Technical Contents

Engineering Guide: High Temp Wire Insulation Sleeve

Engineering Insight: The Critical Role of Material Selection in High Temp Wire Insulation Sleeves

In industrial environments where electrical systems operate under extreme thermal conditions, the performance of high temp wire insulation sleeves is not merely a matter of compliance—it is a determinant of system integrity, safety, and longevity. At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection is the cornerstone of effective insulation design. Off-the-shelf solutions, while cost-attractive, often fail to meet the nuanced demands of real-world applications due to generic formulations that overlook specific thermal, chemical, and mechanical stressors.

Standard insulation sleeves typically utilize materials such as PVC or low-grade silicone rubber, which begin to degrade at temperatures exceeding 105°C. In contrast, industrial applications—particularly in automotive, aerospace, and heavy machinery—routinely expose wiring to continuous temperatures above 200°C, with intermittent spikes beyond 300°C. Under such conditions, inadequate materials exhibit embrittlement, cracking, and loss of dielectric strength, leading to short circuits, fire hazards, and unplanned downtime.

The failure of generic sleeves often stems from an oversimplified understanding of thermal endurance. True high-temperature performance requires materials engineered at the molecular level to resist oxidative degradation and maintain flexibility. Silicone rubber (VMQ) and fluorosilicone (FVMQ) offer excellent thermal stability and resistance to UV and ozone, but their performance varies significantly based on polymer structure and filler composition. For even more demanding environments, perfluoroelastomers (FFKM) or ceramic-impregnated silicone textiles provide superior resistance to both heat and aggressive chemicals.

Equally critical is the distinction between continuous operating temperature and peak exposure tolerance. A sleeve rated for 250°C may survive brief excursions to 300°C, but sustained operation at that level without proper material formulation leads to accelerated aging. This is where customized engineering solutions outperform off-the-shelf alternatives. By tailoring the elastomer matrix, reinforcement fibers, and wall thickness to the specific thermal profile of the application, we ensure reliable dielectric insulation and mechanical protection over the product’s lifecycle.

The following table outlines key material properties relevant to high temp wire insulation sleeves:

| Material | Continuous Use Temp (°C) | Peak Temp (°C) | Dielectric Strength (kV/mm) | Key Advantages | Common Limitations |

|---|---|---|---|---|---|

| Silicone Rubber (VMQ) | 180 | 250 | 20–25 | Flexible, UV/ozone resistant, low toxicity | Moderate chemical resistance |

| Fluorosilicone (FVMQ) | 200 | 260 | 18–22 | Improved fuel and solvent resistance | Higher cost, slightly reduced flexibility |

| Ceramic-Impregnated Silicone | 260 | 1000 (short term) | 15–20 | Exceptional flame resistance, thermal shock resilience | Stiffer, higher installation complexity |

| Perfluoroelastomer (FFKM) | 300 | 350 | 17–19 | Outstanding chemical and thermal stability | Very high cost, limited availability |

Material selection must be driven by application-specific data, not generalized ratings. At Suzhou Baoshida, we collaborate with OEMs to analyze thermal profiles, chemical exposure, and mechanical stress to engineer insulation solutions that perform reliably under actual operating conditions—ensuring safety, compliance, and operational continuity.

Material Specifications

Material Specifications for High-Temp Wire Insulation Sleeves

Suzhou Baoshida Trading Co., Ltd. provides engineered rubber solutions for demanding industrial wire insulation applications. Material selection is critical for ensuring reliability under thermal stress, chemical exposure, and electrical loads. This section details the core elastomer specifications for high-temperature wire insulation sleeves, focusing on Viton (FKM), Nitrile (NBR), and Silicone (VMQ) formulations. Each material undergoes rigorous ASTM D2000 and ISO 37 testing to validate performance parameters. Continuous operating temperature, chemical compatibility, mechanical resilience, and dielectric strength are primary selection criteria. OEMs must align material properties with application-specific environmental profiles to prevent premature failure.

Viton (FKM) represents the premium solution for extreme thermal and chemical resistance. Its fluorocarbon structure sustains continuous operation at 230°C with intermittent peaks to 300°C. Viton exhibits exceptional resistance to aviation fuels, hydraulic fluids, acids, and aromatic hydrocarbons, making it indispensable in aerospace and military wiring systems. Tensile strength typically ranges 10–15 MPa (ASTM D412), with hardness between 60–80 Shore A. While its electrical resistivity exceeds 1×10¹⁴ Ω·cm (ASTM D257), higher material costs necessitate strategic deployment where lower-grade elastomers fail.

