Technical Contents

Engineering Guide: Heavy Duty Metal O Rings

Engineering Insight: The Critical Role of Material Selection in Heavy Duty Metal O-Rings

In the domain of high-performance sealing solutions, heavy duty metal O-rings represent the pinnacle of reliability under extreme operational conditions. These components are engineered to maintain integrity in environments characterized by ultra-high pressures, extreme temperatures, and aggressive chemical exposure—conditions where conventional elastomeric seals fail catastrophically. However, the performance of a metal O-ring is not inherent to its geometry alone; it is fundamentally dictated by the precision of material selection. Off-the-shelf solutions, while cost-attractive, often fail to meet the nuanced demands of industrial applications due to generic material profiles that overlook critical service parameters.

Material selection governs thermal stability, corrosion resistance, mechanical strength, and compatibility with process media. For instance, a metal O-ring exposed to hydrogen sulfide (H₂S) in oil and gas downhole tools requires a nickel-based superalloy such as Inconel 718 to resist sulfide stress cracking. Using a standard 316 stainless steel ring in this environment, even if dimensionally identical, results in rapid embrittlement and seal failure. Similarly, in aerospace applications involving cryogenic fluids, the coefficient of thermal expansion (CTE) must be tightly matched between the O-ring and mating flange. A mismatch can induce micro-gapping upon thermal cycling, leading to leakage paths undetectable during static testing.

Another frequent cause of failure in off-the-shelf metal O-rings is the absence of surface treatment optimization. In high-vacuum semiconductor processing, even trace outgassing from improperly passivated surfaces can contaminate the reaction chamber. Electropolishing or vacuum annealing is often required to achieve the necessary surface purity—steps typically omitted in mass-produced variants.

Furthermore, mechanical properties such as yield strength and creep resistance must align with the operational load profile. In turbine engine sealing, sustained exposure to temperatures exceeding 1,000°F demands materials like Hastelloy X, which retains structural integrity where conventional alloys deform plastically over time.

Custom-engineered metal O-rings from Suzhou Baoshida Trading Co., Ltd. are developed through application-specific material mapping, ensuring compatibility with pressure, temperature, and media conditions. Each solution undergoes rigorous finite element analysis (FEA) and material compatibility testing before deployment.

The following table outlines key material options and their performance characteristics for heavy duty metal O-rings:

| Material | Max Continuous Temp (°C) | Corrosion Resistance | Typical Applications | Key Advantage |

|---|---|---|---|---|

| Inconel 718 | 700 | Excellent (oxidizing & reducing) | Aerospace, Oil & Gas | High strength at elevated temps |

| 316L Stainless Steel | 870 | Good (moderate chlorides) | Chemical Processing, Marine | Cost-effective, weldable |

| Hastelloy C-276 | 1000 | Exceptional (halogens, acids) | Petrochemical, Waste Treatment | Resists pitting & stress corrosion |

| Titanium Grade 2 | 315 | Excellent (chlorides, seawater) | Offshore, Desalination | High strength-to-density ratio |

| Monel 400 | 500 | Outstanding (alkaline, seawater) | Marine, Cryogenics | Resists caustic environments |

Material selection is not a secondary consideration—it is the cornerstone of sealing reliability. At Suzhou Baoshida, we prioritize material science rigor to ensure every heavy duty metal O-ring performs as engineered, not as assumed.

Material Specifications

Material Specifications for Heavy Duty Metal O-Rings

Selection of elastomer compounds for heavy duty metal O-rings demands rigorous evaluation of operational parameters. Suzhou Baoshida Trading Co., Ltd. engineers these seals to withstand extreme pressure, temperature fluctuations, and aggressive chemical exposure inherent in aerospace, oil and gas, and industrial hydraulic systems. Material choice directly impacts seal longevity, leakage prevention, and system safety. Viton, Nitrile, and Silicone represent industry-standard polymers, each optimized for distinct environmental challenges. Understanding their precise chemical and physical properties ensures optimal performance under specified service conditions.

Viton (FKM) fluorocarbon rubber delivers exceptional resistance to high temperatures and complex chemical media. Its molecular structure provides stability in environments ranging from -20°C to 230°C continuous service, with short-term excursions up to 300°C. Viton exhibits superior resistance to jet fuels, hydraulic fluids, aromatics, and acids, making it indispensable for critical aerospace and downhole applications. Typical tensile strength spans 15–20 MPa per ASTM D412, with hardness grades of 70–90 Shore A. Crucially, Viton maintains low compression set below 20% after 70 hours at 200°C, preventing seal relaxation under sustained load.

