Technical Contents

Engineering Guide: Glass Jar Gaskets

Engineering Insight: Material Selection Criticality for Glass Jar Gaskets

Glass jar sealing presents unique engineering challenges demanding precise material science. Standardized rubber gaskets frequently fail in this application due to inadequate consideration of the specific operational stresses inherent in food and beverage packaging cycles. The primary failure drivers stem from thermal excursions during pasteurization or retort processing, direct contact with diverse fill media (acids, oils, alcohols), and the critical requirement for consistent sealing force against rigid glass surfaces over extended shelf life. Off-the-shelf solutions, often formulated for general-purpose sealing, lack the tailored polymer architecture necessary to withstand these combined demands, leading to premature degradation and compromised product integrity.

Common failure modes of non-optimized gaskets include significant swelling when exposed to lipids or organic acids, causing extrusion or loss of sealing force. Inadequate heat resistance results in accelerated compression set during thermal processing, where the rubber permanently loses its ability to rebound, creating permanent gaps. Glass jars exert minimal accommodation for seal deformation; even minor compression set exceeding 25% typically induces leakage. Furthermore, standard formulations may lack sufficient resistance to oxidative aging at elevated temperatures, leading to surface cracking (ozone or thermal) or embrittlement. Crucially, many generic compounds do not meet stringent FDA 21 CFR 177.2600 requirements for repeated food contact, risking regulatory non-compliance and potential migration of harmful substances. The zero-tolerance nature of glass-to-glass sealing magnifies these material deficiencies, where micrometer-level dimensional instability translates directly to seal failure.

The following table compares critical performance parameters of common elastomer families relevant to glass jar applications, highlighting why material selection cannot be generic:

| Material | Continuous Temp Range (°C) | Key Chemical Resistance | Typical Compression Set (70h @ 100°C) | Common Failure Modes in Glass Jars |

|---|---|---|---|---|

| Standard NBR | -30 to +100 | Fair for water, weak acids; Poor for oils | 45-60% | Severe swelling in oils, rapid compression set, ozone cracking |

| Standard EPDM | -50 to +150 | Excellent for water, steam, alkalis; Poor for oils | 35-50% | Swelling in vegetable oils, limited acid resistance |

| Standard Silicone | -60 to +200 | Excellent for water, alcohols; Poor for oils | 25-40% | Swelling in oils/fats, lower tensile strength, extrusion |

| Baoshida Precision Compound | -40 to +150 | Optimized for oils, acids, alcohols | <20% | Engineered resistance to all common failure modes |

Suzhou Baoshida Trading Co., Ltd. addresses these challenges through proprietary rubber compounding. Our engineered solutions utilize high-purity, FDA-compliant base polymers modified with specialized additives to achieve ultra-low compression set, exceptional resistance to food-grade oils and organic acids, and thermal stability exceeding standard formulations. We precisely control durometer (typically 45-55 Shore A) and dimensional tolerances (±0.1mm) to ensure optimal sealing force distribution against the unforgiving glass rim. This material science approach prevents the costly consequences of seal failure: product leakage, spoilage, customer complaints, and brand damage. Generic gaskets represent a false economy; our precision-engineered compounds deliver proven reliability, ensuring seal integrity throughout the product lifecycle and safeguarding your reputation for quality. Material selection is not a cost line item—it is the foundational element of a successful glass jar sealing system.

