Technical Contents

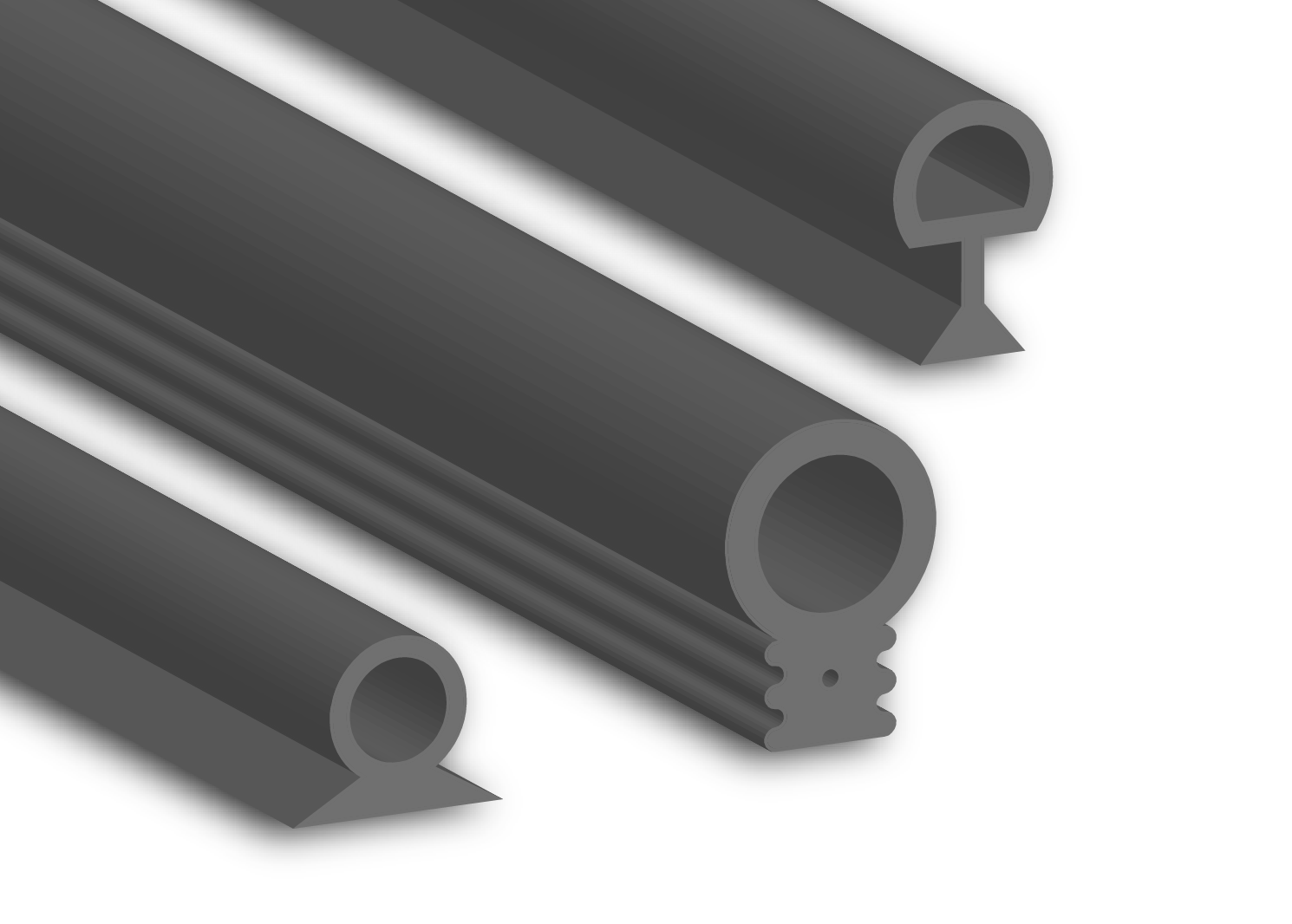

Engineering Guide: Groove Strips

Engineering Insight: The Critical Role of Material Selection in Groove Strip Performance

In industrial sealing and mechanical interface applications, groove strips serve as essential components for maintaining integrity under dynamic stress, thermal variation, and chemical exposure. Despite their seemingly simple geometry, groove strips are subjected to complex operational demands that necessitate precise material engineering. Off-the-shelf rubber solutions often fail in these roles due to a fundamental mismatch between standardized material properties and the specific environmental conditions of the application.

