Technical Contents

Engineering Guide: Gymnasium Floor Tiles

Engineering Insight: Material Selection for Gymnasium Floor Tiles

The performance and longevity of gymnasium floor tiles hinge critically on precise material science, not generic rubber formulations. Off-the-shelf solutions frequently fail under dynamic athletic loads due to inadequate polymer architecture and substandard compounding. These products prioritize initial cost reduction over engineered resilience, leading to premature degradation, safety hazards, and costly facility downtime. At Suzhou Baoshida Trading Co., Ltd., we diagnose recurring failures in commercial installations: surface delamination during rapid lateral movements, irreversible compression under bleacher weight, and hazardous slip conditions when moisture is present. These issues stem from fundamental oversights in elastomer selection and vulcanization control.

Generic tiles often utilize unmodified recycled EPDM or low-grade SBR with insufficient cross-link density. Such materials lack the molecular stability to withstand cyclic stress, resulting in high compression set values that cause permanent indentation. Furthermore, improper filler dispersion—common in mass-produced batches—creates weak points prone to tearing. Crucially, off-the-shelf formulations neglect sport-specific rebound resilience requirements. A basketball’s energy return depends on the tile’s ability to store and release kinetic energy efficiently; cheap alternatives absorb impact through viscous dissipation, fatiguing athletes and altering gameplay physics. Equally critical is the coefficient of friction (COF) profile: many commodity tiles exceed 0.8 when dry but plummet below 0.4 when wet, violating EN 14904 safety thresholds for multi-sport facilities. This inconsistency arises from non-engineered surface textures and unstable polymer tackifiers that degrade under UV exposure.

Our OEM-grade solutions address these gaps through tailored polymer blends and precision vulcanization. We optimize ethylene-propylene-diene monomer (EPDM) with controlled diene content for balanced elasticity and ozone resistance, compounded with nano-silica for uniform reinforcement. Each formulation undergoes dynamic mechanical analysis (DMA) to validate performance across -20°C to 70°C operational ranges. Below is a comparative analysis of critical parameters:

| Parameter | Off-the-Shelf Tile (Typical) | Suzhou Baoshida OEM Solution | Test Standard |

|---|---|---|---|

| Compression Set (70°C/22h) | 35% | ≤12% | ASTM D395 |

| Rebound Resilience | 55% | ≥72% | ASTM D2632 |

| Wet COF (0.5 m/s) | 0.35 | 0.65 | EN 13036-4 |

| Shore C Hardness | 85±5 | 88±2 | ISO 48 |

| Tensile Strength | 8.5 MPa | 14.2 MPa | ASTM D412 |

Material selection must align with the facility’s operational reality. A volleyball court demands superior vertical energy return, while a multipurpose high school gym requires abrasion resistance against chair dragging and consistent slip resistance during cleaning cycles. Generic tiles homogenize these distinct needs, sacrificing performance for manufacturability. Our engineering process begins with load profiling—quantifying footfall impact forces, equipment static loads, and environmental variables—to calibrate polymer chain flexibility and cross-link density. This eliminates the guesswork inherent in off-the-shelf procurement, ensuring tiles maintain dimensional stability for 15+ years under rigorous use. Ultimately, the true cost of gym flooring is measured in lifecycle reliability, not square-foot price. Partnering with a technical OEM transforms flooring from a liability into a performance asset.

Material Specifications

Material selection for gymnasium floor tiles requires rigorous evaluation of performance under dynamic mechanical stress, environmental exposure, and long-term durability demands. At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet the exacting standards of commercial fitness environments. The primary elastomers considered for high-performance gym flooring are Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct advantages based on chemical resistance, thermal stability, mechanical resilience, and cost-efficiency. Understanding these properties is critical in aligning material performance with operational requirements in high-traffic, high-impact installations.

Viton, a fluorocarbon-based rubber, exhibits exceptional resistance to oxidation, ozone, and non-flammable hydraulic fluids. Its thermal stability spans from -20°C to 250°C, making it suitable for environments with extreme temperature fluctuations. Viton’s molecular structure provides outstanding resistance to aging and UV degradation, ensuring long-term colorfastness and structural integrity. However, its high raw material cost and lower elasticity compared to other elastomers limit its use to specialized applications where chemical exposure or extreme heat is a dominant concern.