Nitrile (NBR) offers an optimized balance for cost-sensitive automotive and industrial applications. Standard grades maintain integrity up to 125°C continuous, with specialty formulations reaching 150°C. NBR excels in resistance to petroleum-based oils, greases, and aliphatic hydrocarbons but shows vulnerability to ozone, ketones, and brake fluids. Its tensile strength (12–20 MPa) and hardness range (50–90 Shore A) provide robust mechanical protection for engine compartment wiring. Electrical resistivity remains suitable for most low-voltage systems at >1×10¹³ Ω·cm, though thermal limitations restrict use in high-power electronics.

Silicone (VMQ) delivers unmatched flexibility across broad temperature extremes, operating continuously from -60°C to 200°C. Its inorganic backbone ensures stability against UV, ozone, and steam, with excellent electrical insulation properties (resistivity >1×10¹⁵ Ω·cm). However, Silicone exhibits lower tensile strength (6–10 MPa) and tear resistance compared to Viton or NBR, requiring careful design for abrasion-prone environments. Hardness typically falls within 40–80 Shore A. This material is ideal for medical devices, renewable energy systems, and applications requiring extreme low-temperature flexibility.

The following table summarizes critical comparative specifications for OEM decision-making:

| Material | Continuous Temp Range (°C) | Peak Temp (°C) | Key Chemical Resistance | Hardness Range (Shore A) | Electrical Resistivity (Ω·cm) | Typical Applications |

|---|---|---|---|---|---|---|

| Viton (FKM) | -20 to 230 | 300 | Jet fuels, acids, hydraulic fluids | 60–80 | >1×10¹⁴ | Aerospace wiring, military systems, chemical processing |

| Nitrile (NBR) | -40 to 125 | 150 | Petroleum oils, greases, aliphatic hydrocarbons | 50–90 | >1×10¹³ | Automotive engine harnesses, industrial machinery |

| Silicone (VMQ) | -60 to 200 | 230 | Ozone, UV, steam, mild acids | 40–80 | >1×10¹⁵ | Medical devices, solar inverters, low-temp sensors |

OEMs must validate material suitability against actual operational stressors, including dynamic flexing, fluid immersion duration, and voltage gradients. Suzhou Baoshida’s technical team provides application-specific compound customization and accelerated aging data to ensure seamless integration into high-reliability wire harness systems. Material datasheets with full ASTM test reports are available upon request for engineering validation.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-temperature wire insulation sleeves. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we maintain full control over the entire product development cycle—from concept and material formulation to mould design and final validation. This integrated approach ensures precision, consistency, and rapid time-to-market for customized OEM solutions.

Our formula engineers possess in-depth expertise in polymer chemistry, focusing on silicone, EPDM, and fluororubber (FKM) compounds engineered to withstand extreme thermal environments. They formulate custom rubber blends tailored to specific thermal stability, dielectric strength, and mechanical endurance requirements. Each formulation undergoes rigorous laboratory testing for properties such as heat aging resistance, volume resistivity, tensile strength, and elongation at break, ensuring compliance with international standards including UL, RoHS, and ISO 9001.

Complementing this material science proficiency, our five mould engineers specialize in precision tooling for extrusion and injection processes. They utilize advanced CAD/CAM software and finite element analysis (FEA) to optimize sleeve geometry, wall thickness uniformity, and dimensional tolerances. This enables the production of complex profiles with tight tolerances, critical for high-reliability applications in automotive, aerospace, and industrial electronics.

Our OEM capabilities are built on a foundation of technical agility and scalability. We support clients from prototype development through mass production, offering full documentation packages, material traceability, and process validation reports (including PPAP and IMDS). Whether the requirement is a custom durometer rating, color coding, or enhanced flame retardancy, our engineering team collaborates directly with clients to deliver application-specific solutions.

All manufacturing processes are conducted in-house at our ISO-certified facility, allowing strict quality control and rapid iteration. This vertical integration reduces dependency on external suppliers and accelerates response times during design modifications or troubleshooting.

