Technical Contents

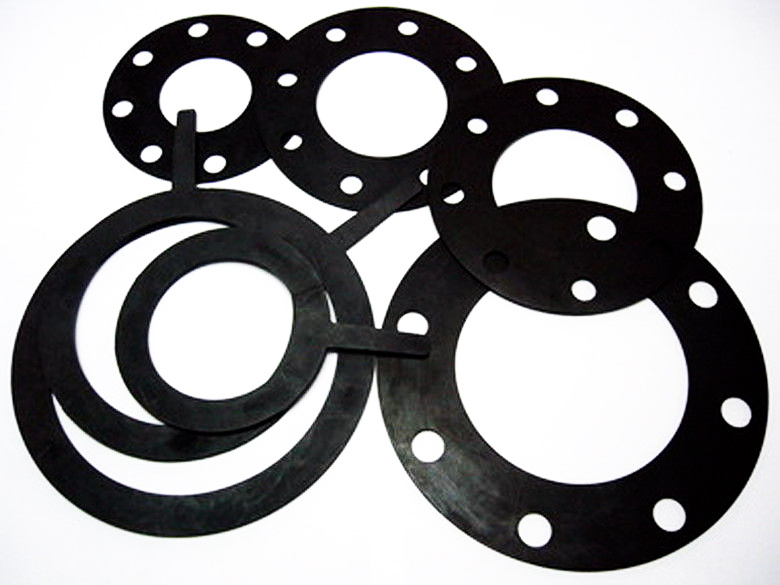

Engineering Guide: Gasket Maker For Gas

Engineering Insight: Material Selection Criticality in Gas Gasket Manufacturing

Gas sealing demands molecular-level precision impossible with generic elastomer formulations. Unlike liquid media, gaseous compounds exploit microscopic permeation pathways and induce chemical degradation at accelerated rates under pressure differentials. Off-the-shelf gasket materials—typically designed for hydraulic or pneumatic air systems—fail catastrophically in gas applications due to three fundamental oversights: inadequate permeation resistance, insufficient chemical compatibility, and poor resilience under thermal cycling.

Standard nitrile rubber (NBR) gaskets, prevalent in industrial hardware stores, exhibit permeation coefficients 10–15 times higher than specialty compounds when exposed to methane or hydrogen. This allows gas migration through polymer matrices even without physical damage. Simultaneously, aggressive gases like hydrogen sulfide (H₂S) or sour gas chemically attack conventional filler systems, causing swelling, embrittlement, or extractive degradation within weeks. Thermal cycling further compounds failure; low-cost materials suffer irreversible compression set above 120°C, losing >40% of sealing force after 500 hours. These failures manifest as undetected fugitive emissions or sudden joint ruptures—unacceptable in gas transmission where safety margins are non-negotiable.

Suzhou Baoshida’s OEM process mandates gas-specific material qualification. We formulate compounds with peroxide-cured fluorocarbon (FKM) or perfluoroelastomer (FFKM) backbones, incorporating nano-dispersed barrier fillers to reduce permeation pathways by 90% versus standard elastomers. Critical additives include zinc oxide scavengers for H₂S resistance and thermally stable plasticizers preventing volatility loss at 300°C. Crucially, we validate against the exact gas composition—not generic “natural gas” assumptions—as trace components (e.g., CO₂, mercaptans) dictate degradation kinetics.

The following comparative analysis demonstrates why commodity solutions fail under gas-specific stresses:

| Material | Gas Permeation (cm³·mm/m²·day·atm) | H₂S Resistance (ASTM D471) | Max Continuous Temp (°C) | Compression Set @200h (200°C) |

|---|---|---|---|---|

| Standard NBR | 18.7 | Severe Swelling (>25%) | 120 | 68% |

| Generic FKM | 1.9 | Moderate Swelling (10–15%) | 230 | 32% |

| Baoshida Gas-FKM | 0.15 | Negligible Swelling (<3%) | 280 | 18% |

This data underscores a core principle: gas sealing requires system-specific engineering. A gasket validated for methane pipelines may fail in biogas systems due to unaccounted siloxanes. Suzhou Baoshida’s OEM protocol includes gas chromatography of client media, accelerated aging per ISO 2230, and finite element analysis of joint stress distribution. We reject one-size-fits-all compromises—every formulation is mapped to pressure, temperature, and chemical exposure profiles.

