Technical Contents

Engineering Guide: Garolite G10 Fr4

Engineering Insight: Material Selection in Garolite G10 FR4 Applications

In high-performance industrial environments, the selection of composite materials is not a matter of convenience—it is a determinant of system integrity, longevity, and operational safety. Garolite G10 FR4, a glass-reinforced epoxy laminate, is widely recognized for its excellent mechanical strength, dielectric properties, and resistance to moisture and chemicals. However, despite its standardized composition, off-the-shelf G10 FR4 sheets frequently underperform in demanding applications. This discrepancy arises not from material inadequacy, but from improper alignment between generic supply and precise engineering requirements.

Many manufacturers source G10 FR4 based solely on nominal specifications such as thickness or sheet size, overlooking critical variables such as resin distribution, fiber orientation, and post-cure processing. These factors directly influence dimensional stability, thermal performance, and delamination resistance—especially under thermal cycling or mechanical stress. Standard commercial grades often exhibit inconsistent fiber-to-resin ratios, leading to anisotropic behavior and premature failure in load-bearing or high-voltage insulation roles.

Furthermore, industrial applications such as electrical insulators in switchgear, structural components in aerospace fixtures, or dielectric supports in power transmission systems demand tight tolerances and predictable performance. Off-the-shelf G10 FR4, typically produced for general-purpose use, rarely meets these thresholds. Variability in manufacturing batches, lack of traceability, and insufficient quality control in secondary suppliers amplify risk in mission-critical assemblies.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material solutions over commodity procurement. Our G10 FR4 is sourced from certified producers employing controlled lamination processes, consistent epoxy formulation, and rigorous post-curing protocols. We support OEMs with lot-specific material certifications, including dielectric strength testing and glass transition temperature (Tg) validation, ensuring repeatability across production cycles.

Material selection must be treated as an integral phase of design engineering, not a procurement afterthought. The cost of failure—whether through electrical breakdown, mechanical fracture, or thermal degradation—far exceeds the premium of precision-grade composites. By aligning material properties with operational stress profiles, engineers can eliminate common failure modes and extend service life in harsh environments.

The following table outlines key technical specifications for precision-grade Garolite G10 FR4, as supplied under controlled industrial standards:

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | 310 MPa | ASTM D638 |

| Flexural Strength | 400 MPa | ASTM D790 |

| Compressive Strength | 250 MPa | ASTM D695 |

| Dielectric Strength (1/8″ thickness) | 500 V/mil | ASTM D149 |

| Arc Resistance | 150 seconds | ASTM D495 |

| Glass Transition Temperature (Tg) | 130°C | DMA or DSC |

| Water Absorption (24h) | 0.1% | ASTM D570 |

| Relative Permittivity (1 MHz) | 4.5 | ASTM D150 |

Precision in material selection is non-negotiable. For industrial rubber and composite solutions, Suzhou Baoshida ensures that Garolite G10 FR4 performs not just to specification, but to application intent.

Material Specifications

Material Specifications: Critical Elastomer Selection for Industrial Applications