The following table outlines typical technical specifications achievable with our high-temperature wire insulation sleeves:

| Property | Test Standard | Typical Value |

|---|---|---|

| Operating Temperature Range | ASTM D865 | -60°C to +200°C (up to +300°C intermittent) |

| Dielectric Strength | ASTM D149 | ≥15 kV/mm |

| Volume Resistivity | ASTM D257 | ≥1×10¹⁵ Ω·cm |

| Tensile Strength | ASTM D412 | ≥6.0 MPa (Silicone), ≥10 MPa (FKM) |

| Elongation at Break | ASTM D412 | ≥200% |

| Hardness (Shore A) | ASTM D2240 | 45–80 (customizable) |

| Flame Resistance | UL 94 | V-0 rated |

With a disciplined engineering framework and deep domain expertise, Suzhou Baoshida delivers high-performance rubber insulation solutions that meet the demanding requirements of modern industrial applications.

Customization Process

Customization Process for High Temperature Wire Insulation Sleeves

At Suzhou Baoshida Trading Co., Ltd., our customization process for high-temperature wire insulation sleeves integrates rigorous engineering with industrial scalability. This structured workflow ensures solutions meet exacting OEM specifications while maintaining material integrity under extreme conditions. The process begins with Drawing Analysis, where our engineering team dissects client-provided technical schematics and performance requirements. We validate critical parameters including operating temperature range, voltage rating, environmental exposure (e.g., ozone, chemicals, abrasion), and dimensional tolerances per ISO 19642 standards. This phase identifies potential design conflicts early, such as insufficient wall thickness for dielectric strength or incompatible bend radii for routing constraints. Client collaboration is essential here to align on feasibility and regulatory compliance targets.

Formulation Development follows, leveraging our proprietary rubber compound library and 15+ years of OEM experience. Our chemists select base polymers—typically silicone rubber (VMQ) for extreme temperatures (>200°C) or ethylene propylene diene monomer (EPDM) for balanced cost-performance up to 150°C—then engineer additives to enhance thermal stability, flame resistance (UL 94 V-0), and electrical insulation. Key considerations include peroxide curing systems for low compression set and nano-fillers to suppress thermal degradation. Material properties are cross-referenced against client specs using our internal database, ensuring the formulation meets all functional thresholds before prototyping.

Prototyping executes the validated design through precision extrusion or molding. Initial sleeves undergo accelerated life testing: thermal aging at 200°C for 720 hours, dielectric strength verification at 30 kV/mm, and tensile/elongation checks per ASTM D412. We measure post-aging property retention (e.g., >75% tensile strength) and validate dimensional stability after thermal cycling. Client feedback on prototype fit/functionality triggers iterative adjustments—such as modifying durometer or wall thickness—until all criteria are satisfied. This phase typically completes within 2–3 weeks, including third-party certification documentation if required.

Seamless transition to Mass Production occurs only after formal client sign-off. We deploy automated extrusion lines with real-time SPC monitoring for critical dimensions (±0.05 mm tolerance) and continuous vulcanization ovens ensuring uniform cross-linking. Every production batch undergoes 100% visual inspection and randomized electrical/thermal validation. Traceability is maintained via laser-etched batch codes linked to raw material certificates and test reports, adhering to ISO 9001:2015. Our Suzhou facility’s 500-ton monthly capacity supports volumes from 5,000 to 500,000+ units with consistent lead times of 15–25 days post-PO.

Material performance benchmarks for common high-temp insulation sleeves are summarized below:

| Material Type | Temp Range (°C) | Voltage Rating (kV) | Tensile Strength (MPa) | Elongation (%) | Hardness (Shore A) |

|---|---|---|---|---|---|

| Silicone (VMQ) | -60 to 250 | 15–35 | ≥6.0 | ≥200 | 45–70 |

| EPDM | -50 to 150 | 10–25 | ≥8.0 | ≥250 | 50–80 |

| FKM | -20 to 200 | 20–30 | ≥10.0 | ≥150 | 60–85 |

This end-to-end process—grounded in material science and industrial execution—delivers wire insulation sleeves that exceed OEM durability and safety demands in automotive, aerospace, and energy applications.