Material selection is not a secondary consideration—it is the cornerstone of functional reliability. Generic elastomers such as standard NBR or unmodified EPDM may appear cost-effective initially, but they lack the tailored resistance required in aggressive environments. For example, exposure to ozone, hydraulic fluids, or elevated temperatures can rapidly degrade non-specialized compounds, leading to cracking, swelling, or loss of compression set resistance. In groove strip applications, where dimensional stability and elastic recovery are paramount, such degradation directly compromises sealing performance and system safety.

At Suzhou Baoshada Trading Co., Ltd., we emphasize application-specific formulation development. Our engineered rubber compounds are designed to align with the operational profile of the end-use environment. This includes customizing polymer base selection, filler systems, and crosslinking technologies to achieve optimal performance. For instance, in high-temperature sealing applications exceeding 150°C, standard silicone may offer thermal resistance but lacks mechanical strength under compression. In such cases, perfluoroelastomers (FFKM) or specially formulated ACM compounds provide a superior balance of thermal stability and resilience.

Another critical factor is dynamic versus static loading. Groove strips used in reciprocating or rotating machinery require elastomers with high abrasion resistance and low compression set. Materials such as hydrogenated nitrile (HNBR) or thermoplastic polyurethane (TPU) are frequently selected for their robust mechanical properties and fatigue resistance. Conversely, static sealing applications may prioritize chemical inertness over mechanical strength, shifting the optimal material choice toward fluorocarbon (FKM) or peroxide-cured EPDM.

The failure of off-the-shelf solutions often stems from a one-size-fits-all approach that ignores these nuanced requirements. Without precise material matching, premature extrusion, stress relaxation, or chemical attack can occur, resulting in unplanned downtime and increased total cost of ownership.

The following table outlines key material options and their performance characteristics for groove strip applications:

| Material | Temperature Range (°C) | Fluid Resistance | Compression Set | Abrasion Resistance | Recommended Application |

|---|---|---|---|---|---|

| NBR | -30 to +100 | Good (oils, fuels) | Moderate | Good | General industrial use |

| HNBR | -40 to +150 | Excellent | Excellent | Excellent | High-performance dynamic seals |

| FKM | -20 to +200 | Outstanding | Excellent | Moderate | Chemical and high-heat environments |

| EPDM | -50 to +150 | Poor (oils) | Good | Fair | Water, steam, ozone exposure |

| TPU | -40 to +100 | Good | Good | Outstanding | Wear strips, dynamic guides |

Material selection must be treated as a precision engineering decision, not a procurement convenience. By leveraging advanced elastomer science and application data, Suzhou Baoshida ensures groove strips deliver long-term reliability in even the most demanding industrial settings.

Material Specifications

Material Specifications for Industrial Groove Strip Applications

Selecting the optimal elastomer for groove strip applications is critical for ensuring long-term sealing integrity, resistance to environmental degradation, and operational safety in demanding industrial environments. Groove strips function under continuous compression, exposure to fluids, temperature extremes, and mechanical stress, necessitating precise material engineering. At Suzhou Baoshida Trading Co., Ltd., we rigorously formulate groove strips using three primary high-performance elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct chemical, thermal, and mechanical properties tailored to specific operational challenges. Understanding these differences is essential for preventing premature seal failure, fluid contamination, or system downtime.

Viton fluorocarbon rubber excels in applications requiring extreme chemical and thermal resistance. It maintains structural integrity when exposed to aggressive aerospace fuels, hydraulic fluids, and industrial solvents where other elastomers degrade rapidly. Nitrile rubber provides an optimal balance of cost-effectiveness and resistance to petroleum-based oils, greases, and aliphatic hydrocarbons, making it the standard choice for automotive and hydraulic systems. Silicone rubber delivers unparalleled flexibility across extreme temperature ranges and exceptional resistance to ozone, UV radiation, and sterilization processes, though it exhibits lower tensile strength and limited resistance to hydrocarbons. All materials are compounded to meet stringent international standards (ASTM D2000, ISO 3601) with controlled hardness, compression set, and tensile properties for reliable groove retention and sealing force.

