Technical Contents

Engineering Guide: Garlock Gasket Material

Engineering Insight: Garlock Gasket Material Selection Fundamentals

Material selection for critical gasket applications transcends basic dimensional compatibility. Off-the-shelf generic rubber compounds frequently fail under industrial process conditions due to inadequate molecular architecture for specific chemical, thermal, and mechanical demands. Standard elastomers like generic nitrile (NBR) or EPDM exhibit predictable limitations when exposed to aggressive media, fluctuating temperatures, or sustained compressive loads. These limitations manifest as premature compression set, chemical degradation, or extrusion failure, directly compromising process integrity and safety. The cost of such failures—unscheduled downtime, product contamination, and environmental incidents—far exceeds the marginal premium of engineered solutions.

Garlock gasket materials exemplify purpose-built engineering, where polymer selection, filler systems, and vulcanization protocols are optimized for defined operational envelopes. Generic materials often utilize cost-driven formulations with broad but shallow performance profiles. In contrast, engineered compounds like Garlock’s GYLON® or THERMa-PUR® series leverage proprietary blends—such as expanded PTFE, reinforced graphite, or perfluoroelastomers—to achieve targeted resilience. For instance, a standard NBR gasket may swell catastrophically in amine service above 100°C, while a fluorocarbon-based Garlock solution maintains seal integrity at 200°C+ with minimal swell. The critical differentiator lies in the precise balance of cross-linking density, filler reinforcement, and polymer backbone stability.

The following table illustrates key performance gaps between standard and engineered gasket materials under demanding conditions:

| Property | Standard NBR/EPDM | Engineered Garlock Material | Critical Failure Risk with Standard Material |

|---|---|---|---|

| Max Continuous Temp | 120°C | 260°C (e.g., GYLON 3510) | Rapid hardening, loss of sealing force |

| Chemical Resistance | Moderate acids/bases | Broad solvent/aromatic resistance | Swelling >40%, extrusion, leakage |

| Compression Set (24h/150°C) | 45-60% | <15% (e.g., THERMa-PUR 1300) | Permanent deformation, bolt load relaxation |

| Steam Resistance | Poor (blistering) | Excellent (up to 550°C steam) | Layer delamination, catastrophic blowout |

OEMs and plant engineers must mandate material validation against actual service parameters—not catalog claims. A gasket functioning adequately in water service may disintegrate in hydrogen sulfide environments due to sulfur vulcanization incompatibility. Suzhou Baoshida Trading Co., Ltd. rigorously cross-references OEM specifications with Garlock’s certified test data under simulated field conditions. We reject one-size-fits-all approaches; instead, we deploy material matrices aligned with ASME PCC-1 guidelines and fluid compatibility databases.

The recurring failure of off-the-shelf gaskets stems from unaddressed synergistic stressors: thermal cycling accelerating oxidative aging, combined pressure pulsation and chemical attack inducing micro-cracking, or improper durometer selection causing insufficient recovery. Engineered Garlock materials mitigate these risks through co-polymer design and reinforcement strategies invisible in generic alternatives. Investing in validated material selection is not a cost—it is risk capital allocated against operational continuity. Partner with precision seal specialists to convert gasket specifications from procurement line items into engineered reliability assets.