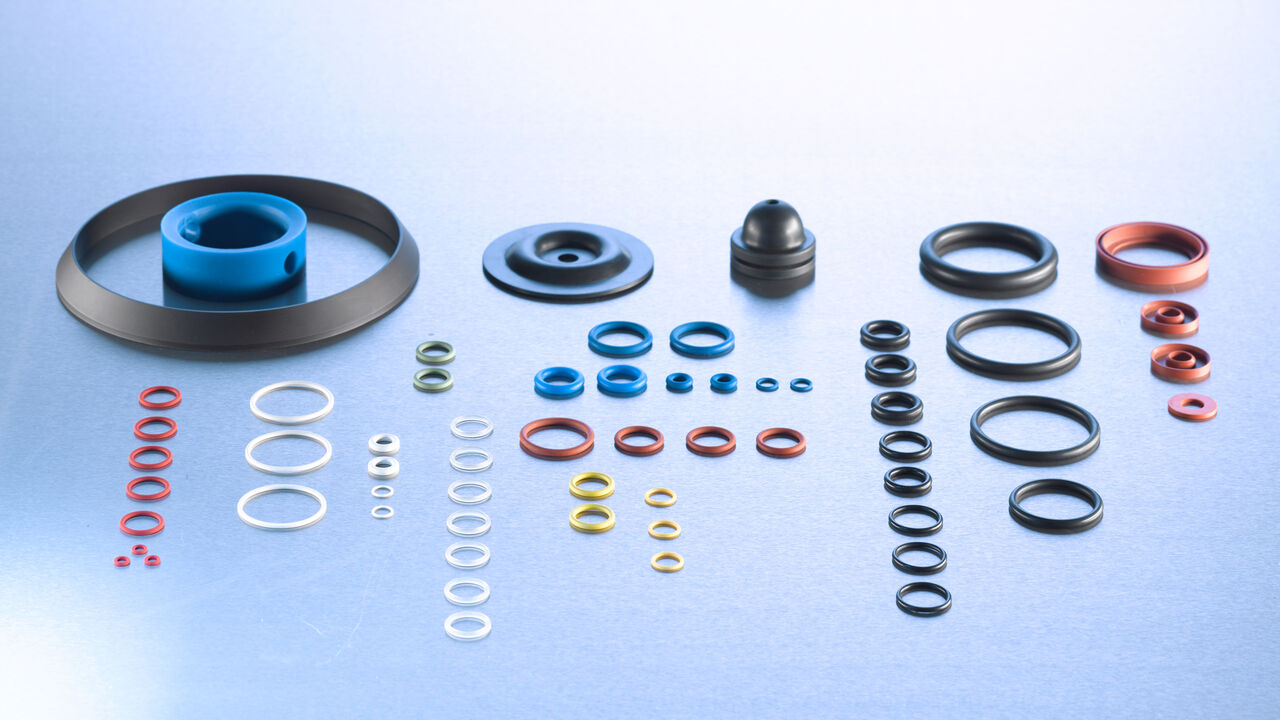

Suzhou Baoshida Trading Co., Ltd. clarifies a critical distinction: Garolite G10 and FR4 are fiberglass-reinforced epoxy laminates, not rubber compounds. Our Industrial Rubber Solutions division specializes in elastomeric materials for sealing, vibration damping, and fluid handling. This section details specifications for three core rubber formulations—Viton, Nitrile, and Silicone—essential for precision OEM manufacturing. Misapplication of non-rubber composites like G10/FR4 in dynamic sealing scenarios risks catastrophic failure due to inadequate flexibility and compression set resistance.

Viton fluorocarbon rubber (FKM) delivers exceptional resistance to high temperatures, fuels, oils, and aggressive chemicals. Standard grades operate continuously from -20°C to 230°C, with specialty variants extending to 300°C. Its tensile strength typically ranges 10–18 MPa, and hardness spans 60–90 Shore A. Viton’s low gas permeability and resilience against ozone make it indispensable for aerospace hydraulic systems and semiconductor manufacturing seals. However, its high cost and poor resistance to ketones and low-temperature flexibility below -20°C necessitate careful application vetting.

Nitrile rubber (NBR) remains the industry standard for cost-effective oil and fuel resistance. With a continuous service range of -30°C to 120°C (short-term peaks to 150°C), it offers tensile strength of 15–25 MPa and hardness between 40–90 Shore A. Its acrylonitrile content directly correlates with oil resistance; high-ACN grades (45%) withstand biodiesel and lubricants but sacrifice low-temperature performance. NBR dominates automotive fuel lines and hydraulic O-rings due to abrasion resistance and extrusion stability, though it degrades under ozone exposure and polar solvents.

Silicone rubber (VMQ) excels in extreme temperature stability (-60°C to 200°C) and biocompatibility. Standard grades achieve 5–10 MPa tensile strength and 30–80 Shore A hardness. Its inertness, UV resistance, and FDA compliance drive adoption in medical devices and food processing seals. Silicone maintains flexibility at cryogenic temperatures but exhibits lower tensile strength and poor resistance to petroleum-based fluids, requiring protective coatings in fuel-rich environments.

The comparative analysis below quantifies critical parameters for informed material selection:

| Material | Temperature Range (°C) | Hardness Range (Shore A) | Tensile Strength (MPa) | Key Chemical Resistances | Key Limitations |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to 230 (+300 intermittent) | 60–90 | 10–18 | Fuels, oils, acids, ozone | Ketones, esters, low-temperature flexibility |

| Nitrile (NBR) | -30 to 120 (+150 intermittent) | 40–90 | 15–25 | Aliphatic hydrocarbons, water, hydraulic fluids | Ozone, polar solvents, brake fluids |

| Silicone (VMQ) | -60 to 200 | 30–80 | 5–10 | Water, steam, oxygen, UV | Petroleum oils, fuels, acids, low tensile strength |

Suzhou Baoshida Trading Co., Ltd. emphasizes that material selection must align with dynamic stress profiles, media exposure, and regulatory requirements. Our engineering team validates compound formulations against ASTM D2000 and ISO 3601 standards to ensure dimensional stability and longevity in mission-critical OEM assemblies. Consult our technical dossier for grade-specific compression set data and extrusion tolerance protocols.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in deep technical expertise and a rigorous approach to material science and precision manufacturing. With a dedicated team comprising five specialized mould engineers and two certified rubber formula engineers, we deliver high-performance industrial rubber solutions tailored to the demanding requirements of modern OEM applications. Our engineers operate at the intersection of material innovation and production efficiency, ensuring that every component meets exacting standards for durability, dimensional accuracy, and environmental resistance.

