Technical Contents

Engineering Guide: Heater Gasket Material

Engineering Insight Heater Gasket Material Selection Criticality

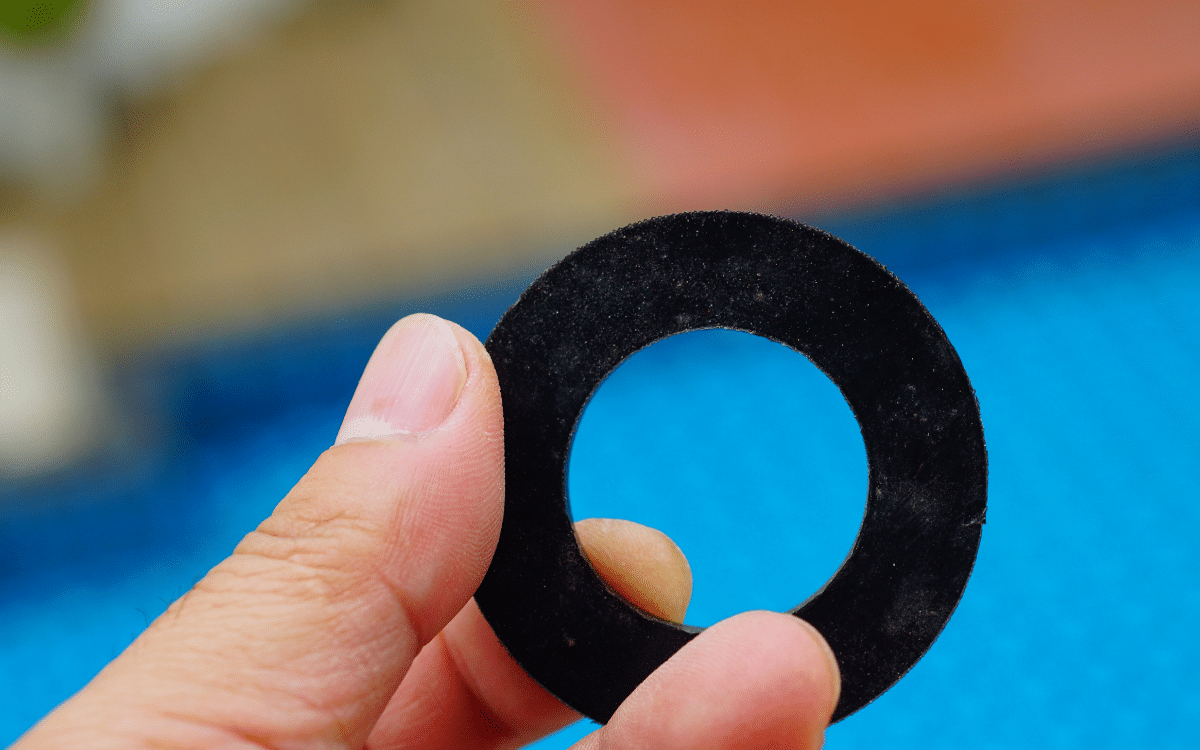

Material selection for heater gasket applications transcends basic dimensional fit; it is the fundamental determinant of operational reliability, safety, and lifecycle cost in thermal management systems. Off-the-shelf rubber gaskets frequently fail prematurely in these demanding environments due to inadequate engineering for the specific confluence of thermal, chemical, and mechanical stresses inherent to heater operation. Generic compounds, often formulated for general sealing or lower-temperature applications, lack the tailored polymer architecture and additive systems required to withstand sustained high temperatures, aggressive thermal cycling, and exposure to process media or combustion byproducts. This mismatch manifests as catastrophic failures including hardening, cracking, excessive compression set, extrusion, or chemical degradation, leading to costly downtime, safety hazards, and warranty liabilities. The core issue lies in the assumption that all elastomers behave similarly under thermal load; reality dictates that molecular stability, crosslink density, and filler compatibility are non-negotiable parameters requiring precise optimization.

