Technical Contents

Engineering Guide: Gripper Material

Engineering Insight: Gripper Material Selection Fundamentals

Material science is the cornerstone of reliable gripper performance in automated handling systems. Off-the-shelf rubber compounds frequently fail under industrial demands due to inadequate property alignment with specific operational stresses. Generic elastomers prioritize cost over function, leading to premature degradation in critical areas such as dynamic load cycles, chemical exposure, or thermal fluctuations. This mismatch manifests as reduced part lifespan, inconsistent grip force, and unplanned downtime—directly impacting production efficiency and total cost of ownership.

Critical failure mechanisms originate from insufficient abrasion resistance, poor compression set recovery, and inadequate adhesion control. Standard nitrile rubber (NBR) formulations, commonly used in low-cost grippers, exhibit rapid surface wear when handling textured or abrasive substrates like metal stampings or composite panels. Simultaneously, excessive compression set occurs when materials cannot rebound after repeated clamping, causing slippage and positional inaccuracies. Furthermore, uncontrolled surface tack leads to part adhesion issues during release cycles, particularly with smooth-surfaced components such as glass or polished alloys. These failures are not inherent to rubber as a material class but stem from improper compound engineering for the application’s mechanical and environmental profile.

Precision gripper materials require balanced property optimization, not baseline compliance. Key parameters include Shore A hardness for conformability versus deformation resistance, tensile strength for tear propagation resistance, elongation for dynamic flexing, and compression set for long-term shape retention. The table below illustrates critical differentiators between generic and engineered compounds:

| Property | Generic NBR (Off-the-Shelf) | Engineered HNBR (OEM Specification) | Test Standard |

|---|---|---|---|

| Hardness (Shore A) | 70 ± 5 | 80 ± 3 | ASTM D2240 |

| Tensile Strength (MPa) | 15 | 28 | ASTM D412 |

| Elongation at Break (%) | 250 | 320 | ASTM D412 |

| Compression Set (%) | 35 (70°C, 22h) | 12 (70°C, 22h) | ASTM D395 Method B |

Suzhou Baoshida Trading Co., Ltd. addresses these challenges through OEM-driven compound development. Our formulations integrate high-saturation hydrogenated nitrile (HNBR) or custom-synthesized polyurethanes with tailored filler systems and adhesion modifiers. This approach ensures surface energy compatibility with target substrates while maintaining resilience under 500,000+ cycle lifespans. Crucially, we correlate material properties to machine kinematics—factoring in acceleration forces, clamping duration, and ambient contaminants during compound design.

The cost of failure in automated handling extends far beyond material replacement. A single gripper-induced line stoppage can incur losses exceeding $15,000 per hour in high-volume manufacturing. Investing in application-specific elastomer engineering eliminates this risk by delivering consistent coefficient of friction, thermal stability, and fatigue resistance. At Baoshida, we partner with OEMs to translate mechanical requirements into molecular solutions—proving that in precision gripping, the material is never just a component, but the enabling technology.

