Technical Contents

Engineering Guide: High Density Polyethylene Chopping Board

Engineering Insight: Material Selection in High Density Polyethylene Chopping Boards

In industrial food processing and commercial kitchen environments, the high density polyethylene (HDPE) chopping board is not merely a consumable—it is a critical interface between operational efficiency, hygiene compliance, and long-term cost management. Despite its apparent simplicity, the performance of an HDPE chopping board is fundamentally governed by material formulation, density control, and structural homogeneity. Off-the-shelf solutions often fail under sustained industrial use due to inadequate polymer grade selection, inconsistent manufacturing processes, and lack of performance validation under real-world conditions.

Standard commercial-grade HDPE boards typically utilize recycled or reprocessed resins to reduce cost. While economically attractive, these materials frequently exhibit inconsistent melt flow indices, variable molecular weight distributions, and residual contaminants. Such inconsistencies lead to premature wear, increased surface gouging, and microfissure formation—prime sites for bacterial colonization. Furthermore, non-industrial formulations often lack UV stabilizers and anti-static additives, increasing susceptibility to environmental degradation and particulate adhesion.

At Suzhou Baoshida Trading Co., Ltd., we approach HDPE chopping board engineering as a precision material science challenge. Our industrial-grade boards are formulated using virgin high-density polyethylene resins with controlled melt flow rates (typically 0.3–0.5 g/10 min at 190°C under 2.16 kg load) to ensure optimal processability and final part integrity. The material is compounded with food-safe stabilizers and antimicrobial agents that are homogenously dispersed during twin-screw extrusion, eliminating weak zones and ensuring compliance with FDA 21 CFR 177.1520 and EU 10/2011 regulations.

Critical to long-term performance is the balance between hardness and impact resistance. Excessively rigid boards may resist cutting but are prone to chipping and delamination under repeated mechanical stress. Conversely, overly ductile materials deform and retain knife marks, creating harborage points. Our engineered solution achieves an optimal Shore D hardness of 60–65, coupled with a notched Izod impact strength exceeding 50 J/m, verified through ASTM D256 testing protocols.

The following table outlines key material specifications that differentiate industrial-grade HDPE chopping boards from standard off-the-shelf alternatives:

| Property | Industrial-Grade HDPE (Baoshida) | Standard Commercial HDPE |

|---|---|---|

| Resin Type | Virgin HDPE (PE-HD 50) | Recycled/regrind blend |

| Density (g/cm³) | 0.945–0.955 | 0.930–0.940 |

| Melt Flow Index (g/10 min) | 0.3–0.5 | 0.8–1.2 |

| Shore D Hardness | 60–65 | 55–60 |

| Tensile Strength (MPa) | ≥30 | 20–25 |

| Impact Strength (Izod, J/m) | ≥50 | 30–40 |

| Food Contact Compliance | FDA, EU 10/2011 | Partial or unverified |

| Antimicrobial Additive | Yes (Ag+ ion release system) | No |

In high-frequency cutting environments, material selection directly influences cross-contamination risk, maintenance cycles, and total cost of ownership. Off-the-shelf boards may appear cost-effective initially but incur hidden expenses through premature replacement, downtime, and non-compliance penalties. Precision-engineered HDPE, formulated for sustained mechanical and hygienic performance, is not a commodity—it is a engineered system component.

Material Specifications

Material Specifications for Industrial Rubber Components in Food Processing Equipment

Suzhou Baoshida Trading Co., Ltd. clarifies a critical distinction: high-density polyethylene (HDPE) is the standard thermoplastic for chopping boards, not elastomers like Viton, Nitrile, or Silicone. These rubber materials serve distinct roles in food processing machinery—seals, gaskets, and conveyor belts—not direct food-contact surfaces like cutting boards. HDPE excels in chopping board applications due to its non-porous structure, impact resistance, and FDA compliance for repeated food contact. Conversely, industrial rubbers require rigorous validation for incidental food exposure in equipment housings, hydraulic systems, or sealing interfaces. Misapplication risks contamination, regulatory non-compliance, and premature failure.

