Technical Contents

Engineering Guide: Heavy Duty Rubber O Rings

Engineering Insight: The Critical Role of Material Selection in Heavy Duty Rubber O Rings

In industrial sealing applications, heavy duty rubber O rings are subjected to extreme conditions including high pressure, elevated temperatures, aggressive chemical exposure, and mechanical stress. While standard off-the-shelf O rings may appear to offer a cost-effective solution, their failure in demanding environments underscores a fundamental truth: material selection is not a secondary consideration—it is the cornerstone of reliable performance.

Generic O rings are typically manufactured from common elastomers such as standard nitrile (NBR) or natural rubber, designed for general-purpose use. These materials lack the resilience required in heavy-duty applications. When exposed to high temperatures or corrosive media, they degrade rapidly, leading to seal failure, equipment downtime, and potential safety hazards. The root cause often lies not in design flaws but in inappropriate material compatibility.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material selection based on application-specific parameters. For instance, fluorocarbon rubber (FKM) offers exceptional resistance to oils, fuels, and high temperatures up to 200°C, making it ideal for automotive and aerospace applications. For environments involving strong acids or halogenated hydrocarbons, perfluoroelastomers (FFKM) provide near-chemical inertness, albeit at a higher cost—justified in critical sealing systems.

Similarly, ethylene propylene diene monomer (EPDM) excels in steam and water applications but performs poorly in hydrocarbon environments. Using EPDM in an oil-lubricated system, even if pressure and temperature appear compatible, will result in rapid swelling and mechanical failure. This mismatch exemplifies why off-the-shelf solutions fail: they prioritize availability over compatibility.

Material selection also impacts compression set resistance, tensile strength, and low-temperature flexibility. A seal operating in arctic conditions requires silicone (VMQ) or hydrogenated nitrile (HNBR), which retain elasticity below -40°C. Conversely, in high-abrasion scenarios such as hydraulic cylinders, polyurethane (AU/EU) offers superior mechanical strength and wear resistance.

Below is a comparative overview of common elastomers used in heavy duty O rings:

| Material | Temperature Range (°C) | Key Chemical Resistance | Typical Applications |

|---|---|---|---|

| NBR | -30 to +100 | Oils, fuels, hydraulic fluids | General industrial hydraulics |

| FKM | -20 to +200 | Fuels, acids, steam, oxidizing agents | Aerospace, petrochemical |

| EPDM | -50 to +150 | Water, steam, alkalis, ketones | HVAC, water treatment |

| HNBR | -40 to +150 | Oils, ozone, hot water | Automotive, offshore |

| FFKM | -15 to +300 | All industrial chemicals, solvents | Semiconductor, pharmaceutical |

| AU/EU | -40 to +100 | Oils, oxygen, ozone | Pneumatics, mining equipment |

Material selection must be guided by a comprehensive understanding of the operational environment. At Suzhou Baoshida, we collaborate with OEMs and end-users to analyze fluid media, thermal cycles, pressure loads, and service life expectations—ensuring every heavy duty O ring is engineered for success, not just convenience.

Material Specifications

Material Specifications for Heavy Duty Rubber O Rings

Selection of the optimal elastomer compound is paramount for ensuring critical sealing integrity in demanding industrial applications. At Suzhou Baoshida Trading Co., Ltd., our precision-engineered heavy duty O rings utilize rigorously tested formulations of Viton (FKM), Nitrile (NBR), and Silicone (VMQ) to meet extreme operational challenges. Understanding the distinct material properties is essential for OEMs to prevent premature failure under pressure, temperature extremes, or chemical exposure. Each compound offers specific advantages dictated by its molecular structure and crosslink density, directly influencing service life and reliability in hostile environments. Performance degradation due to incompatible material selection remains a leading cause of seal failure; therefore, precise specification against application parameters is non-negotiable.

Viton (Fluoroelastomer, FKM) represents the pinnacle for severe chemical and high-temperature resistance. Our standard heavy duty Viton compounds maintain sealing integrity from -20°C to +230°C continuous service, with brief excursions to 250°C. They exhibit exceptional resistance to jet fuels, hydraulic fluids, mineral oils, aromatic hydrocarbons, and many acids. Typical tensile strength exceeds 15 MPa (ASTM D412), with elongation at break around 200%. Viton is the mandatory choice for aerospace, semiconductor manufacturing, and aggressive chemical processing where Nitrile or Silicone would rapidly deteriorate. Compression set resistance is critical at elevated temperatures; our Viton formulations achieve ≤25% compression set after 70 hours at 200°C (ASTM D395 Method B).