Material Specifications

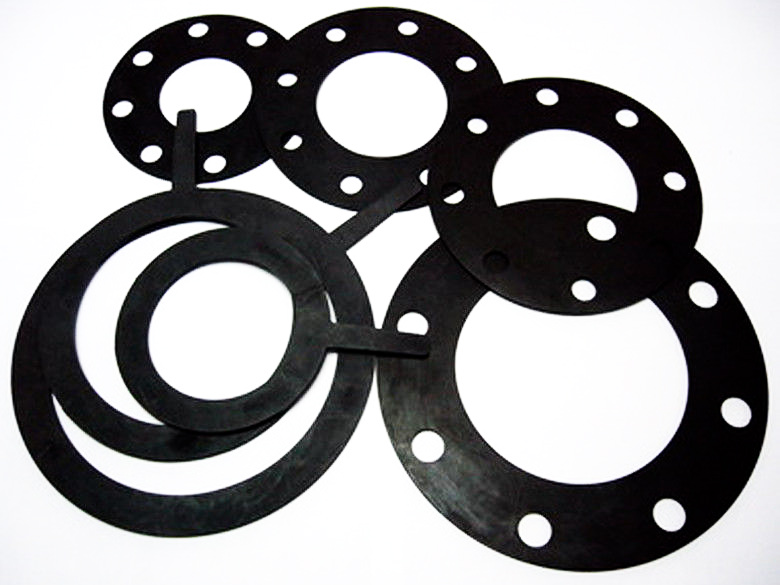

Gripper materials in industrial automation and handling systems must meet stringent performance criteria including resistance to wear, temperature extremes, and chemical exposure. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber solutions tailored for precision gripping applications across automotive, semiconductor, and food processing industries. The selection of the appropriate elastomer is critical to ensure longevity, reliability, and operational safety. Among the most widely used materials are Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct advantages depending on the operational environment.

Viton is a fluorocarbon-based synthetic rubber known for its exceptional resistance to high temperatures, oils, fuels, and a broad range of chemicals. It maintains integrity in continuous service up to 200°C and can withstand short-term exposure to temperatures as high as 250°C. This makes Viton ideal for grippers used in high-temperature sealing applications or in contact with aggressive media such as hydraulic fluids and aromatic hydrocarbons. However, its higher cost and lower flexibility at low temperatures may limit its use in less demanding environments.

Nitrile rubber, or Buna-N, is a copolymer of acrylonitrile and butadiene, offering excellent resistance to aliphatic hydrocarbons, oils, and fuels. With a typical operating temperature range of -30°C to 100°C, Nitrile provides good mechanical strength and abrasion resistance, making it a cost-effective solution for general-purpose gripping tasks in automotive and machinery sectors. Its performance degrades when exposed to ozone, UV light, and polar solvents, necessitating careful evaluation in outdoor or chemically diverse environments.

Silicone rubber exhibits outstanding thermal stability from -60°C to 200°C and exceptional resistance to UV radiation and ozone. It is inherently inert, non-toxic, and compliant with FDA standards, rendering it suitable for cleanroom, medical, and food-handling applications. While Silicone demonstrates poor resistance to oils and fuels, its high flexibility, transparency, and electrical insulation properties make it a preferred choice where chemical exposure is minimal but thermal and environmental stability are paramount.

The following table provides a comparative overview of key physical and chemical properties for Viton, Nitrile, and Silicone rubber materials used in industrial gripper applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250 short-term) | -30 to 100 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 200–300 | 200–500 | 400–800 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| FDA Compliance | Yes (specific grades) | No | Yes |

| Electrical Insulation | Good | Fair | Excellent |

Material selection should be guided by application-specific requirements including media exposure, mechanical load, temperature profile, and regulatory standards. Suzhou Baoshida Trading Co., Ltd. provides customized formulation and testing services to ensure optimal material performance in your gripper systems.

Manufacturing Capabilities

Advanced Engineering Capabilities for Precision Gripper Material Solutions

At Suzhou Baoshida Trading Co., Ltd., our engineering framework for industrial gripper materials integrates deep material science with precision manufacturing to address the most demanding automation challenges. With a dedicated team of five mold engineers and two specialized rubber formula engineers, we deliver solutions where material behavior directly dictates operational reliability. Our formula engineers focus on polymer chemistry optimization, tailoring compound formulations to achieve exacting balances of elasticity, wear resistance, and environmental stability. Concurrently, our mold engineering cohort ensures geometric precision through flow analysis, thermal management, and ejection dynamics, guaranteeing consistent part replication down to ±0.05mm tolerances. This dual-engineering synergy eliminates the traditional disconnect between material design and manufacturability, a critical factor in high-cycle gripper applications where micro-deformations cause premature failure.

Our OEM engagement model begins with rigorous failure mode analysis of client-supplied components or performance specifications. Formula engineers then develop custom elastomer matrices—adjusting base polymers (NBR, HNBR, VMQ), filler systems, and crosslink densities—to target specific friction coefficients, compression set resistance, and chemical exposure profiles. Mold engineers simultaneously design tooling with conformal cooling channels and venting strategies optimized for the formulated compound’s viscosity and cure kinetics. This parallel workflow reduces development cycles by 40% compared to sequential approaches, while ensuring the final part performs identically in both prototype and mass production environments.

