Technical Contents

Engineering Guide: High Temperature Exhaust Hose

Engineering Insight: Material Selection Criticality in High Temperature Exhaust Hose Performance

Catastrophic failures in high temperature exhaust hose applications frequently stem from inadequate material selection, where off-the-shelf commodity solutions prove fundamentally unsuited for the extreme operational envelope. Standard rubber compounds, often formulated for cost minimization rather than performance, cannot withstand the synergistic assault of continuous thermal exposure exceeding 200°C, aggressive chemical constituents in modern exhaust streams (including unburned hydrocarbons, sulfur oxides, and acidic condensates), and dynamic mechanical stresses. Generic EPDM or basic silicone formulations exhibit rapid thermal degradation, leading to hardening, cracking, and catastrophic loss of sealing integrity. Crucially, these materials lack resistance to specific chemical attack mechanisms prevalent in exhaust systems; sulfur compounds induce severe embrittlement in many elastomers, while continuous exposure to hot oil mist accelerates swelling and tensile strength loss in non-resistant grades. Off-the-shelf hoses frequently utilize insufficient reinforcement architectures or adhesion systems, resulting in ply separation under thermal cycling. The consequence is premature field failure, unplanned downtime, and significant safety hazards – risks wholly avoidable through rigorous, application-specific material engineering.

True performance demands elastomers engineered at the molecular level for thermal stability and chemical inertness. Fluorocarbon rubber (FKM) remains the benchmark for extreme environments due to its exceptional resistance to heat, oils, and chemicals, though cost and low-temperature flexibility limitations necessitate careful formulation balancing. Advanced silicone variants (VMQ) offer wider temperature ranges but require reinforcement against compression set and permeation at sustained high temperatures. Polyacrylate rubber (ACM) provides a cost-effective mid-range solution for moderately high temperatures but suffers in ozone and fuel resistance. The critical differentiator lies not merely in base polymer choice, but in the precision of the compound formulation: specialized antioxidants, bespoke cure systems resistant to reversion, and high-temperature stable fillers are non-negotiable. Adhesion promoters must maintain bond strength between rubber layers and braided reinforcements through thousands of thermal cycles from ambient to peak operating temperatures. OEM-grade solutions mandate this level of material science rigor, moving far beyond generic catalog offerings.

The performance gap between engineered and commodity solutions is quantifiable through key material properties:

| Material | Continuous Temp (°C) | Peak Temp (°C) | Key Weaknesses in Exhaust Application |

|---|---|---|---|

| Standard EPDM | 135 | 150 | Severe sulfur embrittlement, poor oil resistance, rapid hardening above 150°C |

| Basic Silicone (VMQ) | 200 | 230 | High permeability, poor compression set resistance, weak adhesion to reinforcements |

| Fluorocarbon (FKM) | 230 | 280 | Higher cost, reduced low-temp flexibility, requires specialized processing |

| Engineered ACM | 175 | 200 | Moderate ozone/fuel resistance, limited peak temp vs FKM |

Suzhou Baoshida Trading Co., Ltd. rejects the compromise inherent in off-the-shelf exhaust hose procurement. Our engineering process begins with exhaustive analysis of the specific thermal profile, chemical exposure, pressure dynamics, and lifecycle requirements of the client’s application. We then develop proprietary rubber formulations – often hybrid systems leveraging FKM as a base with tailored modifiers – validated through accelerated aging tests simulating 10,000+ hours of real-world duty. This collaborative formulation development, integrating deep material science with OEM operational data, is the sole reliable path to eliminating preventable exhaust hose failures and ensuring system longevity under the most demanding thermal conditions. Precision rubber chemistry is not an expense; it is the foundation of operational reliability.

Material Specifications

Material Specifications for High Temperature Exhaust Hose

The performance and longevity of high temperature exhaust hoses are critically dependent on the selection of appropriate elastomeric materials. At Suzhou Baoshida Trading Co., Ltd., we specialize in industrial rubber solutions engineered to withstand extreme thermal, chemical, and mechanical environments. For exhaust systems operating under elevated temperatures and exposure to aggressive media such as oils, fuels, and combustion byproducts, the choice of base polymer directly influences service life and system reliability. The three primary elastomers used in high temperature exhaust hose manufacturing are Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers a distinct balance of thermal stability, chemical resistance, mechanical strength, and cost-efficiency.