Nitrile (Acrylonitrile Butadiene Rubber, NBR) provides the optimal balance of cost and performance for petroleum-based fluid applications. Standard heavy duty NBR compounds operate effectively from -40°C to +120°C, with low-temperature variants reaching -50°C. Resistance to aliphatic hydrocarbons, water, hydraulic fluids, and lubricating oils is excellent, though performance degrades significantly with exposure to ozone, ketones, esters, or brake fluids. Typical tensile strength ranges from 10-20 MPa, with elongation between 250-400%. Its superior abrasion resistance and lower cost make NBR the dominant material for hydraulic systems, automotive fuel handling, and general industrial machinery where extreme temperatures or aggressive chemicals are absent.

Silicone (Polysiloxane, VMQ) excels in extreme temperature flexibility and physiological inertness. Heavy duty silicone O rings function reliably from -60°C to +200°C continuous, with specialty grades exceeding 230°C. They offer outstanding resistance to ozone, UV radiation, and oxygen aging, coupled with excellent electrical insulation properties. However, silicone possesses poor resistance to petroleum fuels, lubricants, and low-molecular-weight siloxanes, and exhibits lower tensile strength (5-8 MPa) and higher gas permeability compared to Viton or NBR. Its biocompatibility and thermal stability make it indispensable for medical devices, food processing, high-temperature lighting, and aerospace environmental control systems.

The following comparative table details critical performance specifications for standard heavy duty formulations under controlled test conditions per relevant ASTM/ISO standards.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -40 to +120 | -60 to +200 |

| Tensile Strength (MPa) | ≥ 15 | 10 – 20 | 5 – 8 |

| Elongation at Break (%) | ~200 | 250 – 400 | 300 – 600 |

| Hardness Range (Shore A) | 60 – 90 | 50 – 90 | 30 – 80 |

| Compression Set (70h) | ≤ 25% @ 200°C | ≤ 25% @ 100°C | ≤ 20% @ 200°C |

| Key Chemical Resistance | Fuels, Oils, Acids | Petroleum Oils, Water | Ozone, UV, Steam |

| Key Limitations | Ketones, Amines | Ozone, Polar Solvents | Petroleum Fuels |

OEM selection must prioritize the dominant environmental stressors. Suzhou Baoshida Trading Co., Ltd. provides comprehensive material certification and application engineering support to ensure optimal compound selection for your specific heavy duty sealing requirement, guaranteeing operational safety and longevity.

Manufacturing Capabilities

Engineering Excellence in Heavy Duty Rubber O Ring Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our reputation in the precision rubber seals industry. With a dedicated team of 5 mould engineers and 2 specialized rubber formula engineers, we deliver technically advanced, high-performance heavy duty rubber O rings tailored to the exacting demands of industrial applications. Our integrated engineering approach ensures that every component is optimized for durability, chemical resistance, and operational reliability under extreme conditions.

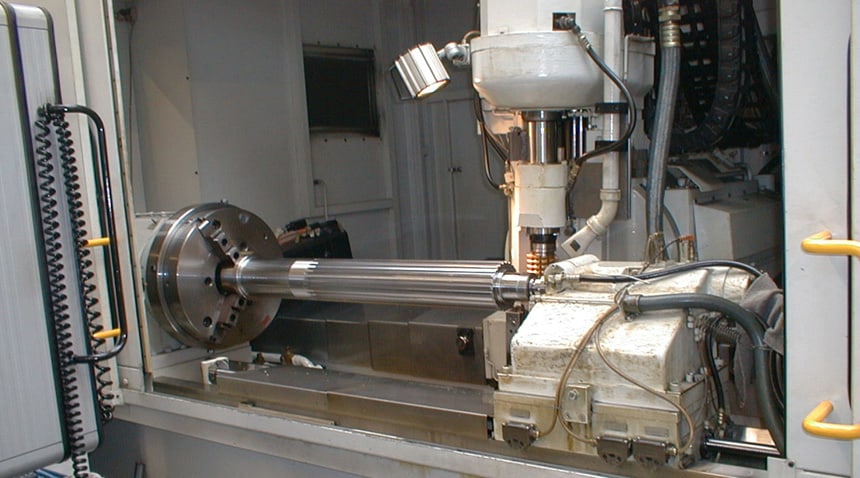

Our mould engineering team brings over 60 combined years of experience in precision tooling design and manufacturing. Each engineer specializes in finite element analysis (FEA), tolerance optimization, and rapid prototyping using advanced CAD/CAM systems. This expertise enables us to develop complex, multi-cavity moulds with micron-level accuracy, ensuring consistent part geometry and sealing performance. We maintain in-house CNC machining and EDM facilities, allowing full control over lead time and quality during the tooling phase.

