Technical Contents

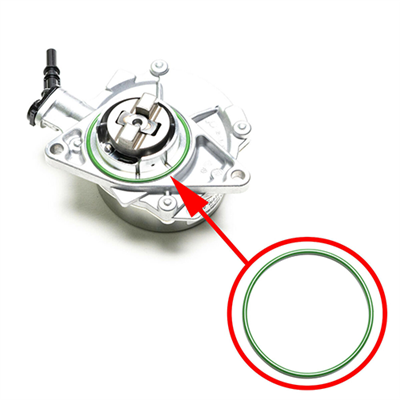

Engineering Guide: Gasket Vacuum Pump

Engineering Insight: Material Selection Criticality in Vacuum Pump Gasket Performance

Vacuum pump gasket failure remains a persistent operational challenge across semiconductor, pharmaceutical, and analytical instrumentation sectors. While off-the-shelf elastomeric seals present an initial cost advantage, their frequent premature degradation under demanding vacuum conditions incurs significantly higher lifetime costs through process contamination, unplanned downtime, and repeated rework. The fundamental flaw lies in the misapplication of general-purpose rubber compounds to environments requiring extreme material precision. Standard gasket materials lack the engineered molecular stability necessary to withstand the combined stresses of deep vacuum, aggressive process chemistries, and thermal cycling inherent in modern vacuum systems.

The primary failure mechanisms stem from inadequate material properties. Under vacuum, generic compounds exhibit excessive outgassing, releasing volatile components that contaminate sensitive processes and degrade ultimate vacuum levels. Simultaneously, permeation rates for gases like helium or nitrogen in standard materials such as NBR or EPDM are unacceptably high, directly limiting pumping efficiency and achievable vacuum. Furthermore, compression set resistance at elevated operating temperatures—common in high-throughput vacuum systems—is often insufficient in commodity elastomers, leading to permanent seal deformation and loss of sealing force. Chemical exposure to cleaning agents or process byproducts further accelerates degradation in non-specified materials, causing swelling, hardening, or cracking. These failures are not random but predictable outcomes of using materials未经 rigorous vacuum-specific validation.

Precision-engineered vacuum gasket compounds address these failure points through targeted polymer chemistry and filler systems. Perfluoroelastomers (FFKM) and specialty perfluorinated ethers (FFKM variants) offer near-undetectable outgassing, ultra-low gas permeability, and exceptional resistance to both thermal degradation exceeding 300°C and aggressive solvents. Critical material properties must be quantified under simulated operational conditions, not merely referenced from generic datasheets. OEM validation protocols must include ASTM E595 outgassing testing, precise permeability measurements per ASTM D1434, and compression set evaluation per ASTM D395 under vacuum and elevated temperature.

The performance delta between standard and vacuum-optimized materials is quantifiable, as demonstrated in the comparative analysis below:

| Material Type | Max Continuous Temp (°C) | Vacuum Permeability (He, cm³·mm/m²·day·atm) | Compression Set @150°C/72h (%) | Key Chemical Vulnerability |

|---|---|---|---|---|

| Standard NBR | 100 | 15.2 | 45 | Oils, Oxygen, Ozone |

| Standard EPDM | 150 | 0.8 | 32 | Hydrocarbons, Steam |

| Precision FFKM | 325 | 0.001 | 8 | None significant |

Suzhou Baoshida Trading Co., Ltd. emphasizes that vacuum integrity is non-negotiable. Our engineered rubber solutions undergo stringent OEM qualification protocols, ensuring gaskets maintain dimensional stability, minimal permeation, and zero particle generation throughout their service life. Selecting material based solely on initial price ignores the total cost of ownership; precision compounds deliver operational reliability by design, preventing the cascading failures inherent in generic alternatives. Partnering with a specialist in vacuum-grade elastomer formulation is essential for achieving consistent, high-performance vacuum system operation.

Material Specifications

Material selection for gasket vacuum pumps is a critical engineering decision that directly influences performance, longevity, and operational safety. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered to meet the stringent demands of vacuum pump applications. Our expertise spans advanced elastomers including Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct advantages based on chemical exposure, temperature range, and mechanical stress.

