Technical Contents

Engineering Guide: High Temperature Weather Stripping

Engineering Insight: High Temperature Weather Stripping – The Critical Role of Material Selection

In industrial applications involving extreme thermal exposure, the performance of weather stripping is not merely a function of design or compression set resistance—it is fundamentally dictated by material selection. Standard off-the-shelf weather stripping solutions, typically formulated from conventional elastomers such as EPDM or natural rubber, are engineered for ambient or moderately elevated temperature environments. When subjected to continuous operating temperatures exceeding 150°C, these materials undergo rapid thermal degradation, resulting in hardening, cracking, loss of elasticity, and ultimately, seal failure. This presents a critical risk in sectors such as automotive engine compartments, aerospace systems, industrial ovens, and power generation equipment, where environmental sealing integrity directly impacts safety, efficiency, and regulatory compliance.

The failure of generic weather stripping under high heat stems from inherent chemical instability in polymer backbones and additive systems not designed for thermal endurance. For instance, EPDM, while excellent for UV and ozone resistance, begins to oxidize significantly above 150°C, leading to chain scission and crosslink breakdown. Similarly, silicone rubber (VMQ), often perceived as a high-temperature solution, can maintain flexibility up to 200°C but suffers from poor abrasion resistance and low tensile strength, limiting its mechanical durability in dynamic sealing applications.

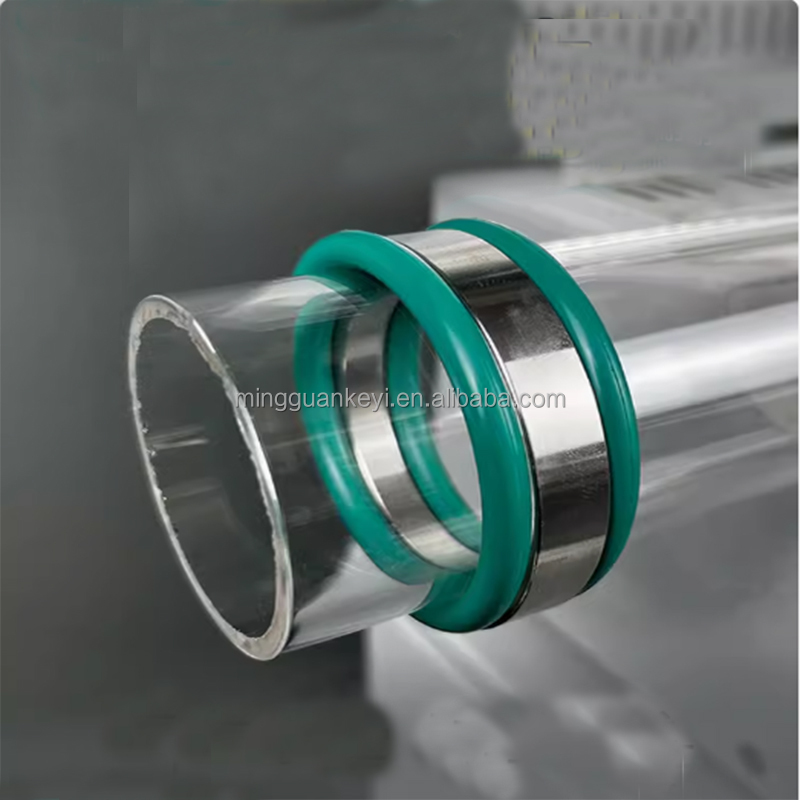

Precision-engineered high temperature weather stripping requires advanced elastomer systems capable of maintaining physical properties across extended thermal cycles. At Suzhou Baoshida Trading Co., Ltd., we specialize in formulations based on fluorocarbon rubber (FKM), hydrogenated nitrile (HNBR), and perfluoroelastomers (FFKM), each selected for specific thermal and chemical service envelopes. FKM compounds, for example, exhibit continuous service capability up to 230°C with exceptional resistance to oils, fuels, and oxidative environments. HNBR extends the performance boundary of NBR with improved thermal stability and mechanical robustness, suitable for dynamic seals in turbocharged engines or industrial turbines.

