| Acid Resistance (50% H2SO4, 100°C) | Severe Swelling/Degradation | Excellent Retention | Critical for chemical processing integrity |

| Seal Integrity Duration | Days to Weeks | Months to Years | Drastically reduces unplanned maintenance |

Suzhou Baoshida Trading Co., Ltd. emphasizes that successful sealing is not merely about selecting a gasket, but selecting the engineered solution for the specific fluid, temperature, pressure, and flange geometry. Generic materials represent a false economy; their initial cost savings are invariably eclipsed by the cumulative costs of leakage remediation, process interruption, and potential safety hazards. Blue Gard 3000’s formulation directly addresses the molecular-level weaknesses of standard elastomers under stress. As your OEM partner, we rigorously qualify this material against application-specific protocols, ensuring the compound’s chemistry delivers the required barrier properties, resilience, and longevity. Material selection is the foundational engineering decision in sealing system design – precision formulation is non-negotiable for operational reliability and safety in demanding industrial environments.

Material Specifications

Garlock Blue-Gard 3000 is an advanced industrial sealing material engineered for high-performance applications across demanding environments. Manufactured by Garlock Sealing Technologies, this gasket material features a reinforced synthetic rubber compound designed to deliver exceptional resistance to heat, pressure, and a broad range of chemical exposures. As a critical component in pipeline systems, flange connections, and process equipment, Blue-Gard 3000 ensures long-term reliability in industries such as oil and gas, chemical processing, power generation, and pulp and paper. At Suzhou Baoshida Trading Co., Ltd., we specialize in providing high-grade industrial rubber solutions, including precision-cut gaskets and sealing components made from Garlock Blue-Gard 3000, tailored to meet OEM and industrial specifications.

The performance of Blue-Gard 3000 is significantly influenced by the elastomeric materials used in conjunction with it. Among the most commonly specified elastomers in industrial sealing applications are Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers a distinct balance of thermal stability, chemical compatibility, and mechanical resilience, making material selection a vital step in system design.

Viton is widely recognized for its outstanding resistance to high temperatures, aromatic hydrocarbons, and aggressive chemicals. It performs reliably in continuous service up to 200°C (392°F) and demonstrates minimal swelling in oil and fuel environments. This makes Viton an ideal choice for high-pressure, high-temperature applications where chemical exposure is severe.

Nitrile rubber, or Buna-N, offers excellent resistance to petroleum-based oils, fuels, and hydraulic fluids. It maintains good mechanical properties across a moderate temperature range of -30°C to 120°C (-22°F to 248°F). While not as thermally stable as Viton, Nitrile provides a cost-effective solution for general-purpose sealing in automotive, aerospace, and industrial hydraulic systems.

Silicone rubber excels in extreme temperature applications, functioning effectively from -60°C to 230°C (-76°F to 446°F). It offers superior flexibility at low temperatures and excellent resistance to ozone and UV radiation. However, its mechanical strength and resistance to oils and solvents are limited compared to Viton and Nitrile, making it best suited for non-lubricated, static, or low-stress environments such as food processing, medical devices, and electrical insulation.

The following table provides a comparative overview of key physical and chemical properties for these elastomeric materials when used in conjunction with Garlock Blue-Gard 3000 sealing systems.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 | -30 to 120 | -60 to 230 |

| Temperature Range (°F) | -4 to 392 | -22 to 248 | -76 to 446 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Aromatic Hydrocarbons | Very Good | Poor | Poor |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Compression Set Resistance | Very Good | Good | Fair |

| Common Applications | Chemical processing, aerospace, refinery | Hydraulics, automotive, fuel systems | Medical, food, electrical, extreme cold/heat |

Selecting the appropriate elastomer ensures optimal sealing performance and longevity when integrating Garlock Blue-Gard 3000 into industrial systems. Suzhou Baoshida Trading Co., Ltd. supports OEMs and industrial clients with technical guidance, material certification, and custom fabrication services to meet exacting operational demands.