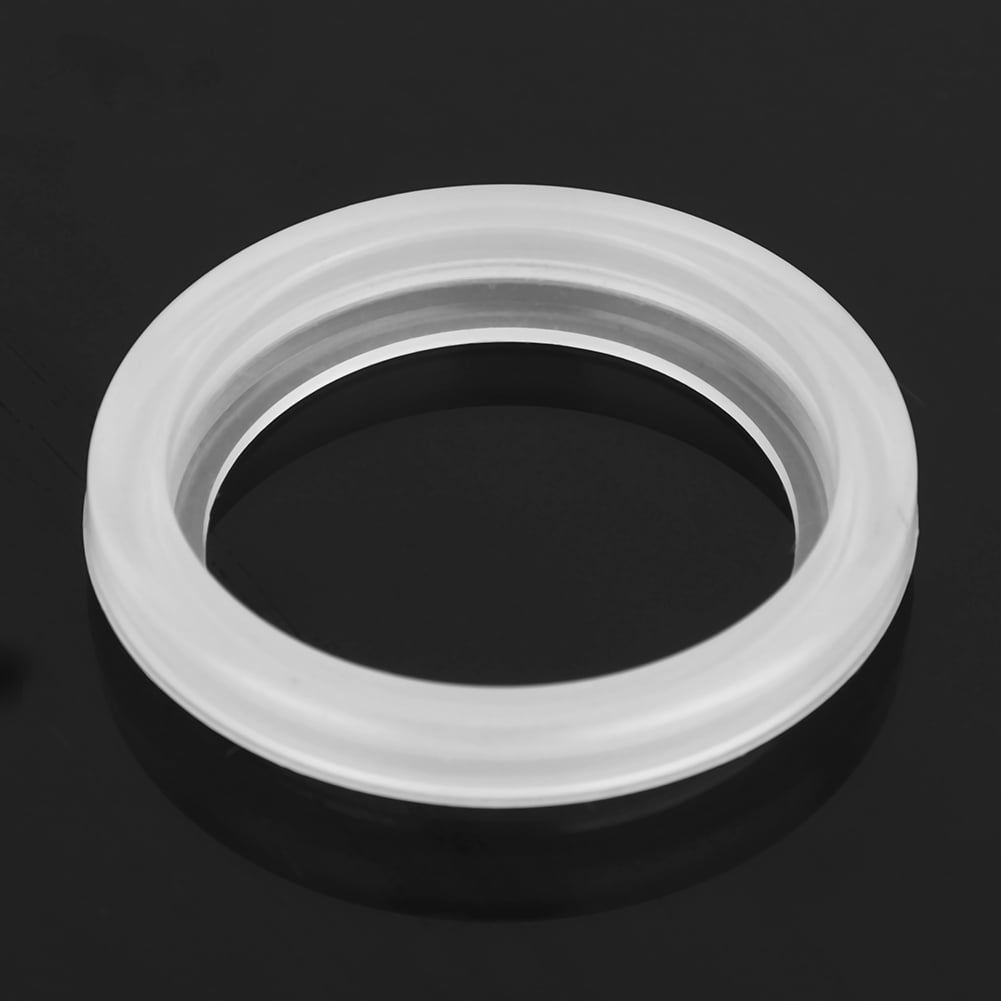

Material Specifications

Material selection is a critical factor in the performance and longevity of glass jar gaskets, particularly in industrial and commercial applications where sealing integrity, chemical resistance, and temperature stability are paramount. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered to meet the rigorous demands of food, pharmaceutical, and chemical packaging industries. Our primary elastomer options—Viton, Nitrile (NBR), and Silicone—are selected based on application-specific requirements including media compatibility, operational temperature, and mechanical stress.

Viton, a fluorocarbon-based rubber (FKM), is renowned for its exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. With a continuous service range from -20°C to +200°C, Viton gaskets maintain seal integrity in extreme environments. This material is ideal for applications involving exposure to aromatic hydrocarbons, chlorinated solvents, and strong acids. Its low gas permeability and excellent aging characteristics make it a preferred choice for high-performance sealing where failure is not an option. However, Viton exhibits lower flexibility at low temperatures compared to Silicone and higher cost than Nitrile, which must be considered in cost-sensitive designs.

Nitrile rubber (NBR) offers a balanced combination of oil resistance, abrasion resistance, and mechanical strength at a competitive price point. It performs reliably in temperature ranges from -30°C to +100°C, with short-term peaks up to +120°C. NBR is particularly effective in sealing applications involving aliphatic hydrocarbons, water-based fluids, and vegetable oils. Its good compression set resistance ensures long-term sealing force retention, making it suitable for reusable glass jar systems in food processing and industrial storage. While NBR is less resistant to ozone, UV, and polar solvents than Viton or Silicone, it remains a cost-effective solution for moderate environments.

Silicone rubber (VMQ) excels in extreme temperature applications, with a service range from -60°C to +200°C. It demonstrates outstanding resistance to weathering, ozone, and UV radiation, along with excellent flexibility at low temperatures. Silicone is non-toxic and compliant with FDA and USP Class VI standards, making it ideal for food, beverage, and pharmaceutical jar sealing. It maintains elasticity over time and resists hardening or cracking, ensuring consistent sealing performance. However, Silicone has relatively low tensile strength and poor resistance to petroleum-based oils, limiting its use in hydrocarbon-rich environments.

The following table summarizes key performance characteristics of these materials for informed selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 | -30 to +100 | -60 to +200 |

| Chemical Resistance | Excellent | Good to Very Good | Fair to Good |

| Oil/Fuel Resistance | Excellent | Very Good | Poor |

| Compression Set Resistance | Excellent | Good | Very Good |

| Flexibility at Low Temp | Moderate | Good | Excellent |

| FDA Compliance | Select Grades | Limited | Yes (Standard) |

| Cost Level | High | Low to Moderate | Moderate to High |

Each material presents distinct advantages depending on the operational environment. Proper selection ensures optimal sealing performance, regulatory compliance, and cost efficiency in glass jar applications.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Seal Development for Glass Jar Applications

