Technical Contents

Engineering Guide: Gasket Motor

Engineering Insight: Gasket Motor – The Critical Role of Material Selection

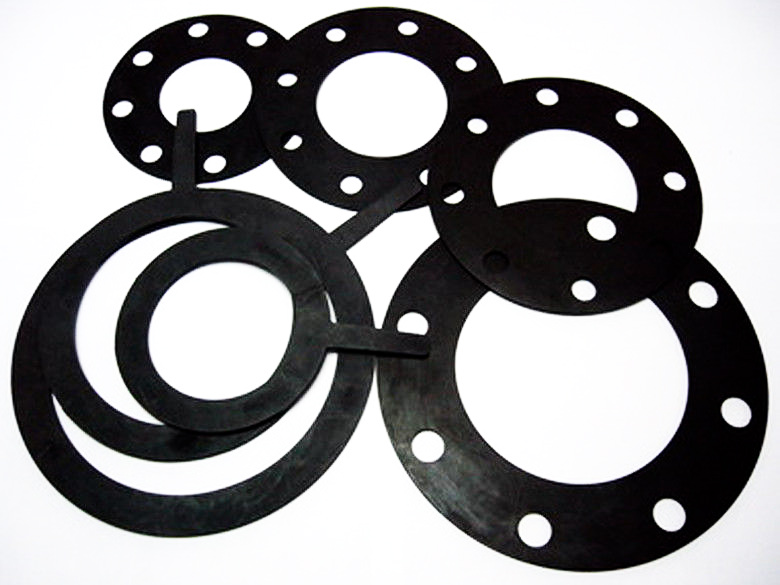

In the precision engineering of gasket motors, material selection is not merely a design consideration—it is a decisive factor in long-term reliability, performance consistency, and operational safety. Gasket motors, commonly found in automotive, industrial automation, and HVAC systems, rely on elastomeric seals to maintain pressure integrity, prevent fluid leakage, and resist mechanical deformation under dynamic loads. Off-the-shelf gasket solutions often fail in these demanding environments due to a fundamental mismatch between generic material properties and the specific thermal, chemical, and mechanical conditions of the application.

Standard rubber compounds such as generic NBR (nitrile butadiene rubber) or EPDM are frequently used in mass-produced gaskets due to their low cost and general-purpose performance. However, in gasket motor applications, these materials can degrade prematurely when exposed to elevated temperatures, aggressive lubricants, or continuous compression cycling. For example, standard NBR begins to harden and crack above 100°C, while many motor housings routinely exceed this threshold during operation. Similarly, exposure to synthetic ester-based oils or halogenated refrigerants can cause swelling and loss of sealing force in inappropriate elastomers.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific formulation development. Our engineered rubber compounds are tailored to match the exact service environment of the gasket motor, including temperature range, fluid compatibility, compression set resistance, and dynamic stress exposure. By selecting high-performance materials such as hydrogenated nitrile (HNBR), fluorocarbon (FKM), or perfluoroelastomers (FFKM), we ensure sustained sealing integrity even under extreme conditions. These advanced elastomers offer superior resistance to thermal aging, chemical attack, and compression deformation—key failure modes in motor gasket applications.

Moreover, the physical geometry of the gasket interacts critically with material behavior. A compound with excellent chemical resistance may still fail if it lacks the appropriate modulus or elongation to accommodate housing misalignment or thermal expansion. Therefore, material selection must be integrated with mechanical design and finite element analysis to predict real-world performance accurately.

The consequence of under-specifying gasket materials extends beyond leakage. Seal failure in a motor system can lead to lubricant loss, contamination ingress, increased friction, and eventual mechanical breakdown—resulting in unplanned downtime and costly repairs. Custom-engineered solutions from Baoshida are validated through rigorous testing protocols, including accelerated aging, fluid immersion, and dynamic compression set analysis, ensuring reliability over the product lifecycle.

Below is a comparative overview of common elastomers used in gasket motor applications:

| Material | Temperature Range (°C) | Key Fluid Resistance | Compression Set Resistance | Typical Use Case |

|---|---|---|---|---|

| NBR | -30 to 100 | Mineral oils, water | Moderate | Low-cost, low-temperature motors |

| HNBR | -40 to 150 | Synthetic oils, glycols | High | High-performance automotive motors |

| FKM | -20 to 200 | Fuels, acids, esters | Very High | Aerospace and high-temperature systems |

| EPDM | -50 to 150 | Water, steam, brake fluid | Moderate | HVAC and coolant systems |

Material selection is a science-driven process that demands deep application knowledge. At Baoshida, we partner with OEMs to move beyond off-the-shelf compromises and deliver precision rubber seals engineered for mission-critical performance.