Viton, a fluorocarbon-based rubber, is the premium choice for applications requiring resistance to continuous high temperatures up to 250°C and intermittent peaks approaching 300°C. It exhibits exceptional resistance to engine oils, fuels, acids, and ozone, making it ideal for turbocharger hoses, exhaust recirculation systems, and under-hood applications in heavy-duty and performance vehicles. Its molecular structure provides low permeability and outstanding aging characteristics, though it is less flexible at low temperatures compared to silicone or nitrile.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is widely used in industrial and automotive applications due to its excellent resistance to petroleum-based oils and fuels. With a continuous operating temperature range up to 120°C and short-term tolerance to 150°C, NBR is cost-effective and mechanically robust. However, its performance degrades rapidly above 150°C, limiting its use in high-exhaust zones unless reinforced or compounded for thermal stability. It is often selected for lower-temperature exhaust components where oil resistance is paramount.

Silicone rubber (VMQ) provides superior flexibility and thermal stability, capable of continuous service from -60°C to 230°C, with brief exposure tolerance to 260°C. It offers excellent resistance to ozone and UV radiation but has lower resistance to petroleum-based fluids compared to Viton and Nitrile. Silicone is frequently used in low-pressure exhaust ducting, sensor lines, and non-fuel-exposed areas where wide temperature cycling and flexibility are required.

The following table compares key physical and chemical properties of these materials to guide material selection based on application demands.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Continuous Use Temperature | -20°C to 250°C | -30°C to 120°C | -60°C to 230°C |

| Peak Temperature Resistance | Up to 300°C | Up to 150°C | Up to 260°C |

| Fuel and Oil Resistance | Excellent | Excellent | Poor to Fair |

| Ozone and UV Resistance | Excellent | Good | Excellent |

| Flexibility at Low Temp | Moderate | Good | Excellent |

| Compression Set Resistance | Excellent | Moderate | Good |

| Common Applications | Turbocharger hoses, EGR systems | Oil return lines, low-temp exhaust | Sensor lines, heat sleeves |

Material selection must consider the full operational profile, including media exposure, pressure fluctuations, and dynamic movement. Suzhou Baoshida Trading Co., Ltd. provides custom formulation and testing support to ensure optimal performance in demanding exhaust environments.

Manufacturing Capabilities

Engineering Capability: Precision Development for High-Temperature Exhaust Hose Systems

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise in rubber formulation and precision tooling to deliver mission-critical high-temperature exhaust hose solutions. Our engineering backbone comprises five dedicated Mold Engineers and two specialized Rubber Formula Engineers, operating within Suzhou’s globally recognized manufacturing hub. This integrated team ensures every component meets stringent thermal, mechanical, and durability requirements inherent to modern exhaust systems.

Our Mold Engineers focus on precision tooling design and validation, utilizing advanced CAD/CAM systems to optimize flow dynamics, wall thickness uniformity, and reinforcement integration. Each mold undergoes rigorous thermal cycling analysis to prevent warpage during high-volume production, ensuring dimensional stability up to 300°C continuous operation. Critical tolerances are maintained within ±0.15mm across complex geometries, directly impacting sealing integrity and vibration resistance in end applications.

Complementing this, our Rubber Formula Engineers pioneer material science solutions for extreme environments. Through proprietary polymer blending protocols and additive optimization, we develop custom elastomer compounds resistant to turbocharger gases, oil mist, and thermal degradation. Key innovations include multi-phase curing systems that enhance cross-link density without sacrificing flexibility, and nano-silica reinforcement for abrasion resistance exceeding 120 kPa pressure surges. Every formulation undergoes accelerated aging tests per ASTM D573, simulating 10,000+ hours of real-world exposure.

This dual-engineering synergy enables robust OEM collaboration. We translate client thermal profiles and spatial constraints into validated production processes, from initial concept to PPAP submission. Our OEM workflow incorporates closed-loop dimensional validation using CMM metrology and in-line pressure decay testing, guaranteeing 100% compliance with SAE J200 and ISO 1307 standards. Clients receive full material traceability, including Durometer stability reports across -40°C to 280°C ranges, and comprehensive failure mode analysis for design refinement.

