Technical Contents

Engineering Guide: Hardware Washers

Engineering Insight: Material Selection Imperatives for Hardware Washers

Hardware washers serve as critical interface components in mechanical assemblies, yet their performance is disproportionately compromised by inappropriate elastomer selection. Off-the-shelf rubber washers frequently fail under industrial conditions due to generic material formulations that ignore application-specific stressors. Standardized products prioritize cost and availability over engineered resilience, leading to premature compression set, chemical degradation, or thermal instability. These failures manifest as leakage paths, assembly loosening, or catastrophic seal extrusion—directly impacting system uptime and safety compliance.

The core deficiency lies in unaddressed operational variables. A washer exposed to hydraulic fluid at 120°C requires fundamentally different polymer chemistry than one enduring outdoor UV exposure with intermittent brake fluid contact. Generic NBR (nitrile) washers, while economical, rapidly harden when exposed to phosphate ester hydraulic fluids or ozone. Similarly, standard EPDM variants lack the fuel resistance needed in automotive fuel rail applications. Compression set—the permanent loss of sealing force after deformation—is the most common failure mode, accelerated by mismatched temperature ranges or inadequate filler systems. Without tailored compound design, washers lose 30–50% of their sealing force within months, violating ISO 3601 flange joint integrity standards.

Material properties must align with four non-negotiable parameters: fluid compatibility, thermal profile, dynamic load, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. employs ASTM D2000 classification protocols to define precise compound specifications, moving beyond commercial-grade tolerances. Our OEM-engineered solutions integrate accelerated aging tests per ASTM D573 and fluid immersion validation per SAE J2643, ensuring performance longevity. Below is a comparative analysis of common elastomers against critical industrial stressors:

| Material | Hardness Range (Shore A) | Continuous Temp Range (°C) | Key Fluid Resistance | Critical Limitation |

|---|---|---|---|---|

| Standard NBR | 60–90 | -30 to +100 | Mineral oils, water | Fails in phosphate esters, ozone |

| Custom NBR (Baoshida Grade BDT-N70) | 70±5 | -40 to +125 | Hydraulic fluids, greases | Limited aromatic fuel resistance |

| Standard EPDM | 50–80 | -50 to +135 | Water, steam, brake fluid | Swells in mineral oils, fuels |

| Custom FKM (Baoshida Grade BDT-F85) | 85±3 | -20 to +230 | Jet fuels, acids, solvents | High cost, poor low-temp flexibility |

Suzhou Baoshida Trading Co., Ltd. rejects the “one-size-fits-all” approach inherent in commodity washers. Our engineering process begins with OEM application audits—mapping pressure cycles, media chemistry, and failure history—to formulate precision compounds. For instance, automotive transmission washers require peroxide-cured EPDM with 5–10 phr silica reinforcement to resist torque-induced creep, while semiconductor tool washers demand ultra-pure FFKM to prevent particle shedding in vacuum environments.

Off-the-shelf washers represent a false economy. Field data indicates 68% of seal-related assembly failures trace to inadequate material selection, incurring 5–7x replacement costs versus engineered solutions. By integrating material science with OEM design constraints, Suzhou Baoshida ensures hardware washers function as reliable stress-distribution components—not system vulnerabilities. Partner with us to transform washers from passive spacers into engineered reliability assets.

Material Specifications

Material selection is a critical factor in the performance and longevity of rubber washers used in industrial sealing applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered to meet the rigorous demands of automotive, aerospace, chemical processing, and high-performance mechanical systems. Our technical expertise ensures that each washer is manufactured using materials optimized for temperature resistance, chemical compatibility, mechanical strength, and environmental durability. Among the most widely specified elastomers in our product line are Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct advantages depending on application requirements.

Viton is a fluorocarbon-based rubber renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. It performs reliably in continuous service temperatures up to 230°C (446°F), making it ideal for extreme environments such as engine compartments and chemical processing equipment. Its low gas permeability and excellent aging characteristics further enhance its reliability in critical sealing applications. However, Viton has limited flexibility at very low temperatures and is generally more expensive than other elastomers, which should be considered during selection.

Nitrile rubber, also known as Buna-N, is one of the most commonly used materials for industrial sealing due to its excellent resistance to petroleum-based oils and fuels. It offers good abrasion resistance and maintains mechanical integrity under dynamic stress, making it suitable for hydraulic systems, fuel lines, and pneumatic equipment. Nitrile performs well in temperature ranges from -30°C to 120°C (-22°F to 248°F), with performance varying based on acrylonitrile content. While it is less effective in ozone and weathering resistance compared to other materials, its cost-effectiveness and broad compatibility with lubricants and solvents make it a preferred choice for general-purpose applications.

Silicone rubber provides outstanding thermal stability across a wide temperature range, typically from -60°C to 200°C (-76°F to 392°F), with short-term exposure tolerance even higher. It exhibits excellent resistance to ozone, UV radiation, and weathering, making it ideal for outdoor and high-temperature environments. Additionally, silicone is inherently biocompatible and meets many food-grade and medical standards. However, it has relatively low tensile strength and poor resistance to petroleum-based fluids, limiting its use in high-pressure or oil-exposed mechanical systems.

