Technical Contents

Engineering Guide: Gland Packing For Valves

Engineering Insight: The Critical Role of Material Selection in Gland Packing for Valves

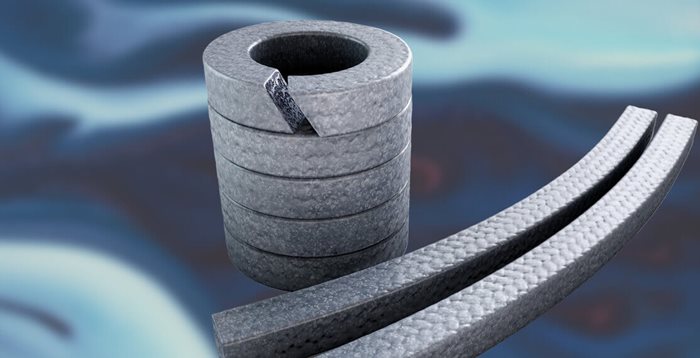

Gland packing for valves serves as a primary sealing solution in dynamic applications where shafts, stems, or spindles move under pressure and temperature. While often viewed as a commodity component, the performance and longevity of gland packing are fundamentally tied to precise material selection. Off-the-shelf solutions, though cost-effective initially, frequently fail due to their generic design and lack of customization to operational parameters. These failures manifest as leakage, stem wear, increased maintenance cycles, and unplanned downtime—costly outcomes in industrial environments.

The core challenge lies in the diversity of service conditions across industries. A packing material suitable for water service at ambient temperature may degrade rapidly in high-temperature steam or aggressive chemical environments. Material compatibility must be evaluated not only against the process media but also against pressure, thermal cycling, stem surface finish, and movement type (linear, rotary, or oscillating). Polytetrafluoroethylene (PTFE), for example, offers excellent chemical resistance and low friction but lacks resilience under high compressive loads and can cold-flow over time. Aramid fibers provide high tensile strength and thermal stability but may degrade in strong acids or oxidizing environments. Graphite-based packings excel in high-temperature applications, particularly steam, but are unsuitable for use in reducing sulfides due to potential stress corrosion cracking in stainless steel components.

Furthermore, the braiding structure and lubrication method significantly influence performance. Densely braided packings offer better extrusion resistance in high-pressure systems, while loose braid constructions accommodate misalignment and thermal expansion. Internal lubricants such as PTFE, graphite, or molybdenum disulfide reduce friction and stem wear but must be selected to remain stable under operating conditions.

Custom-engineered gland packing solutions account for these variables through material hybridization, specialized braid patterns, and performance testing under simulated service conditions. At Suzhou Baoshida Trading Co., Ltd., we prioritize application-specific formulation, ensuring that each packing solution aligns with the mechanical, thermal, and chemical demands of the system.

The table below outlines common gland packing materials and their typical performance characteristics:

| Material | Max Temp (°C) | Pressure Resistance (bar) | Chemical Resistance | Key Applications |

|---|---|---|---|---|

| PTFE | 260 | 20 | Excellent | Acids, solvents, water |

| Aramid Fiber | 280 | 35 | Good | Pulp & paper, water, mild chemicals |

| Flexible Graphite | 650 (in steam) | 30 | Very Good | Steam, oils, high-temp processes |

| Carbon Fiber | 450 (inert) | 40 | Good | High-pressure pumps, cryogenics |

| Ceramic Fiber | 1260 | 15 | Limited | Extreme heat, non-corrosive gases |

Selecting the correct gland packing is not a one-size-fits-all endeavor. Relying on standard off-the-shelf products risks premature failure and operational inefficiency. Precision engineering, material science, and application insight are essential to achieving reliable, long-term sealing performance.

Material Specifications

Material Specifications for Gland Packing in Valve Applications

Selecting the appropriate elastomer for gland packing is critical to ensuring valve integrity under operational stress, chemical exposure, and thermal cycling. At Suzhou Baoshida Trading Co., Ltd., we prioritize material science precision to match elastomer properties with client-specific media, pressure, and temperature demands. Our engineered solutions for Viton, Nitrile, and Silicone compounds undergo rigorous ASTM D2000 classification testing to guarantee performance consistency. Below we detail the core specifications governing material selection for industrial valve gland packing.

Viton (FKM) fluorocarbon elastomers deliver exceptional resistance to aggressive chemicals, including hydrocarbons, acids, and steam. With a continuous service temperature range of -20°C to +230°C, Viton maintains sealing integrity in high-temperature oil and gas applications where oxidation and swelling compromise lesser materials. Its tensile strength exceeds 15 MPa (ASTM D412), with elongation at break ≥200%, ensuring resilience against extrusion in dynamic valve stems. Viton is the standard for sour gas service per NACE MR0175 but exhibits limitations in ketones and low-temperature flexibility below -40°C.

Nitrile (NBR) butadiene-acrylonitrile rubber provides optimal cost-performance balance for petroleum-based media. Operating effectively between -40°C and +120°C, NBR resists mineral oils, fuels, and hydraulic fluids. Its acrylonitrile content (34–45%) directly correlates with oil resistance; higher ACN yields superior swell resistance but reduced low-temperature flexibility. NBR achieves tensile strength of 10–20 MPa and elongation of 250–400% (ASTM D412), making it ideal for water, glycol, and moderate-pressure valve applications. However, NBR degrades rapidly when exposed to ozone, chlorinated solvents, or phosphate esters.