The following table summarizes core technical specifications achievable through our engineering framework:

| Parameter | Specification Range | Test Standard | Performance Target |

|---|---|---|---|

| Continuous Temp. | -40°C to 280°C | ASTM D573 | Zero hardening >250°C/1000h |

| Burst Pressure | ≥ 1.8 MPa | SAE J200 | 3x operational safety margin |

| Material Composition | ACM/EPDM Blends | ASTM D2000 | Type EC, Class AA |

| Ozone Resistance | 50 pphm, 40°C, 20% strain | ASTM D1149 | Zero cracking after 240h |

| Reinforcement | Spiral Wire + Aramid Cord | ISO 1307 | 15% elongation at break |

By unifying material science with precision manufacturing, Suzhou Baoshida delivers exhaust hoses that mitigate thermal fatigue and chemical attack in heavy-duty, automotive, and industrial applications. Our engineering team’s proactive problem-solving reduces client validation cycles by 30% while ensuring compliance with global emissions and safety mandates. Partner with us for solutions engineered at the molecular and mechanical interface.

Customization Process

Customization Process for High Temperature Exhaust Hoses at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., the customization of high temperature exhaust hoses follows a rigorous, science-driven process designed to meet the exact thermal, mechanical, and environmental demands of industrial and automotive applications. Our engineering workflow ensures material integrity, dimensional accuracy, and long-term performance under extreme operating conditions.

The process begins with Drawing Analysis, where our rubber formula engineers conduct a detailed review of customer-provided technical drawings and performance specifications. This includes assessing inner and outer diameters, wall thickness, bend radius, flange configurations, and required service temperature ranges. We also evaluate dynamic factors such as vibration resistance, pressure pulsation, and exposure to aggressive media like diesel particulate matter, sulfur oxides, and unburned hydrocarbons. This phase is critical in identifying potential failure points and establishing material and structural design parameters.

Following drawing validation, our team proceeds to Formulation Development. Based on the thermal and chemical exposure profile, we select from a range of high-performance elastomers, including silicone rubber (VMQ), fluorosilicone (FVMQ), ethylene propylene diene monomer (EPDM), and fluoroelastomers (FKM). Reinforcement is achieved through embedded fiberglass or aramid fiber braiding, while stainless steel helix wires may be integrated for crush resistance and EMI shielding. The compound is engineered to maintain flexibility at low temperatures while resisting thermal degradation up to 300°C continuously, and higher in intermittent cycles. Additives are precisely dosed to enhance ozone resistance, UV stability, and flame retardancy (meeting UL 94 V-0 if required).

Once the formulation is finalized, we move to Prototyping. Using precision extrusion and curing techniques, we produce a limited batch of hoses for physical testing. These prototypes undergo rigorous validation, including thermal aging (per ASTM D573), burst pressure testing (SAE J20), flex endurance, and chemical immersion analysis. Dimensional conformity is verified using coordinate measuring machines (CMM) to ensure compliance with ISO 3309 tolerances.

Upon customer approval, the project transitions to Mass Production. Our automated production lines ensure batch-to-batch consistency, supported by in-line quality monitoring and statistical process control (SPC). All hoses are serialized and traceable, with full material certification (RoHS, REACH, and OEM-specific standards) provided.

| Parameter | Standard Specification | Customizable Range |

|---|---|---|

| Temperature Resistance | -60°C to +300°C continuous | Up to +350°C intermittent |

| Inner Diameter | 25–150 mm | 15–200 mm |

| Wall Thickness | 3.0–6.0 mm | 2.5–8.0 mm |

| Pressure Rating | 1.5 bar (standard) | Up to 5.0 bar with reinforcement |

| Material Options | VMQ, FKM, EPDM, FVMQ | Hybrid laminates available |

| Reinforcement | Fiberglass or aramid braid | Stainless steel helix optional |

| Flame Resistance | UL 94 V-1 (standard), V-0 on request | OEM-specific ratings supported |

This structured approach enables Suzhou Baoshida to deliver high temperature exhaust hoses that meet the exacting standards of global OEMs while ensuring reliability, durability, and compliance.

Contact Engineering Team

Contact Suzhou Baoshida for Precision High-Temperature Exhaust Hose Solutions

Industrial exhaust systems operating under extreme thermal stress demand engineered rubber solutions that guarantee longevity and safety. Standard elastomeric compounds fail catastrophically when exposed to continuous temperatures exceeding 200°C, leading to premature cracking, fluid leakage, and system failure. Suzhou Baoshida Trading Co., Ltd. specializes in formulating and manufacturing high-temperature exhaust hoses using proprietary rubber compounds validated for sustained performance in demanding OEM applications. Our engineering team leverages decades of material science expertise to develop hoses that resist thermal degradation, ozone exposure, and dynamic flex fatigue—critical parameters often overlooked in generic supply chains. We understand that your design specifications require more than off-the-shelf components; they demand precision-engineered interfaces between engine dynamics and environmental resilience.