Material Specifications

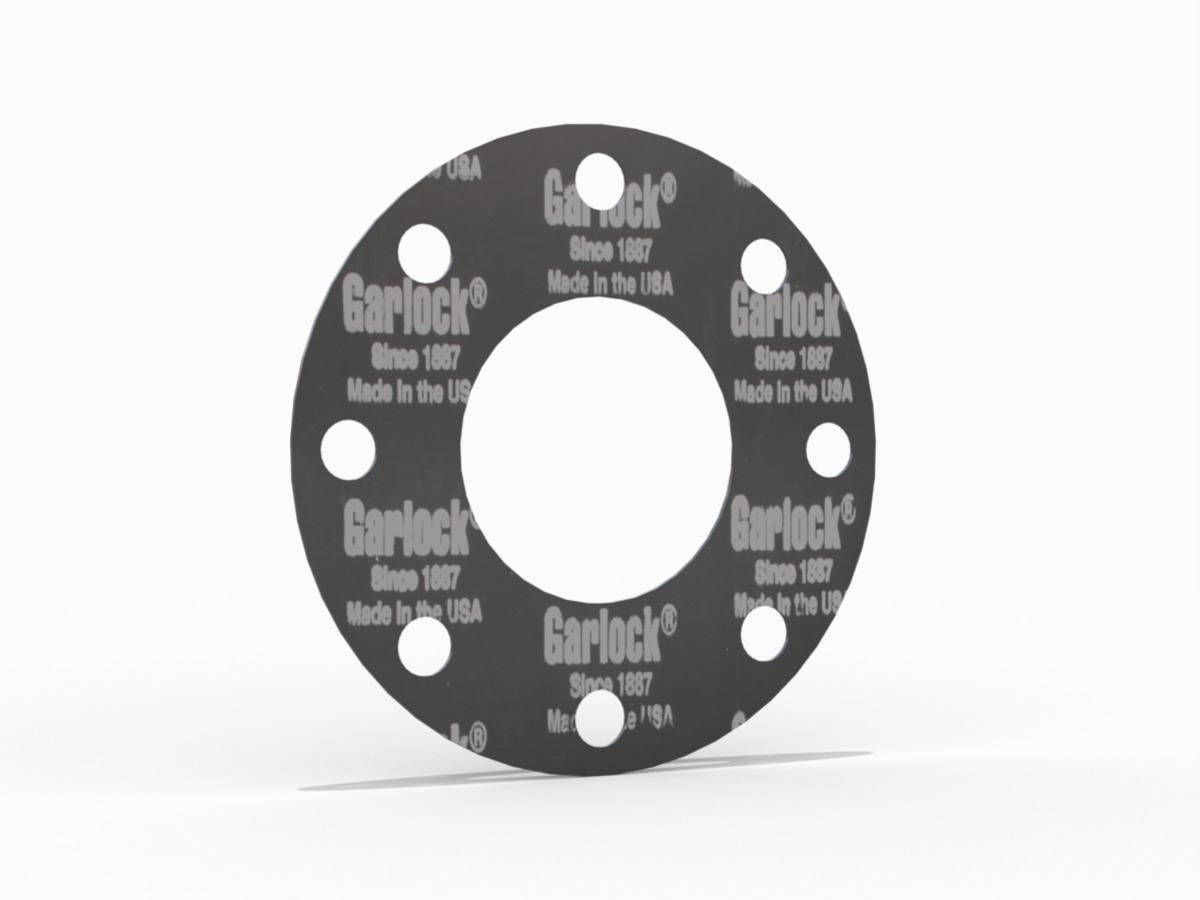

Garlock gasket materials are engineered for high-performance sealing applications across diverse industrial environments, including chemical processing, oil and gas, pharmaceuticals, and power generation. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals that meet rigorous OEM standards, ensuring reliability under extreme temperature, pressure, and chemical exposure. Our technical selection focuses on three core elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct advantages tailored to operational demands.

Viton is a fluorocarbon-based rubber renowned for its exceptional resistance to high temperatures, aggressive chemicals, and hydrocarbons. With continuous service capability up to 230°C (446°F) and intermittent peaks near 260°C (500°F), Viton is ideal for sealing applications involving fuels, oils, acids, and steam. Its low gas permeability and excellent aging characteristics make it a preferred choice in aerospace and petrochemical industries where long-term integrity is critical.

Nitrile rubber, or Buna-N, is a cost-effective solution for applications involving petroleum-based fluids, hydraulic oils, and aliphatic hydrocarbons. It offers good mechanical strength and abrasion resistance, with an operational temperature range of -40°C to +120°C (-40°F to +248°F). While not as chemically resistant as Viton, Nitrile provides superior sealing performance in dynamic systems such as pumps and compressors where exposure to oils and greases is common.