The cost of field failure—safety incidents, environmental penalties, and unplanned downtime—dwarfs the marginal premium of precision-engineered solutions. Partner with an OEM that treats gas sealing as a molecular science, not a commodity transaction.

Material Specifications

Material selection is a critical factor in the performance and longevity of gasket makers used in gas sealing applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered to meet the stringent demands of industrial, automotive, and chemical processing environments. Our expertise in elastomer formulation ensures optimal compatibility, resilience, and sealing integrity under variable thermal, chemical, and mechanical stress conditions. For gasket makers in gas systems, three primary materials are recommended: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each offers distinct advantages depending on the operational parameters of the application.

Viton is widely regarded as the premium choice for high-performance gas sealing due to its exceptional resistance to hydrocarbons, fuels, oils, and a broad range of aggressive chemicals. With continuous service temperatures ranging from -20°C to 200°C (and intermittent exposure up to 250°C), Viton maintains structural integrity in extreme thermal environments. Its low gas permeability and excellent aging characteristics make it ideal for natural gas, propane, and petrochemical applications where reliability and safety are paramount. Additionally, Viton exhibits strong resistance to ozone and UV degradation, enhancing durability in outdoor installations.

Nitrile rubber, or Buna-N, is a cost-effective solution for applications involving aliphatic hydrocarbons, liquefied petroleum gas (LPG), and compressed air systems. It performs well in temperature ranges from -30°C to 100°C, with short-term peaks up to 125°C. Nitrile offers excellent abrasion resistance and mechanical strength, making it suitable for dynamic sealing environments. While its chemical resistance is inferior to Viton, particularly against aromatic hydrocarbons and chlorinated solvents, it remains a preferred choice for general-purpose gas sealing where exposure to oils and fuels is moderate.

Silicone rubber provides outstanding flexibility and thermal stability across a wide temperature spectrum, from -60°C to 200°C. While not recommended for high-pressure gas systems due to its lower tensile strength and higher gas permeability, silicone excels in low-stress, high-purity environments such as medical gas lines or food-grade applications. It demonstrates excellent resistance to oxygen, ozone, and weathering, but limited resistance to hydrocarbons and fuels restricts its use in many industrial gas sealing scenarios.

The selection of the appropriate elastomer must be based on a comprehensive evaluation of temperature, chemical exposure, pressure, and regulatory requirements. Below is a comparative summary of the three materials for gasket makers in gas applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250) | -30 to 100 (up to 125) | -60 to 200 |

| Gas Permeability | Low | Moderate | High |

| Fuel and Oil Resistance | Excellent | Good | Poor |

| Chemical Resistance | Excellent | Moderate | Poor to Fair |

| Ozone/UV Resistance | Excellent | Good | Excellent |

| Tensile Strength | High | High | Moderate |

| Compression Set Resistance | Excellent | Good | Good |

| Typical Gas Applications | Natural gas, propane, LNG | LPG, compressed air | Medical, food-grade gases |

Understanding these material characteristics enables engineers and procurement specialists to make informed decisions that enhance system safety, reduce maintenance cycles, and ensure compliance with industry standards.

Manufacturing Capabilities

Engineering Capability: Precision Gas Seal Development at Suzhou Baoshida

Suzhou Baoshida Trading Co., Ltd. delivers exceptional engineering rigor specifically for demanding gas sealing applications. Our core strength lies in the integrated expertise of our dedicated technical team, comprising five specialized Mold Design Engineers and two advanced Rubber Formula Engineers. This dual-engineering focus ensures that every gasket maker solution addresses both the precise physical geometry required for sealing integrity and the exacting chemical resistance and performance characteristics demanded by gas environments. We do not merely manufacture; we engineer molecular architecture and dimensional precision to solve complex sealing challenges inherent in gas transmission, storage, and processing systems.

Our Rubber Formula Engineers possess deep expertise in elastomer science, focusing exclusively on formulations capable of withstanding aggressive gases, wide temperature excursions, and long-term compression set requirements. They meticulously develop and validate proprietary FKM (Fluoroelastomer), FFKM (Perfluoroelastomer), and specialty HNBR compounds. This involves optimizing polymer selection, filler systems, curative packages, and additive blends to achieve critical properties such as ultra-low gas permeability, exceptional resistance to hydrocarbons, hydrogen, sour gas components (H₂S), and cryogenic temperatures. Rigorous laboratory testing under simulated service conditions validates performance before any compound progresses to prototyping, ensuring the molecular foundation of the seal is flawless.