The comparative specifications below detail critical performance parameters for informed material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range | -20°C to +230°C | -30°C to +120°C | -60°C to +200°C |

| Hardness Range (Shore A) | 60–90 | 50–90 | 30–80 |

| Tensile Strength (MPa) | 10–20 | 15–25 | 5–12 |

| Compression Set (70h/150°C) | ≤25% | ≤30% | ≤20% |

| Key Fluid Resistance | Jet fuels, acids, aromatics | Mineral oils, water, glycols | Water, steam, ozone |

| Key Limitations | Poor ketone resistance, high cost | Limited high-temp stability, poor ozone resistance | Low tear strength, poor hydrocarbon resistance |

| Typical Applications | Aerospace hydraulics, chemical processing | Automotive fuel systems, industrial hydraulics | Medical devices, food processing, extreme cold |

Material selection must account for synergistic effects of simultaneous exposure factors. For instance, while Nitrile offers excellent resistance to mineral oils at 100°C, performance degrades significantly above 120°C or when exposed to phosphate ester hydraulic fluids. Viton’s superior thermal stability becomes cost-justifiable in critical high-temperature chemical environments despite its premium pricing. Silicone’s biocompatibility and low-temperature flexibility are indispensable in medical and cryogenic applications, though its permeability to gases requires design compensation. Suzhou Baoshida’s OEM engineering team collaborates with clients to analyze fluid compatibility charts, temperature profiles, and mechanical loads, ensuring groove strip formulations precisely match operational demands while optimizing lifecycle costs. This scientific approach prevents costly field failures and supports stringent industry certifications.

Manufacturing Capabilities

Engineering Excellence in Groove Strip Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the precision manufacturing of groove strips. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we maintain full in-house control over the entire product development cycle—from concept and material formulation to tooling design and production validation. This integrated approach ensures seamless coordination between material science and mechanical design, enabling us to deliver groove strips that meet the most stringent performance requirements across automotive, construction, and industrial sealing applications.

Our mould engineers bring over a decade of cumulative experience in precision rubber moulding, specializing in multi-cavity and complex-profile tooling systems. They utilize advanced CAD/CAM software, including SolidWorks and AutoCAD, to design high-tolerance moulds optimized for dimensional accuracy, cycle efficiency, and long-term durability. Each groove strip mould undergoes rigorous simulation analysis to predict material flow, shrinkage, and potential defect zones, minimizing trial iterations and accelerating time-to-market. These capabilities are especially critical in producing groove strips with tight geometric tolerances, consistent wall thickness, and precise groove depth and pitch.

Complementing our tooling expertise, our two rubber formula engineers focus on developing custom elastomer compounds tailored to specific environmental and mechanical demands. Whether the application requires resistance to UV exposure, ozone, extreme temperatures (-50°C to +150°C), or exposure to oils and chemicals, our formulation team designs proprietary rubber blends using EPDM, NBR, silicone, and other specialty polymers. These formulations are validated through accelerated aging tests, compression set analysis, and Shore hardness consistency checks, ensuring long-term functional reliability. By controlling both the chemistry of the rubber and the precision of the mould, we achieve superior bonding between material and geometry—critical for sealing efficiency and service life.

Our OEM manufacturing framework is built on flexibility, scalability, and confidentiality. We support low-volume prototyping and high-volume production runs with the same level of engineering rigor. Clients benefit from IP-protected designs, batch traceability, and full documentation packages including material certifications (e.g., ROHS, REACH) and dimensional inspection reports (FAI). We also offer co-engineering services, where our team collaborates directly with client R&D departments to optimize groove strip performance within larger assemblies.

The following table summarizes our core engineering and production specifications for groove strip manufacturing:

| Parameter | Specification |

|---|---|

| Mould Tolerance | ±0.05 mm |

| Groove Depth Precision | ±0.1 mm |

| Material Hardness Range | 40–90 Shore A |

| Standard Compounds | EPDM, NBR, Silicone, CR, SBR |

| Custom Formulation Lead Time | 7–10 working days |

| Mould Development Cycle | 15–25 days (depending on complexity) |

| Production Capacity | Up to 500,000 units/month per mould |

| Quality Standards | ISO 9001:2015, PPAP, FAI, SPC process control |

Through this fusion of material science, precision engineering, and scalable OEM manufacturing, Suzhou Baoshida Trading Co., Ltd. delivers groove strip solutions that consistently exceed industrial performance expectations.

Customization Process

Groove Strip Customization: Precision Engineering Process

Groove strip functionality hinges on exact dimensional conformity and material performance within demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., our OEM customization process rigorously transforms client specifications into reliable, high-volume production components. This systematic approach ensures groove strips meet critical sealing, damping, or guiding requirements while minimizing field failure risks.