Contact Engineering Team

Contact Suzhou Baoshida for High-Temperature Wire Insulation Sleeve Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance industrial rubber solutions tailored to the rigorous demands of modern manufacturing, energy, and automation sectors. Our high-temperature wire insulation sleeves are engineered for exceptional thermal resistance, mechanical protection, and long-term reliability in extreme environments. Whether your application involves exposure to continuous heat, chemical agents, or abrasive conditions, our products are designed to exceed industry standards and ensure operational safety.

We understand that selecting the right insulation sleeve is not just about material compatibility—it’s about system integrity. That’s why our technical team, led by Mr. Boyce, provides personalized support to help you identify the optimal solution based on your operating temperature, voltage requirements, environmental exposure, and installation method. As an OEM-focused supplier, we offer custom formulations, dimensional configurations, and volume production capabilities to support your manufacturing timelines and quality benchmarks.

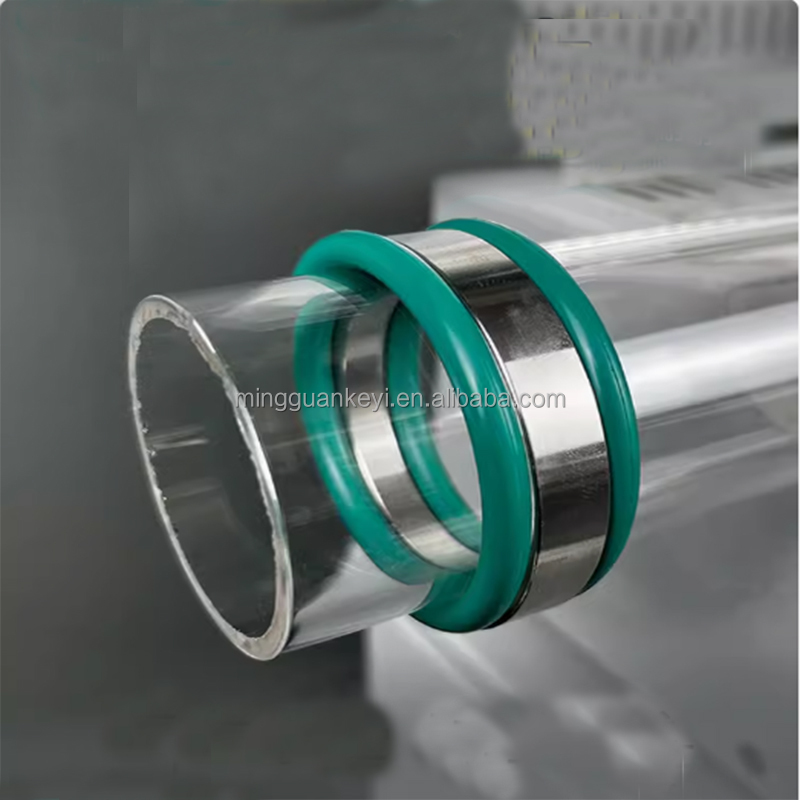

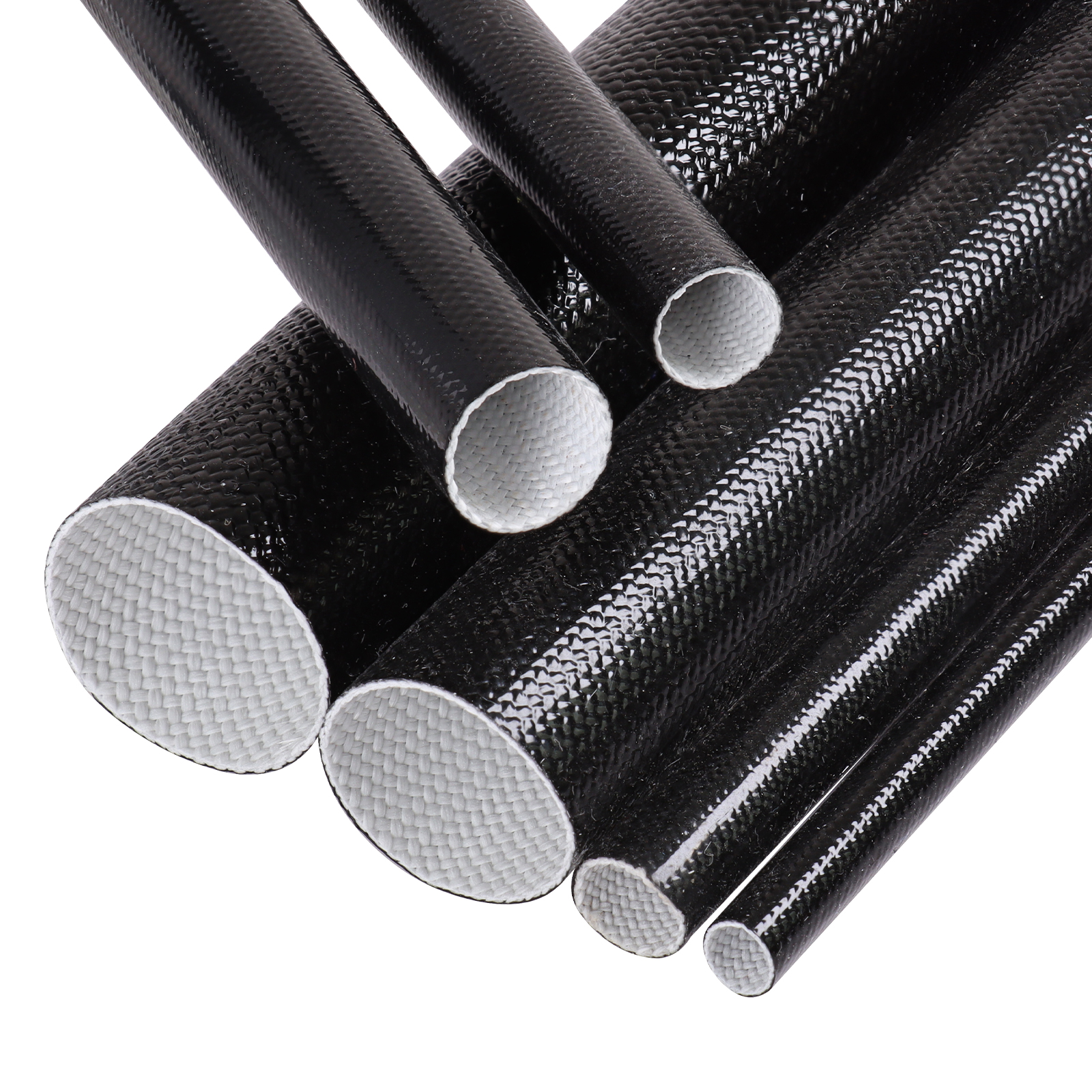

Our silicone rubber and fiberglass-reinforced insulation sleeves are manufactured under strict quality controls, ensuring uniform wall thickness, consistent dielectric strength, and compliance with international safety certifications. We serve clients across electronics, automotive, aerospace, and industrial automation industries, providing not only reliable products but also technical documentation, material test reports, and application guidance.