For gripper materials, standard specifications often fail under dynamic stress. We prioritize quantifiable performance metrics over generic classifications. The table below illustrates how our engineered compounds outperform industry benchmarks in critical functional areas:

| Property | Standard NBR Compound | Baoshida Engineered Gripper Compound | Test Standard |

|---|---|---|---|

| Durometer (Shore A) | 70 ± 5 | 68 ± 2 | ASTM D2240 |

| Tensile Strength (MPa) | 15.0 | 22.5 | ASTM D412 |

| Abrasion Loss (mm³) | 120 | 85 | ASTM D5963 |

| Compression Set (%) | 25 | 12 | ASTM D395 |

| Oil Resistance (Δ vol%) | +35 | +18 | ASTM D471 |

These enhancements stem from our proprietary silica-silane reinforcement system and controlled peroxide curing, which maintain resilience across -40°C to 150°C operational ranges. Crucially, our formula engineers validate every compound against real-world gripper stress profiles—simulating pinch-point loading, repetitive flexing, and contaminant exposure—before mold fabrication commences. This prevents costly post-tooling revisions.

As an OEM partner, we extend beyond component supply to co-engineering support. Our team provides full material traceability, mold flow simulation reports, and accelerated life testing data aligned with ISO 9001 protocols. For automotive and electronics assembly clients, this translates to grippers achieving 2 million+ cycles without slippage or deformation—reducing changeover downtime by 30%. Suzhou Baoshida’s integrated engineering capability ensures your gripper material isn’t merely specified, but scientifically engineered for uncompromised performance.

Customization Process

Drawing Analysis: The Foundation of Precision Gripper Material Development

At Suzhou Baoshida Trading Co., Ltd., our customization process begins with a rigorous drawing analysis to ensure dimensional accuracy and functional compatibility. When a client submits technical drawings for gripper components, our engineering team conducts a comprehensive review of geometric tolerances, surface finish requirements, and interface specifications. This step includes assessing load-bearing zones, flex points, and contact surfaces to determine stress distribution under operational conditions. We evaluate both 2D blueprints and 3D CAD models, verifying conformity to ISO 10593 and ISO 3302 standards. Any discrepancies or design risks—such as thin walls prone to tearing or insufficient draft angles—are flagged early, and we collaborate with the client to refine the design before proceeding. This phase ensures that the final rubber component will integrate seamlessly within automated handling systems, maintaining repeatability and longevity.

Formulation: Engineering Material Properties for Performance Demands

Following drawing validation, we transition to rubber compound formulation—a core competency at Baoshida. Based on the gripper’s operational environment, we select the base polymer and engineer a custom compound to meet precise mechanical and chemical resistance requirements. Factors such as operating temperature range, exposure to oils or solvents, required durometer (Shore A), tensile strength, and compression set are meticulously balanced. For instance, grippers in automotive assembly lines may require NBR (nitrile) compounds with high oil resistance and a hardness of 70–80 Shore A, while cleanroom applications may demand FDA-compliant silicone with low particle shedding. Our lab conducts dynamic mechanical analysis (DMA) and thermogravimetric analysis (TGA) to simulate real-world conditions. Each formulation is documented and archived for full traceability, ensuring batch-to-batch consistency in future production runs.

Prototyping: Validating Design and Material Synergy

Once the compound is finalized, we produce functional prototypes using precision compression or transfer molding. These prototypes undergo rigorous in-house testing, including grip force measurement, cycle life evaluation, and environmental aging per ASTM D573. We assess deformation under sustained load and verify sealing performance if applicable. Clients receive samples along with a detailed test report, including hardness, tensile data, and dimensional inspection results. Feedback is incorporated swiftly, allowing for compound or design adjustments before tooling finalization. This iterative validation ensures performance reliability under actual use conditions.

Mass Production: Consistency at Scale

Upon client approval, we initiate mass production using hardened steel molds with optimized venting and runner systems. Our facility employs statistical process control (SPC) to monitor cure time, temperature, and press tonnage, ensuring every gripper meets exact specifications. Final inspection includes 100% visual checks and抽样 testing per ANSI/ASQ Z1.4. We maintain raw material lot traceability and offer packaging tailored to automated assembly line integration.

