Technical Contents

Engineering Guide: Gummi Formteile

Engineering Insight: Material Selection in Gummi Formteile Manufacturing

Material selection constitutes the foundational determinant of performance and longevity in gummi formteile (rubber molded parts). Off-the-shelf solutions frequently fail under operational demands due to oversimplified compound formulations that neglect the intricate interplay between chemical composition, environmental stressors, and mechanical requirements. Generic rubber compounds prioritize cost reduction over application-specific resilience, leading to premature degradation such as compression set, chemical swelling, or thermal cracking. These failures manifest as seal leakage, structural fatigue, or complete component rupture—directly impacting OEM production uptime and end-product reliability.

The critical flaw in standardized rubber parts lies in their inability to address compound-specific variables. A single grade of NBR may suffice for basic oil resistance at 80°C, but fail catastrophically in aerospace hydraulic systems requiring simultaneous resistance to Skydrol fluid, -55°C flexibility, and 15,000-hour service life. Material science demands precise balancing of polymer backbone, filler dispersion, curative systems, and additive packages. For instance, optimizing sulfur vs. peroxide curing alters heat resistance by 40°C while affecting compression set by 25%. Off-the-shelf compounds rarely document such trade-offs, leaving engineers to diagnose failures post-deployment.

Suzhou Baoshida Trading Co., Ltd. emphasizes engineered material solutions validated through application-specific testing protocols. Below compares critical performance parameters between generic and engineered compounds:

| Property | Standard NBR Compound | Suzhou Baoshida Engineered NBR | Test Standard |

|---|---|---|---|

| Low Temperature Flex | -30°C | -50°C | ISO 1817 |

| Compression Set (70h/100°C) | 35% | 12% | ASTM D395 |

| Fuel C Resistance (70h/23°C) | 18% Volume Swell | 8% Volume Swell | ISO 1817 |

| Tensile Strength Retention (168h/125°C) | 55% | 82% | ASTM D573 |

| Abrasion Loss (DIN) | 120 mm³ | 45 mm³ | ISO 4649 |

These metrics demonstrate how engineered compounds mitigate failure modes inherent in commoditized alternatives. The 23°C improvement in low-temperature flexibility prevents seal hardening in Arctic hydraulic systems, while reduced compression set ensures consistent sealing force in high-cycle pneumatic valves. Crucially, volume swell data reveals that standard NBR absorbs aggressive fluids 2.25x faster—directly correlating to seal extrusion and system contamination.

OEMs must recognize that rubber is not a homogeneous material but a tunable system requiring molecular-level customization. Suzhou Baoshida’s OEM management process integrates application profiling, accelerated aging simulations, and finite element analysis to define compound architectures that anticipate real-world stressors. This approach eliminates the cost of field failures—where a single production line stoppage often exceeds the lifetime value of a properly engineered gummi formteil. Material selection is not a procurement decision; it is an engineering imperative dictating system integrity.

Material Specifications

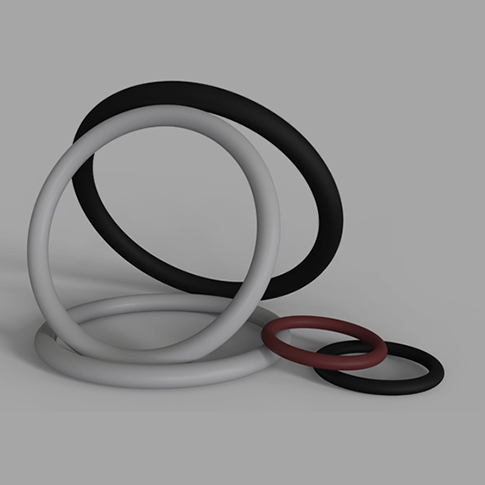

Material selection is a critical determinant in the performance and longevity of gummi formteile (rubber molded components) across industrial applications. At Suzhou Baoshida Trading Co., Ltd., we engineer precision rubber components to meet exacting OEM requirements, leveraging advanced elastomer compounds such as Viton, Nitrile (NBR), and Silicone. Each material exhibits distinct physical, thermal, and chemical resistance properties, enabling tailored solutions for sectors including automotive, aerospace, pharmaceuticals, and fluid handling systems.

Viton, a fluorocarbon-based elastomer (FKM), delivers exceptional resistance to high temperatures, aggressive chemicals, oils, and fuels. With continuous service capability up to 200°C and intermittent exposure tolerance reaching 250°C, Viton is ideal for sealing applications in extreme environments. Its low gas permeability and outstanding aging characteristics make it a preferred choice for critical dynamic and static seals in engine systems, chemical processing, and semiconductor manufacturing. However, Viton exhibits higher material cost and reduced flexibility at low temperatures compared to alternative elastomers.