For OEMs integrating rubber components into food-grade machinery, material selection must prioritize NSF/ANSI 51 certification, thermal stability, and chemical resistance against sanitizers (e.g., chlorine, peracetic acid). Viton (FKM) offers superior resistance to oils and high temperatures (up to 230°C) but carries higher costs, making it suitable for high-pressure valve seals in fryer systems. Nitrile (NBR) provides economical fuel and grease resistance (up to 120°C) for pump seals but degrades under ozone exposure. Silicone (VMQ) delivers exceptional flexibility across -60°C to 200°C and complies with FDA 21 CFR 177.2600 for indirect contact, ideal for conveyor belts in packaging lines. Crucially, none replace HDPE in chopping boards; they enable machinery reliability.

The following table details rubber specifications for equipment integration, not chopping board fabrication:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–12 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Key Chemical Resistance | Acids, oils, fuels | Oils, greases | Water, steam |

| Food Safety Compliance | NSF 51, FDA 21 CFR | NSF 51 (limited) | NSF 51, FDA 21 CFR |

| Typical Equipment Use | High-temp seals | Hydraulic seals | Conveyor belts |

Suzhou Baoshida emphasizes that HDPE chopping boards demand virgin-grade polymer with melt flow index (MFI) 0.3–1.0 g/10min (ASTM D1238) and density 0.941–0.965 g/cm³ (ASTM D792) to prevent warping. Rubber components in adjacent machinery must never compromise this primary food-contact zone. Our OEM partnerships enforce strict material traceability—certified lots, lot-specific CoAs, and accelerated aging tests per ISO 188—to ensure rubber parts withstand 5,000+ cleaning cycles without leaching. For chopping board production, specify HDPE only; for supporting equipment, select Viton, NBR, or VMQ using the above parameters. Contact our engineering team for application-specific validation protocols.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering division is anchored in deep technical expertise and industrial precision, specifically tailored to meet the rigorous demands of high-performance polymer applications. While our core focus lies in industrial rubber solutions, our material science proficiency extends seamlessly into high-density polyethylene (HDPE) product development, particularly in engineered items such as HDPE chopping boards designed for commercial and industrial use. This cross-polymer competency is driven by a dedicated team of 5 mould engineers and 2 specialized formula engineers who work in tandem to deliver optimized, OEM-grade solutions.

Our mould engineers possess extensive experience in precision tooling design, cavity optimization, and cycle time reduction for injection and compression moulding processes. They utilize advanced CAD/CAM software and simulation tools to predict flow behavior, minimize warpage, and ensure dimensional stability in final HDPE products. This capability is critical when manufacturing chopping boards that require uniform thickness, sharp edge definition, and resistance to impact and thermal cycling. The integration of cooling channel analysis and gate positioning ensures consistent batch-to-batch quality and extended mould life.

Complementing this is our formula engineering team, which specializes in polymer modification and additive integration. While HDPE is inherently durable and chemically resistant, our engineers enhance its functional properties through controlled blending techniques. These include improving surface hardness, scratch resistance, and microbial resistance—key performance indicators for food-contact chopping boards. Our formulation process adheres to strict regulatory standards, including FDA and EU compliance for food-safe polymers. By tailoring the melt flow index, density, and additive package, we ensure that each HDPE formulation aligns precisely with the intended application and processing method.

Our OEM capabilities are built on a foundation of collaborative development. We work directly with clients to translate functional requirements into technical specifications, from initial concept sketches to production-ready tooling and validated formulations. This end-to-end control allows us to offer private-label manufacturing, custom branding, and packaging solutions, all supported by in-house quality assurance protocols such as ISO 9001-compliant testing and batch traceability.

The following table outlines the key technical specifications achievable for our HDPE chopping boards through our integrated engineering approach:

| Parameter | Standard Value | Customizable Range | Test Method |

|---|---|---|---|

| Density | 0.95–0.96 g/cm³ | 0.94–0.97 g/cm³ | ASTM D792 |

| Tensile Strength | ≥30 MPa | Up to 35 MPa | ASTM D638 |

| Flexural Modulus | ≥1.0 GPa | 0.8–1.3 GPa | ASTM D790 |

| Impact Resistance (Izod) | ≥40 J/m | Up to 60 J/m | ASTM D256 |

| Hardness (Shore D) | 65–70 | 60–75 | ASTM D2240 |

| Operating Temperature | -40°C to +80°C | Extended on request | ISO 11357 |

| FDA / EU Compliance | Yes | Fully customizable | 21 CFR 177.1520, EC 10/2011 |

Through the synergy of advanced mould design and precision polymer formulation, Suzhou Baoshida delivers HDPE chopping boards that meet the highest benchmarks in durability, safety, and manufacturability.