Generic materials typically fail due to premature compression set under thermal cycling, chemical degradation from process fluids or oxidation byproducts, and insufficient thermal stability at operational peaks. For instance, standard nitrile rubber (NBR) may function adequately at 120°C but rapidly degrades beyond 150°C, losing resilience and seal integrity. Similarly, many standard EPDM formulations exhibit poor resistance to certain oils or amines encountered in heater systems, leading to swelling and loss of mechanical properties. Silicone, while thermally capable, often suffers from poor tear strength and compression set resistance under prolonged high-load conditions common in heater flanges. These failures are not random but predictable outcomes of using materials not engineered for the specific thermal profile, pressure dynamics, and chemical environment of the application. The consequence is a false economy where initial cost savings are obliterated by repeated maintenance, production stoppages, and potential equipment damage.

Material performance must be evaluated against the precise operational envelope. The following table highlights critical differentiators between common elastomer families in heater gasket service:

| Material Type | Max Continuous Temp (°C) | Compression Set Resistance (22h/150°C) | Chemical Resistance (Key Concerns) | Common Failure Modes in Heaters |

|---|---|---|---|---|

| Standard NBR | 120-135 | Poor to Moderate | Poor: Oils, ozone, heat | Hardening, cracking, loss of seal force |

| Standard EPDM | 150-175 | Moderate | Poor: Hydrocarbons, steam amines | Swelling, extrusion, reduced resilience |

| Standard Silicone | 200-230 | Poor | Moderate: Water, some chemicals | Tear, permanent deformation, creep |

| Engineered FKM | 230-250+ | Excellent | Excellent: Oils, fuels, acids | Cost-driven omission, not performance |

Suzhou Baoshida Trading Co., Ltd. addresses this critical gap through precision rubber compound engineering. We reject the one-size-fits-all approach, instead developing custom formulations—often based on advanced FKM, specialty silicone, or peroxide-cured EPDM variants—specifically validated against the customer’s thermal cycle profile, media exposure, and mechanical load requirements. Our OEM collaboration process integrates material science with application physics, ensuring the gasket maintains elastic recovery, chemical inertness, and dimensional stability throughout its intended service life. This engineered solution eliminates the hidden costs of off-the-shelf failures, delivering predictable performance and maximizing system uptime in demanding thermal applications. Material selection is not a commodity decision; it is the cornerstone of reliable heater operation.

Material Specifications

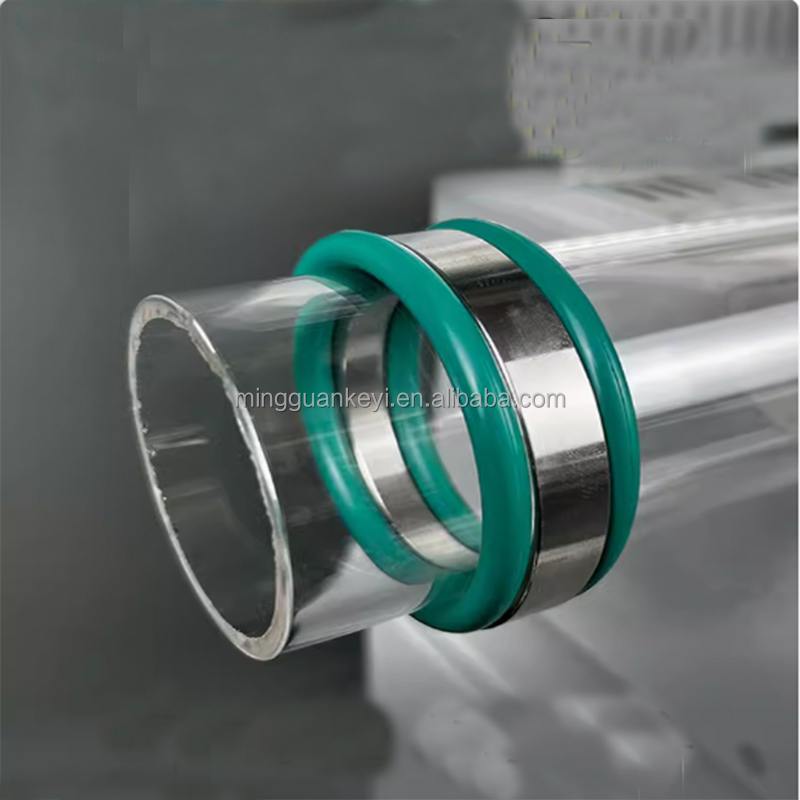

Material selection for heater gasket applications is critical to ensuring long-term performance under thermal cycling, pressure differentials, and exposure to oils, fuels, or other process media. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered for industrial heating systems, where reliability, dimensional stability, and chemical resistance are paramount. Our core materials—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—each offer distinct advantages depending on the operational environment. Understanding the physical and chemical properties of these elastomers enables optimal gasket performance and extended service life.