Complementing this material science mastery, our five Mold Design Engineers translate sealing requirements into precise physical reality. They utilize advanced CAD/CAM software and finite element analysis (FEA) to model stress distribution, compression behavior, and potential failure modes under gas pressure loads. This enables the design of molds that produce gaskets with exacting dimensional tolerances, optimal surface finish to prevent leakage paths, and consistent cross-section geometry critical for uniform sealing force. Their expertise spans complex multi-cavity molds for high-volume production and intricate single-cavity designs for specialized low-volume gas applications, always prioritizing repeatability and minimizing flash that could compromise gas integrity.

Our OEM capabilities are built upon this engineering synergy, providing seamless integration from specification to certified production. We manage the entire process: collaborative requirement definition, material formulation validation, precision mold design and fabrication, rigorous in-process quality control using calibrated metrology, and comprehensive final testing per customer and industry standards. Full material traceability, batch-specific certification (including ASTM D2000 line callouts), and adherence to ISO 9001 quality management systems are standard. This end-to-end engineering control guarantees that every gasket maker component shipped meets the stringent reliability and safety demands of global gas infrastructure and equipment manufacturers.

Material Performance Specifications for Critical Gas Applications

| Property | Test Standard | Target Value (Typical FKM/FFKM) | Significance for Gas Seals |

|---|---|---|---|

| Compression Set (70h @ 150°C) | ASTM D395 Method B | < 15% | Ensures long-term sealing force retention under heat |

| Gas Permeability (He, H₂) | ASTM D1434 | Extremely Low | Minimizes gas migration through elastomer |

| Tensile Strength | ASTM D412 | ≥ 10 MPa | Maintains structural integrity under pressure |

| Elongation at Break | ASTM D412 | ≥ 150% | Accommodates assembly tolerances without failure |

| Fluid Resistance (IRMR) | ASTM D471 | Volume Swell < 15% | Critical resistance to hydrocarbon gases and condensates |

| Temperature Range | Material Specific | -25°C to +230°C (FKM) / -15°C to +327°C (FFKM) | Operational reliability across gas service conditions |

| Gas Compatibility | Custom Testing | Pass (No cracking, excessive swell) | Direct validation against specific gas mixtures |

Customization Process

Drawing Analysis

The customization process for gasket maker for gas applications begins with rigorous drawing analysis. At Suzhou Baoshida Trading Co., Ltd., engineering teams conduct dimensional verification, tolerance evaluation, and material compatibility assessment based on client-provided technical drawings. Critical parameters such as sealing surface geometry, flange load distribution, and operating clearance are analyzed using CAD-integrated simulation tools. This phase ensures dimensional accuracy and identifies potential stress concentration zones that may compromise seal integrity under operational conditions. All features, including bolt hole alignment, groove depth, and compression limits, are cross-referenced against industry standards such as ASME B16.20 and ISO 9001:2015. Any deviations or optimization opportunities are communicated to the client for technical alignment prior to material selection.

Formulation Development

Following drawing validation, the rubber formulation is engineered to meet the specific chemical, thermal, and mechanical demands of gas sealing environments. Suzhou Baoshida leverages proprietary elastomer science to develop compounds resistant to natural gas, propane, butane, and associated hydrocarbon derivatives. Base polymers such as FKM (fluoroelastomer), EPDM (ethylene propylene diene monomer), and NBR (nitrile butadiene rubber) are selected based on temperature range, chemical exposure, and compression set requirements. Additives including reinforcing fillers, anti-degradants, and cure modifiers are precision-blended to achieve target hardness, tensile strength, and gas permeability resistance. Each formulation is documented under controlled batch records and subjected to preliminary lab testing for cure kinetics and rheological behavior. Material data sheets (MDS) and compatibility charts are generated for client review and approval.

Prototyping and Validation

A functional prototype is produced using CNC-machined molds or precision die-cutting, depending on geometry complexity. Prototypes undergo a battery of performance tests, including compression deflection analysis, leak rate measurement under pressurized gas (up to 25 bar), and thermal cycling from -40°C to +200°C. Dimensional conformity is verified using coordinate measuring machines (CMM) with tolerances held to ±0.05 mm. Feedback from prototype testing informs design or material refinements, ensuring optimal fit, form, and function. Clients receive test reports, physical samples, and revalidation data to confirm readiness for scale-up.