Customization Process

Customization Process for High-Density Polyethylene Chopping Boards

Suzhou Baoshida Trading Co., Ltd. executes a rigorous, science-driven customization workflow for industrial HDPE chopping boards, ensuring optimal performance in food processing environments. Our process begins with comprehensive Drawing Analysis, where engineering teams dissect client CAD specifications to validate geometric tolerances, structural integrity, and manufacturability. Critical parameters such as edge radius, thickness uniformity (±0.2 mm), and drainage channel geometry are cross-referenced against ISO 2768-mK standards. Material constraints—including minimum wall thickness for injection molding stability and stress concentration points—are identified to prevent warpage or premature fatigue during use. This phase integrates finite element analysis (FEA) to simulate load distribution under repeated knife impact, guaranteeing compliance with NSF/ANSI 2 standards for food contact surfaces.

Subsequent Formulation leverages Suzhou Baoshida’s proprietary polymer science expertise. Standard HDPE (MFI 0.3–0.5 g/10 min) is enhanced through controlled copolymerization and additive integration. Key modifications include:

Impact modifiers (5–8 phr elastomeric polyolefins) to elevate notched Izod impact strength to ≥65 J/m

Antimicrobial agents (silver-ion zeolites, 0.8–1.2 wt%) validated per JIS Z 2801

UV stabilizers (HALS compounds) for outdoor durability without compromising FDA 21 CFR §177.1520 compliance

Formulations undergo accelerated aging tests (85°C/85% RH for 500 hours) to confirm long-term stability of colorants and functional additives.

Prototyping employs precision-engineered molds with conformal cooling channels, producing 3–5 sample batches for empirical validation. Each prototype undergoes:

Knife resistance testing (ASTM F2399) with 50,000+ simulated cuts using standardized blades

Thermal cycling (-20°C to 70°C) to assess dimensional stability

Surface roughness measurement (Ra ≤ 0.8 μm) via profilometry to inhibit bacterial adhesion

Client feedback on ergonomics, weight distribution, and functional features (e.g., grip zones) triggers iterative refinements before tooling finalization.

Mass Production transitions validated designs to high-volume manufacturing under ISO 9001-certified protocols. Automated injection molding systems maintain melt temperatures within ±2°C tolerance, while real-time cavity pressure monitoring ensures consistent packing density. Every production lot undergoes:

Spectroscopic verification of polymer composition (FTIR per ASTM E1252)

Dimensional audit via CMM (Coordinate Measuring Machine) against original GD&T specifications

Batch traceability through blockchain-enabled material logs

Final boards are packaged in sterile, recyclable film with full material disclosure certificates, ready for global OEM integration.

Key Performance Specifications Comparison

| Property | Standard HDPE Board | Baoshida Custom Formulation | Test Method |

|---|---|---|---|

| Tensile Strength | 20–25 MPa | 28–32 MPa | ASTM D638 |

| Notched Izod Impact | 35–45 J/m | ≥65 J/m | ASTM D256 |

| Melt Flow Index (190°C) | 0.3–0.5 g/10 min | 0.4–0.6 g/10 min | ASTM D1238 |

| Microbial Reduction | None | >99.9% (6h) | JIS Z 2801 |

| Thermal Deflection Temp | 75°C | 85°C | ASTM D648 (0.46 MPa) |

This structured approach ensures Suzhou Baoshida delivers chopping boards that exceed industrial durability, hygiene, and regulatory requirements while maintaining cost efficiency at scale.

Contact Engineering Team

For industrial-grade high density polyethylene (HDPE) chopping boards designed to meet the stringent demands of food processing, commercial kitchens, and sanitary manufacturing environments, Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered solutions backed by advanced polymer expertise. As a specialized provider within the Industrial Rubber Solutions sector, we integrate material science with functional durability to produce HDPE chopping boards that offer exceptional impact resistance, chemical stability, and compliance with international food safety standards.

Our HDPE chopping boards are formulated using high-purity, virgin-grade polyethylene resins, ensuring consistent density, low moisture absorption, and resistance to microbial growth. Each board undergoes rigorous quality control protocols, including dimensional stability testing and surface finish calibration, to guarantee performance under continuous industrial use. Whether deployed in meat processing facilities, pharmaceutical cleanrooms, or large-scale catering operations, our products maintain structural integrity across wide temperature ranges and repeated sanitization cycles.