Manufacturing Capabilities

Engineering Capability: Precision Formulation and OEM Execution for Garlock Blue Gard 3000

Suzhou Baoshida Trading Co., Ltd. leverages a dedicated engineering cohort of five specialized mold engineers and two advanced rubber formula engineers to deliver exacting manufacturing solutions for demanding industrial compounds like Garlock Blue Gard 3000. This technical synergy ensures every component transcends standard specifications through rigorous material science and precision tooling design. Our formula engineers possess deep expertise in nitrile rubber (NBR) and hydrogenated nitrile (HNBR) systems, enabling precise molecular tailoring of Blue Gard 3000 formulations to optimize thermal stability, fluid resistance, and compression set performance under extreme operational conditions. Concurrently, our mold engineering team employs advanced simulation software to resolve complex flow dynamics, cure kinetics, and dimensional tolerancing challenges inherent in high-precision sealing applications. This integrated approach eliminates common failure modes such as flash generation, incomplete cavity filling, or post-cure distortion, directly enhancing product lifecycle reliability.

Our OEM capabilities are engineered for seamless scalability and intellectual property security. We operate under strict confidentiality protocols, managing tooling ownership, material traceability, and production documentation per client-specific requirements. The process begins with collaborative design validation, where our engineers conduct finite element analysis (FEA) to predict seal behavior under thermal cycling and pressure loads. Subsequent phases include iterative prototype refinement using client-supplied fluid media and accelerated aging tests aligned with ASTM D2000 standards. Crucially, our dual-engineer model ensures formulation adjustments—such as modifying acrylonitrile content for enhanced oil resistance or incorporating specialized additives for low-temperature flexibility—are validated against mold performance data in real time. This prevents costly rework during scale-up and guarantees consistent part conformance across production batches exceeding 500,000 units.

Client-specific formulations undergo stringent validation against critical performance metrics. The table below illustrates baseline properties achievable for Garlock Blue Gard 3000 equivalents, though all parameters are adjustable per OEM specifications:

| Property | Test Method | Typical Value |

|---|---|---|

| Tensile Strength (MPa) | ASTM D412 | ≥ 20.0 |

| Elongation at Break (%) | ASTM D412 | ≥ 250 |

| Hardness (Shore A) | ASTM D2240 | 70 ± 5 |

| Compression Set (70h/150°C) (%) | ASTM D395 | ≤ 25 |

| Operating Temperature Range (°C) | ISO 1817 | -30 to +150 |

| Fluid Resistance (IRM 903) | ASTM D471 | Volume Swell ≤ 25% |

This technical infrastructure positions Suzhou Baoshida as a strategic partner for OEMs requiring mission-critical sealing solutions. We transform material science into industrial reality through engineered precision, ensuring Garlock Blue Gard 3000-based products consistently meet the uncompromising demands of hydraulic systems, automotive powertrains, and chemical processing equipment. Our commitment to data-driven process control and collaborative engineering eliminates performance uncertainty in high-stakes applications.

Customization Process

Drawing Analysis

The customization process for Garlock Blue Gard 3000 begins with a comprehensive drawing analysis, a critical phase that ensures dimensional accuracy and functional compatibility. At Suzhou Baoshida Trading Co., Ltd., our engineering team reviews technical blueprints provided by the client, focusing on geometric tolerances, sealing surface requirements, and operational constraints. We assess cross-sectional profiles, inner and outer diameters, and any non-standard features such as grooves, chamfers, or eccentricities. Utilizing CAD-based evaluation tools, we perform interference checks and validate compliance with ISO 3601, AS568, or custom OEM standards. This stage also includes a feasibility assessment for mold design and material behavior under compression or elongation. Clear communication with the client is maintained to resolve ambiguities and confirm performance expectations under dynamic or static sealing conditions.

Formulation Development

Following drawing validation, the formulation stage tailors the elastomeric compound to meet specific environmental and mechanical demands. Garlock Blue Gard 3000 is inherently a high-performance nitrile rubber (NBR) reinforced with aramid fiber, offering excellent abrasion resistance and low fluid absorption. However, we adjust the polymer matrix, filler content, and cure system based on application parameters such as temperature range, chemical exposure, and pressure cycles. For instance, in high-temperature environments exceeding 120°C, we incorporate thermal stabilizers and optimize the crosslink density. In applications involving aggressive hydraulic fluids, we modify the NBR acrylonitrile content to enhance oil resistance. Each formulation is documented under strict batch traceability protocols and subjected to preliminary lab testing for hardness, tensile strength, and compression set. The resulting compound is then cleared for prototype tooling.