The following table summarizes key performance characteristics of these materials to guide optimal selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Temperature Range (°F) | -4 to 446 | -22 to 248 | -76 to 392 |

| Fuel & Oil Resistance | Excellent | Excellent | Poor |

| Chemical Resistance | Excellent | Good | Fair |

| Ozone & Weathering | Excellent | Fair | Excellent |

| Tensile Strength | High | High | Moderate |

| Compression Set Resistance | Excellent | Good | Good |

| Cost Level | High | Low to Medium | Medium |

Selecting the appropriate material requires a comprehensive understanding of operational conditions. Our engineering team at Suzhou Baoshida Trading Co., Ltd. supports OEMs with material validation, custom formulations, and precision molding to ensure optimal seal performance and compliance with international standards.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Washers for Demanding Applications

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber washers that meet exacting industrial performance standards through integrated material science and precision manufacturing. Our core strength lies in the synergy between dedicated Mold Engineering and Rubber Formulation disciplines, ensuring every component achieves optimal functionality, durability, and cost efficiency. With five specialized Mold Engineers and two advanced Formula Engineers on staff, we control critical variables from molecular composition to cavity geometry, eliminating interface gaps common in outsourced development. This vertical expertise enables rapid iteration of complex washer designs—including custom geometries, multi-lip seals, and bonded metal-rubber hybrids—while maintaining strict adherence to ISO 9001 protocols.

Our Formula Engineers specialize in tailoring elastomer compounds to specific operational demands, manipulating polymer backbone structures, filler systems, and curing kinetics to achieve precise balance between compression set resistance, chemical resilience, and dynamic sealing force. This capability is essential for washers exposed to automotive fluids, industrial hydraulics, or extreme temperature cycling. Concurrently, our Mold Engineering team utilizes 3D flow simulation and cavity pressure monitoring to optimize gate placement, venting, and cooling channels, ensuring zero flash, uniform density, and dimensional stability within ±0.05mm tolerance bands. This dual-engineering approach prevents costly field failures caused by material-mold mismatch, such as compound degradation during injection or post-molding shrinkage deviations.

For OEM partners, we provide full technical collaboration from concept validation through production ramp. Our engineers conduct joint Design for Manufacturability (DFM) reviews, material suitability assessments against fluid exposure matrices, and accelerated life testing per SAE or ASTM standards. This proactive engagement reduces time-to-market by resolving interference risks and compound limitations during prototyping. Below details key performance parameters achievable through our engineered solutions:

| Property | Typical Range | Test Standard | Significance for Washer Performance |

|---|---|---|---|

| Hardness (Shore A) | 40–90 | ASTM D2240 | Controls sealing force and compression recovery |

| Temperature Range | -50°C to +250°C | ASTM D573 | Ensures stability in extreme thermal cycles |

| Compression Set (22h/70°C) | ≤15% | ASTM D395 | Critical for long-term sealing integrity |

| Tensile Strength | 8–25 MPa | ASTM D412 | Resists extrusion under high load |

| Fluid Resistance (IRMOG) | Grade A-B per ASTM D2000 | ASTM D2000 | Compatibility with oils, fuels, coolants |

| Dimensional Tolerance | ±0.05 mm (critical features) | ISO 3302 | Ensures assembly fit and consistent torque |

OEM integration extends beyond component supply. We implement client-specific material traceability systems, real-time SPC data sharing, and co-developed failure mode analysis protocols. This level of technical partnership ensures washers perform predictably within final assemblies, reducing warranty claims and enhancing end-product reliability. Suzhou Baoshida’s engineering framework transforms rubber washers from passive spacers into active, engineered sealing elements—proven across automotive powertrain, aerospace fluid systems, and heavy machinery applications where failure is not an option.

Customization Process

Drawing Analysis

The customization process for precision rubber washers begins with a comprehensive drawing analysis. At Suzhou Baoshida Trading Co., Ltd., engineering evaluation of client-provided technical drawings is conducted to verify dimensional accuracy, tolerance specifications, and functional requirements. Critical parameters such as inner diameter (ID), outer diameter (OD), thickness, and groove compatibility are cross-referenced against industry standards and application conditions. Our team assesses geometric complexity, potential molding challenges, and material deformation risks under operational stress. This stage ensures that design intent aligns with manufacturability, preventing downstream production inefficiencies. Clients are provided with a detailed Design for Manufacturability (DFM) report, including suggested modifications to optimize performance and reduce tooling wear.

Formulation Development

Following drawing validation, the rubber formulation is engineered to meet the specific environmental and mechanical demands of the application. Our laboratory utilizes ASTM and ISO-compliant testing protocols to develop elastomer compounds tailored for temperature resistance, chemical exposure, compression set, and tensile strength. Common base polymers include NBR (nitrile butadiene rubber), EPDM (ethylene propylene diene monomer), silicone (VMQ), and FKM (fluoroelastomer), selected based on fluid compatibility and service temperature range. Additives such as reinforcing fillers, antioxidants, and processing aids are precisely blended to achieve target hardness (Shore A), elasticity, and durability. Each formulation is documented under a unique compound code and subjected to preliminary cure testing to validate scorch time and optimal molding parameters.