Viton is a fluorocarbon-based rubber known for exceptional resistance to high temperatures, oxidation, and a broad range of aggressive chemicals, including hydrocarbons, acids, and fuels. With a continuous service temperature range up to 230°C, Viton is ideal for high-heat environments such as industrial ovens, combustion chambers, and exhaust systems. Its low compression set ensures long-term sealing integrity under sustained load, making it a preferred choice for critical sealing applications where failure is not an option. However, Viton has limited flexibility at low temperatures and higher material cost compared to alternatives.

Nitrile rubber, or Buna-N, offers excellent resistance to oils, greases, and aliphatic hydrocarbons, making it widely used in hydraulic and fuel-handling systems. It performs reliably within a temperature range of -30°C to 120°C, with some formulations extending to 150°C for short durations. Nitrile gaskets provide good abrasion resistance and mechanical strength, suitable for dynamic or semi-dynamic sealing scenarios. While cost-effective and readily available, Nitrile exhibits poor resistance to ozone, UV radiation, and polar solvents, limiting its use in outdoor or chemically aggressive environments.

Silicone rubber excels in extreme temperature applications, with a service range from -60°C to 200°C, and short-term exposure capability up to 300°C. It maintains flexibility at low temperatures and offers good electrical insulation properties. Silicone is resistant to ozone, UV, and weathering, making it suitable for outdoor or cleanroom environments. However, it has lower tensile strength and abrasion resistance compared to Viton and Nitrile, and is not recommended for applications involving concentrated acids or hydrocarbons.

The following table summarizes key performance characteristics of these materials for heater gasket applications:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 (150 peak) | -60 to 200 (300 peak) |

| Tensile Strength (MPa) | 15–20 | 10–20 | 5–8 |

| Elongation at Break (%) | 150–250 | 200–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 40–90 | 30–80 |

| Compression Set (22 hrs, 150°C) | Low | Moderate | Low to Moderate |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Poor | Excellent |

| Electrical Insulation | Good | Fair | Excellent |

Selection of the appropriate material must balance thermal exposure, chemical compatibility, mechanical loading, and cost. Suzhou Baoshida Trading Co., Ltd. provides customized gasket solutions with precise material formulation and dimensional tolerances to meet OEM specifications.

Manufacturing Capabilities

Engineering Capability: Precision Material Science for Heater Gasket Performance

Suzhou Baoshida Trading Co., Ltd. delivers unparalleled reliability in heater gasket manufacturing through a dedicated engineering core integrating advanced rubber formulation science with precision mold design. Our technical foundation rests on seven specialized engineers: five focused mold design and tooling optimization, and two dedicated rubber formula engineers. This dual-discipline structure ensures every gasket component is engineered holistically, from molecular compound composition to final cavity geometry, specifically addressing the demanding thermal cycling, chemical exposure, and sealing force requirements inherent in industrial and appliance heater applications.

Our formula engineers possess deep expertise in elastomer chemistry, specializing in tailoring compounds for extreme temperature stability and long-term compression set resistance – critical failure points in heater gaskets. They systematically modify base polymers (EPDM, FKM, Silicone), cure systems, and functional fillers to achieve target properties. For instance, optimizing peroxide cure systems in high-temperature EPDM formulations reduces compression set by up to 15% compared to standard sulfur-cured equivalents at 200°C, directly extending gasket service life. Similarly, our silicone formulations incorporate specialized thermal stabilizers to maintain flexibility and sealing force integrity beyond 300°C continuous operation, preventing hardening and cracking under thermal stress. This granular control over material behavior is non-negotiable for preventing heater leaks and failures.