Our formula development process is rooted in systematic polymer chemistry and real-world performance validation. The two in-house rubber formula engineers lead the design and optimization of compound formulations, focusing on enhancing mechanical properties such as tensile strength, elongation at break, thermal stability, and chemical resistance. These formulations are specifically engineered to align with the operational environments of sectors including automotive, aerospace, industrial automation, and energy systems. By controlling the formulation at the molecular level, we ensure consistent batch-to-batch reproducibility and long-term reliability under stress.

Complementing our formulation expertise, our five mould engineers bring precision to part geometry and production scalability. They are responsible for the complete lifecycle of mould development—from CAD-based design and finite element analysis (FEA) to prototype validation and high-volume tooling. Utilizing advanced simulation software, they optimize flow dynamics, curing behavior, and part ejection to minimize defects and cycle times. This integrated approach reduces time-to-market and supports rapid iteration for custom OEM projects.

We specialize in manufacturing Garolite G10 and FR4 composites, which are epoxy-resin reinforced with glass fabric, offering exceptional electrical insulation, mechanical strength, and resistance to moisture and heat. These materials are widely used in electrical insulators, structural components, and high-precision fixtures. Our in-house technical team ensures that every product meets international standards while being customized to client-specific performance criteria.

The synergy between our formula and mould engineering teams enables us to offer full OEM services—from concept and material selection to prototyping, validation, and mass production. Our facility supports strict quality control protocols, including ISO-compliant testing and traceability systems, ensuring every component performs reliably in critical applications.

Below are key technical specifications for Garolite G10 and FR4 materials we commonly process:

| Property | Garolite G10 | FR4 |

|---|---|---|

| Tensile Strength (MPa) | ≥310 | ≥340 |

| Flexural Strength (MPa) | ≥400 | ≥450 |

| Compressive Strength (MPa) | ≥300 | ≥320 |

| Dielectric Strength (kV/mm) | ≥15 | ≥16 |

| Glass Transition Temp (°C) | ~140 | ~130 |

| Water Absorption (24h, %) | ≤0.1 | ≤0.2 |

| Flame Rating | UL 94 HB | UL 94 V-0 |

This combination of advanced engineering talent, material science proficiency, and precision manufacturing positions Suzhou Baoshida as a trusted partner for high-integrity industrial solutions.

Customization Process

Garolite G10/FR4 Customization Process: Precision Engineering Pathway

Suzhou Baoshida Trading Co., Ltd. executes a rigorously defined customization protocol for Garolite G10/FR4 components, ensuring optimal performance alignment with demanding industrial applications. This engineered thermoset laminate, distinct from rubber formulations yet central to our advanced material portfolio, requires meticulous attention to electrical insulation, mechanical stability, and thermal resistance parameters. Our process transcends standard manufacturing, integrating deep material science expertise with OEM-specific requirements through four critical, sequential phases.

Initial engagement mandates comprehensive Drawing Analysis. Our engineering team conducts a forensic review of client CAD files and technical specifications, scrutinizing dimensional tolerances, hole placements, layer stack-ups, and surface finish requirements against inherent G10/FR4 material behavior. We identify potential manufacturability conflicts early, such as minimum bend radii exceeding material capabilities or critical thickness variations impacting dielectric strength. This phase establishes the foundational blueprint, confirming feasibility and defining precise material grade selection—G10 for general mechanical use or FR4 for superior flame resistance in electrical contexts—before resource commitment.

Subsequently, Formulation Engineering commences. Leveraging proprietary data on epoxy resin systems, woven glass fabric architectures, and curing agent profiles, we tailor the laminate’s core properties. Key variables adjusted include resin viscosity for optimal impregnation, catalyst concentration for controlled gel time, and post-cure thermal profiles. This stage directly influences critical performance metrics like Glass Transition Temperature (Tg), Coefficient of Thermal Expansion (CTE), and arc resistance. Material batches are compounded under stringent environmental controls to eliminate moisture ingress or particulate contamination, ensuring batch-to-batch consistency essential for high-reliability sectors.

Following formulation validation, Prototyping delivers tangible verification. Utilizing precision CNC machining or laser cutting per approved drawings, we produce functional prototypes. These undergo Suzhou Baoshida’s in-house qualification testing suite, measuring actual dielectric strength, flexural modulus, and flammability ratings against target specifications. Client feedback on prototype fit, form, and function triggers immediate iterative refinements. Only upon documented client sign-off, confirming all electrical and mechanical benchmarks are met, does the process advance.

