Technical Contents

Engineering Guide: Grounding Matts

Engineering Insight: The Critical Role of Material Selection in Grounding Mats

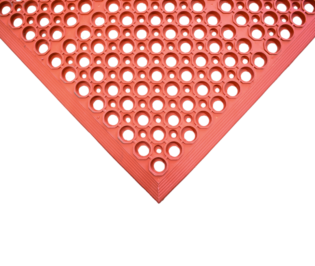

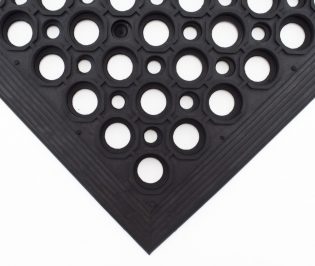

In industrial environments where electrostatic discharge (ESD) poses a risk to sensitive equipment, personnel safety, and process integrity, grounding mats serve as a fundamental line of defense. However, the performance and longevity of these mats are not guaranteed by form alone—material selection is the decisive factor. Off-the-shelf grounding mats, often constructed from generic rubber compounds or low-cost polymers, frequently fail under real-world operational stress due to inadequate electrical properties, poor environmental resistance, and insufficient mechanical durability.

The core function of a grounding mat is to provide a controlled pathway for static charges to dissipate safely to earth. This requires a precise balance of surface and volume resistivity. Materials that are too conductive risk short-circuiting electronic components, while those that are too insulative prevent effective charge dissipation. High-performance grounding mats must maintain a surface resistivity in the range of 10^5 to 10^9 ohms/square, ensuring ESD-safe conditions without creating a shock hazard.

Common commercial mats utilize carbon-black-filled SBR (styrene-butadiene rubber) or PVC, which may meet initial resistivity requirements but degrade rapidly under thermal cycling, UV exposure, or chemical contamination. For instance, plasticizers in PVC can leach out over time, increasing brittleness and altering electrical performance. Similarly, SBR compounds swell or crack when exposed to industrial oils and solvents, compromising both mechanical and electrical integrity.

At Suzhou Baoshida Trading Co., Ltd., we engineer grounding mats using specialty elastomers such as ESD-rated nitrile rubber (NBR) and conductive silicone, compounded with stable conductive additives like carbon nanotubes or intrinsically dissipative polymers. These materials offer superior resistance to ozone, oils, and temperature extremes, ensuring consistent performance across thousands of grounding cycles.

Below is a comparison of typical material properties used in industrial grounding mats:

| Material | Surface Resistivity (ohms/square) | Tensile Strength (MPa) | Operating Temperature Range (°C) | Chemical/Oil Resistance | Long-Term Stability |

|---|---|---|---|---|---|

| Standard SBR | 10^6 – 10^8 | 12 – 18 | -20 to +70 | Low | Moderate |

| PVC (plasticized) | 10^5 – 10^7 | 10 – 15 | -10 to +60 | Moderate | Poor |

| ESD Nitrile Rubber (NBR) | 10^5 – 10^8 | 18 – 25 | -30 to +100 | High | Excellent |

| Conductive Silicone | 10^4 – 10^7 | 6 – 10 | -50 to +200 | Moderate | Excellent |

The data underscores why engineered materials outperform generic alternatives. ESD NBR, in particular, offers an optimal balance of electrical control, mechanical strength, and environmental resilience—critical for deployment in automotive assembly lines, semiconductor handling, and chemical processing facilities.

Material selection is not a cost-driven compromise; it is a precision engineering decision. At Baoshida, we reject one-size-fits-all solutions, focusing instead on application-specific formulations that ensure reliability, safety, and compliance with international ESD standards such as ANSI/ESD S20.20 and IEC 61340-5-1. For industrial users, the choice of grounding mat material directly impacts operational continuity and risk mitigation—factors that off-the-shelf products consistently fail to address.