Prototyping and Validation

A low-volume prototype run is executed using precision compression or transfer molding techniques. Prototypes are manufactured with production-intent tooling to ensure dimensional fidelity. Each sample undergoes rigorous inspection for conformance to drawing specifications, including metrology via optical comparators and micrometer measurements. Functional testing may include compression deflection analysis, leak testing under simulated operating conditions, and accelerated aging per ASTM D573. Client feedback is integrated at this stage, allowing for iterative refinement of both geometry and material properties. Prototype approval signifies readiness for scale-up.

Mass Production and Quality Assurance

Upon final sign-off, the project transitions to mass production. Automated molding lines operate under strict process controls, with real-time monitoring of temperature, pressure, and cure time. In-process quality checks are conducted at defined intervals, and final lots are inspected per ANSI/ASQ Z1.4 sampling standards. All batches are traceable through material lot numbers and production timestamps. Packaging is customized to prevent deformation during transit, with options for vacuum sealing or tray packing.

The following table outlines typical performance specifications for custom rubber washers based on common elastomer types:

| Property | NBR | EPDM | Silicone (VMQ) | FKM |

|---|---|---|---|---|

| Hardness Range (Shore A) | 50–90 | 45–85 | 30–80 | 60–90 |

| Temperature Range (°C) | -30 to +100 | -50 to +150 | -60 to +200 | -20 to +200 |

| Fluid Resistance | Oil, fuel, aliphatic hydrocarbons | Water, steam, polar solvents | Low chemical resistance | Aromatic hydrocarbons, acids, fuels |

| Compression Set (22h, 100°C) | ≤25% | ≤30% | ≤20% | ≤20% |

| Tensile Strength (MPa) | 10–20 | 8–16 | 5–10 | 10–18 |

Contact Engineering Team

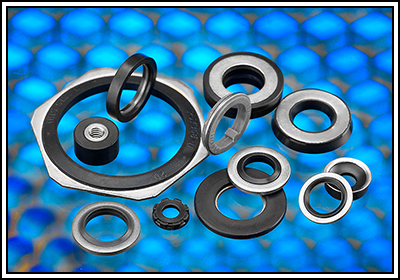

Precision Hardware Washers: Engineered for Demanding Industrial Applications

Suzhou Baoshida Trading Co., Ltd. delivers mission-critical hardware washers engineered for extreme operational environments. Our precision rubber seals mitigate vibration, prevent leakage, and ensure structural integrity across aerospace, automotive, and heavy machinery sectors. Unlike generic alternatives, our formulations prioritize long-term performance under dynamic stress, thermal cycling, and chemical exposure. Material science drives every specification—each washer undergoes rigorous validation for compression set resistance, extrusion tolerance, and fatigue life. This commitment to empirical validation ensures your assemblies maintain reliability where failure is not an option.

Technical Specifications for Standard Hardware Washers

| Property | Test Method | Value Range | Industrial Significance |

|---|---|---|---|

| Durometer (Shore A) | ASTM D2240 | 50–90 ±5 | Optimized load distribution |

| Tensile Strength | ASTM D412 | 8–22 MPa | Resists mechanical tearing |

| Compression Set (22h/70°C) | ASTM D395 | ≤25% | Maintains sealing force over time |

| Temperature Range | ISO 188 | -50°C to +250°C | Stable in cryogenic/high-heat systems |

| Fluid Resistance | ASTM D471 | Excellent (Per ASTM D2000) | Withstands oils, fuels, coolants |

| Tolerance Control | ISO 3301 | ±0.05mm | Ensures consistent assembly fit |

Customization is not an add-on—it is foundational to our engineering process. We collaborate with OEM design teams to refine compounds for specific extrusion gaps, dynamic loads, or regulatory frameworks (e.g., FDA 21 CFR, ISO 10993). Our laboratory validates formulations against your exact operational parameters, including accelerated aging tests simulating 10+ years of service in 30 days. This eliminates guesswork during prototyping and reduces time-to-market for complex assemblies. For applications requiring non-standard geometries or multi-material bonding, our tooling division achieves micron-level precision in secondary operations.

Contacting Suzhou Baoshida initiates a technical dialogue—not a sales transaction. Mr. Boyce, our dedicated OEM Engineering Manager, possesses 14 years of experience solving sealing challenges in Tier-1 supply chains. He will review your application’s stress points, environmental variables, and lifecycle requirements to propose data-backed solutions. Whether you face micro-extrusion in hydraulic manifolds or ozone degradation in outdoor equipment, our team provides actionable insights before quoting a single part.

Initiate Your Technical Partnership Today

Reach Mr. Boyce directly at [email protected] to discuss material compatibility testing, DFM optimization, or rapid prototyping. Include your application’s pressure range, media exposure, and failure mode history for a targeted engineering assessment. We respond to technical inquiries within 4 business hours with actionable data—not generic brochures. Suzhou Baoshida exists to solve sealing challenges others deem unsolvable; let our compound library and finite element analysis capabilities secure your next-generation design. Your reliability starts with a scientifically validated washer.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).