Nitrile (NBR) butadiene-acrylonitrile rubber offers an optimal balance of cost efficiency and performance for petroleum-based systems. With a standard operating range of -30°C to 120°C (extended formulations reach 150°C), NBR excels in resistance to aliphatic hydrocarbons, lubricants, and water. Its acrylonitrile content (typically 40–50%) directly correlates with oil resistance and low-temperature flexibility. Standard grades achieve 15–25 MPa tensile strength and 30–60% elongation, with hardness values of 60–90 Shore A. While vulnerable to ozone and polar solvents, NBR remains the dominant choice for hydraulic and pneumatic seals due to its abrasion resistance and extrusion tolerance under 5000 psi.

Silicone (VMQ) polymers provide unmatched flexibility across extreme temperature gradients. Serviceable from -60°C to 200°C continuous, silicone retains elasticity in cryogenic conditions where other elastomers fracture. It demonstrates excellent resistance to oxygen, ozone, and ionizing radiation but limited compatibility with hydrocarbons and fuels. Typical tensile strength is 5–8 MPa with elongation exceeding 300%, though compression set performance (25–40% after 22 hrs at 150°C) necessitates careful design consideration. Silicone’s biocompatibility and electrical insulation properties make it ideal for semiconductor manufacturing and medical device applications.

The following table details critical comparative specifications for engineering validation.

| Material | Temperature Range (°C) | Tensile Strength (MPa) | Elongation (%) | Hardness (Shore A) | Key Chemical Resistances |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to 230 | 15–20 | 150–300 | 70–90 | Jet fuels, hydraulic fluids, acids, aromatics |

| Nitrile (NBR) | -30 to 120 (150 ext.) | 15–25 | 200–400 | 60–90 | Aliphatic hydrocarbons, lubricants, water |

| Silicone (VMQ) | -60 to 200 | 5–8 | 300–600 | 40–80 | Oxygen, ozone, radiation, steam |

Material selection must align with fluid compatibility charts, pressure-temperature curves, and dynamic stress analysis. Suzhou Baoshida provides OEMs with compound-specific ASTM D2000 callouts and custom formulation data to mitigate field failure risks. Consult our engineering team for application-specific validation testing protocols.

Manufacturing Capabilities

Engineering Capability: Precision Development for Heavy Duty Metal O-Rings

At Suzhou Baoshida Trading Co., Ltd., our engineering capability in the domain of precision rubber seals—particularly heavy duty metal O-rings—is anchored in deep technical expertise and a vertically integrated development process. With a dedicated team comprising five experienced mould engineers and two specialized rubber formula engineers, we maintain full control over the design, material formulation, prototyping, and production phases. This integrated approach ensures that every component meets the rigorous performance demands of industrial applications involving extreme temperatures, pressures, and chemical exposure.

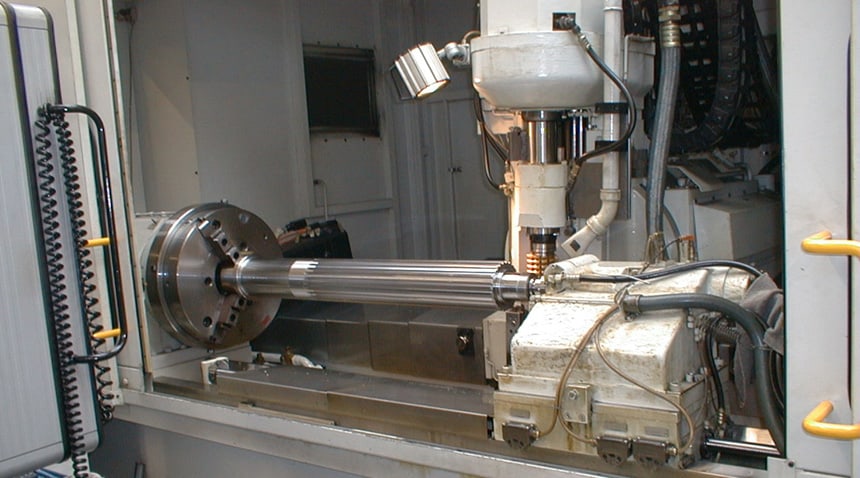

Our mould engineers possess over a decade of cumulative experience in precision tooling for metal-elastomer composite seals. They utilize advanced CAD/CAM software, including SolidWorks and AutoCAD, to develop high-tolerance moulds that ensure consistent geometry and dimensional accuracy. Finite Element Analysis (FEA) is routinely applied during the design stage to simulate compression behavior, stress distribution, and sealing performance under operational loads. This predictive modeling reduces prototyping cycles and accelerates time-to-market without compromising reliability.