Nitrile rubber (NBR) remains one of the most widely used materials for oil-resistant gummi formteile. It offers excellent mechanical strength, abrasion resistance, and compatibility with aliphatic hydrocarbons, hydraulic fluids, and greases. Operating effectively within a temperature range of -30°C to 100°C (with low-temperature variants extending to -50°C), Nitrile provides a balanced performance profile for cost-sensitive, high-volume applications such as O-rings, gaskets, and diaphragms in automotive and industrial hydraulics. While NBR degrades under exposure to ozone, UV radiation, and polar solvents, its formulation versatility allows for customization in acrylonitrile content to enhance oil resistance or low-temperature flexibility.

Silicone rubber (VMQ) excels in applications demanding extreme temperature stability and biocompatibility. It maintains elastomeric properties from -60°C to 200°C, with short-term resistance up to 300°C. Its inherent resistance to oxidation, UV, and ozone, combined with low toxicity and compliance with FDA and USP Class VI standards, makes silicone the material of choice for medical devices, food processing seals, and outdoor electrical insulation. Though lower in tensile strength and abrasion resistance than Viton or NBR, silicone’s electrical insulation properties and transparency to gases are advantageous in specialized sensing and ventilation components.

The following table summarizes key technical specifications for these elastomers to guide material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (250 intermittent) | -30 to 100 (-50 with special grades) | -60 to 200 (300 intermittent) |

| Tensile Strength (MPa) | 15–20 | 10–30 | 5–8 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–600 |

| Hardness Range (Shore A) | 60–90 | 50–90 | 30–80 |

| Fluid Resistance (Oil/Fuel) | Excellent | Good to Excellent | Poor |

| Chemical Resistance | Excellent | Fair | Good |

| Compression Set Resistance | Excellent | Good | Good |

| Electrical Insulation | Good | Fair | Excellent |

| FDA/USP Compliance | Limited grades | No | Yes (specific grades) |

Selection of the optimal elastomer must consider not only baseline material properties but also application-specific factors such as dynamic loading, sealing pressure, media exposure, and regulatory compliance. Suzhou Baoshida Trading Co., Ltd. supports OEMs with material testing, formulation adjustment, and precision molding to ensure gummi formteile perform reliably under real-world conditions.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Formulation and Mold Design for Industrial Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the cornerstone of reliable Gummi Formteile manufacturing. We deploy a dedicated team of five specialized Mold Engineers and two advanced Formula Engineers, ensuring seamless integration from material science to precision molding. This dual-expertise structure eliminates siloed development, enabling holistic optimization of rubber compounds and mold geometries for demanding industrial environments. Our Formula Engineers focus on bespoke polymer chemistry, tailoring formulations to meet exact chemical resistance, thermal stability, and mechanical performance requirements. Simultaneously, Mold Engineers leverage 3D simulation tools to refine cavity design, gating systems, and thermal management, directly translating compound behavior into consistent part integrity.

Material innovation is rigorously validated through in-house testing against international standards including ASTM D2000 and ISO 37. We systematically address challenges such as compression set reduction in dynamic seals, abrasion resistance for mining components, and low-temperature flexibility for automotive applications. Critical parameters like cure kinetics, filler dispersion, and polymer-filler interactions are optimized at the molecular level, ensuring repeatability across production scales. This scientific approach minimizes scrap rates and extends service life in end-use conditions.

Our OEM capabilities are engineered for complexity and scalability. We support clients from prototype development through serial production, offering full traceability via integrated ERP systems. Each project undergoes Failure Mode and Effects Analysis (FMEA) during design, with real-time process monitoring during manufacturing. This includes cavity pressure sensors, inline rheometry, and automated dimensional inspection against GD&T specifications. Clients receive comprehensive technical dossiers detailing compound formulations, mold flow analysis reports, and validation test data—ensuring compliance with stringent industry regulations such as DIN 7716 for storage and ISO/TS 16949 for automotive supply chains.

Material performance specifications for common industrial compounds are summarized below:

| Material Type | Hardness Range (Shore A) | Temperature Range (°C) | Key Applications | Fluid Resistance Highlights |

|---|---|---|---|---|

| EPDM | 40–90 | -50 to +150 | Automotive seals, HVAC gaskets | Excellent ozone/weathering; good brake fluid resistance |

| NBR | 40–95 | -30 to +120 | Fuel/oil handling seals, rollers | Superior petroleum/fuel resistance; moderate water resistance |

| Silicone | 30–80 | -60 to +230 | Medical devices, high-temp seals | Exceptional thermal stability; biocompatible grades available |

| FKM | 60–90 | -20 to +250 | Aerospace, chemical processing | Outstanding chemical/fuel resistance; high-cost critical applications |

This engineering framework ensures that every Gummi Formteil we produce meets the exact functional demands of industrial machinery, transportation systems, and energy infrastructure. By unifying formula science with precision mold engineering, Suzhou Baoshida delivers solutions where material behavior and geometric accuracy converge—eliminating field failures and reducing total cost of ownership for our OEM partners. Our commitment to data-driven development and process control establishes a benchmark for reliability in global rubber manufacturing.

Customization Process

Customization Process for Rubber Molding Components at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., the customization of rubber molding components—known technically as gummi formteile—follows a systematic, precision-driven process designed to meet the exact performance, environmental, and dimensional requirements of industrial clients. Our engineering workflow ensures material compatibility, mechanical reliability, and production scalability, from initial concept to final delivery.