Mold engineers translate these precise material requirements into robust, high-yield production tooling. They utilize advanced CAD/CAM and mold flow simulation to ensure optimal material distribution, minimize flash, and control critical dimensions like thickness tolerance (±0.05mm achievable) and groove geometry. This synergy guarantees that the engineered material properties are fully realized in the final part, eliminating discrepancies between lab-tested compound performance and production reality. Consistent part geometry directly impacts sealing uniformity and thermal management at the heater interface.

The following table summarizes key performance characteristics of our standard heater gasket material formulations, validated per ASTM/ISO standards:

| Material Type | Continuous Operating Temp (°C) | Compression Set (200°C/72h) % | Thermal Conductivity (W/m·K) | Key Application Focus |

|---|---|---|---|---|

| High-Temp EPDM | 150 | ≤ 25 | 0.20 – 0.25 | Water heaters, HVAC heat exchangers |

| Standard FKM (Viton® Type) | 200 | ≤ 18 | 0.18 – 0.22 | Industrial process heaters, oil/gas |

| High-Purity Silicone | 250 | ≤ 20 | 0.15 – 0.20 | Medical/Pharma heating, semiconductor |

| Custom Peroxide-EPDM | 175 | ≤ 22 | 0.22 – 0.27 | Enhanced longevity in cycling applications |

Our OEM capability is engineered for seamless integration into client supply chains. We manage the entire process from initial thermal sealing requirement analysis through compound development, mold fabrication (using hardened P20 or H13 steel), SPC-controlled production, and final validation testing. Clients benefit from full technical ownership transfer – including detailed material certifications (ASTM D2000), mold design files, and process documentation – ensuring continuity and IP protection. We excel at rapid prototyping using client-specific heater interface data to validate sealing performance before full-scale tooling, significantly de-risking new product introductions. This end-to-end engineering control, grounded in material science and precision manufacturing, is how Suzhou Baoshida guarantees thermal sealing integrity where failure is not an option.

Customization Process

Technical Guide: Custom Heater Gasket Material Development Process

At Suzhou Baoshida Trading Co., Ltd., our engineering-driven approach ensures that every custom heater gasket material is optimized for performance, durability, and compatibility with demanding thermal and mechanical environments. Our systematic customization process begins with precision drawing analysis and culminates in scalable, high-fidelity mass production.

The process initiates with Drawing Analysis, where our rubber formula engineers meticulously review OEM-provided technical drawings and application parameters. Critical dimensions, sealing surfaces, flange load tolerances, and thermal exposure zones are evaluated. We assess compression set requirements, operating temperature ranges, and potential chemical exposure to determine baseline material behavior. This phase ensures dimensional accuracy and functional alignment with the end-use environment.

Following drawing validation, we proceed to Formulation Design. Our team selects base polymer systems—commonly silicone (VMQ), fluorosilicone (FVMQ), EPDM, or FKM—based on thermal stability, chemical resistance, and mechanical resilience. For heater gaskets, long-term performance at elevated temperatures (up to 300°C) is paramount. We tailor compound formulations by adjusting filler types (e.g., silica, mica), crosslinking systems (peroxide vs. platinum cure), and additives for improved thermal conductivity or electrical insulation. Each formulation is designed to maintain sealing integrity under repeated thermal cycling and mechanical stress.

Once the formulation is finalized, we move to Prototyping. Using precision die-cutting, water-jet cutting, or molded processes, we produce prototype gaskets from the engineered compound. Prototypes undergo rigorous in-house testing, including compression deflection analysis, thermal aging per ASTM D573, and leak testing under simulated operational conditions. Dimensional verification is performed using coordinate measuring machines (CMM) to ensure conformance to drawing tolerances (±0.1 mm typical). Feedback from testing is integrated into final material or design refinements.

Upon customer approval, we transition to Mass Production. Our ISO-certified manufacturing lines ensure batch-to-batch consistency through strict process controls and real-time QC monitoring. All production batches are traceable, with full material certifications (RoHS, REACH, FDA if applicable). We support volumes from 1,000 to over 500,000 units per month, with automated packaging options for direct OEM line integration.