Mass Production

Upon prototype approval, the project transitions to automated mass production. Suzhou Baoshida employs closed-loop molding systems with real-time process monitoring to maintain batch consistency. Each production lot undergoes 100% visual inspection and statistical sampling for physical property verification per ASTM standards. Final packaging is customized to prevent deformation and contamination during transit. Full traceability is maintained via lot numbering and digital quality records.

| Property | FKM | EPDM | NBR |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 | -40 to +150 | -30 to +120 |

| Gas Resistance | Excellent | Good | Moderate |

| Hardness (Shore A) | 60–90 | 50–80 | 55–90 |

| Tensile Strength (MPa) | ≥15 | ≥10 | ≥12 |

| Compression Set (%) | ≤20 | ≤25 | ≤30 |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Gas Gasket Solutions

Gas handling systems demand uncompromising sealing integrity. Leakage risks extend beyond operational inefficiency to critical safety hazards and environmental non-compliance. Standard gasket makers often fail under the unique chemical aggressiveness, thermal cycling, and pressure differentials inherent in gas applications. Suzhou Baoshida Trading Co., Ltd. addresses these challenges through scientifically formulated rubber compounds engineered for molecular-level substrate adhesion and long-term resilience. Our gasket makers undergo rigorous parametric validation against ASTM D2000 and ISO 2230 standards, ensuring dimensional stability across -60°C to +300°C operational envelopes. We prioritize material science over generic solutions, delivering formulations that resist permeation from methane, hydrogen, LPG, and industrial process gases while maintaining elasticity under sustained load.

The following table summarizes core technical specifications for our primary gas-grade gasket maker formulations. These values represent baseline performance; actual parameters are optimized per OEM fluid dynamics and metallurgical substrate analysis.

| Material Type | Temperature Range (°C) | Key Properties | Gas Compatibility | Certifications |

|---|---|---|---|---|

| Fluorosilicone (FVMQ) | -60 to +200 | Low gas permeability, ozone resistance | Natural gas, biogas, CO₂ | UL 94 V-0, FDA 21 CFR 177.2600 |

| Perfluoroelastomer (FFKM) | -20 to +325 | Exceptional chemical inertness, ultra-low outgassing | Hydrogen, ethylene, chlorine | ISO 10993, SEMI F57 |

| Hydrogenated Nitrile (HNBR) | -50 to +150 | High tensile strength, fuel resistance | Propane, butane, syngas | ISO 17497-1, RoHS 3 |

| Specialty FKM Blend | -40 to +250 | Optimized for thermal shock resistance | Ammonia, nitrogen, argon | ISO 10208, PED 2014/68/EU |

| EPDM Gas-Grade | -55 to +150 | Steam tolerance, low compression set | Steam-methane reforming gas | NSF/ANSI 61, EN 12566-3 |

Our engineering team collaborates directly with OEM design departments to resolve complex sealing challenges. We conduct substrate-specific adhesion testing using industry-standard peel strength protocols (ASTM D903) and simulate real-world gas exposure conditions in controlled chambers. This eliminates field failure risks associated with incompatible material selection. Suzhou Baoshida maintains ISO 9001:2015-certified production facilities with traceable batch documentation, ensuring repeatability for high-volume manufacturing programs. We provide full technical data packages including material safety data sheets (MSDS), finite element analysis (FEA) compatibility reports, and accelerated aging test results per ASTM D573.

Do not compromise gas system integrity with off-the-shelf sealants. Contact Mr. Boyce, our dedicated OEM Solutions Manager, to initiate a technical consultation. He will coordinate material sampling, conduct joint failure mode analysis for your specific application, and develop a customized gasket maker specification meeting your exact pressure, temperature, and regulatory requirements. Mr. Boyce possesses 14 years of experience resolving sealing failures in gas compression, LNG transport, and semiconductor manufacturing environments. His expertise ensures seamless integration of our formulations into your production workflow with zero process disruption.

Reach Mr. Boyce directly at [email protected] to request application-specific technical documentation or schedule an engineering review. Include your system’s gas composition, operating pressure range, and substrate materials for immediate preliminary assessment. Suzhou Baoshida commits to a 24-hour technical response window for all gas sealing inquiries. Partner with us to transform sealing reliability from a maintenance concern into a competitive advantage. Your gas system’s integrity warrants engineered precision—not generic solutions.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).