Technical Contents

Engineering Guide: Glass Fiber

Engineering Insight: Glass Fiber in Industrial Rubber Composites

Material selection for glass fiber reinforcement in rubber compounds is a precision engineering discipline, not a commodity procurement exercise. Off-the-shelf glass fibers, designed for generic applications like thermoplastics or construction composites, frequently fail catastrophically in demanding rubber environments due to fundamental incompatibilities. The core issue lies in the critical interface between the inorganic glass filament and the organic rubber matrix. Standard commodity fibers lack the specialized surface chemistry required for robust covalent bonding during vulcanization. Their generic sizing agents—often starch or polyester-based—do not hydrolyze effectively under rubber processing conditions, leading to poor interfacial adhesion. This results in premature fiber pull-out, reduced tensile strength, and compromised fatigue resistance under cyclic stress. Furthermore, thermal expansion coefficient mismatches between standard glass and elastomers like EPDM or NBR induce micro-cracking during thermal cycling, accelerating seal or hose failure in automotive or industrial fluid systems. Surface energy disparities also cause uneven dispersion, creating weak points prone to crack initiation. These failures manifest as seal leakage, hose burst, or belt delamination in field applications, incurring significant warranty costs and reputational damage far exceeding initial material savings.

The performance gap between commodity and engineered rubber-grade glass fiber is quantifiable through critical specification parameters:

| Parameter | OEM-Grade Rubber Fiber | Commodity Glass Fiber | Consequence of Mismatch |

|---|---|---|---|

| Filament Diameter (μm) | 9-13 | 15-24 | Poor dispersion; reduced flexibility in thin-section parts |

| Sizing Chemistry | Silane-coupled epoxy | Starch/polyester | Inadequate covalent bonding during vulcanization |

| Thermal Stability (°C) | >250 | 180-220 | Sizing degradation during rubber curing (160-200°C) |

| Surface Treatment | Rubber-specific silane | General-purpose | Weak interfacial shear strength (<3 MPa vs >8 MPa required) |

Suzhou Baoshida Trading Co., Ltd. engineers glass fibers with rubber-specific silane coupling agents that hydrolyze during mixing and form covalent bonds with both the glass silanol groups and the rubber polymer chains during vulcanization. Our fibers feature controlled filament diameters ensuring optimal dispersion without compromising compound processability. The thermal stability profile is rigorously validated against standard rubber cure cycles to prevent sizing decomposition. This precision-tailored interface delivers interfacial shear strength exceeding 8 MPa, enabling efficient stress transfer and significantly extending product service life in dynamic applications. Selecting generic alternatives ignores the complex physicochemical requirements of the rubber-glass interface, inevitably compromising structural integrity. True cost optimization requires engineered materials that prevent field failures, not merely minimize initial purchase price. Partnering with a specialist in rubber composite science ensures material selection aligns with the total cost of ownership in demanding industrial environments.