Material Specifications

Material Specifications for Industrial ESD Grounding Mats

Suzhou Baoshida Trading Co., Ltd. provides precision-engineered grounding mats critical for electrostatic discharge (ESD) control in semiconductor manufacturing, electronics assembly, and explosive handling environments. These mats require controlled surface resistivity (10⁶–10⁹ ohms per ASTM D257) to safely dissipate static while maintaining mechanical integrity under operational stress. Our formulations prioritize chemical stability, thermal resilience, and consistent electrical performance. Below we detail three core elastomer systems validated for industrial grounding applications: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material addresses distinct environmental and functional demands, with selection dependent on temperature exposure, chemical contact, and regulatory requirements.

Viton fluorocarbon rubber excels in extreme chemical and thermal environments. Its high fluorine content provides exceptional resistance to fuels, acids, and solvents, making it ideal for aerospace and petrochemical grounding zones. Viton maintains stable resistivity up to 250°C but incurs higher material costs. Nitrile butadiene rubber offers optimal cost-performance balance for general industrial use. With acrylonitrile content tailored between 33–50%, NBR delivers robust oil and grease resistance while sustaining surface resistivity from -30°C to 120°C. It is the standard choice for automotive and assembly line workstations due to abrasion durability and rapid static dissipation. Silicone rubber is specified for ultra-clean or high-temperature applications exceeding 200°C. Platinum-cured VMQ formulations ensure low particle generation per ISO Class 5 cleanroom standards and flexibility down to -60°C, though they exhibit moderate fuel resistance. Silicone’s biocompatibility also suits medical device manufacturing.

All materials undergo rigorous percolation threshold validation to embed conductive carbon black or metal-coated particles without compromising mechanical properties. Hardness is maintained at 50–70 Shore A per ISO 48-4 to balance ergonomic comfort and dimensional stability. Tensile strength exceeds 10 MPa (ASTM D412), and elongation at break remains above 200% to prevent cracking during installation. Critical to grounding efficacy, volume resistivity is calibrated to 10⁴–10⁶ ohm·cm during vulcanization, ensuring reliable charge dissipation across the mat’s service life.

The comparative specifications below outline key performance parameters for informed material selection:

| Material | Key Properties | Temperature Range (°C) | ESD Performance | Chemical Resistance | Primary Applications |

|---|---|---|---|---|---|

| Viton (FKM) | High fluorine content, low gas permeability | -20 to +250 | Stable resistivity at extreme temps | Exceptional: acids, fuels, halogens | Semiconductor cleanrooms, chemical processing, aerospace |

| Nitrile (NBR) | Adjustable acrylonitrile ratio, high abrasion resistance | -30 to +120 | Fast static dissipation, cost-effective | Excellent: oils, greases, aliphatic hydrocarbons | Automotive assembly, electronics workbenches, packaging lines |

| Silicone (VMQ) | Platinum-cured, low compression set | -60 to +230 | Consistent in wide temp range | Moderate: solvents; poor: concentrated acids | Medical device manufacturing, high-temp electronics, cleanrooms |

Material selection must align with facility-specific ESD protocols per ANSI/ESD S20.20. Suzhou Baoshida’s OEM engineering team collaborates with clients to validate formulations against operational stressors, including cyclic thermal loading, chemical immersion, and continuous grounding current. All mats include traceable lot numbering for full supply chain accountability and undergo 100% resistivity testing prior to shipment. For mission-critical deployments, we recommend Viton in chemically aggressive settings, NBR for cost-sensitive high-volume facilities, and Silicone where ultra-pure or cryogenic performance is mandated. Contact our technical division for application-specific validation data and custom compound development.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Solutions for Industrial Grounding Mats

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the design and production of high-performance grounding mats. With a dedicated team of five mould engineers and two specialized rubber formula engineers, we integrate material science with precision manufacturing to deliver OEM grounding mats that meet exacting technical and safety standards.

Our formula engineers possess deep expertise in polymer chemistry and conductive elastomer systems. They formulate custom rubber compounds tailored to specific electrical resistance requirements, mechanical durability, and environmental resistance. Whether the application demands surface resistivity in the range of 10^4 to 10^6 ohms for ESD protection or enhanced tracking resistance for high-voltage environments, our formulations are engineered to perform consistently under operational stress. Additives such as carbon black, conductive fillers, and anti-aging agents are precisely calibrated to balance conductivity, flexibility, and longevity.