Silicone rubber excels in extreme temperature environments, maintaining flexibility from -60°C to +200°C (-76°F to +392°F). It is highly resistant to ozone and UV radiation, making it suitable for outdoor and medical applications. However, silicone has lower tensile strength and poor resistance to hydrocarbon fuels, limiting its use in high-pressure mechanical systems. Its biocompatibility and low toxicity support compliance with FDA and USP Class VI standards, ideal for pharmaceutical and food processing seals.

Selection of the appropriate gasket material requires a comprehensive understanding of media compatibility, thermal exposure, mechanical stress, and regulatory requirements. Below is a comparative specification table for Viton, Nitrile, and Silicone rubber materials commonly used in Garlock-style gasket fabrication.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -40 to 120 | -60 to 200 |

| Temperature Range (°F) | -4 to 446 | -40 to 248 | -76 to 392 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–400 | 200–600 |

| Hardness (Shore A) | 70–90 | 60–85 | 40–80 |

| Fluid Resistance (Oils/Fuels) | Excellent | Good | Poor |

| Chemical Resistance | Excellent | Fair | Fair |

| Ozone/UV Resistance | Excellent | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Fair |

| FDA Compliance Available | Yes (specific grades) | No | Yes |

At Suzhou Baoshida Trading Co., Ltd., we ensure all rubber compounds meet international quality benchmarks, supporting OEM integration with documented traceability and performance validation. Material selection directly impacts seal lifecycle and system safety—precision engineering begins with the right elastomer.

Manufacturing Capabilities

Engineering Capability: Precision Formulation and OEM Execution for Garlock Gasket Materials

Suzhou Baoshida Trading Co., Ltd. leverages deep engineering expertise specifically honed for the demanding requirements of industrial sealing solutions, particularly within the Garlock gasket material portfolio. Our core strength resides in the dedicated integration of 5 Advanced Mould Engineers and 2 Specialized Rubber Formula Engineers, forming a cohesive unit that bridges theoretical material science with practical manufacturing excellence. This structure ensures every gasket component, whether standard or highly customized, is developed and produced with uncompromising precision and performance integrity.

Our Formula Engineering team possesses profound knowledge of elastomer chemistry and composite material behavior. They meticulously analyze and optimize formulations against Garlock’s stringent specifications, focusing on critical parameters such as polymer selection, filler systems, crosslink density, and additive packages. This scientific approach directly translates to superior gasket performance characteristics: exceptional resistance to compression set under sustained load, precise control of modulus for optimal sealing force distribution, enhanced thermal stability across wide operational ranges, and tailored chemical compatibility for specific aggressive media encountered in refineries, chemical plants, and power generation facilities. We do not merely replicate; we refine and validate formulations to meet or exceed the exacting demands of the most challenging OEM applications.

Complementing this material science rigor, our Mould Engineering division excels in transforming optimized formulations into flawless physical products. Utilizing advanced CAD/CAM systems and precision CNC machining, they design and manufacture molds with micron-level tolerances, critical for achieving consistent gasket thickness, dimensional accuracy, and edge definition. This capability is paramount for complex geometries, multi-layer constructions, and applications requiring stringent surface finish requirements to prevent leakage paths. Our engineers rigorously simulate molding processes to eliminate defects like flash, voids, or uneven curing, ensuring batch-to-batch repeatability essential for high-integrity sealing systems.

This integrated engineering capability forms the backbone of our OEM service model. We partner directly with global equipment manufacturers, providing full technical support from initial concept and material selection through prototyping, validation testing, and high-volume production. Our process includes detailed material certification per Garlock standards, comprehensive dimensional inspection reports, and stringent in-process quality controls aligned with ISO 9001 protocols. Clients benefit from reduced development cycles, minimized risk of field failures, and gaskets engineered for seamless integration into their specific machinery.