Material Specifications

Material Specifications for Precision Gasket Motors

Selecting the optimal elastomer for gasket motor applications is critical for ensuring long-term sealing integrity, operational safety, and compliance with industrial environmental demands. At Suzhou Baoshida Trading Co., Ltd., our precision rubber seals undergo rigorous material validation to withstand specific thermal, chemical, and mechanical stresses inherent in motor systems. This section details the core material specifications for Viton, Nitrile, and Silicone rubbers, emphasizing performance boundaries and application alignment.

Viton (fluorocarbon rubber, FKM) represents the premium solution for extreme environments. Its molecular structure provides exceptional resistance to high temperatures, aggressive chemicals, and oils. Viton maintains sealing performance continuously up to 230°C (446°F) with short-term excursions to 300°C (572°F). It exhibits superior stability against aromatic and chlorinated hydrocarbons, acids, and jet fuels, making it indispensable for automotive turbocharger gaskets, aerospace actuators, and chemical processing equipment. Compression set values typically remain below 25% after 70 hours at 200°C, ensuring reliable recovery under sustained load.

Nitrile rubber (acrylonitrile butadiene rubber, NBR) delivers an optimal balance of cost efficiency and functional performance for standard industrial motor gaskets. With acrylonitrile content dictating oil resistance, high-grade NBR formulations withstand continuous exposure to mineral oils, greases, and hydraulic fluids at temperatures up to 120°C (248°F). Its tensile strength (15–25 MPa) and abrasion resistance suit dynamic sealing applications like engine oil pans and transmission housings. However, NBR exhibits vulnerability to ozone, weathering, and polar solvents, necessitating protective additives for outdoor use.

Silicone rubber (polysiloxane) excels in applications demanding extreme temperature flexibility and biocompatibility. It operates reliably from -60°C (-76°F) to 230°C (446°F), with specialized grades extending to 300°C. Silicone maintains elasticity across this broad range, resisting compression set (≤20% at 200°C/70h) and exhibiting excellent electrical insulation properties. While limited in hydrocarbon resistance, it is ideal for food-grade, medical, and high-temperature electrical motor gaskets where steam, ozone, or UV exposure occurs. Tear strength remains moderate (8–15 kN/m), requiring careful design for high-shear environments.

The following table summarizes critical performance parameters for precision gasket motor selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Continuous Temp Range | -20°C to +230°C | -30°C to +120°C | -60°C to +230°C |

| Short-Term Max Temp | 300°C | 150°C | 300°C |

| Tensile Strength (MPa) | 10–20 | 15–25 | 5–12 |

| Compression Set (70h) | ≤25% @ 200°C | ≤30% @ 100°C | ≤20% @ 200°C |

| Oil Resistance (ASTM) | Excellent | Good to Excellent | Poor |

| Ozone Resistance | Excellent | Poor | Excellent |

| Typical Motor Applications | Turbochargers, Chemical Pumps | Oil Pans, Fuel Systems | Electric Motor Insulation, Food Processing |

Material selection must align with fluid compatibility, thermal cycling profiles, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. leverages OEM-specific compound formulations and ISO 9001-certified testing protocols to ensure each gasket motor seal meets exacting performance criteria. Our engineering team collaborates directly with clients to validate material suitability against real-world operational parameters, minimizing field failure risks and optimizing service life. Precision in elastomer specification is non-negotiable for motor reliability in critical industrial ecosystems.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of precision rubber seal manufacturing, delivering engineered solutions tailored to the rigorous demands of the gasket motor industry. Central to our technical excellence is a dedicated engineering team comprising five specialized mould engineers and two advanced rubber formula engineers. This integrated team ensures that every component we produce meets exacting performance, durability, and dimensional accuracy requirements.