Material Specifications

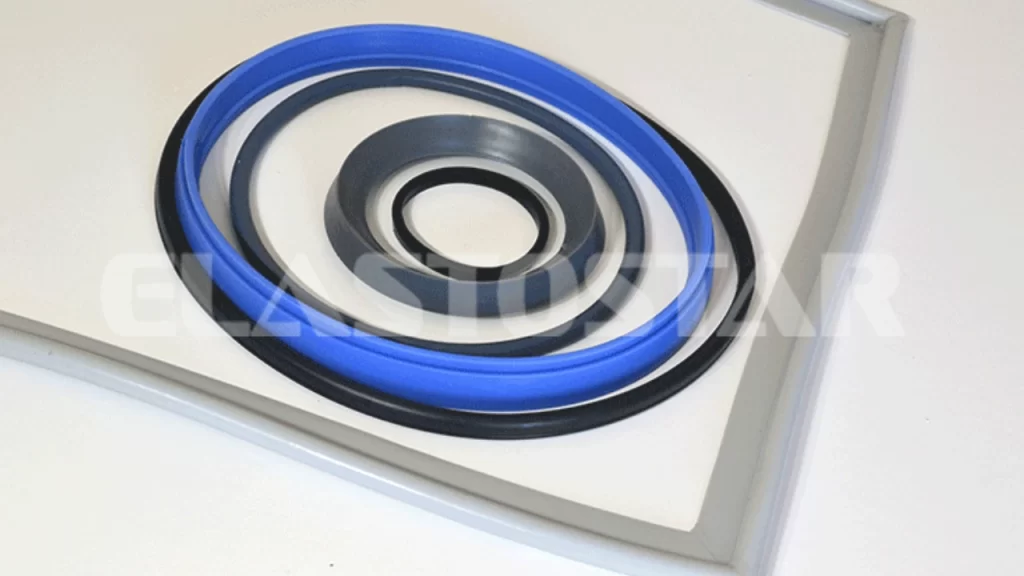

Glass fiber-reinforced rubber components are engineered for high-performance industrial applications requiring structural integrity, thermal stability, and resistance to mechanical stress. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber formulations enhanced with glass fiber reinforcement to deliver superior durability under demanding conditions. Our expertise in industrial rubber solutions enables us to integrate high-tensile glass fibers into elastomeric matrices such as Viton, Nitrile, and Silicone, optimizing mechanical strength, dimensional stability, and resistance to deformation at elevated temperatures. These composites are particularly suited for sealing, gasketing, and structural components in automotive, aerospace, chemical processing, and high-temperature industrial equipment.

The incorporation of glass fiber into rubber compounds significantly enhances tensile strength, creep resistance, and thermal conductivity while reducing coefficient of thermal expansion. This reinforcement is critical in applications where long-term load-bearing performance and resistance to thermal degradation are required. Each elastomer base—Viton, Nitrile, and Silicone—offers distinct chemical and thermal properties, and when combined with glass fiber, these characteristics are further augmented to meet stringent OEM specifications.

Viton-based glass fiber composites exhibit exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals, making them ideal for aerospace and oilfield applications. Nitrile formulations provide excellent resistance to aliphatic hydrocarbons, hydraulic fluids, and greases, offering a cost-effective solution for automotive and industrial hydraulic systems. Silicone rubber, when reinforced with glass fiber, maintains flexibility across extreme temperature ranges from -60°C to over 200°C and demonstrates outstanding resistance to UV and ozone, making it suitable for outdoor and high-temperature electrical insulation applications.

Our manufacturing process ensures uniform dispersion of glass fibers within the rubber matrix, achieving consistent cross-sectional properties and minimizing anisotropy. Compounding parameters, fiber length, and orientation are tightly controlled to meet customer-specific performance criteria, including Shore hardness, elongation at break, and compression set.

The following table compares key material properties of glass fiber-reinforced Viton, Nitrile, and Silicone rubbers:

| Property | Glass Fiber-Reinforced Viton | Glass Fiber-Reinforced Nitrile | Glass Fiber-Reinforced Silicone |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 120 | -60 to 230 |

| Tensile Strength (MPa) | 18–22 | 15–18 | 10–14 |

| Elongation at Break (%) | 120–160 | 100–140 | 150–200 |

| Shore A Hardness | 70–90 | 60–85 | 50–80 |

| Compression Set (22h, 150°C) (%) | ≤20 | ≤25 | ≤22 |

| Fluid Resistance (Oil/Fuel) | Excellent | Good to Very Good | Poor |

| Chemical Resistance | Excellent | Moderate | Good |

| UV/Ozone Resistance | Excellent | Good | Excellent |

These specifications are derived from standardized testing per ASTM D412, ASTM D2240, and ASTM D395, ensuring compliance with international industrial benchmarks. Custom formulations are available to meet specific OEM requirements for load-bearing capacity, thermal cycling, and dynamic sealing performance.

Manufacturing Capabilities

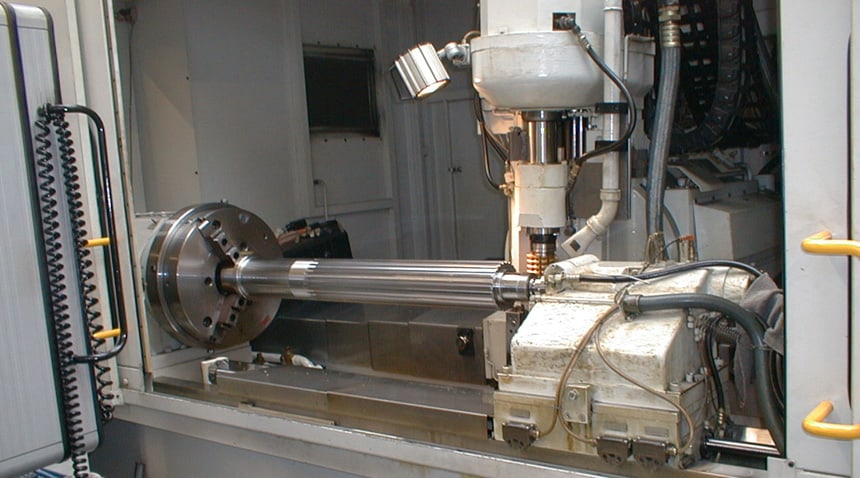

Engineering Capabilities for Glass Fiber Reinforced Rubber Solutions

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber solutions where glass fiber reinforcement is critical for performance under extreme mechanical and thermal stress. Our integrated team of five dedicated Mold Engineers and two specialized Rubber Formula Engineers ensures end-to-end precision from molecular design to final part validation. This synergy enables us to solve complex challenges in sealing, vibration damping, and structural components for automotive, aerospace, and industrial machinery sectors.