Suzhou Baoshida Trading Co., Ltd. maintains a dedicated core of seven specialized engineering professionals to deliver superior glass jar gasket solutions. This team comprises five precision mould engineers and two advanced rubber formula engineers, operating synergistically to address the stringent functional and regulatory demands of food, beverage, and pharmaceutical packaging. Our formula engineers possess deep expertise in elastomer science, meticulously designing custom rubber compounds that achieve the critical balance of sealing force, compression set resistance, and media compatibility required for hermetic glass jar closure. They optimize molecular architecture and crosslink density to ensure consistent performance across thermal cycles and extended shelf life, utilizing sophisticated rheometry and dynamic mechanical analysis (DMA) to validate compound behavior under simulated end-use conditions. Concurrently, our mould engineering team leverages advanced CAD/CAM systems and cavity pressure mapping to develop high-precision tooling. This ensures dimensional accuracy within tight tolerances (±0.05mm), optimal material flow, and minimal flash generation – essential factors for achieving uniform seal compression and preventing leakage or contamination.

Material science integration directly enables our robust OEM capabilities. We manage the entire product realization process in-house, from initial client specification review through compound formulation, tooling design and fabrication, process validation, and final production release. Our engineers collaborate closely with client R&D and packaging teams to translate functional requirements into validated rubber seal specifications. This includes comprehensive finite element analysis (FEA) for stress distribution prediction under closure torque and thermal cycling, ensuring long-term seal integrity. Rigorous validation protocols per ASTM D2000 and ISO 3302 standards are applied, alongside full traceability documentation for FDA 21 CFR 177.2600 compliance in food-contact applications. The seamless integration of formulation science and precision tooling expertise guarantees that every gasket meets exacting performance criteria while optimizing production efficiency and yield.

Critical Glass Jar Gasket Material Specifications

| Parameter | Typical Range/Value | Test Standard | Significance for Glass Jar Performance |

|---|---|---|---|

| Material Types | EPDM, Silicone, FKM, NBR | ASTM D2000 | Media resistance (oils, acids), temperature range |

| Hardness (Shore A) | 40 – 70 | ASTM D2240 | Seal force, ease of application, resealability |

| Temperature Range | -40°C to +150°C (EPDM) | ASTM D573 | Sterilization compatibility, cold chain integrity |

| -60°C to +230°C (Silicone) | |||

| Compression Set (22h/70°C) | ≤ 25% (Type A) | ASTM D395 | Long-term sealing force retention, leak prevention |

| Tensile Strength | ≥ 8.0 MPa | ASTM D412 | Durability during application and removal |

| Elongation at Break | ≥ 250% | ASTM D412 | Flexibility for consistent sealing on jar rims |

| FDA Compliance | Fully Compliant | 21 CFR 177.2600 | Mandatory for food, beverage, pharmaceutical use |

This engineering framework, combining deep material science with precision manufacturing control, allows Suzhou Baoshida to rapidly develop and scale custom gasket solutions. We provide comprehensive technical documentation, including material certifications, process capability studies (CpK ≥ 1.67), and detailed validation reports, ensuring a seamless transition from prototype to high-volume production while meeting the exacting quality expectations of global OEMs.

Customization Process

Drawing Analysis: Precision Interpretation of Client Specifications

The customization process for glass jar gaskets begins with rigorous drawing analysis, a critical phase that ensures dimensional accuracy and functional compatibility. At Suzhou Baoshida Trading Co., Ltd., our engineering team evaluates technical drawings provided by clients, focusing on inner diameter (ID), outer diameter (OD), thickness, tolerance class, and groove design. We cross-reference these dimensions with international standards such as ISO 3601 and AS568 to validate feasibility. Special attention is given to sealing interface geometry, as improper groove-to-gasket ratios can lead to compression set or extrusion under pressure. Our CAD-integrated review system allows for 3D modeling simulation, detecting potential fitment issues before material selection. Any discrepancies or optimization opportunities are communicated directly to the client for approval, ensuring alignment before advancing to formulation.

Rubber Formulation: Tailoring Material Properties to Application Demands

Once dimensional parameters are confirmed, we proceed to rubber formulation—a science-driven stage where elastomer chemistry is customized to meet performance criteria. For glass jar gaskets, common base polymers include Nitrile Butadiene Rubber (NBR) for oil resistance, Silicone (VMQ) for high-temperature stability, and EPDM for ozone and weather resistance. Additives such as reinforcing fillers, plasticizers, and curing agents are precisely metered to achieve target hardness (Shore A 40–80), compression set (<25% at 70°C for 24h), and elongation at break (>150%). Each compound is developed in accordance with FDA 21 CFR 177.2600 for food-grade compliance when required. Accelerated aging tests, including heat resistance at 100°C for 72 hours, are conducted to validate long-term performance. The finalized formulation is documented and archived for batch traceability.