Complementing our tooling expertise, our rubber formula engineers specialize in developing custom elastomer compounds tailored to specific environmental conditions. Whether the application requires resistance to high-temperature steam, aggressive hydrocarbons, or corrosive chemicals, we formulate compounds using FKM, FFKM, ACM, or specialty silicone systems, reinforced with controlled filler dispersion and optimized cure kinetics. These formulations are validated through accelerated aging tests, compression set analysis, and dynamic sealing trials to ensure long-term durability.

Our OEM capabilities are structured to support clients from concept to mass production. We offer complete design for manufacturing (DFM) feedback, material selection guidance, and rapid prototyping using in-house CNC machining and rubber curing facilities. Clients benefit from iterative testing and validation, with full traceability and documentation aligned with ISO 9001 standards. This collaborative engineering model enables us to deliver application-specific metal O-rings that outperform generic alternatives in critical sealing environments.

The following table outlines key technical specifications achievable through our engineering and manufacturing platform:

| Parameter | Capability Range |

|---|---|

| Inner Diameter (ID) | 10 mm – 500 mm |

| Cross-Section Tolerance | ±0.05 mm (Rubber), ±0.03 mm (Metal Core) |

| Operating Temperature Range | -40°C to +320°C (FKM), up to +350°C (FFKM) |

| Hardness (Shore A) | 60–90 ±5 |

| Surface Finish (Ra) | ≤0.8 µm (Metal Core) |

| Compression Set (ASTM D395) | ≤15% @ 200°C, 70 hrs |

| Mould Lead Time | 7–14 days (prototype) |

| Production Cycle | 15–25 days (batch, 1,000 pcs) |

This combination of human expertise, technical infrastructure, and OEM flexibility positions Suzhou Baoshida as a trusted engineering partner for mission-critical sealing solutions in aerospace, oil & gas, semiconductor, and high-performance automotive sectors.

Customization Process

Customization Process for Heavy Duty Metal O Rings

At Suzhou Baoshida Trading Co., Ltd., our customization process for heavy duty metal o rings integrates precision engineering with rigorous material science to ensure optimal performance in extreme industrial environments. This structured workflow guarantees compliance with OEM specifications while mitigating field failure risks.

Drawing Analysis

Initial engagement begins with comprehensive GD&T review of client-provided technical drawings. We validate critical dimensions including inner diameter tolerance (±0.05 mm), cross-section consistency, and metal core geometry against ISO 3601 standards. Concurrently, our engineering team assesses operational parameters—temperature extremes, pressure cycles, and chemical exposure—to identify potential stress points. This phase includes material compatibility mapping using ASTM D2000 guidelines, ensuring the elastomer selection aligns with fluid media such as hydraulic oils, acids, or supercritical CO₂. Non-conformities are resolved via collaborative design-for-manufacturability sessions within 72 hours.

Formulation Development

Based on operational data, our rubber formula engineers develop bespoke elastomer compounds. Standard formulations leverage FKM (Viton®) or FFKM bases for temperatures up to 327°C, but custom variants incorporate nano-silica reinforcement for abrasion resistance or peroxide curing for low-compression-set performance. Key properties are optimized through iterative lab trials:

Shore A hardness (70–90) balanced for sealing force versus extrusion resistance

Compression set <15% after 70 hours at 200°C (ASTM D395)

Tensile strength >15 MPa with elongation >200%

Critical material specifications are formalized in the table below for client validation prior to prototyping.

