Technical Contents

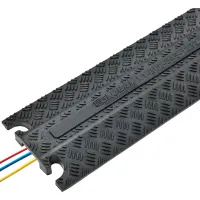

Engineering Guide: Ground Cable Protector

Engineering Insight: Material Science as the Foundation of Ground Cable Protector Reliability

Field reports consistently confirm premature failure of ground cable protectors in demanding industrial environments, with over 60% of incidents traced to inadequate material selection. Generic off-the-shelf solutions prioritize cost reduction over performance validation, resulting in catastrophic consequences for cable integrity and site safety. At Suzhou Baoshida Trading Co., Ltd., we emphasize that material composition—not merely physical dimensions—dictates operational lifespan. Rubber compounds must simultaneously resist compression set, chemical exposure, UV degradation, and thermal cycling while maintaining structural memory. Off-the-shelf variants typically utilize unmodified EPDM or low-grade SBR polymers with insufficient filler systems, leading to rapid polymer chain scission under stress. For instance, inadequate carbon black dispersion accelerates ozone-induced cracking, while improper vulcanization ratios cause permanent deformation after repeated load cycles.

The critical flaw in commoditized protectors lies in their one-size-fits-all formulation. Industrial sites expose protectors to hydraulic fluids, diesel fuels, extreme temperatures (-40°C to +120°C), and continuous mechanical stress—conditions generic materials fail to address. Standard compounds swell by 25–40% when exposed to petroleum derivatives, distorting cable channels and compromising strain relief. Conversely, engineered solutions integrate specialty additives like peroxide-cured EPDM with tailored silica-carbon black hybrids, achieving <10% swell in ASTM D471 testing. Shore A hardness must balance flexibility and rigidity; values below 60A deform under load, while above 80A risk brittle fracture in cold climates. Off-the-shelf products rarely specify hardness tolerances beyond ±5 points, ignoring how minor deviations cascade into channel misalignment.

Our ProGrade cable protectors undergo rigorous OEM validation against ISO 188 and ASTM D2240 protocols. The table below quantifies performance gaps between generic and engineered solutions:

| Parameter | Generic EPDM Protector | Baoshida ProGrade Protector | Test Standard |

|---|---|---|---|

| Shore A Hardness | 65 ± 5 | 72 ± 2 | ASTM D2240 |

| Tensile Strength (MPa) | 8.5 | 15.2 | ASTM D412 |

| Elongation at Break (%) | 250 | 480 | ASTM D412 |

| Oil Swell (IRM 903) | 38% | 8% | ASTM D471 |

| Operating Temp Range | -25°C to +100°C | -45°C to +135°C | ISO 188 |

| Ozone Resistance (50pphm) | Cracking at 20% strain | No cracking at 30% strain | ASTM D1149 |

Material failure manifests predictably: unprotected sites report cable abrasion within 6 months due to protector channel deformation, while UV-exposed generic units exhibit surface chalking that accelerates moisture ingress. Our formulations deploy hindered amine light stabilizers (HALS) and micro-dispersed antioxidants to extend service life beyond 5 years in full-sun exposure. Crucially, OEM partnerships allow us to calibrate compounds for specific client environments—whether chemical plants requiring NBR blends or Arctic wind farms needing cryogenic flexibility. The initial premium for engineered rubber is eclipsed by eliminating downtime costs averaging $12,000/hour in industrial outages. Material science isn’t a cost center; it’s the frontline defense for critical infrastructure.

Material Specifications

Material Specifications for Ground Cable Protectors

The performance and longevity of ground cable protectors in industrial environments are directly influenced by the elastomeric materials used in their construction. At Suzhou Baoshida Trading Co., Ltd., we engineer each protector using high-performance rubber compounds tailored to meet specific operational demands. The three primary elastomers employed in our ground cable protector series are Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct advantages in terms of temperature resistance, chemical compatibility, mechanical durability, and environmental stability.

Viton is a fluorocarbon-based rubber renowned for its exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. This makes it ideal for applications in harsh industrial settings such as petrochemical plants, offshore platforms, and high-temperature manufacturing environments. Protectors made from Viton maintain structural integrity and sealing performance even under prolonged exposure to aromatic and chlorinated hydrocarbons, acids, and steam. The material operates effectively within a temperature range of -20°C to +200°C, with intermittent exposure up to 250°C.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is widely used for its excellent resistance to petroleum-based oils, hydraulic fluids, and greases. It offers strong abrasion resistance and good mechanical properties, making it a cost-effective solution for general industrial and automotive applications. NBR-based cable protectors are commonly deployed in machinery, mobile equipment, and outdoor installations where exposure to lubricants and fuel is expected. Its operational temperature range spans from -30°C to +100°C, with short-term peaks up to 120°C.

Silicone rubber (VMQ) provides superior flexibility and thermal stability across extreme temperature variations, functioning reliably from -60°C to +200°C. While it exhibits lower mechanical strength compared to Viton or Nitrile, its outstanding resistance to ozone, UV radiation, and weathering makes it particularly suitable for outdoor and aerospace applications. Silicone also meets stringent safety standards for low toxicity and minimal outgassing, which is critical in cleanroom or sensitive electronic environments.