The table below summarizes typical performance specifications for our custom heater gasket materials:

| Property | Silicone (VMQ) | Fluorosilicone (FVMQ) | FKM (Viton®) | EPDM |

|---|---|---|---|---|

| Temperature Range (°C) | -60 to 260 | -60 to 230 | -20 to 250 | -50 to 150 |

| Compression Set (22 hrs, 177°C) | ≤20% | ≤25% | ≤15% | ≤20% |

| Tensile Strength (MPa) | 6–9 | 5–8 | 10–15 | 7–10 |

| Hardness (Shore A) | 50–80 | 55–80 | 60–90 | 50–80 |

| Fluid Resistance | Good (water, steam) | Excellent (fuels, oils) | Outstanding (oils, acids) | Excellent (water, glycols) |

Every stage of our customization workflow is engineered for precision, repeatability, and compliance with industrial sealing standards. Suzhou Baoshida delivers not just materials—but engineered sealing solutions.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Heater Gasket Material Solutions

Selecting the optimal heater gasket material is a critical engineering decision impacting thermal efficiency, system longevity, and operational safety. Generic solutions often fail under the demanding conditions of industrial heating applications, leading to premature seal failure, energy loss, and costly downtime. Suzhou Baoshida Trading Co., Ltd. specializes in the formulation and manufacturing of high-performance rubber compounds engineered specifically for heater gasket applications. Our expertise lies in translating complex thermal and mechanical requirements into reliable sealing performance through advanced polymer science and rigorous OEM collaboration. We understand that factors such as continuous operating temperature, thermal cycling resistance, chemical exposure from heating media, compression set under load, and extrusion resistance are non-negotiable parameters for success. Our engineered elastomers are validated through stringent in-house testing protocols simulating real-world industrial environments, ensuring your heating systems maintain integrity and efficiency throughout their operational lifecycle.

The following table represents key performance characteristics achievable with our specialized heater gasket formulations. These values are indicative of our standard high-temperature compound families; final specifications are tailored to your exact application requirements through collaborative development.

| Property | Test Method | Typical Value Range (FKM/FFKM Focus) | Typical Value Range (High-Grade EPDM) |

|---|---|---|---|

| Continuous Service Temp | ASTM D2240 | -25°C to +250°C (Std FKM) | -50°C to +150°C |

| Up to +325°C (Specialty FFKM) | |||

| Compression Set (70h, 150°C) | ASTM D395 B | ≤ 25% | ≤ 30% |

| Tensile Strength | ASTM D412 | ≥ 10 MPa | ≥ 9 MPa |

| Hardness (Shore A) | ASTM D2240 | 60 – 80 | 60 – 80 |

| Fluid Resistance (IRM 903) | ASTM D471 | Volume Swell ≤ 15% | Volume Swell ≤ 25% |

| Thermal Conductivity | ASTM E1461 | 0.15 – 0.25 W/m·K | 0.15 – 0.20 W/m·K |

Partnering with Suzhou Baoshida means engaging directly with rubber formulation engineers who possess deep expertise in the thermodynamics of sealing interfaces. We move beyond off-the-shelf materials to develop compounds that address your specific thermal gradients, pressure profiles, and environmental exposures. Our process begins with a detailed technical consultation to map your application’s critical parameters, followed by targeted compound development, prototype validation under simulated conditions, and seamless scale-up to high-volume OEM production. This collaborative engineering approach minimizes risk and accelerates time-to-market for your next-generation heating systems.

Initiate the process for a precision-engineered heater gasket solution by contacting Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineering lead. Mr. Boyce possesses over 12 years of experience in solving complex sealing challenges for industrial thermal management systems. He will facilitate a direct technical dialogue between your engineering team and our R&D specialists to ensure the proposed material solution aligns precisely with your performance criteria and manufacturing constraints. Provide your application details, including operating temperature range, media exposure, pressure conditions, flange geometry, and target service life. Mr. Boyce will coordinate a comprehensive technical review and propose a tailored compound development pathway with clear validation milestones.

Contact Mr. Boyce directly at [email protected] to schedule your confidential engineering consultation. Include your specific heater gasket requirements and project timeline in your initial communication to enable the most productive discussion. Our team commits to responding to all technical inquiries within 24 business hours. Suzhou Baoshida Trading Co., Ltd. is positioned to be your strategic partner in delivering heater gasket materials that exceed the demanding standards of modern industrial equipment, ensuring reliability, efficiency, and uncompromised safety. Let us apply our material science expertise to solve your most challenging thermal sealing applications.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).