The following table summarizes key performance attributes achievable with our engineered Garlock material solutions:

| Material Type | Temperature Range (°C) | Max Pressure (bar) | Key Chemical Resistance | Typical OEM Application |

|---|---|---|---|---|

| Compressed Fiber (Style 3000) | -200 to +550 | 250 | Steam, Acids, Solvents, Oils | Flange Sealing, Heat Exchangers |

| Flexible Graphite (Style 3500) | -240 to +550 (Inert) | 300 | Extreme Temp, Most Chemicals (Ox. Acids) | High-Temp Valves, Reactors |

| PTFE (Style 3200) | -200 to +260 | 150 | Virtually All Chemicals, Ultra-Pure | Semiconductor, Pharma, Aggressive Chem |

| Rubber-Based (Style 1000) | -50 to +150 | 100 | Water, Air, Mild Chemicals, Oils | Pumps, Compressors, General Ind. |

Suzhou Baoshida’s engineering synergy delivers not just gaskets, but validated sealing performance solutions. Our Formula and Mould Engineers, combined with robust OEM processes, provide the technical assurance industrial clients require for mission-critical applications, directly reducing operational risk and enhancing system reliability.

Customization Process

Drawing Analysis

The customization process for Garlock gasket material begins with rigorous drawing analysis, a critical phase that ensures dimensional accuracy, material compatibility, and functional performance under real-world operating conditions. At Suzhou Baoshida Trading Co., Ltd., our engineering team conducts a comprehensive review of customer-provided technical drawings, focusing on key parameters such as flange type, bolt pattern, surface finish, operating pressure, and temperature range. We validate geometrical tolerances per ISO 11737 and ASME B16.21 standards, ensuring that every contour, hole diameter, and sealing surface is precisely interpreted. Any ambiguity or potential design conflict is flagged for immediate consultation with the client. This stage also includes finite element analysis (FEA) when required, particularly for high-stress or non-standard applications, to predict deformation and compression behavior under load.

Material Formulation

Following drawing validation, we proceed to material formulation, leveraging our expertise in polymer science and industrial sealing. Garlock gasket materials are available in a wide range of elastomeric and non-elastomeric compounds, including compressed fiber, PTFE, graphite, and reinforced rubber variants. Our rubber formula engineers select or develop a compound based on chemical exposure, thermal stability, and mechanical stress. For instance, applications involving aggressive acids may require Kalrez®-grade perfluoroelastomers, while steam lines often demand flexible graphite with stainless steel reinforcement. Each formulation is documented under strict batch traceability protocols, ensuring repeatability and compliance with ASTM F104, F146, and FDA 21 CFR 177.2600 where applicable. Custom additives such as anti-extrusion agents or thermal stabilizers are incorporated to enhance performance in extreme environments.

Prototyping and Validation

Once the material is formulated, we produce a prototype gasket using precision die-cutting or CNC waterjet technology, depending on complexity and volume. Prototypes undergo a battery of tests including compression recovery (ASTM F36), creep relaxation (ASTM F1388), and chemical immersion analysis. We conduct leak testing under simulated operating conditions using helium mass spectrometry or pressure decay methods. Feedback from this phase informs final adjustments to thickness, durometer, or reinforcement structure. Client approval is required before transitioning to full-scale production.

Mass Production and Quality Assurance

Upon prototype validation, the project moves into mass production. Our manufacturing lines operate under ISO 9001-certified processes, with in-line monitoring of cutting force, curing time, and dimensional consistency. Each batch is inspected for visual defects, thickness variation, and hardness (Shore A scale), with certification provided per customer request.

The following table outlines key specifications for common Garlock gasket materials used in our customization process:

| Material Type | Temperature Range (°C) | Pressure Resistance (bar) | Media Resistance | Hardness (Shore A) |

|---|---|---|---|---|

| Garlock BLUE-GARD 3000 | -200 to 550 | 400 | Acids, solvents, steam | 75–85 |

| Garlock GYLON 3500 | -205 to 260 | 310 | General chemicals, water, oils | 65–75 |

| Garlock GRAPH-LOCK | -240 to 650 | 500 | High-temp steam, acids, hydrocarbons | 80–90 |

| Garlock THERMa-PUR | -40 to 300 | 250 | Hot oil, thermal fluids | 85–95 |

This systematic approach ensures that every custom gasket meets the highest standards of reliability, safety, and performance in precision industrial applications.