The process begins with Drawing Analysis, where our technical team evaluates customer-provided CAD models or 2D technical drawings. This stage involves a detailed review of critical dimensions, tolerances, surface finish requirements, and part geometry. We assess potential molding challenges such as undercuts, wall thickness uniformity, and ejection feasibility. Our engineers also verify compliance with international standards such as ISO 3302 for dimensional tolerances and ISO 2768 for general geometric specifications. Any design ambiguities or risks are communicated promptly for resolution prior to material selection.

Following drawing validation, the Formulation Phase commences. Our Rubber Formula Engineers develop a compound tailored to the operational environment of the component. Key factors include temperature range, exposure to oils, chemicals, ozone, or UV radiation, dynamic stress, and compression set requirements. We specialize in compounding a wide range of elastomers, including NBR, EPDM, FKM, silicone (VMQ), and NR, with precise filler, accelerator, and curing agent ratios. Each formulation is documented and archived for batch traceability and repeatability.

Once the material is finalized, we proceed to Prototyping. Utilizing precision steel molds or rapid tooling methods, we produce small-batch samples for functional testing. Prototypes undergo rigorous evaluation, including hardness testing (Shore A), tensile strength, elongation at break, and volume swell analysis in simulated service media. Dimensional inspection is performed using coordinate measuring machines (CMM) to ensure conformity to print specifications. Client feedback is incorporated at this stage, with iterative adjustments made if necessary.

Upon approval, the project transitions into Mass Production. Our automated compression, transfer, and injection molding lines ensure high consistency and throughput. In-process quality checks, including first-article inspection and statistical process control (SPC), are implemented throughout. Final products are packaged per client specifications, with full documentation including material certificates (e.g., RoHS, REACH) and test reports.

This structured approach ensures that every gummi formteil we manufacture delivers optimal performance in demanding industrial applications.

| Parameter | Standard | Testing Method |

|---|---|---|

| Hardness Range | 30–90 Shore A | ISO 48-4 |

| Tensile Strength | Up to 25 MPa | ISO 37 |

| Elongation at Break | Up to 600% | ISO 37 |

| Compression Set (70h, 70°C) | ≤25% | ISO 815-1 |

| Dimensional Tolerance | ISO 3302 Class M3 | ISO 3302 |

Contact Engineering Team

Precision Partnership for Industrial Rubber Solutions: Engage Suzhou Baoshida

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and high-volume OEM manufacturing, delivering mission-critical Gummi Formteile for global industrial applications. Our engineering-driven approach ensures rubber components meet exacting functional, environmental, and longevity requirements—from automotive sealing systems to industrial machinery dampeners. As your dedicated Rubber Formula Engineer and OEM Manager, I emphasize that component failure is not an option in precision engineering. Our value lies in transforming complex material challenges into reliable, cost-optimized production realities through proprietary compound development and process control.

We specialize in custom elastomer formulations where standard catalog solutions fall short. Our Suzhou facility integrates ISO 9001-certified production with in-house R&D labs, enabling rapid iteration from prototype to serial supply. Critical capabilities include hydrogenated nitrile (HNBR) for high-temperature fuel systems, peroxide-cured silicone for medical-grade biocompatibility, and fluorocarbon (FKM) compounds resistant to aggressive chemicals. Every formulation undergoes rigorous validation per ASTM, DIN, and OEM-specific protocols, including compression set testing at 150°C for 72 hours and dynamic fatigue analysis.

The table below summarizes core technical parameters achievable through our engineered solutions:

| Parameter | Standard Capability Range | Custom Solution Range | Testing Standard |

|---|---|---|---|

| Hardness (Shore A) | 30–90 | 20–95 | ASTM D2240 |

| Temperature Resistance | -40°C to +150°C | -60°C to +300°C | ISO 188 |

| Tensile Strength | 8–25 MPa | 5–35 MPa | ASTM D412 |

| Compression Set (70h/100°C) | ≤25% | ≤15% | ASTM D395 |

| Media Resistance | Oil, water, ozone | Jet fuel, acids, plasma | Custom immersion tests |

Why select Suzhou Baoshida as your strategic partner? We eliminate supply chain vulnerability through dual-sourcing of raw materials and dedicated production cells for single-customer programs. Our engineering team collaborates directly with your design phase, utilizing finite element analysis (FEA) to predict seal performance under load and thermal cycling. Crucially, we maintain German-speaking technical staff to ensure seamless communication with EU-based OEMs, bridging cultural and linguistic gaps in specification interpretation.

For Gummi Formteile demanding zero-defect performance, initiate collaboration with our technical OEM management team. Provide your material datasheet, 3D model, and application environment details to receive a targeted solution proposal within 72 hours. We commit to transparent costing, traceable batch records, and on-time delivery metrics exceeding 99.2%.

Contact Mr. Boyce, OEM Manager, for immediate technical consultation: [email protected]. Specify your compound requirements, annual volume, and critical performance thresholds to activate our engineering response protocol. Suzhou Baoshida does not sell rubber—we engineer reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).