Below are the key technical specifications of our standard HDPE chopping board offering:

| Property | Specification | Test Method |

|---|---|---|

| Density | 0.95–0.96 g/cm³ | ASTM D792 |

| Tensile Strength | ≥30 MPa | ASTM D638 |

| Flexural Modulus | ≥1.1 GPa | ASTM D790 |

| Impact Strength (Izod, Notched) | ≥45 J/m | ASTM D256 |

| Maximum Continuous Use Temperature | 80°C (176°F) | ISO 75 |

| Water Absorption (24 hrs) | <0.01% | ASTM D570 |

| FDA / EU Compliance | Compliant with FDA 21 CFR 177.1520 and EU 10/2011 | — |

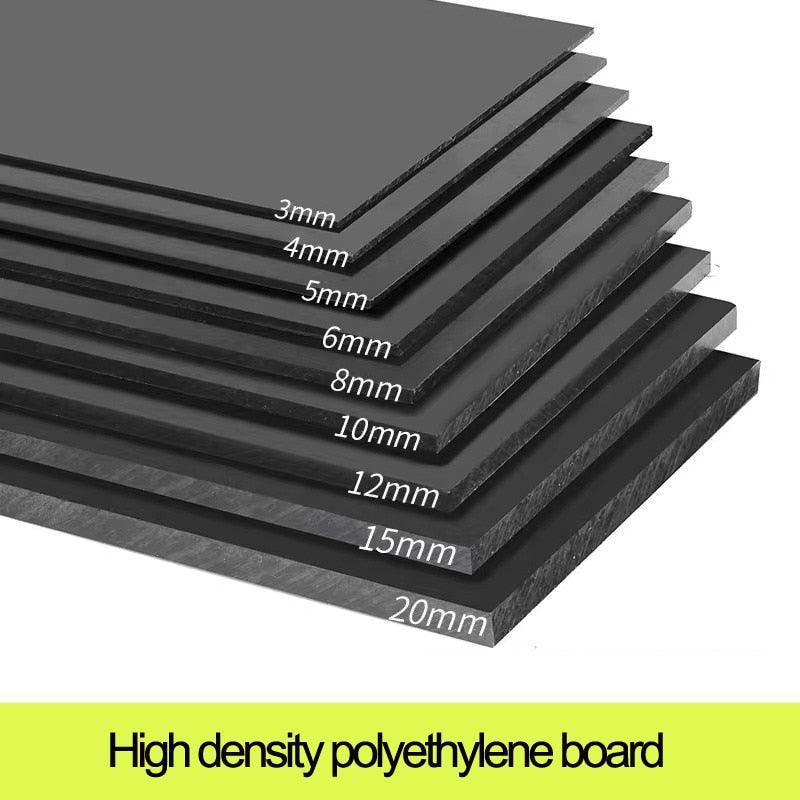

| Available Thicknesses | 20 mm, 30 mm, 40 mm, 50 mm | Customizable |

| Standard Sizes | 600×900 mm, 1000×1200 mm | OEM options available |

| Surface Finish | Smooth, non-porous, anti-slip optional | Matte or textured |

All products are manufactured under ISO 9001-certified processes, with full traceability and batch certification available upon request. Customization options include laser engraving, color coding (white, black, blue, green), embedded mounting holes, and antimicrobial additive integration for enhanced hygiene control.

To discuss your specific application requirements or request material test reports, technical data sheets, and sample submissions, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. With over a decade of experience in polymer formulation and industrial component sourcing, Mr. Boyce provides direct technical engagement to ensure material performance aligns precisely with operational demands.

For prompt assistance, email Mr. Boyce at [email protected]. Include details such as intended use environment, load conditions, dimensional needs, and regulatory certifications required. Our team supports global OEM partnerships, offering container-load production, third-party inspection coordination (SGS, BV), and logistics management across North America, Europe, and Southeast Asia.

Partner with Suzhou Baoshida for technically validated HDPE chopping board solutions engineered for longevity, safety, and seamless integration into high-throughput industrial workflows. Your next-generation material supply begins with a single technical consultation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).