Complementing our mould engineering strength is our advanced rubber compounding capability. Our two formula engineers hold advanced degrees in polymer science and have extensive experience in developing custom elastomer formulations for extreme environments. They conduct rigorous material testing across temperature extremes, pressure cycles, and exposure to aggressive media such as oils, acids, and hydraulic fluids. By formulating in-house, we eliminate dependency on third-party compounds and ensure full traceability and IP protection for OEM clients.

We specialize in OEM manufacturing, supporting global industrial clients from concept to mass production. Our engineering team collaborates directly with client R&D departments to refine specifications, perform DFM (Design for Manufacturability) reviews, and validate prototypes under real-world conditions. This collaborative model reduces time-to-market and ensures seamless integration of our O rings into critical systems such as hydraulic machinery, offshore equipment, and heavy-duty automotive assemblies.

Our production processes are supported by a certified quality management system (ISO 9001:2015), with full documentation for material lot tracking, process validation, and dimensional inspection. All rubber compounds are tested for compression set, tensile strength, elongation, and hardness according to ASTM standards.

The table below outlines key engineering and performance specifications we support in heavy duty rubber O ring manufacturing:

| Parameter | Specification Range |

|---|---|

| Material Types | Nitrile (NBR), EPDM, Viton® (FKM), Silicone, Neoprene, HNBR, ACM, AEM |

| Hardness Range (Shore A) | 40 to 90 ±5 |

| Temperature Resistance | -50°C to +250°C (material-dependent) |

| Tolerance (ID & CS) | ±0.05 mm to ±0.15 mm (per ISO 3601) |

| Mould Capacity | Up to 500 mm inner diameter, multi-cavity configurations |

| Custom Formulation Lead Time | 10–15 working days (including testing) |

| Sample Development Cycle | 7–14 days from design approval |

Our engineering team is committed to innovation, precision, and long-term partnership with industrial OEMs. By combining deep technical expertise with agile manufacturing, Suzhou Baoshida delivers heavy duty rubber O rings that perform reliably in the world’s most demanding environments.

Customization Process

Customization Process for Heavy Duty Rubber O Rings

At Suzhou Baoshida Trading Co., Ltd., our heavy duty rubber O ring customization follows a rigorously controlled sequence to ensure industrial reliability. This process begins with comprehensive drawing analysis, where engineering teams dissect client-provided specifications against ISO 3601 and ASTM D2000 standards. We verify cross-section tolerances, groove dimensions, and application parameters including pressure differentials, media exposure, and dynamic movement. Critical deviations—such as insufficient squeeze allowance or incompatible surface finishes—are flagged during joint review sessions with the client to prevent field failure. Material selection constraints derived from this phase directly inform the subsequent formulation stage.

Formulation development leverages our proprietary compound database and accelerated aging models. Engineers select base polymers—typically FKM, HNBR, or EPDM—based on fluid resistance and thermal stability requirements. Additive packages are precision-calibrated to achieve target hardness, compression set resistance, and low-temperature flexibility. For instance, aerospace-grade FKM formulations incorporate peroxide curing systems to withstand jet fuel immersion at 200°C while maintaining Shore A 80±5 hardness. Each compound undergoes predictive simulation for thermomechanical degradation before physical prototyping, reducing iteration cycles by 40%.

Prototyping employs CNC-machined molds and hydraulic presses under ISO 9001-controlled conditions. We produce 50–100 units per variant for functional validation, including:

Fluid immersion testing per ASTM D471

Compression set measurement at 150°C for 70 hours

Dynamic leakage testing under 5,000 psi cyclic pressure

Client-specific validation protocols are integrated upon request. Data from these trials refines the compound and process parameters, with failure analysis reports documenting root causes for rejected batches.