Complementing our formulation expertise, our five in-house mould engineers specialize in the design and optimization of compression and transfer mould tooling. They utilize CAD/CAM software and finite element analysis (FEA) to simulate material flow, curing dynamics, and stress distribution, ensuring dimensional accuracy and repeatability across production batches. This synergy between material and mould design enables us to produce grounding mats with tight tolerances, uniform thickness, and consistent electrical performance across large surface areas.

We offer full OEM service capability, from initial concept and technical specification review to prototyping, validation, and mass production. Our clients benefit from a collaborative engineering process, where design for manufacturability (DFM) principles are applied early to reduce lead times and eliminate production bottlenecks. Every grounding mat is developed in alignment with international standards such as IEC 61340-5-1 (ESD control) and ASTM F1496 (resistivity testing), ensuring compliance and reliability.

Our production infrastructure supports both small-batch custom orders and high-volume manufacturing, with rapid tooling turnaround and strict quality control protocols. All compounds undergo rigorous testing for volume resistivity, tensile strength, tear resistance, and thermal stability before approval.

Below is a summary of typical technical specifications achievable with our engineered rubber compounds for grounding mats:

| Property | Standard Range | Test Method |

|---|---|---|

| Volume Resistivity | 10⁴ – 10⁸ Ω·cm | ASTM D257 |

| Surface Resistivity | 10⁵ – 10⁹ Ω/sq | IEC 61340-2-3 |

| Hardness (Shore A) | 50 – 70 | ASTM D2240 |

| Tensile Strength | ≥ 10 MPa | ASTM D412 |

| Elongation at Break | ≥ 250% | ASTM D412 |

| Operating Temperature | -30°C to +80°C | ISO 188 |

| Tear Resistance | ≥ 25 kN/m | ASTM D624 |

Suzhou Baoshida Trading Co., Ltd. combines advanced rubber formulation, precision tooling, and OEM agility to deliver grounding mats that meet the highest industrial standards. Our engineering team is committed to innovation, reliability, and technical partnership with every client.

Customization Process

Customization Process for Industrial Grounding Mats

At Suzhou Baoshida Trading Co., Ltd., our grounding mat customization follows a rigorously controlled engineering workflow to ensure compliance with stringent ESD safety standards and client-specific operational demands. This process eliminates guesswork through data-driven material science and iterative validation, transforming conceptual requirements into certified production-ready solutions.

Drawing Analysis initiates the engagement. Our engineering team dissects technical schematics, focusing on dimensional tolerances, surface texture requirements, and electrical pathway geometry. Critical parameters such as edge continuity for equipotential bonding and seam integrity under mechanical stress are evaluated against IEC 61340-5-1 and ANSI/ESD S20.20. We identify potential manufacturing constraints early—such as minimum bend radii for rolled installations or thermal expansion coefficients for high-temperature environments—to prevent downstream rework. Client feedback on these analyses is mandatory before formulation begins.

Formulation Engineering leverages our 15-year compound database and in-house testing capabilities. Conductive properties are precisely tuned via carbon black dispersion levels and polymer backbone selection (typically EPDM or Nitrile variants). Volume resistivity targets (10^3–10^9 Ω/sq) dictate filler concentration, while Shore A hardness (45–75) and tensile strength (>10 MPa) are balanced against flexibility needs. Critical parameters are validated through accelerated aging tests simulating 5+ years of industrial wear. Below are typical specification ranges for reference:

| Parameter | Standard Range | Test Method |

|---|---|---|

| Volume Resistivity | 10^4–10^8 Ω/sq | ASTM D257 |

| Surface Resistivity | 10^5–10^9 Ω/sq | ANSI/ESD STM7.1 |

| Shore A Hardness | 50–70 | ASTM D2240 |

| Tensile Strength | 12–18 MPa | ASTM D412 |

| Dielectric Breakdown | >20 kV/mm | ASTM D149 |

Prototyping employs CNC-machined molds for first-article samples. Each prototype undergoes electrical mapping at 50+ grid points to verify uniform conductivity, alongside peel adhesion tests for multi-layer constructions. Clients receive full material test reports (MTRs) including lot-specific resistivity curves and FTIR validation of polymer composition. Two iterative cycles are included to refine edge sealing or grounding stud integration based on real-world mockups.