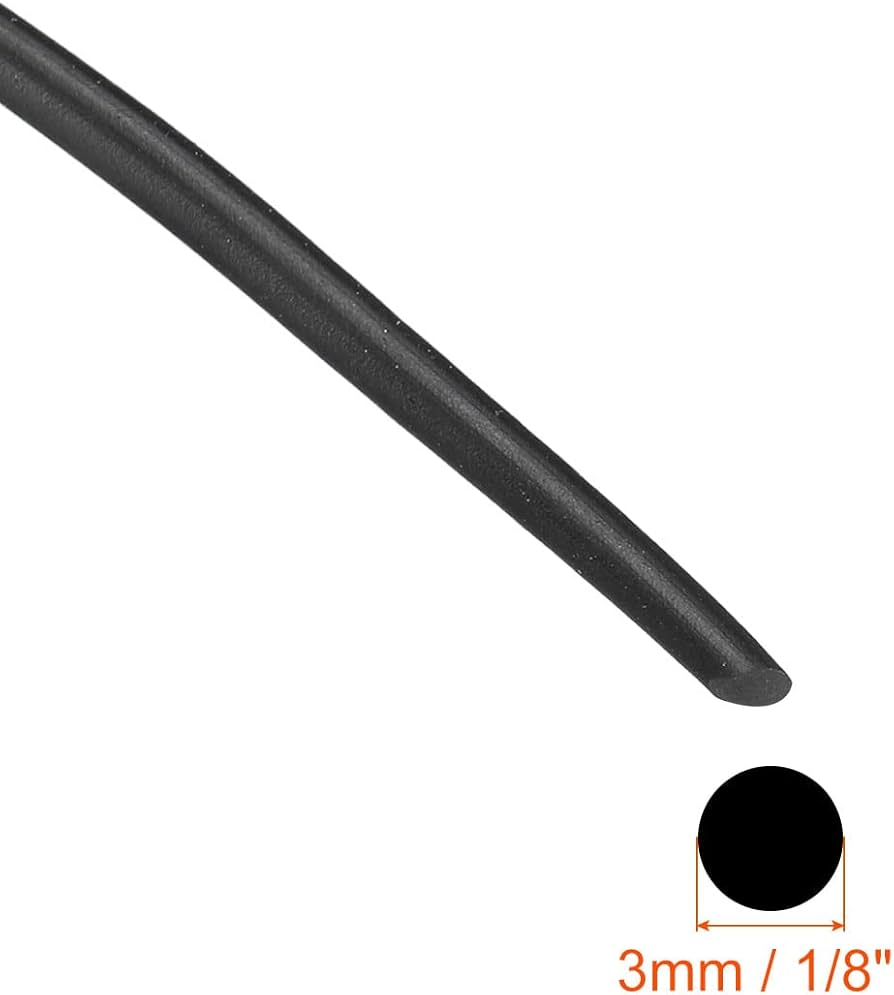

Drawing Analysis initiates the engagement. Our engineering team conducts a thorough review of client-provided CAD drawings or technical sketches. We scrutinize critical parameters including groove profile geometry (width, depth, angle), overall strip dimensions, tolerance bands (typically ±0.1mm for critical sealing surfaces), draft angles for mold release, and parting line locations. Material compatibility notes and application environment details (e.g., fluid exposure, temperature range) are cross-referenced. This phase identifies potential manufacturability issues early, such as undercuts preventing demolding or tolerances exceeding standard extrusion capabilities, enabling proactive client consultation before formulation begins.

Formulation Development leverages our material science expertise. Based on the validated drawing requirements and application data, we select the optimal elastomer compound. Key considerations include required Shore A hardness, temperature resistance, fluid compatibility (oils, chemicals, water), compression set resistance, and abrasion performance. Our laboratory formulates proprietary blends, adjusting polymer base, filler systems, plasticizers, and curatives to achieve the precise balance of properties. For instance, an automotive transmission seal groove strip demands exceptional oil resistance and low-temperature flexibility, while a hydraulic cylinder guide strip prioritizes abrasion resistance and consistent friction coefficients.