Contact Engineering Team

Elevate Your Sealing Performance with Precision-Engineered Garlock Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of advanced rubber sealing technology, specializing in the strategic supply and technical integration of Garlock gasket materials for mission-critical industrial applications. Our engineering team possesses deep expertise in polymer architecture and failure-mode analysis, ensuring that every Garlock specification—whether GYLON® EPIX™, GRAPH-LOCK™, or THERMa-PUR®—is precisely matched to your operational demands. In environments where thermal cycling, aggressive chemical exposure, or extreme pressure differentials threaten system integrity, our material science proficiency transforms sealing challenges into engineered reliability. We do not merely distribute; we collaborate to optimize compression set resistance, creep relaxation behavior, and long-term service life within your unique assembly parameters.

Critical performance metrics for Garlock materials must align with stringent OEM tolerances and regulatory frameworks. The following table summarizes key specifications for common high-performance grades, reflecting data validated through our in-house quality control protocols per ASTM F37 and ISO 7483 standards.

| Material Grade | Temperature Range (°C) | Max Pressure (bar) | Chemical Resistance Profile | Typical Applications |

|---|---|---|---|---|

| GYLON® 3504 | -200 to +260 | 100 | Acids, alkalis, solvents, steam | Chemical processing, pulp & paper |

| GRAPH-LOCK™ 3510 | -200 to +315 | 200 | Hydrocarbons, cryogenics, high-purity fluids | Oil & gas, LNG, semiconductor |

| THERMa-PUR® 1600 | -200 to +1000 | 70 | Oxidizing agents, combustion byproducts | Power generation, aerospace |

| EPIX™ 3540 | -200 to +260 | 150 | Enhanced creep resistance, wide pH range | Refining, pharmaceutical |

These parameters represent baseline capabilities; actual performance is contingent upon flange geometry, bolt load distribution, and installation methodology. Suzhou Baoshida provides comprehensive technical consultation to mitigate common failure vectors such as extrusion, chemical degradation, or thermal decomposition. Our OEM partnership model includes material certification traceability, batch-specific test reports, and joint failure analysis—ensuring compliance with ASME, PED, and API standards while minimizing unplanned downtime.

Technical Collaboration Pathway

Initiate a precision sealing solution by engaging directly with our Chief Technical Officer, Mr. Boyce. His 18-year tenure in elastomer formulation and failure diagnostics positions him uniquely to address complex sealing scenarios where off-the-shelf materials fall short. Contact Mr. Boyce via email at [email protected] to submit application specifics including fluid media, temperature/pressure profiles, flange dimensions, and historical failure data. We will respond within 4 business hours with a preliminary material recommendation and testing protocol. For urgent operational disruptions, include “CRITICAL SEALING EVENT” in the subject line to trigger our 24-hour rapid-response engineering assessment.

Suzhou Baoshida operates under ISO 9001:2015 and IATF 16949 frameworks, with direct supply chain integration to Garlock’s global manufacturing network. This guarantees authentic material provenance and eliminates counterfeit risk—a non-negotiable factor in safety-critical infrastructure. Our value extends beyond material supply; we deliver forensic analysis of field failures, custom compounding guidance for proprietary formulations, and lifecycle cost modeling to justify total cost of ownership reductions.

Do not compromise sealing integrity on generic specifications. Partner with an organization whose engineering rigor matches your operational standards. Contact Mr. Boyce immediately to transform your gasket performance metrics through science-driven material selection and proactive technical stewardship. Your system’s reliability depends on the precision of its weakest interface—ensure that interface is engineered, not assumed.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).