Silicone (VMQ) excels in extreme temperature stability from -60°C to +200°C and offers outstanding resistance to ozone and UV radiation. While tensile strength is moderate (6–10 MPa), its high elongation (≥300%) provides reliable sealing in cryogenic or high-purity systems. Silicone is non-toxic and FDA-compliant, suiting food, pharmaceutical, and semiconductor valves. Critical limitations include poor resistance to petroleum oils, low tear strength, and susceptibility to compression set under sustained load.

The comparative analysis below summarizes key parameters for informed material selection:

| Material | Temperature Range (°C) | Key Chemical Resistances | Tensile Strength (MPa) | Elongation at Break (%) | Primary Industrial Applications |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to +230 | Hydrocarbons, acids, steam, fuels | ≥15 | ≥200 | Oil & gas valves, chemical processing, aerospace |

| Nitrile (NBR) | -40 to +120 | Mineral oils, water, alcohols, glycols | 10–20 | 250–400 | Hydraulic systems, water treatment, general industrial valves |

| Silicone (VMQ) | -60 to +200 | Ozone, UV, water, steam | 6–10 | ≥300 | Food processing, pharmaceuticals, cryogenics, medical devices |

Suzhou Baoshida Trading Co., Ltd. emphasizes that gland packing failure often stems from unverified material assumptions. Our OEM partnerships include media compatibility validation per ASTM D471 and thermal aging tests per ASTM D573 to preempt field failures. Always cross-reference chemical exposure charts with actual service conditions—particularly for mixed-media environments where synergistic degradation occurs. For critical applications, we recommend pilot testing with client-specific media to finalize elastomer selection. Precision in material specification directly translates to extended valve service life and reduced operational downtime.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Gland Packing Solutions

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the design and production of high-performance gland packing for valves. With a dedicated team comprising five experienced mould engineers and two specialized rubber formula engineers, we maintain full in-house control over the entire product development cycle—from concept and material formulation to tooling design and performance validation.

Our mould engineers bring over a decade of cumulative experience in precision rubber component manufacturing, focusing on optimizing geometries for dynamic sealing applications. They utilize advanced CAD/CAM software to design and simulate gland packing profiles, ensuring dimensional accuracy, optimal compression set resistance, and consistent performance under fluctuating pressure and temperature conditions. Finite element analysis (FEA) is routinely applied to predict stress distribution and extrusion behavior, enabling us to refine packing designs for critical industrial environments such as oil & gas, chemical processing, and power generation.

Complementing this mechanical expertise, our two rubber formula engineers specialize in elastomer chemistry and compound development. They formulate custom rubber compounds tailored to specific service conditions, including resistance to aggressive media, high-temperature stability, and low compression creep. By selecting appropriate base polymers—such as NBR, EPDM, FKM, and HNBR—and optimizing filler systems, cure chemistry, and additives, we ensure that each gland packing delivers long-term sealing integrity. Our formulation process is supported by rigorous laboratory testing, including compression set, tensile strength, hardness, and fluid resistance evaluations per ASTM and ISO standards.

This integrated engineering approach enables us to offer comprehensive OEM services, where we collaborate directly with valve manufacturers to co-develop gland packing that meets exact OEM specifications. Whether reverse-engineering legacy components or designing next-generation sealing solutions, we provide full technical documentation, material traceability, and batch-to-batch consistency. Our clients benefit from reduced development lead times, improved sealing performance, and compliance with international quality requirements.

We support both standard and custom cross-sections, with capabilities in multi-rib, chevron, and split-ring configurations. All tooling is manufactured in-house using CNC machining and EDM processes, ensuring tight tolerances and rapid prototyping.

The following table outlines key technical specifications for our standard gland packing compounds:

| Property | NBR (Standard) | EPDM (High Temp) | FKM (Chemical Resistant) | HNBR (High Performance) |

|---|---|---|---|---|

| Hardness (Shore A) | 70 ± 5 | 75 ± 5 | 80 ± 5 | 85 ± 5 |

| Tensile Strength (MPa) | ≥15 | ≥12 | ≥10 | ≥20 |

| Elongation at Break (%) | ≥250 | ≥200 | ≥150 | ≥220 |

| Compression Set (22h @ 100°C) | ≤25% | ≤30% | ≤20% | ≤18% |

| Temperature Range (°C) | -30 to +100 | -40 to +150 | -20 to +200 | -40 to +170 |

| Fluid Resistance | Oil, water, aliphatic | Water, steam, polar fluids | Aromatics, acids, fuels | Oil, steam, moderate acids |

Through this fusion of material science and precision engineering, Suzhou Baoshida delivers gland packing solutions that exceed operational demands and support the reliability of critical valve systems worldwide.