Our commitment to technical excellence is reflected in the rigorous validation of every hose iteration. Below are core specifications representative of our standard high-temperature exhaust hose offering, engineered for automotive and industrial turbine applications:

| Parameter | Specification | Test Standard |

|---|---|---|

| Material Composition | Reinforced Silicone Rubber Compound | ASTM D2000 Line Call |

| Continuous Service Temp | -60°C to +250°C | ISO 188 |

| Peak Short-Term Temp | +300°C (15 min) | ISO 188 |

| Burst Pressure | ≥ 2.5 MPa | SAE J2044 |

| Vacuum Resistance | ≤ 75 kPa at 23°C | SAE J1402 |

| Reinforcement | High-Tensile Polyester Braid | ISO 1402 |

| Certifications | ISO 9001, IATF 16949, RoHS Compliant | Internal Audit |

These figures represent baseline capabilities; Suzhou Baoshida routinely customizes formulations to meet project-specific thermal profiles, chemical exposures, and mechanical load requirements. Our OEM partnership model integrates early in your design phase, providing material datasheets, FEA support, and prototype validation to mitigate downstream integration risks. Unlike commodity suppliers, we prioritize compound stability over cost-cutting—ensuring your exhaust system maintains integrity across 10,000+ thermal cycles.

Do not compromise reliability with hoses formulated for marginal thermal margins. The cost of system failure in high-temperature environments far exceeds the value engineering investment in a proven solution. Mr. Boyce, our dedicated OEM Technical Manager, possesses direct authority to initiate collaborative development cycles and expedite qualification testing for your application. He will connect you with our rubber formulation chemists and process engineers to address compound-specific queries, regulatory hurdles, and volume production timelines. Contact him immediately to receive:

A detailed technical dossier including full material test reports (MTRs)

Customized compound recommendations based on your thermal duty cycle

Prototype lead time and tooling cost analysis

Reach Mr. Boyce at [email protected] to schedule a technical consultation. Specify your project’s temperature range, pressure profile, and annual volume requirements in your initial inquiry. Suzhou Baoshida responds to all OEM engineering requests within 4 business hours with actionable data—not generic sales brochures. Partner with us to transform thermal management challenges into competitive advantages through scientifically validated rubber technology. Your exhaust system’s durability begins with the right molecular architecture.

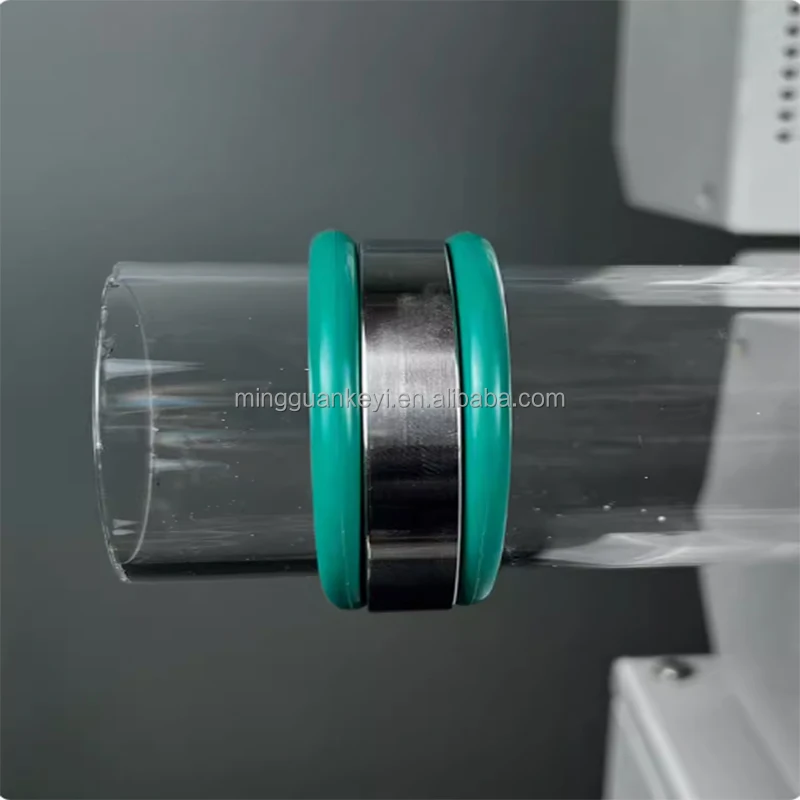

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).