Prototyping: Functional Validation Under Real-World Conditions

A low-volume prototype run follows formulation approval, producing 50–100 sample gaskets using precision compression or injection molding. These prototypes undergo dimensional inspection via digital micrometers and optical comparators, ensuring conformity within ±0.1 mm tolerance. Functional testing includes leak rate measurement under simulated sealing pressure (typically 1–3 bar), torque evaluation on actual jar lids, and cycle testing for reusability. Samples are also subjected to environmental exposure—humidity, temperature cycling, and chemical resistance—to verify durability. Client feedback on prototype performance is integrated into final design refinements, closing the loop before ramp-up.

Mass Production: Consistency at Scale with Full Traceability

Upon client sign-off, gaskets enter mass production in our ISO 9001-certified facility. Automated molding lines ensure uniform curing time and pressure, while inline inspection systems monitor flash, voids, and dimensional drift. Every production lot is tested for hardness, tensile strength, and compression set per ASTM standards. Final packaging includes anti-static bags or trays with lot-number labeling for full traceability.

| Property | Test Standard | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 50–70 |

| Tensile Strength | ASTM D412 | ≥8 MPa |

| Elongation at Break | ASTM D412 | ≥180% |

| Compression Set (24h @ 70°C) | ASTM D395 | ≤20% |

| Temperature Range | — | -40°C to +120°C (NBR) |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Glass Jar Gasket Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of precision rubber seal manufacturing, delivering engineered gasket solutions that ensure hermetic integrity, regulatory compliance, and extended service life for glass jar applications across food, pharmaceutical, and cosmetic industries. Our technical team leverages advanced polymer science and rigorous OEM collaboration protocols to transform material specifications into high-performance sealing components. With decades of cumulative expertise in elastomer formulation and compression molding, we address critical challenges such as chemical resistance, thermal stability, and dimensional consistency under dynamic sealing pressures.

Our engineering process begins with a deep analysis of your jar geometry, fill medium, and end-use environment. We then deploy proprietary formulation matrices to select optimal compounds—ensuring compatibility with acidic, oily, or aqueous contents while meeting stringent FDA 21 CFR 177.2600 or EU 10/2011 standards. Unlike generic suppliers, we prioritize compression set resistance below 25% (ASTM D395 Method B) and Shore A hardness tolerances of ±3 points, guaranteeing reliable resealability after repeated openings. This scientific approach minimizes leakage risks and extends product shelf life, directly impacting your brand’s reputation and reducing waste in distribution chains.

Partnering with Suzhou Baoshida means accessing end-to-end OEM support. From initial CAD-based tolerance validation to rapid prototyping and batch traceability via integrated ERP systems, we synchronize our production cadence with your assembly line requirements. Our facility operates under ISO 9001:2015 and IATF 16949 frameworks, with in-house labs conducting real-time testing for tensile strength, elongation, and extractables. This commitment to precision engineering translates to gaskets that consistently achieve ≤0.1mm dimensional variance—critical for high-speed capping machinery.

For immediate technical consultation or custom gasket development, contact Mr. Boyce, our dedicated OEM Manager. He will initiate a structured assessment of your sealing requirements, including material compatibility analysis, cost-optimized production planning, and compliance documentation support. Provide your jar specifications, annual volume, and performance targets to receive a tailored solution within 72 hours.

Standard Glass Jar Gasket Material Specifications

| Material Type | Hardness (Shore A) | Temperature Range (°C) | Key Compliance Standards | Typical Applications |

|---|---|---|---|---|

| FDA White NBR | 50 ± 3 | -30 to +100 | FDA 21 CFR 177.2600 | Food preserves, sauces |

| Platinum Silicone | 60 ± 3 | -60 to +200 | USP Class VI, EU 10/2011 | Pharmaceuticals, cosmetics |

| EPDM (Peroxide Cure) | 45 ± 3 | -50 to +150 | NSF/ANSI 51, 3A | Dairy, acidic beverages |

| FKM (Viton™ Grade) | 70 ± 3 | -20 to +200 | FDA Extractables | Aggressive solvents, oils |

Initiate your technical consultation by emailing Mr. Boyce at [email protected]. Include critical parameters such as jar thread dimensions (e.g., T-100, T-110), internal diameter tolerances, and media pH levels to accelerate solution design. For urgent requests, reference project code GJG-2024 in your correspondence. Our engineering team responds within one business day with a preliminary feasibility assessment and material recommendation. Trust Suzhou Baoshida to convert sealing challenges into competitive advantages through uncompromising material science and responsive OEM partnership. Your next-generation glass jar integrity begins with a single email.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).