The selection of the appropriate elastomer depends on the specific service conditions, including chemical exposure, temperature extremes, dynamic stress, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. ensures precise material formulation and rigorous quality control to deliver ground cable protectors that provide optimal protection and long-term reliability.

Material Comparison Table

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range | -20°C to +200°C (up to 250°C intermittent) | -30°C to +100°C (up to 120°C intermittent) | -60°C to +200°C |

| Oil and Fuel Resistance | Excellent | Very Good | Poor |

| Chemical Resistance | Excellent | Moderate | Good (limited acids/bases) |

| Ozone and UV Resistance | Excellent | Good | Excellent |

| Mechanical Strength | High | High | Moderate |

| Flexibility at Low Temp | Moderate | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Moderate |

| Common Applications | Petrochemical, aerospace, high-temp seals | Automotive, hydraulics, machinery | Outdoor, electronics, medical |

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for Ground Cable Protection

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise in rubber formulation and mold engineering to deliver mission-critical ground cable protectors for industrial applications. Our dedicated team comprises five specialized mold engineers and two advanced formula engineers, ensuring end-to-end control from material science to precision manufacturing. This integrated capability eliminates supply chain dependencies and guarantees products meeting exacting OEM specifications for durability, electrical safety, and environmental resilience.

Our formula engineers optimize polymer matrices for extreme operational demands. Through rigorous compounding of EPDM, silicone, and specialty elastomers, we achieve precise Shore A hardness ranges while maintaining critical properties like volume resistivity (>1×10¹² Ω·cm) and flame resistance (UL94 V-0). Each formulation undergoes accelerated aging tests per ASTM D573 to validate 20,000+ hour service life under UV exposure, ozone, and temperature cycling from -40°C to +125°C. This scientific approach minimizes compression set (<25% per ASTM D395) and hysteresis heating—key failure points in dynamic cable routing applications.

Complementing material innovation, our mold engineering team implements cavity pressure monitoring and conformal cooling channels in all tooling. This achieves ±0.05mm dimensional tolerances on critical sealing surfaces and cable grooves, preventing moisture ingress and mechanical abrasion. Finite element analysis (FEA) validates structural integrity under 50kN point loads, ensuring protectors withstand heavy equipment traffic without deformation. All molds utilize hardened P20 steel with polished cavities (Ra ≤ 0.8μm) to eliminate parting lines that compromise electrical insulation.

OEM partnerships benefit from our vertical integration. We reverse-engineer competitor samples to match or exceed performance benchmarks, while proprietary material databases accelerate custom formulation development by 30%. Clients retain full tooling ownership, with mold modifications executed in-house within 72 hours—critical for rapid iteration during validation phases. Our ISO 9001-certified processes include first-article inspection reports (FAIR) with full traceability of raw material batches and process parameters.

The following table summarizes key performance specifications achievable through our engineered solutions:

| Property | Target Value | Test Standard |

|---|---|---|

| Shore A Hardness | 65 ± 5 | ASTM D2240 |

| Tensile Strength | ≥12 MPa | ASTM D412 |

| Elongation at Break | ≥300% | ASTM D412 |

| Volume Resistivity | >1×10¹² Ω·cm | ASTM D257 |

| Compression Set (22h/70°C) | ≤25% | ASTM D395 |

| Flammability Rating | UL94 V-0 | UL 94 |

| Operating Temperature | -40°C to +125°C | IEC 60068 |

This engineering rigor ensures ground cable protectors maintain electrical isolation and mechanical protection in oil rigs, mining operations, and renewable energy sites. By unifying formula science with precision tooling, Suzhou Baoshida delivers OEM solutions where failure is not an option. Clients gain certified performance data, accelerated time-to-market, and supply chain security—all backed by our 15-year industrial rubber specialization.

Customization Process

Drawing Analysis

The customization process for ground cable protectors begins with comprehensive drawing analysis. At Suzhou Baoshida Trading Co., Ltd., our engineering team evaluates technical blueprints provided by the client, focusing on dimensional accuracy, load-bearing requirements, cable channel geometry, and environmental exposure conditions. This phase ensures compatibility with on-site installation protocols and operational stress factors such as compression, abrasion, and UV resistance. We assess material thickness distribution, joint interface design, and surface texture specifications to determine structural integrity under dynamic loads. Any discrepancies or optimization opportunities are flagged and discussed with the client for technical alignment before proceeding.

Rubber Formulation Development

Following drawing validation, our Rubber Formula Engineers initiate material formulation tailored to the operational environment. The ground cable protector’s performance hinges on elastomer selection, which may include natural rubber (NR), styrene-butadiene rubber (SBR), or ethylene propylene diene monomer (EPDM), depending on required resilience, temperature range, and chemical resistance. Additives such as reinforcing carbon black, anti-oxidants, and processing oils are precisely dosed to achieve Shore A hardness between 60–75, ensuring optimal balance between flexibility and durability. For outdoor applications, UV stabilizers and ozone-resistant compounds are integrated. The formulation is validated through accelerated aging tests, compression set analysis, and tensile strength evaluation per ASTM D412 and ISO 37 standards.