Our mould engineering team brings extensive experience in the design, simulation, and optimization of precision tooling for rubber compression, transfer, and injection moulding processes. Each engineer utilizes advanced CAD/CAM software, including SolidWorks and AutoCAD, to develop robust mould designs that support tight tolerances, complex geometries, and high-cycle production durability. Finite Element Analysis (FEA) is routinely applied to predict material flow, identify potential defect zones, and optimize gate placement and cooling channels, resulting in consistent part quality and reduced time-to-market.

Complementing our mould expertise, our two in-house rubber formula engineers specialize in developing custom elastomer compounds optimized for specific operational environments. Whether the application demands resistance to high temperature, oil, ozone, or dynamic compression, our formulation team tailors material properties at the molecular level. We routinely work with NBR, EPDM, FKM, silicone, and ACM, modifying cure systems, filler content, and plasticizers to achieve precise hardness, compression set resistance, and sealing force characteristics. This capability ensures that our rubber compounds are not only compatible with gasket motor operating conditions but also contribute to extended service life and reliability.

Our OEM manufacturing capabilities are built on a foundation of vertical integration and technical agility. We support full product development cycles—from concept and material selection to prototyping, validation, and mass production. Clients benefit from IP-protected designs, batch traceability, and strict adherence to international quality standards such as ISO 9001. Our facility supports low-volume custom runs as well as high-volume automated production, with in-house testing for tensile strength, hardness, volume swell, and accelerated aging.

The following table outlines key engineering and material specifications supported in our gasket motor seal production:

| Parameter | Capability Range | Testing Standard |

|---|---|---|

| Hardness (Shore A) | 40–90 | ASTM D2240 |

| Tensile Strength | 8–25 MPa | ASTM D412 |

| Elongation at Break | 150–600% | ASTM D412 |

| Compression Set (70h @ 100°C) | ≤25% | ASTM D395 |

| Operating Temperature | -40°C to +250°C (FKM) | ASTM D1329 |

| Volume Swell in Oil (IRM 903, 24h @ 100°C) | ≤30% | ASTM D471 |

| Tolerance (per ISO 3302) | Class M2 to M3 | ISO 3302 |

This combination of advanced engineering talent, material science proficiency, and scalable OEM infrastructure enables Suzhou Baoshida to deliver high-performance rubber seals that meet the evolving needs of modern gasket motor applications.

Customization Process

Gasket Motor Customization Process: Precision Engineering from Concept to Volume Supply

At Suzhou Baoshida Trading Co., Ltd., our customization process for precision rubber gasket motors integrates rigorous material science with industrial manufacturing discipline. This structured workflow ensures optimal sealing performance under extreme operational demands while adhering to OEM timelines and cost targets. Each phase undergoes documented validation to eliminate field failure risks.

Drawing Analysis: Translating Engineering Intent into Material Reality

We initiate with comprehensive GD&T and functional requirement dissection of client-provided drawings. Critical focus areas include compression set tolerance (±0.05mm), dynamic stress points, fluid exposure profiles, and thermal cycling parameters. Our engineers cross-reference AS568, ISO 3601, and OEM-specific standards to identify hidden constraints—such as incompatible surface finishes or unaccounted chemical swell factors—that could compromise seal integrity. This phase concludes with a formal feasibility report detailing dimensional risk mitigation strategies.

Formulation: Molecular-Level Material Optimization

Based on the drawing analysis, our rubber compounding laboratory develops proprietary elastomer formulations. We prioritize base polymer selection (FKM, ACM, HNBR, or custom blends) aligned with temperature extremes, fluid resistance, and compression load requirements. Key additives—reinforcing silica, peroxide curatives, and specialty antioxidants—are precisely dosed to achieve target properties. For instance, aerospace-grade gaskets demand FKM variants with 70-85 Shore A hardness and -40°C low-temperature flexibility, while automotive turbocharger seals require ACM compounds resistant to 180°C continuous oil exposure. All formulations undergo ASTM D2000 classification validation prior to prototyping.

Prototyping: Validating Performance Under Simulated Conditions

Prototypes are manufactured using production-intent tooling and cured under controlled time-temperature profiles. We conduct accelerated life testing per SAE J20 rubber standards, including:

Compression set measurement (ASTM D395 Method B) at 100°C for 22 hours

Fluid immersion testing in specified media (e.g., ATF, biodiesel, aviation hydraulic fluid)

Dynamic fatigue cycling to 500,000 strokes

Test data is benchmarked against OEM performance thresholds, with formulation adjustments made within 72 hours if deviations occur. Typical lead time for qualified prototypes is 4-6 weeks.