Prototyping and Validation

Prototyping serves as the functional verification step, where small-batch samples are produced using precision molding techniques. We fabricate initial runs in-house using steel cavity molds machined to the exact geometry specified. These prototypes undergo rigorous physical and chemical testing, including compression deflection analysis, fluid immersion resistance (per ASTM D471), and dynamic seal performance in simulated operating conditions. Dimensional inspection is performed using coordinate measuring machines (CMM) to ensure conformity within ±0.1 mm tolerances. Clients receive test reports and sample sets for field evaluation. Feedback is integrated into final adjustments before release to mass production.

Mass Production and Quality Assurance

Once approved, the project transitions to automated mass production with continuous quality monitoring. Each batch is inspected for visual defects, dimensional consistency, and physical properties in accordance with ISO 9001 protocols. We maintain full documentation for traceability, including raw material certifications and process control charts.

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 80 ± 5 |

| Tensile Strength | ASTM D412 | ≥18 MPa |

| Elongation at Break | ASTM D412 | ≥200% |

| Compression Set (24h, 100°C) | ASTM D395 | ≤25% |

| Fluid Resistance (IRM 903, 70°C) | ASTM D471 | Volume Swell ≤15% |

Contact Engineering Team

Technical Engagement for Garlock Blue Gard 3000 Industrial Seal Implementation

Suzhou Baoshida Trading Co., Ltd. serves as your precision engineering partner for integrating Garlock Blue Gard 3000 into demanding industrial fluid sealing systems. This advanced elastomeric compound delivers critical performance in high-temperature, high-pressure environments where conventional materials fail. Its unique perfluoroelastomer (FFKM) formulation ensures exceptional resistance to aggressive chemicals, steam, and thermal degradation, directly addressing seal leakage and premature failure in chemical processing, semiconductor manufacturing, and oil & gas applications. Our engineering team possesses certified expertise in Blue Gard 3000’s material science, enabling precise specification alignment with your operational parameters. We rigorously validate each seal’s dimensional tolerances, compression set, and extrusion resistance against OEM design requirements, ensuring seamless integration into critical machinery.

The following technical specifications define Blue Gard 3000’s operational boundaries for engineering validation:

| Property | Value | Test Standard |

|---|---|---|

| Temperature Range | -20°C to +315°C (short-term +327°C) | ASTM D2000 |

| Maximum Pressure | 200 bar (static) / 100 bar (dynamic) | ISO 3601 |

| Tensile Strength | ≥ 10.3 MPa | ASTM D412 |

| Elongation at Break | ≥ 150% | ASTM D412 |

| Compression Set (24h, 204°C) | ≤ 30% | ASTM D395 |

| Key Chemical Resistance | Strong acids, bases, amines, steam, plasma | ASTM D471 |

These metrics are non-negotiable for applications involving aggressive media like wet chlorine, hydrogen peroxide, or high-purity solvents. Suzhou Baoshida’s quality assurance protocols exceed Garlock’s baseline testing, incorporating application-specific validation under simulated service conditions. We provide full material traceability, including Certificates of Conformance (CoC) and Material Safety Data Sheets (MSDS), ensuring compliance with ISO 9001 and industry-specific regulatory frameworks. Our technical documentation package includes finite element analysis (FEA) support for complex sealing geometries, mitigating risk during equipment commissioning.

For immediate technical consultation on Blue Gard 3000 seal selection, custom molding, or failure analysis, contact Mr. Boyce, our dedicated OEM Engineering Manager. Mr. Boyce holds 12 years of specialized experience in FFKM application engineering and direct collaboration with Garlock’s global R&D division. He will facilitate:

Technical review of your sealing challenge with material compatibility assessment

Customized prototyping and accelerated life-cycle testing protocols

Seamless integration pathways for volume production with zero-defect quality targets

Do not proceed with generic elastomer substitutions that compromise system integrity. Engage Suzhou Baoshida’s engineering team to leverage Blue Gard 3000’s molecular stability for mission-critical applications. Contact Mr. Boyce directly at [email protected] to initiate a technical dialogue. Include your application parameters, failure history (if applicable), and target production volume for a prioritized engineering response within 24 business hours. Our commitment is to deliver not merely a product, but a validated sealing solution that extends mean time between failures (MTBF) and reduces total cost of ownership. Partner with precision—contact Suzhou Baoshida today.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).