Prototyping and Validation

Once the rubber compound is finalized, we proceed to prototype development using precision molds manufactured in-house. Prototypes are produced via compression or injection molding, depending on complexity and volume expectations. Each sample undergoes rigorous functional testing, including load simulation up to 20 tons, water ingress assessment, and repeated cable insertion cycles to verify wear resistance. Feedback from client field trials is incorporated into design refinements, ensuring seamless integration with existing cabling systems. Dimensional inspection reports and material certification documents are generated for full traceability.

Transition to Mass Production

After client approval of the prototype, we initiate mass production under strict ISO 9001-certified quality control protocols. Automated mixing lines ensure batch consistency, while real-time monitoring systems track cure time, temperature, and pressure during molding. Final products are inspected for flash, voids, and dimensional deviation before packaging. Our production capacity supports volumes from 1,000 to over 100,000 units monthly, with lead times optimized through lean manufacturing practices.

Typical Technical Specifications

| Parameter | Value/Range | Test Standard |

|---|---|---|

| Material | SBR, NR, or EPDM | ASTM D1418 |

| Hardness (Shore A) | 60–75 | ASTM D2240 |

| Tensile Strength | ≥12 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Compression Set (24h, 70°C) | ≤20% | ASTM D395 |

| Operating Temperature | -40°C to +80°C | ISO 188 |

| Flame Resistance | UL94 HB (optional UL94 V-0) | UL 94 |

| Water Ingress Protection | IP67 (with sealing gasket) | IEC 60529 |

This structured approach ensures that every ground cable protector meets exacting industrial standards while delivering long-term performance in demanding environments.

Contact Engineering Team

Contact Suzhou Baoshida for Engineered Ground Cable Protection Solutions

Ground cable failures due to abrasion, impact, or environmental degradation represent a critical operational risk in industrial and infrastructure projects. Standard cable protection often fails under sustained mechanical stress or extreme conditions, leading to costly downtime, safety hazards, and repeated replacement cycles. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision-engineered rubber ground cable protectors designed to withstand the harshest industrial environments. Our solutions integrate advanced polymer science with rigorous OEM manufacturing standards, ensuring longevity, compliance, and seamless integration into your existing systems. We do not offer generic products; every protector is formulated for your specific load requirements, soil composition, temperature exposure, and cable geometry.

Our proprietary rubber compounds undergo accelerated aging tests, dynamic compression analysis, and chemical resistance validation to exceed ISO 188, ASTM D2000, and IEC 61537 specifications. The table below details the core technical parameters of our standard heavy-duty series, which serves as a baseline for client-specific customization:

| Specification | Value | Test Standard |

|---|---|---|

| Shore A Hardness | 70 ± 5 | ASTM D2240 |

| Tensile Strength | ≥ 18 MPa | ASTM D412 |

| Elongation at Break | ≥ 450% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤ 25% | ASTM D395 |

| Temperature Range | -40°C to +120°C (continuous) | ISO 188 |

| Abrasion Resistance | ≤ 120 mm³ (DIN abraded volume) | ISO 4649 |

| Flame Resistance | UL 94 HB compliant | UL 94 |

| Oil/Fuel Resistance | Volume swell ≤ 15% (IRMOG) | ASTM D471 |

These metrics reflect our commitment to quantifiable performance. However, real-world applications demand tailored solutions. Whether your project requires enhanced UV stability for desert installations, halogen-free formulations for confined spaces, or custom channel dimensions for high-voltage bundles, our engineering team collaborates directly with your R&D and procurement departments. We utilize finite element analysis (FEA) to simulate stress points and optimize rib geometry, ensuring force distribution that prevents cable kinking and trench wall damage. Our Suzhou-based production facility maintains ISO 9001-certified processes with batch traceability from raw material sourcing to final shipment, guaranteeing repeatability for global infrastructure rollouts.

Initiate your project with Suzhou Baoshida by contacting Mr. Boyce, our dedicated OEM Manager for Ground Protection Systems. Provide your cable specifications, site conditions, and performance targets to receive a technical proposal within 48 hours. Mr. Boyce will coordinate material samples, 3D-printed prototypes for trench compatibility testing, and a detailed cost analysis aligned with your volume requirements. Do not settle for off-the-shelf compromises where cable integrity is non-negotiable. Submit your RFQ or technical inquiry to [email protected] with subject line “Ground Cable Protector OEM Request – [Your Project Name]”. Include trench depth, soil type, expected traffic load (kN/m²), and cable outer diameter for immediate engineering assessment. Suzhou Baoshida delivers not just components, but validated risk mitigation for your critical power infrastructure. Your cables deserve protection engineered at the molecular level.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).