Mass Production: Sustaining Precision at Scale

Upon prototype approval, we transition to IATF 16949-certified production lines with real-time SPC monitoring. Every batch undergoes:

In-line durometer verification (±2 Shore A tolerance)

Visual inspection via AI-powered optical systems

Random destructive testing for tensile strength and elongation

Our closed-loop material tracking system ensures traceability from raw polymer lots to finished gaskets, with PPAP Level 3 documentation provided. Standard volume lead time is 8-10 weeks for 50,000+ units.

Critical Material Specifications for Gasket Motor Applications

| Property | Standard FKM Range | Baoshida BD-700 Series | Customizable Range | Test Standard |

|---|---|---|---|---|

| Hardness (Shore A) | 60-80 | 75 ± 2 | 55-90 | ASTM D2240 |

| Tensile Strength (MPa) | 10-15 | 14.2 min | 8-20 | ASTM D412 |

| Compression Set (%) | ≤25 | ≤18 @ 150°C/70h | ≤15 | ASTM D395 B |

| Temp Range (°C) | -20 to +230 | -40 to +250 | -55 to +300 | ISO 1817 |

| Fluid Resistance (ASTM 3) | Moderate | Excellent | Optimized per fluid | SAE J2643 |

This end-to-end process eliminates the guesswork in gasket motor sealing, transforming engineering specifications into field-proven components. Suzhou Baoshida delivers not just parts, but validated sealing solutions backed by 15 years of OEM partnership expertise in precision rubber technology.

Contact Engineering Team

For precision-critical applications in the automotive, industrial machinery, and powertrain sectors, selecting the right gasket motor sealing solution is not a matter of convenience—it is a requirement for operational integrity, longevity, and safety. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber seals designed to meet the exacting demands of modern motor systems. Our expertise lies in formulating high-performance elastomers tailored to resist thermal degradation, chemical exposure, compression set, and dynamic stress—common failure points in gasket motor environments.

Our product development process begins with material science. Whether your application requires Nitrile (NBR) for oil resistance, Fluorocarbon (FKM/Viton®) for extreme temperature stability, or Silicone (VMQ) for flexibility across a broad thermal range, we formulate compounds with precise durometer ratings, elongation properties, and compression deflection characteristics. Every gasket is manufactured under ISO-compliant conditions, ensuring dimensional accuracy, repeatability, and compliance with international quality standards.

We understand that motor gaskets must perform under fluctuating thermal cycles, vibration, and exposure to aggressive fluids such as engine oils, coolants, and fuel blends. That is why our engineering team collaborates directly with OEMs and Tier suppliers to analyze operating conditions, seal interface geometry, and load profiles. This data-driven approach allows us to deliver gasket solutions that minimize leakage paths, maintain clamping force, and extend service life.

The following table outlines typical material specifications used in our gasket motor applications:

| Material | Hardness (Shore A) | Temperature Range (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Key Resistance Properties |

|---|---|---|---|---|---|

| NBR | 60–90 | -30 to +120 | 10–20 | 200–400 | Oil, fuel, water, abrasion |

| FKM | 65–80 | -20 to +230 | 12–18 | 150–250 | High heat, chemicals, oils |

| VMQ | 40–80 | -60 to +200 | 6–10 | 200–600 | Extreme cold, ozone, UV |

| EPDM | 50–85 | -50 to +150 | 8–15 | 250–400 | Steam, water, weathering |

All compounds are subject to rigorous testing protocols, including compression set (ASTM D395), thermal aging (ASTM D573), fluid immersion (ASTM D471), and dimensional inspection via CMM. Custom formulations and rapid prototyping are available upon request.

To ensure seamless integration into your production workflow, we offer technical documentation, material certifications, and on-site engineering support. Our global logistics network enables reliable delivery to manufacturing hubs across Asia, Europe, and North America.

For immediate technical consultation or to request sample kits for evaluation, contact Mr. Boyce at [email protected]. Provide your application parameters, performance requirements, and target volume, and our team will deliver a tailored gasket motor sealing solution within 72 hours. At Suzhou Baoshida Trading Co., Ltd., we don’t just supply rubber—we engineer reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).