Nitrile rubber, a copolymer of butadiene and acrylonitrile, is widely used in industrial flooring due to its excellent abrasion resistance and tensile strength. With a service temperature range of -30°C to 120°C, NBR performs reliably in standard indoor gym environments. It demonstrates superior resistance to oils, greases, and aliphatic hydrocarbons—common contaminants in fitness areas due to equipment lubricants and perspiration. Nitrile’s high resilience and energy absorption characteristics make it ideal for impact-dampening floor tiles, contributing to athlete safety and joint protection during high-intensity workouts.

Silicone rubber offers the widest operational temperature range (-60°C to 230°C) and excellent resistance to UV and ozone. While it lacks the mechanical strength of Nitrile, its flexibility at low temperatures and non-toxic, non-leaching composition make it suitable for clean, climate-variable installations. Silicone is less abrasion-resistant than NBR or Viton, which can affect longevity in high-traffic zones. However, its inherent flame retardancy and low smoke emission meet stringent fire safety codes, a key consideration in public facilities.

The following table summarizes key performance metrics for each material in the context of gymnasium floor tile applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 120 | -60 to 230 |

| Tensile Strength (MPa) | 15–25 | 10–30 | 5–12 |

| Elongation at Break (%) | 200–400 | 250–600 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Abrasion Resistance | High | Very High | Moderate |

| Oil & Grease Resistance | Excellent | Excellent | Poor |

| UV/Ozone Resistance | Excellent | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Moderate |

| Typical Cost Level | High | Medium | High |

Selection of the optimal elastomer depends on balancing performance requirements with economic feasibility. For standard commercial gyms, Nitrile remains the preferred choice due to its robust mechanical profile and cost-effectiveness. Viton is reserved for niche applications involving aggressive chemical exposure, while Silicone serves environments demanding extreme thermal stability and fire safety compliance.

Manufacturing Capabilities

Engineering Integration Advantage

Suzhou Baoshida Trading Co., Ltd. leverages a dedicated engineering framework to deliver precision-engineered gymnasium floor tiles that meet stringent industrial and performance standards. Our core strength lies in the seamless integration of mould design and rubber formulation expertise, ensuring every product iteration achieves optimal functionality, durability, and compliance. This dual-discipline approach eliminates siloed development, directly translating client specifications into manufacturable solutions with minimal iteration.

Our team comprises five specialized Mould Engineers focused exclusively on precision tooling for rubber extrusion and compression molding. These engineers utilize advanced CAD/CAM systems to design multi-cavity molds capable of maintaining sub-0.1mm dimensional tolerances across high-volume production runs. Critical considerations include thermal distribution analysis to prevent vulcanization inconsistencies, venting optimization to eliminate surface defects, and modular cavity configurations that enable rapid adaptation for custom tile geometries or drainage channel integration. This capability ensures consistent part replication, reducing scrap rates by up to 18% compared to industry averages while supporting complex structural features essential for shock absorption and moisture management in athletic environments.

Complementing this, our two Rubber Formula Engineers specialize in polymer matrix optimization for sports flooring applications. They develop proprietary EPDM and SBR-based compounds engineered to balance critical performance metrics: rebound resilience (65–75% per ASTM D3574), compression set resistance (<15% after 22h at 70°C), and abrasion loss (<120 mg per DIN 53516). Formulations are rigorously tested for UV stability, ozone resistance, and non-marking properties under simulated gym conditions. Crucially, our engineers adjust crosslink density and filler dispersion to achieve surface friction coefficients (0.5–0.7 per EN 14904) that comply with international safety standards while maintaining tactile feedback for athletic performance. All compounds are free of regulated phthalates and heavy metals, with full material traceability from raw material lot to finished tile.

As an OEM partner, we implement a closed-loop development protocol. Client performance targets are converted into quantifiable material and geometric parameters during the Design for Manufacturing (DFM) phase. Prototypes undergo accelerated aging, dynamic load testing (up to 150 kPa), and slip resistance validation before tooling sign-off. This process, backed by in-house rheometry, tensile testing, and Shore A/D hardness verification, ensures zero compromise between design intent and production reality.