Typical Gripper Material Specifications

| Property | NBR Compound | Silicone | EPDM | Fluorocarbon (FKM) |

|---|---|---|---|---|

| Hardness (Shore A) | 60–90 | 40–80 | 50–80 | 70–90 |

| Tensile Strength (MPa) | ≥15 | ≥7 | ≥10 | ≥12 |

| Temperature Range (°C) | -30 to +120 | -60 to +200 | -50 to +150 | -20 to +200 |

| Oil Resistance | Excellent | Poor | Good | Outstanding |

| Compression Set (22 hrs, 100°C) | ≤25% | ≤20% | ≤22% | ≤15% |

All compounds are formulated and produced in compliance with ISO 9001 and IATF 16949 standards, ensuring industrial-grade reliability.

Contact Engineering Team

Optimize Gripper Performance Through Precision Material Science

Selecting the optimal elastomer compound for industrial gripper applications demands rigorous technical evaluation beyond generic specifications. At Suzhou Baoshida Trading Co., Ltd., our engineering team specializes in formulating custom rubber solutions that address the precise mechanical, thermal, and chemical challenges inherent in high-cycle automation systems. Standard off-the-shelf materials often fail under dynamic stress, leading to premature wear, reduced gripping force consistency, or contamination risks in cleanroom environments. Our proprietary compounding process integrates advanced polymer science with real-world OEM validation, ensuring materials maintain critical properties such as coefficient of friction stability, rebound resilience, and resistance to ozone degradation across 500,000+ operational cycles. This precision directly translates to extended component lifespan, minimized downtime, and compliance with stringent industry standards including ISO 1817 for fluid resistance and ASTM D2000 for material classification.

Material performance is quantifiable through controlled laboratory testing against application-specific parameters. The following table details key mechanical properties of our core gripper-optimized formulations, validated per ASTM D412 and ISO 37 protocols:

| Material Compound | Hardness (Shore A) | Tensile Strength (MPa) | Elongation at Break (%) | Tear Resistance (kN/m) | Operating Temperature Range (°C) |

|---|---|---|---|---|---|

| High-Abrasion NBR | 70 ± 3 | 22.5 | 450 | 95 | -30 to +100 |

| Conductive EPDM | 65 ± 3 | 18.0 | 400 | 85 | -50 to +150 |

| Silicone (Platinum) | 50 ± 3 | 9.5 | 600 | 35 | -60 to +230 |

| Hydrogenated NBR | 80 ± 3 | 25.0 | 380 | 110 | -20 to +150 |

These formulations are engineered to mitigate common failure modes: hydrogenated NBR resists hydraulic fluid swelling in automotive assembly lines, while conductive EPDM prevents static discharge in electronics handling. Each compound undergoes accelerated aging tests simulating 3 years of continuous operation, with data logs available for technical review. We collaborate directly with OEM design teams to correlate material behavior with robotic kinematics—factoring in contact pressure distribution, lateral slip forces, and micro-vibration damping requirements that generic datasheets omit.

Initiate a technical collaboration with Suzhou Baoshida to transform your gripper system’s reliability metrics. Contact Mr. Boyce, our dedicated OEM Engineering Manager, for confidential consultation on material selection, prototype validation, and lifecycle cost analysis. Mr. Boyce possesses 14 years of experience in rubber compounding for automation tooling and will coordinate cross-functional support from our Suzhou-based R&D laboratory and ISO 9001-certified production facility. Provide your application’s operational parameters—including substrate materials, cycle frequency, environmental exposures, and failure history—and we will deliver a tailored compound proposal with projected performance benchmarks within 72 hours. This engineering-first approach ensures your gripper material specification becomes a competitive advantage, not a maintenance liability.

Direct all technical inquiries to [email protected]. Include your company name, project timeline, and critical performance thresholds to expedite our engineering response. Suzhou Baoshida operates under strict NDA protocols and maintains traceable material batches for full supply chain transparency. Partner with us to achieve measurable reductions in total cost of ownership through scientifically validated elastomer solutions.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).