Mass Production deployment integrates full statistical process control. Automated press systems apply calibrated heat and pressure profiles derived from prototyping, while inline metrology checks thickness uniformity and warpage. Every production lot undergoes 100% visual inspection and抽样 testing per ASTM D709 or IEC 60242 standards. Suzhou Baoshida’s OEM partnership model includes real-time production dashboards and tiered quality assurance protocols, guaranteeing seamless transition from prototype approval to certified volume delivery without performance drift.

Critical Garolite G10/FR4 Performance Specifications

| Parameter | Test Standard | G10 Typical Range | FR4 Typical Range | Suzhou Baoshida Tolerance Control |

|---|---|---|---|---|

| Tensile Strength (MPa) | ASTM D638 | 310 – 345 | 300 – 340 | ±5 MPa |

| Flexural Strength (MPa) | ASTM D790 | 480 – 520 | 450 – 500 | ±10 MPa |

| Dielectric Strength (kV/mm) | ASTM D149 | 18 – 22 | 16 – 20 | ±0.5 kV/mm |

| Glass Transition Temp (°C) | ASTM E1356 | 130 – 140 | 125 – 135 | ±3°C |

| Flammability Rating | UL 94 | HB | V-0 | Certified V-0 validation |

This structured methodology, underpinned by Suzhou Baoshida’s material science authority and process discipline, transforms client specifications into mission-critical Garolite G10/FR4 components with zero compromise on industrial performance or reliability.

Contact Engineering Team

Contact Suzhou Baoshida Trading Co., Ltd. for Premium Garolite G10/FR4 Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial composite material supply, offering precision-engineered Garolite G10 and FR4 materials tailored for high-performance applications across aerospace, electrical insulation, automation, and heavy machinery sectors. As a trusted OEM manager and rubber formula engineer, we ensure every product meets rigorous international standards for thermal stability, mechanical strength, and dielectric performance. Our specialization in industrial rubber solutions extends into advanced laminated phenolics and epoxy-glass composites, with Garolite G10 and FR4 being central to our technical portfolio.

Garolite G10 and FR4 are high-pressure thermoset laminates composed of woven glass fabric reinforced with epoxy resin. These materials are distinguished by their exceptional strength-to-weight ratios, excellent electrical insulation properties, and resistance to moisture, chemicals, and high temperatures. While G10 is non-flame-retardant, FR4 includes flame-retardant additives, making it suitable for applications requiring compliance with safety standards such as UL94 V-0. Both materials are widely used in the production of insulating components, structural supports, jigs, fixtures, and circuit board substrates.

At Suzhou Baoshida, we maintain strict quality control protocols throughout sourcing and distribution. Our materials are sourced from certified manufacturers and subjected to comprehensive testing for tensile strength, flexural modulus, arc resistance, and comparative tracking index (CTI) to ensure consistency and reliability. We supply Garolite G10/FR4 in various thicknesses, sheet sizes, and tolerances, customizable to meet specific engineering requirements. Whether you require machined parts or raw stock, our team provides technical support from material selection to final application integration.

For engineers, procurement managers, and OEMs seeking dependable supply chains and technical expertise in industrial composites, direct engagement with our team ensures optimal outcomes. Mr. Boyce, our dedicated technical liaison, specializes in material specifications, performance validation, and custom solution development. His role is to bridge your application needs with the correct material grade, ensuring compatibility with machining processes, environmental exposure, and regulatory demands.

We invite you to contact Mr. Boyce directly at [email protected] to discuss your project requirements, request technical datasheets, or obtain a quotation. Prompt response, technical accuracy, and supply chain transparency are our commitments to global partners.

Below is a comparative specification table for standard Garolite G10 and FR4 materials:

| Property | Garolite G10 | FR4 | Test Standard |

|---|---|---|---|

| Tensile Strength (MPa) | ≥310 | ≥340 | ASTM D638 |

| Flexural Strength (MPa) | ≥430 | ≥450 | ASTM D790 |

| Compressive Strength (MPa) | ≥300 | ≥310 | ASTM D695 |

| Dielectric Strength (kV/mm) | ≥18 | ≥20 | ASTM D149 |

| Arc Resistance (seconds) | ≥180 | ≥150 | ASTM D495 |

| Water Absorption (24h, %) | ≤0.07 | ≤0.10 | ASTM D570 |

| Operating Temperature (°C) | -50 to +130 | -50 to +130 | — |

| Flame Resistance | No | Yes (UL94 V-0) | UL 94 |

Initiate your next high-performance material project with confidence. Contact Mr. Boyce today at [email protected] for expert guidance and reliable supply of Garolite G10 and FR4 materials from Suzhou Baoshida Trading Co., Ltd.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).