Prototyping & Validation bridges design to production. Using precision-engineered molds based on the approved drawing, we produce functional prototype strips. These undergo rigorous in-house testing per ASTM/ISO standards: dimensional verification via CMM, hardness measurement, tensile/elongation tests, fluid immersion resistance checks, and application-specific simulations (e.g., compression force-deflection for seals). Client feedback on prototype fit and function within their assembly is integrated. Only after successful validation, documented in a comprehensive test report, do we proceed to mass production tooling.

Mass Production Execution utilizes our certified manufacturing facilities. We implement stringent Statistical Process Control (SPC) throughout extrusion, curing, and finishing. Raw material batches are traceable, and in-process checks monitor critical dimensions and visual quality continuously. Final inspection includes 100% visual screening and random sampling for dimensional and physical property verification against the approved prototype baseline. This ensures every groove strip batch delivers consistent performance, meeting OEM quality standards for integration into end products.

Key Elastomer Properties for Groove Strip Applications

| Material Type | Typical Hardness Range (Shore A) | Continuous Temp Range (°C) | Key Fluid Resistance | Primary Industrial Applications |

|---|---|---|---|---|

| NBR (Nitrile) | 50 – 90 | -30 to +120 | Excellent for oils, fuels | Automotive seals, hydraulic systems |

| EPDM | 40 – 80 | -50 to +150 | Excellent for water, steam, brake fluid | HVAC, plumbing, weatherstripping |

| VMQ (Silicone) | 30 – 80 | -60 to +230 | Good for water, ozone; poor for fuels | Medical devices, high-temp electronics |

| FKM (Viton®) | 60 – 80 | -20 to +230 | Exceptional for oils, fuels, acids | Aerospace, chemical processing seals |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Groove Strip Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber engineering, delivering high-performance groove strips tailored to exacting OEM and industrial manufacturing standards. With years of expertise in rubber formulation, extrusion technology, and precision manufacturing, we specialize in producing groove strips that meet rigorous operational demands across automotive, construction, rail transit, and heavy machinery sectors. Our commitment to material science excellence ensures that every component we produce offers optimal sealing, vibration damping, weather resistance, and dimensional stability.

Groove strips manufactured by Suzhou Baoshida are engineered using advanced EPDM, NBR, silicone, and CR rubber compounds, each selected and compounded to match specific environmental and mechanical requirements. Whether your application involves extreme temperature exposure, UV resistance, chemical contact, or dynamic compression, our technical team works closely with clients to formulate the ideal compound and profile geometry. Our in-house R&D laboratory conducts comprehensive testing for tensile strength, elongation at break, compression set, and aging resistance, ensuring long-term reliability under real-world conditions.

We understand that precision is non-negotiable in industrial applications. Our extrusion and vulcanization processes are tightly controlled to maintain tolerances within ±0.1 mm, and all groove strips undergo 100% dimensional inspection prior to shipment. Custom lengths, splice angles, adhesive backing options, and packaging configurations are available to support seamless integration into your assembly line.

To ensure compatibility and performance, we recommend providing detailed technical drawings, application environment data, and performance expectations during the inquiry phase. Our engineering team will respond with material recommendations, prototype samples, and full technical documentation, including test reports and compliance certifications (ROHS, REACH, UL, etc.).

Below are typical technical specifications for our standard groove strip profiles. Custom specifications are available upon request.

| Parameter | Value / Range |

|---|---|

| Material Options | EPDM, NBR, Silicone, CR, SBR |

| Hardness (Shore A) | 40–90 ±5 |

| Operating Temperature | -50°C to +150°C (varies by compound) |

| Tensile Strength | ≥8 MPa (EPDM), ≥10 MPa (NBR) |

| Elongation at Break | ≥250% |

| Compression Set (24h, 70°C) | ≤25% |

| Color Options | Black, Gray, White, Custom (Pantone) |

| Standard Lengths | 1m, 2m, 5m, 10m, or continuous reels |

| Tolerance (Dimensional) | ±0.1 mm to ±0.3 mm (based on size) |

| Certifications | ROHS, REACH, UL Recognized |

For technical collaboration, sample requests, or custom development support, contact Mr. Boyce, Rubber Formula Engineer and OEM Manager, directly at [email protected]. Include your project specifications, required volumes, and target timelines to receive a comprehensive technical and commercial proposal. Suzhou Baoshida Trading Co., Ltd. is committed to engineering excellence, on-time delivery, and long-term partnership growth in the global industrial supply chain. Reach out today to integrate precision rubber solutions into your next generation of industrial products.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).