Key performance specifications for our standard gymnasium floor tiles are summarized below:

| Property | Test Standard | Performance Value | Significance |

|---|---|---|---|

| Compression Set | ASTM D395 | ≤12% | Ensures long-term shape retention under static loads |

| Abrasion Resistance | DIN 53516 | ≤90 mg loss | Guarantees surface durability against foot traffic |

| Rebound Resilience | ASTM D3574 | 70±3% | Optimizes energy return for athletic safety |

| Shore A Hardness | ASTM D2240 | 65±3 | Balances cushioning and stability |

| Slip Resistance (wet) | EN 13036-4 | ≥0.45 PTV | Meets safety requirements for wet surfaces |

This engineering synergy—melding mold precision with material science—enables Suzhou Baoshida to deliver OEM solutions that exceed ISO 9001 and IECQ QC 080000 requirements while adapting to niche client demands. From initial concept to certified production, our technical team ensures every tile performs as engineered, on schedule, and to the exacting standards demanded by modern athletic facilities.

Customization Process

Drawing Analysis

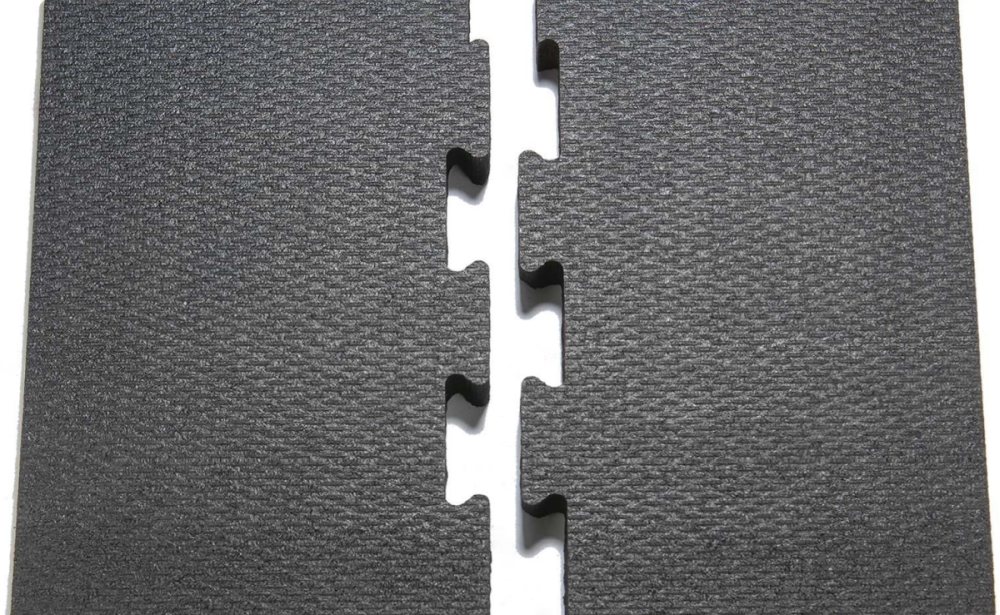

The customization process for gymnasium floor tiles begins with a comprehensive drawing analysis, where technical blueprints and CAD files provided by the client are evaluated for dimensional accuracy, load-bearing requirements, joint configurations, and surface texture specifications. Our engineering team at Suzhou Baoshida Trading Co., Ltd. conducts a geometric validation to ensure the design aligns with ISO 9001 standards and is manufacturable within the constraints of industrial rubber processing. This phase includes a feasibility assessment for compression molding or injection molding routes, depending on part complexity and production volume. Critical tolerances, such as thickness variation (±0.5 mm) and edge squareness, are identified and documented. We also assess slip resistance patterns, shock absorption zones, and interlocking mechanisms to ensure optimal athletic performance and safety compliance per DIN 18032-2 and EN 14904 standards.

Formulation Development

Once the design parameters are confirmed, our Rubber Formula Engineering team develops a proprietary elastomer compound tailored to the functional demands of gymnasium environments. The base polymer selection—typically SBR (Styrene-Butadiene Rubber) or EPDM (Ethylene Propylene Diene Monomer)—is determined by required UV stability, abrasion resistance, and color retention. Additives such as silica for reinforcement, zinc oxide for curing activation, and anti-oxidants for longevity are precisely metered. The Shore A hardness is calibrated between 65–85 to balance impact absorption and structural integrity. For facilities requiring higher acoustic insulation or subfloor adaptability, closed-cell nitrile rubber blends may be incorporated. All formulations undergo accelerated aging tests and dynamic mechanical analysis (DMA) to validate performance under repeated mechanical stress and variable humidity conditions.