Viton is a fluoropolymer elastomer renowned for its exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. With continuous service capability up to 200°C and intermittent resistance to 250°C, Viton gaskets are ideal for high-performance vacuum pumps operating in harsh industrial environments such as petrochemical processing, semiconductor manufacturing, and aerospace systems. Its low gas permeability and excellent compression set resistance ensure reliable sealing under sustained vacuum conditions. However, Viton exhibits limited flexibility at sub-zero temperatures and higher material cost compared to alternatives.

Nitrile rubber, or Buna-N, remains one of the most widely used elastomers in industrial sealing due to its excellent resistance to petroleum-based oils, hydraulic fluids, and aliphatic hydrocarbons. It performs reliably within a temperature range of -30°C to +100°C, with short-term peaks up to 120°C. Nitrile gaskets are particularly suitable for general-purpose vacuum pumps in machinery, automotive, and manufacturing sectors where cost efficiency and oil resistance are prioritized. While NBR offers good mechanical strength and abrasion resistance, it is less effective against ozone, UV exposure, and polar solvents.

Silicone rubber provides outstanding thermal stability across a broad range, typically from -60°C to +200°C, with certain formulations tolerating brief excursions beyond. It exhibits excellent resistance to ozone and UV radiation, making it well-suited for cleanroom environments, medical equipment, and food-grade vacuum systems. Silicone’s low toxicity and compliance with FDA and USP Class VI standards enhance its utility in sensitive applications. However, it has lower tensile strength and abrasion resistance compared to Viton and Nitrile, and its high gas permeability may limit effectiveness in high-vacuum scenarios unless reinforced.

The following table summarizes key physical and chemical properties of these materials for comparative evaluation:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 (up to 250 intermittent) | -30 to +100 (up to 120 intermittent) | -60 to +200 |

| Tensile Strength (MPa) | 15–25 | 10–20 | 5–12 |

| Elongation at Break (%) | 200–300 | 250–400 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor to Fair |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Gas Permeability | Low | Moderate | High |

| Compression Set Resistance | Excellent | Good | Good |

Selection of the optimal elastomer requires a comprehensive assessment of operational parameters. Suzhou Baoshida Trading Co., Ltd. supports OEMs and industrial clients with material testing, custom formulation, and precision manufacturing to ensure gasket performance under real-world vacuum pump conditions.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Seals for Gasket Vacuum Pumps

Suzhou Baoshida Trading Co., Ltd. delivers mission-critical elastomeric solutions for vacuum pump gaskets through integrated engineering expertise and rigorous OEM processes. Our facility leverages seven dedicated specialists—five Mold Engineers and two Formula Engineers—to address the extreme demands of vacuum environments, where seal failure directly compromises system integrity. This synergy ensures materials and geometries are co-optimized for ultra-low outgassing, thermal stability, and compression set resistance under continuous vacuum stress.

Mold Engineers deploy advanced CAD/CAM simulation (SolidWorks, Moldflow) to eliminate flash, knit lines, and dimensional drift in complex gasket profiles. Concurrently, Formula Engineers develop proprietary FKM and EPDM compounds meeting ASTM D2000 QC requirements, with custom modifications for vacuum-specific challenges. Key innovations include peroxide-cured systems minimizing volatile organic compounds (VOCs) and nano-silica reinforcement enhancing resilience at temperatures from -40°C to 230°C. Every formulation undergoes outgassing validation per ASTM E595, ensuring total mass loss (TML) <0.50% and collected volatile condensable materials (CVCM) <0.05%—critical thresholds for semiconductor and analytical instrument applications.

Our OEM workflow begins with joint design reviews to de-risk manufacturability, followed by rapid prototyping using in-house 3D-printed molds for geometry validation. Production transitions seamlessly to high-precision steel molds with tight tolerances (±0.05mm), monitored via real-time SPC systems. All components adhere to ISO 9001:2015 protocols, with full traceability from raw material certificates to final PPAP documentation. This closed-loop approach reduces time-to-market by 30% while guaranteeing zero-defect delivery for Tier-1 vacuum pump manufacturers.