Mass Production commences only after formal client sign-off on the golden sample. We implement SPC (Statistical Process Control) monitoring at extrusion and vulcanization stages, with real-time resistivity checks every 30 minutes. All batches are traceable via laser-etched lot codes, and final inspection includes 100% visual screening for surface defects plus quarterly third-party certification audits. Our Suzhou facility’s ISO 9001-certified line ensures ≤0.25% defect rates, with dedicated production cells minimizing cross-contamination risks for conductive compounds.

This phased approach transforms complex ESD requirements into reliable, auditable manufacturing outcomes—reducing client time-to-deployment by 30% while guaranteeing operational safety in semiconductor, aerospace, and medical device environments. Partner with us to convert your grounding mat specifications into a validated supply chain asset.

Contact Engineering Team

For industrial operations where safety, precision, and durability are non-negotiable, grounding mats represent a critical component in protecting both personnel and sensitive equipment. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance industrial rubber solutions engineered to meet the rigorous demands of modern manufacturing, electronics assembly, cleanrooms, and electrostatic discharge (ESD) control environments. Our grounding mats are formulated using advanced conductive rubber compounds that ensure consistent surface resistivity, long-term reliability, and compliance with international safety standards.

Each grounding mat produced under our technical supervision undergoes stringent quality control, including volumetric resistivity testing, tensile strength verification, and accelerated aging protocols. We utilize a proprietary blend of natural and synthetic rubber reinforced with carbon black and other conductive additives to achieve optimal electron dissipation without compromising mechanical integrity. Whether you require roll-based sheeting for large-scale floor installation or custom-cut workstation pads with snap connectors, our team ensures dimensional accuracy, chemical resistance, and seamless integration into existing ESD management systems.

We understand that OEM partnerships and bulk procurement demand more than just product supply — they require technical collaboration, material traceability, and responsive support. This is why we assign dedicated engineering liaisons to every client, ensuring full transparency from formulation to final delivery. Our production facility in Suzhou is equipped with state-of-the-art calendaring, vulcanization, and surface treatment lines, enabling us to maintain tight tolerances and rapid turnaround times without sacrificing quality.

To facilitate seamless integration into global supply chains, our grounding mats are available in multiple configurations and performance tiers. Below is a representative specification table for our standard conductive rubber grounding mat series:

| Property | Test Method | Value |

|---|---|---|

| Surface Resistivity | ASTM D257 | 10^4 – 10^6 ohms/sq |

| Volume Resistivity | ASTM D257 | < 10^4 ohms-cm |

| Tensile Strength | ASTM D412 | ≥ 10 MPa |

| Elongation at Break | ASTM D412 | ≥ 250% |

| Hardness (Shore A) | ASTM D2240 | 55 ± 5 |

| Thickness Tolerance | ISO 3302 | ±0.2 mm |

| Operating Temperature | — | -20°C to +80°C |

| Color | — | Black (custom colors available) |

| Available Forms | — | Sheets, Rolls, Die-Cut Pads |

All materials are free from hazardous substances in compliance with RoHS and REACH directives, and certificates of conformance are provided with every shipment.

For technical inquiries, custom formulation requests, or bulk pricing discussions, please contact Mr. Boyce, our OEM and Technical Sales Manager, directly at [email protected]. Mr. Boyce brings over 12 years of experience in industrial rubber applications and leads our client integration team, ensuring your specifications are met with scientific precision and manufacturing excellence. We respond to all inquiries within 12 business hours and offer sample kits for performance validation upon request.

Partner with Suzhou Baoshida Trading Co., Ltd. — where material science meets industrial reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).