| Property | Test Standard | Target Value | Industrial Significance |

|---|---|---|---|

| Temperature Range | ASTM D573 | -40°C to +327°C | Survives cryogenic to high-heat cycles |

| Pressure Rating | ISO 3601-2 | 700 bar static | Prevents extrusion in hydraulic systems |

| Media Resistance | ISO 1817 | Grade A in H1 oil | Zero swelling in aggressive fluids |

| Hardness (Shore A) | ASTM D2240 | 80 ±5 | Optimal seal interface force |

Prototyping & Validation

Pre-production prototypes undergo accelerated life testing in simulated application conditions. Five sample rings per variant are subjected to 10,000 pressure cycles at 90% of rated capacity, followed by helium leak testing per SAE AS4716. We measure dimensional stability post-exposure and analyze failure modes via SEM. Client approval requires ≤0.01 cc/min leakage rate and no core detachment. This phase typically concludes in 10–15 business days with full traceability documentation.

Mass Production

Upon prototype sign-off, production transitions to our ISO 13485-certified facility with real-time SPC monitoring. Metal cores are laser-measured at 100% frequency, while elastomer batches undergo Mooney viscosity checks (ML 1+4 @ 121°C) before molding. Each ring receives individual visual inspection per ISO 3601-3 and automated hardness validation. Final lots include full material certificates, batch-specific compression set data, and 3D scan reports for critical dimensions. Continuous improvement loops feed production data back into formulation databases, ensuring long-term reliability for high-volume OEM partnerships.

This end-to-end process—grounded in material science and industrial pragmatism—delivers metal o rings that exceed AS568 and ISO 12209 requirements while minimizing total cost of ownership for demanding applications.

Contact Engineering Team

For industrial applications demanding maximum reliability under extreme conditions, heavy duty metal O-rings represent the pinnacle of sealing technology. These precision-engineered components combine the structural integrity of metal with the sealing performance of elastomers, delivering unmatched resistance to high pressure, extreme temperatures, and aggressive chemical environments. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber and composite seals designed for aerospace, oil & gas, semiconductor manufacturing, and advanced industrial systems where failure is not an option.

Our heavy duty metal O-rings are manufactured to exacting international standards, utilizing advanced materials such as stainless steel (304, 316), Inconel, and titanium, combined with fluorocarbon (FKM), perfluoroelastomer (FFKM), or silicone (VMQ) sealing elements. This hybrid construction ensures long service life, minimal creep, and consistent sealing force across thermal cycles and dynamic loads. Whether you are sealing ultra-high vacuum chambers, hydraulic actuators, or high-temperature reactor vessels, our engineering team can configure the optimal solution for your operational parameters.

We understand that every industrial environment presents unique challenges. That’s why Suzhou Baoshida offers full customization of dimensions, materials, and surface treatments. Our quality management system adheres to ISO 9001 standards, and all critical components undergo rigorous testing for dimensional accuracy, leak rate, and material compatibility. With in-house tooling, rapid prototyping, and direct OEM partnerships, we deliver fast turnaround without compromising precision.

Below are typical specifications for our standard heavy duty metal O-ring configurations. Custom sizes and materials are available upon request.

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 10 mm – 500 mm |

| Cross-Section Diameter | 1.5 mm – 5.0 mm |

| Base Metal Materials | Stainless Steel 304, 316, Inconel 718, Titanium Grade 2 |

| Elastomer Options | FKM (Viton®), FFKM (Kalrez®, Chemraz®), Silicone (VMQ), EPDM |

| Temperature Range | -40°C to +327°C (depending on elastomer) |

| Pressure Resistance | Up to 700 bar (static), 350 bar (dynamic) |

| Surface Finish | Ra ≤ 0.4 µm (metal body) |

| Standards Compliance | ISO 3601, AS568, DIN 3869, ASTM G155 |

| Testing | Helium Leak Test (≤ 1×10⁻⁹ atm·cm³/s), Pressure Cycle Test, Material Certification |

If your application requires a sealing solution that performs under extreme thermal cycling, high mechanical stress, or corrosive exposure, Suzhou Baoshida is your trusted engineering partner. We support global clients with technical documentation, material test reports, and on-site engineering consultation.

For immediate assistance, contact Mr. Boyce, OEM Project Manager, at [email protected]. Please include your application details, required specifications, and volume expectations to receive a tailored proposal. Our team responds to all technical inquiries within 12 business hours. Partner with Suzhou Baoshida for sealing performance you can rely on—precision engineered, rigorously tested, and built for industrial excellence.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).