Material performance is validated against industry benchmarks as shown below:

| Property | FKM Compound (BD-VF100) | EPDM Compound (BD-VE200) | Test Standard |

|---|---|---|---|

| Hardness (Shore A) | 75 ± 3 | 80 ± 3 | ASTM D2240 |

| Tensile Strength (MPa) | 15.2 | 12.8 | ASTM D412 |

| Compression Set (70h/150°C) | 18% | 25% | ASTM D395 Method B |

| Temp Range (°C) | -25 to 230 | -40 to 150 | ISO 188 |

| Outgassing (TML/CVCM) | 0.32% / 0.03% | 0.45% / 0.04% | ASTM E595 |

This engineering framework transforms material science into operational reliability. By embedding formula and mold expertise within the OEM lifecycle—from initial RFQ to量产—we eliminate interface risks inherent in fragmented supply chains. Suzhou Baoshida’s gaskets achieve <50 ppm leakage rates in 10⁻⁹ mbar vacuum systems, directly supporting our clients’ commitments to zero-downtime performance. Partner with us to convert vacuum sealing challenges into competitive advantage through scientifically grounded elastomer engineering.

Customization Process

Gasket Vacuum Pump Customization: From Drawing to Mass Production

At Suzhou Baoshida Trading Co., Ltd., our engineering workflow for custom gasket vacuum pump seals follows a rigorous, science-driven methodology. Each phase is structured to ensure dimensional accuracy, material compatibility, and long-term operational reliability under demanding vacuum and thermal conditions.

The process begins with Drawing Analysis, where our rubber formula engineers conduct a comprehensive review of customer technical drawings. Critical parameters such as cross-sectional dimensions, tolerance classes (ISO 3302), groove design, and surface finish requirements are evaluated. We assess sealing interface dynamics, including compression set targets and expected media exposure (e.g., oil vapor, inert gases, or mild solvents). This stage also involves Finite Element Analysis (FEA) simulation when high-stress applications are anticipated, ensuring the design can withstand cyclic loading and thermal expansion without failure.

Following design validation, we proceed to Formulation Development. Our material scientists select elastomer bases—commonly NBR, FKM, EPDM, or specialty silicones—based on thermal range, chemical resistance, and outgassing performance. For vacuum environments, low volatile content and high resilience are paramount. We formulate compounds with controlled filler dispersion and optimized cure systems to achieve target hardness (Shore A 50–90), compression set (<25% at 150°C for 70 hrs), and vacuum stability per ASTM E595. Each batch is traceable, with full compliance to ROHS and REACH standards.

The Prototyping Phase employs precision compression or injection molding using production-grade tooling. Initial samples are subjected to dimensional inspection via coordinate measuring machines (CMM) and functional testing, including leak rate analysis under vacuum (≤1×10⁻⁶ mbar·L/s) and accelerated aging per ASTM D573. Customers receive test reports and physical samples for fitment evaluation. Iterations, if required, are executed within 7–10 days, ensuring rapid design convergence.

Upon approval, we transition to Mass Production, leveraging automated molding lines with real-time process monitoring. Statistical Process Control (SPC) ensures consistency across batches, with CPK ≥1.33 for critical dimensions. Each lot undergoes 100% visual inspection and抽样 physical testing per ASTM D2000. Packaging is vacuum-sealed with desiccants to prevent contamination prior to shipment.

Our integrated approach guarantees that every custom gasket vacuum pump seal meets the precise functional demands of OEM equipment, from semiconductor processing to medical vacuum systems.