To discuss your specific requirements or request a sample for evaluation, we encourage direct engagement with our technical OEM manager. Mr. Boyce brings over a decade of experience in rubber material engineering and industrial component sourcing, offering deep insight into material behavior under stress and long-term performance in real-world conditions.

Below is a representative specification table for one of our standard high-temperature wire insulation sleeve models. Custom variants are available upon request.

| Property | Specification |

|---|---|

| Material | Silicone Rubber with Fiberglass Braid Reinforcement |

| Operating Temperature Range | -60°C to +200°C (short-term up to +250°C) |

| Voltage Resistance | Up to 600V AC (dielectric strength ≥12 kV/mm) |

| Flame Resistance | Self-extinguishing, meets UL 94 V-0 |

| Tensile Strength | ≥6.5 MPa |

| Elongation at Break | ≥200% |

| Fluid Resistance | Resistant to water, oils, weak acids and bases |

| Standard Compliance | ROHS, REACH, ISO 9001:2015 |

For technical inquiries, sample requests, or OEM collaboration discussions, please contact Mr. Boyce directly at [email protected]. Include your application details, required specifications, and preferred contact method to ensure a prompt and accurate response. We respond to all inquiries within 24 business hours and support multilingual communication for global clients.

Partner with Suzhou Baoshida Trading Co., Ltd. to secure a reliable supply of high-temperature wire insulation sleeves backed by engineering expertise and industrial-grade performance. Your next-generation thermal protection solution begins with a conversation—reach out today.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).