Mass production transitions occur only after client sign-off on prototype performance data. Our Suzhou facility utilizes automated rubber injection molding lines with real-time cavity pressure monitoring. Statistical process control (SPC) tracks key variables: cure time (±3 seconds), mold temperature (±2°C), and durometer consistency (±2 Shore A points). Every production lot undergoes 100% visual inspection and抽样 testing per AQL 1.0, with full material traceability from polymer batch to finished goods. This closed-loop system ensures repeatability for volumes exceeding 500,000 units while maintaining ≤0.25% defect rates in critical automotive and oilfield applications.

Critical Performance Specifications for Heavy Duty O Rings

| Parameter | Standard Range | Test Method | Industrial Significance |

|---|---|---|---|

| Hardness (Shore A) | 70–90 | ASTM D2240 | Balances sealing force and extrusion resistance |

| Temperature Range | -40°C to 250°C | ISO 37 | Ensures functionality in extreme environments |

| Fluid Resistance (ASTM #3) | ΔVolume ≤ 15% | ASTM D471 | Prevents swelling in aggressive hydrocarbons |

| Compression Set (70h/150°C) | ≤ 25% | ISO 815 | Critical for long-term seal integrity |

| Tensile Strength | ≥ 10 MPa | ISO 37 | Resists mechanical damage during installation |

Contact Engineering Team

Contact Suzhou Baoshida for Premium Heavy Duty Rubber O-Rings

When it comes to high-performance sealing solutions in demanding industrial environments, Suzhou Baoshida Trading Co., Ltd. stands as a trusted leader in the precision rubber seals sector. Our heavy duty rubber O-rings are engineered to deliver unmatched reliability under extreme pressure, temperature, and chemical exposure. Designed for applications in aerospace, automotive, oil & gas, heavy machinery, and industrial hydraulics, our O-rings meet stringent international standards for durability and sealing integrity. If your operations require components that perform consistently in harsh conditions, our engineering team is ready to support your technical specifications and volume requirements.

At Suzhou Baoshida, we combine advanced material science with precision manufacturing to produce O-rings that exceed expectations. Our production process integrates rigorous quality control, raw material traceability, and in-house testing to ensure every batch meets exact OEM tolerances. Whether you are sourcing standard sizes or require custom formulations for aggressive media, we offer tailored solutions using high-grade elastomers such as Nitrile (NBR), Ethylene Propylene Diene Monomer (EPDM), Fluorocarbon (FKM/Viton®), Silicone (VMQ), and Hydrogenated Nitrile (HNBR). Each material is selected based on thermal stability, resistance to oils, fuels, ozone, and steam—critical factors in long-term seal performance.

We understand that industrial procurement demands not only technical excellence but also responsive communication, logistical efficiency, and supply chain stability. That is why we assign dedicated technical account managers to ensure seamless collaboration from quotation to delivery. Our global distribution network supports just-in-time inventory models and bulk supply contracts, ensuring consistent availability without compromise on lead time or quality.

For immediate assistance with your heavy duty rubber O-ring requirements, contact Mr. Boyce, our OEM and Technical Sales Manager. With extensive experience in rubber formulation and industrial sealing applications, Mr. Boyce provides expert guidance on material selection, dimensional compliance (AS568, ISO 3601, JIS B 2401), and cost-optimized manufacturing solutions. He is available to review technical drawings, evaluate application conditions, and recommend the optimal elastomer compound for your operational demands.

Key Material Specifications

| Material | Temperature Range (°C) | Hardness (Shore A) | Key Resistance Properties |

|---|---|---|---|

| NBR (Nitrile) | -30 to +120 | 60–90 | Oil, fuel, hydraulic fluids |

| EPDM | -50 to +150 | 50–80 | Steam, water, ozone, UV |

| FKM (Viton®) | -20 to +200 | 65–90 | High-temperature oils, chemicals, fuels |

| HNBR | -40 to +150 | 60–90 | Enhanced oil and heat resistance vs. NBR |

| VMQ (Silicone) | -60 to +200 | 40–80 | Extreme temperatures, oxidation, UV |

To discuss your sealing challenges and receive a detailed technical proposal, email Mr. Boyce directly at [email protected]. Include your application parameters, volume needs, and any relevant specifications for a prompt and accurate response. Suzhou Baoshida is committed to engineering performance, ensuring your systems remain leak-free, efficient, and maintenance-optimized. Partner with us for precision rubber seals built to last.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).