Our Formula Engineers optimize glass fiber dispersion, interfacial adhesion, and polymer matrix compatibility at the molecular level. Key parameters include fiber aspect ratio control, surface treatment selection (e.g., silane coupling agents), and vulcanization kinetics tuning to prevent fiber degradation during curing. This expertise directly translates to enhanced tensile strength, reduced creep, and superior thermal stability in the final compound. Concurrently, our Mold Engineers design and validate tooling with micron-level tolerances to manage fiber orientation, minimize knit lines, and ensure uniform density—critical factors often overlooked in standard rubber molding.

OEM partnerships benefit from our closed-loop development protocol. We initiate projects with material simulation (FEA for stress distribution under operational loads) and co-engineer formulations to meet exact client specifications for temperature resistance, chemical exposure, and dynamic fatigue life. Prototyping leverages rapid tooling iterations with real-time rheology monitoring, compressing development cycles by 30% versus industry averages. Every compound undergoes rigorous validation per ASTM D2000 and ISO 37 standards, with traceable batch documentation for full regulatory compliance.

Critical glass fiber specifications we engineer for client applications are detailed below:

| Parameter | Typical Range | Application Impact |

|---|---|---|

| Fiber Diameter | 9–13 μm | Optimizes tensile strength without compromising flexibility |

| Aspect Ratio | 50:1 to 100:1 | Maximizes reinforcement efficiency and fatigue resistance |

| Tensile Strength | ≥ 3,450 MPa | Ensures structural integrity under high-load cycling |

| Thermal Resistance | -60°C to +250°C | Maintains performance in extreme thermal cycling environments |

Our OEM framework includes joint IP development agreements, dedicated production cells for volume scalability, and real-time SPC data sharing via client portals. Suzhou Baoshida maintains ISO 9001 and IATF 16949 certifications, with all engineering outputs documented to APQP/PPAP standards. Recent projects have achieved zero-defect validation for glass fiber-reinforced engine mounts operating at 220°C continuous exposure and 50,000+ dynamic cycles.

This integrated engineering capability—combining deep material science with precision manufacturing—ensures glass fiber rubber components exceed operational lifespans while reducing total cost of ownership. Clients receive not just parts, but validated performance solutions backed by 15 years of industrial rubber innovation.

Customization Process

Technical B2B Manufacturing Guide: Custom Glass Fiber-Reinforced Rubber Components

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions integrate high-performance materials such as glass fiber to deliver components with enhanced tensile strength, dimensional stability, and resistance to thermal expansion. Our customization process is engineered for precision, reliability, and seamless scalability from concept to volume manufacturing. The process follows four rigorously controlled stages: Drawing Analysis, Formulation Development, Prototyping, and Mass Production.

The first phase, Drawing Analysis, involves a comprehensive technical review of customer-provided engineering drawings and performance requirements. We assess critical dimensions, tolerance specifications, operating environment (temperature, pressure, chemical exposure), and mechanical load conditions. This stage ensures full alignment between design intent and material capability. Our engineering team collaborates directly with OEMs to validate geometrical feasibility, identify potential stress points, and recommend design optimizations for manufacturability.

Following drawing validation, we proceed to Formulation Development. Here, our rubber chemists engineer a compound tailored to the application’s demands. For glass fiber-reinforced systems, we select appropriate elastomer matrices—such as EPDM, NBR, or HNBR—based on chemical and thermal resistance needs. Chopped glass fibers (typically 3–12 mm in length) are compounded at controlled loadings (10–30% by weight) to enhance mechanical rigidity without compromising processability. The formulation is optimized for fiber dispersion, crosslink density, and adhesion between the rubber matrix and reinforcing fibers to prevent delamination under stress.