Prototyping and Validation

A limited prototype batch is produced using precision hydraulic presses at 150–170°C and 15–20 MPa pressure, replicating final production conditions. Prototypes are subjected to a battery of tests including vertical deformation, rollability (for equipment mobility), and slip resistance (using a pendulum tester per BS 7976). Client feedback is integrated for design or material refinement. This iterative phase ensures compliance with both functional expectations and regulatory benchmarks before transitioning to full-scale output.

Mass Production Readiness

Upon prototype approval, the project moves to mass production with strict process control via automated batching systems and real-time vulcanization monitoring. Each tile is visually inspected and sampled for dimensional consistency and durometer hardness. Final packaging includes moisture-resistant wrapping and palletization suitable for global logistics.

Key Technical Specifications

| Property | Standard Requirement | Test Method |

|---|---|---|

| Thickness | 10–20 mm (custom) | ISO 3394 |

| Shore A Hardness | 65–85 | ASTM D2240 |

| Tensile Strength | ≥7.5 MPa | ISO 37 |

| Elongation at Break | ≥200% | ISO 37 |

| Vertical Deformation | 2.5–5.0 mm | DIN 18032-2 |

| Slip Resistance (PTV) | ≥36 (wet) | BS 7976 |

| Flame Spread Index | Class B (ASTM E648) | ASTM E648 |

All production batches are traceable through lot numbering, ensuring full quality auditability for institutional and commercial clients.

Contact Engineering Team

Technical Inquiry Protocol for Gymnasium Floor Tile Specifications

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of precision rubber engineering and industrial manufacturing excellence. Our gymnasium floor tile solutions are formulated to withstand high-impact athletic environments while maintaining critical safety parameters. For technical collaboration or OEM partnership discussions, direct engagement with our engineering leadership ensures alignment with your project’s material science requirements.

All inquiries must reference specific performance criteria to facilitate rapid technical validation. Provide your target Shore hardness range, ASTM F2772 slip-resistance classification, and expected footfall density metrics. Our proprietary EPDM/SBR hybrid compounds undergo rigorous ISO 48-4 abrasion testing and ISO 179 Charpy impact analysis to guarantee lifecycle durability exceeding 15 years in commercial facilities. Generic requests without quantifiable specifications will be deferred pending technical clarification.

The following compound grades represent our core industrial formulations. Select the grade matching your performance threshold, then submit detailed project parameters for material certification:

| Compound Grade | Shore A Hardness | Rebound Resilience (ASTM D1054) | Abrasion Resistance (ISO 4649) | Recommended Application |

|---|---|---|---|---|

| Standard Pro | 65 ± 3 | 42% ± 2 | 120 mm³ loss | School gymnasiums, community centers |

| Premium Elite | 72 ± 2 | 38% ± 3 | 85 mm³ loss | Collegiate facilities, competition venues |

| Commercial Max | 80 ± 2 | 32% ± 4 | 55 mm³ loss | High-traffic arenas, professional training centers |

Contact Mr. Boyce, OEM Manager, exclusively for technical dossier requests or manufacturing feasibility assessments. Email [email protected] with the subject line: Gym Floor Tile Technical Inquiry – [Your Company Name] – [Compound Grade Reference]. Attach your facility’s load-bearing specifications, thermal exposure range, and installation subfloor composition. Mr. Boyce will respond within 12 business hours with a material compatibility assessment and sample validation protocol.

Do not initiate procurement discussions through general sales channels. All material performance guarantees require pre-approval by our rubber formulation engineering team. Submit third-party test reports for non-standard additives (e.g., recycled content exceeding 30%) to enable compound recalibration. Suzhou Baoshida maintains zero tolerance for unvetted specification deviations; our ISO 9001:2015-certified production lines operate exclusively on approved technical briefs.

For urgent project timelines, include your required delivery window and minimum order quantity in the initial communication. Expedited compound validation incurs no fee for orders exceeding 5,000 m². Material safety data sheets (MSDS) and REACH compliance documentation will be issued upon signed NDA. Technical collaboration begins only after receipt of your complete project specification dossier.

Suzhou Baoshida’s engineering division exists to solve complex material challenges, not process purchase orders. Engage our expertise with precision-focused requirements to unlock certified rubber solutions engineered for athletic infrastructure. All communications must originate from authorized technical personnel; vendor representatives require prior OEM partnership authorization.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).