Typical Material Specifications for Vacuum Pump Gaskets

| Property | NBR (Standard) | FKM (High Temp) | EPDM (Chemical Resistant) | Silicone (Wide Temp) |

|---|---|---|---|---|

| Temperature Range (°C) | -30 to +120 | -20 to +200 | -50 to +150 | -60 to +200 |

| Hardness (Shore A) | 70 ±5 | 75 ±5 | 65 ±5 | 55 ±5 |

| Tensile Strength (MPa) | ≥15 | ≥12 | ≥10 | ≥7 |

| Elongation at Break (%) | ≥250 | ≥180 | ≥200 | ≥300 |

| Compression Set (70h, 150°C) | ≤25% | ≤20% | ≤22% | ≤28% |

| Vacuum Outgassing (TML, ASTM E595) | <1.0% | <0.5% | <0.8% | <1.2% |

Contact Engineering Team

Engineering Precision for Vacuum Integrity: Partner with Suzhou Baoshida

Vacuum pump performance hinges on the molecular-level sealing integrity of gaskets. Substandard elastomeric components introduce catastrophic risks: outgassing contaminates sensitive processes, compression set failure compromises vacuum levels, and chemical incompatibility accelerates degradation. At Suzhou Baoshida Trading Co., Ltd., we engineer precision rubber seals specifically for high-vacuum and ultra-high-vacuum (UHV) environments where tolerances are measured in microns and failure is not an option. Our formulations undergo rigorous validation against ISO 21871 and ASTM F3136 standards, ensuring dimensional stability under extreme thermal cycling (-60°C to 300°C) and resistance to aggressive process media like halogenated solvents and plasma byproducts.

Our OEM manufacturing leverages proprietary polymer science to optimize cross-link density and filler dispersion, directly addressing vacuum-specific failure modes. Unlike generic seal suppliers, we prioritize low outgassing rates (verified per ASTM E595), minimal compression set (<15% at 150°C for 72 hours), and exceptional resilience to vacuum-induced embrittlement. This precision is non-negotiable in semiconductor CVD chambers, analytical instrumentation, and aerospace testing systems where seal leakage equates to production downtime or data corruption.

The following table details critical performance parameters for our vacuum-optimized gasket compounds:

| Material Grade | Temperature Range (°C) | Compression Set (ASTM D395) | Outgassing TML (%) | Key Chemical Resistances | Vacuum Rating |

|---|---|---|---|---|---|

| FKM-VMQ Hybrid | -45 to 280 | 12% @ 200°C/72h | 0.8 | Plasma, O₂, SF₆, C₄F₈ | UHV (10⁻⁹ mbar) |

| Perfluoroelastomer (FFKM) | -20 to 325 | 9% @ 250°C/48h | 0.3 | Chlorine, BrF₃, XeF₂ | XHV (10⁻¹² mbar) |

| High-Purity EPDM | -55 to 150 | 18% @ 125°C/22h | 1.2 | Steam, H₂O₂, Alkalines | HV (10⁻⁶ mbar) |

Suzhou Baoshida’s value extends beyond material science. Our integrated OEM workflow includes finite element analysis (FEA) of seal stress distribution, laser profilometry for surface finish validation (Ra ≤ 0.4 µm), and batch-specific traceability to ISO 13485 protocols. We collaborate at the design phase to mitigate flange distortion effects and optimize groove geometries per Parker O-Ring Handbook guidelines, eliminating iterative prototyping delays.

For mission-critical vacuum applications, generic seals are a liability. Partner with an engineering-led supplier who speaks the language of vacuum physics and polymer chemistry. Mr. Boyce, our dedicated Technical OEM Manager, possesses 14 years of experience resolving complex sealing challenges in semiconductor and analytical equipment manufacturing. Initiate a technical consultation by contacting him directly at [email protected]. Provide your application parameters—vacuum level, media exposure, temperature profile, and flange specifications—and receive a validated material recommendation with accelerated sampling within 72 hours.

Do not compromise vacuum integrity through off-the-shelf solutions. Suzhou Baoshida delivers engineered certainty: where every compound formulation, dimensional tolerance, and production lot undergoes vacuum-specific qualification. Contact Mr. Boyce to transform your sealing reliability from a risk factor into a competitive advantage. Precision sealing demands precision partnership—begin the engineering dialogue today.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).