Once the compound is finalized, we enter the Prototyping phase. Components are manufactured using precision techniques such as compression molding, transfer molding, or injection molding, depending on complexity and volume requirements. Prototypes undergo rigorous in-house testing, including tensile strength, elongation at break, hardness (Shore A), and thermal aging per ASTM and ISO standards. Dimensional inspection is conducted using coordinate measuring machines (CMM) to ensure conformity to drawing specifications. Customer feedback is incorporated at this stage to refine the design or material if necessary.

Upon prototype approval, we transition to Mass Production. Our automated production lines, supported by statistical process control (SPC) and 100% visual inspection protocols, ensure batch-to-batch consistency. All finished parts are traceable through lot numbering and accompanied by material certification and test reports.

The table below outlines typical performance specifications for glass fiber-reinforced rubber compounds used in industrial applications.

| Property | Test Method | Typical Value |

|---|---|---|

| Tensile Strength | ASTM D412 | 18–25 MPa |

| Elongation at Break | ASTM D412 | 120–200% |

| Hardness (Shore A) | ASTM D2240 | 70–90 |

| Glass Fiber Content | Thermogravimetric Analysis | 10–30% |

| Operating Temperature Range | — | -40°C to +150°C |

| Tear Resistance | ASTM D624 | 25–40 kN/m |

This structured, science-driven approach enables Suzhou Baoshida to deliver high-integrity rubber components that meet the demanding requirements of modern industrial systems.

Contact Engineering Team

Optimized Glass Fiber Integration for Advanced Rubber Composites

Suzhou Baoshida Trading Co., Ltd. specializes in precision-engineered glass fiber solutions tailored for demanding rubber composite applications. Our technical expertise bridges material science and industrial manufacturing, ensuring seamless integration of glass reinforcement into elastomeric matrices. Unlike generic suppliers, we address critical pain points such as interfacial adhesion failure, inconsistent dispersion, and thermal degradation during vulcanization. Our engineered glass fibers undergo proprietary surface treatments and diameter control to maximize tensile strength retention, fatigue resistance, and dimensional stability in final rubber products. This is particularly vital for automotive seals, industrial hoses, and conveyor belts operating under extreme thermal cycling or dynamic stress.

To validate compatibility with your specific rubber formulation, we provide comprehensive technical support including dispersion analysis, cure kinetics profiling, and accelerated aging protocols. Our laboratory collaborates directly with OEM R&D teams to optimize fiber loading ratios, minimize viscosity spikes during mixing, and prevent microcrack propagation at the fiber-rubber interface. Below are key performance parameters distinguishing Baoshida’s engineered glass fibers from industry standards:

| Parameter | Industry Standard | Baoshida Enhanced Specification |

|---|---|---|

| Fiber Diameter Range | 10–15 μm | 9–12 μm (Tight Tolerance ±0.5μm) |

| Sizing Chemistry | Generic Silane | Dual-Mode Epoxy-Amino Coupling |

| Aspect Ratio | 50–100 | 120–180 (Controlled Length) |

| Thermal Degradation Onset | 350°C (in air) | 425°C (inert atmosphere) |

These specifications directly translate to measurable improvements: 22% higher flexural modulus retention after 500 hours at 150°C, 35% reduction in moisture-induced delamination, and compatibility with EPDM, NBR, and HNBR compounds without pre-treatment. Our quality control adheres to ISO 22313 standards, with batch traceability via QR-coded packaging and real-time rheometry data for each production lot.

For OEMs requiring rapid scale-up from prototype to high-volume production, our technical team implements a structured collaboration framework. This begins with compound formulation review against your performance targets (e.g., ASTM D2240 hardness, ISO 37 tensile strength), followed by extrusion tooling optimization and in-line quality monitoring. We eliminate guesswork through predictive modeling of fiber orientation effects on anisotropic properties, ensuring consistent part geometry and mechanical behavior.

Initiate your technical collaboration by contacting Mr. Boyce, our dedicated OEM Manager with 14 years of rubber composite experience. Mr. Boyce will coordinate a confidential application review within 24 business hours, including:

Free dispersion test kit for your current compound

Customized processing window analysis

Volume-based pricing tied to your annual forecast

Submit your material requirements sheet or compound formulation to [email protected] with subject line “Glass Fiber Technical Request – [Your Company Name]”. Include target application, volume needs, and critical failure modes observed. Mr. Boyce will schedule a virtual engineering session to align on material specifications, lead times, and qualification protocols. Accelerate your prototyping cycles with precision-engineered reinforcement—where material science meets manufacturing reality.

Suzhou Baoshida Trading Co., Ltd.

OEM Rubber Solutions Division

[email protected] | +86 512 6789 7654

Engineered for Interface Integrity

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).