Customization Process

Gland Packing Customization Process: Precision Engineering for Valve Sealing

As Rubber Formula Engineers and OEM Managers at Suzhou Baoshida Trading Co., Ltd., we execute a rigorously defined customization pathway for gland packing solutions. This process ensures optimal performance in dynamic valve sealing applications where pressure, temperature, and chemical exposure demand uncompromising material integrity. Our methodology begins with comprehensive Drawing Analysis, wherein OEM-provided technical schematics undergo dimensional validation against ASME/API standards. Critical parameters—including shaft diameter tolerance, stuffing box depth, operating pressure differentials, and media compatibility—are cross-referenced with our material database. This phase identifies potential failure modes such as extrusion gaps or thermal degradation risks, establishing the foundation for a purpose-built formulation.

Subsequent Formulation development leverages our proprietary polymer science expertise. We select base elastomers—typically hydrogenated nitrile (HNBR), ethylene propylene diene monomer (EPDM), or perfluoroelastomers (FFKM)—based on the target chemical resistance profile. Reinforcing fillers, thermal stabilizers, and friction modifiers are then precision-compounded to achieve target Shore A hardness (70–90), tensile strength (>15 MPa), and compression set resistance (<25% at 150°C). Molecular cross-link density is calibrated to balance resilience against permanent deformation under sustained load, a critical factor in valve stem sealing longevity.

Prototyping follows strict validation protocols. Initial samples are molded to exact OEM dimensions and subjected to simulated service conditions in our in-house test rigs. Performance metrics include leakage rate under cyclic pressure (0–10 MPa), coefficient of friction during stem movement, and thermal cycling stability from -40°C to 250°C. Data from these trials informs iterative refinements, with material composition adjusted to eliminate micro-leak paths or stick-slip phenomena. Only upon achieving zero leakage at 110% of rated pressure do we approve the design for Mass Production.

Final production integrates full traceability via batch-coded raw materials and real-time process monitoring. All gland packing undergoes 100% dimensional inspection using laser micrometers and automated vision systems. Below is a summary of material specifications we commonly deploy for valve applications:

| Material Type | Key Properties | Typical Applications |

|---|---|---|

| Expanded Graphite | 300°C continuous, low friction, non-abrasive | Steam valves, chemical processing |

| PTFE-Encapsulated | Chemical inertness, 260°C max, low creep | Pharmaceutical, semiconductor valves |

| Aramid Fiber-Reinforced | High tensile strength, 288°C intermittent | Oil & gas wellhead valves |

| HNBR-Based Composite | Oil/fuel resistance, 150°C continuous | Hydraulic control valves |

This structured approach—from drawing scrutiny to validated mass production—ensures Suzhou Baoshida delivers gland packing that eliminates fugitive emissions and extends valve service life. Our commitment to scientific precision transforms OEM specifications into reliability-critical sealing components, directly supporting operational safety and regulatory compliance in demanding industrial environments.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Gland Packing Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance industrial rubber solutions tailored to the rigorous demands of valve sealing applications. Our gland packing products are engineered for durability, chemical resistance, and operational efficiency across diverse industrial environments, including oil & gas, chemical processing, power generation, and marine systems. As a trusted OEM partner and technical supplier, we combine material science expertise with precision manufacturing to provide sealing solutions that minimize downtime and extend service life.

When selecting gland packing for valves, performance under pressure, temperature extremes, and exposure to aggressive media is critical. Our formulations leverage advanced elastomeric and fiber-based materials, including PTFE, aramid fibers, graphite, and nitrile rubber compounds, ensuring compatibility with a broad spectrum of fluids and operating conditions. Each product is developed to meet international standards for compression, resilience, and extrusion resistance, providing reliable sealing even in high-cycle and high-pressure valve systems.

We understand that every industrial application presents unique challenges. That’s why Suzhou Baoshida offers customized gland packing solutions based on your specific operational parameters. Whether you require low-friction packing for frequent actuation, high-temperature resistance for steam service, or corrosion-resistant materials for acidic environments, our engineering team works directly with clients to optimize material selection and dimensional tolerances.

To support our clients effectively, we maintain rigorous quality control protocols throughout production, including batch testing, dimensional verification, and material traceability. All gland packing products are supplied with full technical documentation, including chemical compatibility charts, installation guidelines, and performance data sheets.

For technical consultation, product selection, or custom development support, we invite you to contact Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer. Mr. Boyce brings over 15 years of experience in industrial sealing applications and is available to assist with material recommendations, failure analysis, and on-site technical support.

| Property | Typical Value | Test Standard |

|---|---|---|

| Temperature Range | -200°C to +600°C | ASTM D1418 |

| Pressure Resistance | Up to 40 bar (dynamic), 60 bar (static) | ISO 7005 |

| Shaft Speed Compatibility | Up to 5 m/s | DIN 3761-3 |

| Chemical Resistance | Excellent against acids, alkalis, hydrocarbons | ASTM D471 |

| Density | 1.3 – 1.8 g/cm³ | ISO 2781 |

Reach out today to ensure your valve systems operate with maximum reliability and minimal leakage. Partner with Suzhou Baoshida for engineered sealing performance you can trust.

Contact Mr. Boyce at [email protected] for immediate technical support, sample requests, or OEM collaboration opportunities.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).