Material selection must also account for compression set performance at elevated temperatures—a key indicator of long-term sealing force retention. Poor compression set leads to gapping and leakage, even if the material appears intact. Advanced curing systems, such as peroxide vulcanization, are employed to enhance network stability and reduce permanent deformation under load.

The following table outlines comparative performance characteristics of common elastomers used in high temperature weather stripping applications:

| Material | Continuous Use Temperature (°C) | Compression Set (22 hrs @ 150°C) | Key Advantages | Limitations |

|---|---|---|---|---|

| EPDM | 130–150 | 25–40% | Excellent weathering resistance | Poor oil/fuel resistance, limited thermal stability |

| VMQ (Silicone) | 180–200 | 15–30% | Good low-temp flexibility, electrical insulation | Low tensile strength, poor abrasion resistance |

| FKM (Fluorocarbon) | 200–230 | 10–20% | Superior chemical and thermal resistance | Higher cost, limited low-temperature performance |

| HNBR | 160–180 | 12–25% | High mechanical strength, dynamic resilience | Moderate chemical resistance compared to FKM |

Off-the-shelf solutions often compromise on such tailored performance by utilizing cost-driven formulations that do not address the synergistic effects of heat, pressure, and environmental exposure. True reliability in high temperature sealing demands application-specific engineering—where material science, service conditions, and mechanical design converge. At Baoshida, we prioritize engineered solutions over commodity products, ensuring long-term performance in the most demanding industrial environments.

Material Specifications

Material Specifications for High Temperature Weather Stripping

Selection of elastomeric compounds for high temperature weather stripping demands rigorous evaluation of thermal stability, compression set resistance, and chemical compatibility. At Suzhou Baoshida Trading Co., Ltd., we prioritize materials that maintain sealing integrity under extreme thermal cycling and aggressive environmental exposure. Viton (FKM), Silicone (VMQ), and Nitrile (NBR) represent industry-standard solutions, each with distinct performance boundaries. Viton excels in continuous service up to 230°C, offering exceptional resistance to oils, fuels, and ozone degradation. Its molecular structure provides low gas permeability, critical for aerospace and automotive turbocharger applications where hydrocarbon exposure coincides with elevated temperatures. Silicone remains the benchmark for flexibility retention between -60°C and 200°C, with outstanding UV and weather resistance. However, its lower tensile strength necessitates careful design considerations for high-stress dynamic seals. Nitrile delivers cost-effective performance for moderate heat environments (up to 120°C), featuring superior abrasion resistance and fuel compatibility, though it exhibits accelerated hardening above 100°C in oxygen-rich atmospheres.

Material performance must align precisely with operational parameters. Viton’s high fluorine content ensures minimal swelling in aggressive media but increases compound cost. Silicone’s inherent thermal stability makes it ideal for static seals in solar thermal systems and oven doors, yet its poor tear strength limits dynamic use. Nitrile remains prevalent in hydraulic and transmission systems where temperatures rarely exceed 100°C, though its acrylonitrile content must be optimized to balance oil resistance and low-temperature flexibility. Compression set values below 25% after 70 hours at 150°C are non-negotiable for Viton and Silicone formulations to prevent permanent seal failure. All compounds require stringent peroxide curing systems to maximize thermal resilience, avoiding conventional sulfur cures that degrade above 120°C.

The following table details critical specifications for high-temperature weather stripping applications:

| Material | Continuous Temperature Range | Key Properties | Primary Applications |

|---|---|---|---|

| Viton (FKM) | -20°C to +230°C | Exceptional chemical/fuel resistance, low gas permeability, high ozone stability | Turbocharger hoses, jet engine seals, chemical processing gaskets |

| Silicone (VMQ) | -60°C to +200°C | Superior flexibility retention, excellent UV/weather resistance, low toxicity | Solar panel edge seals, oven door gaskets, medical device housings |

| Nitrile (NBR) | -30°C to +120°C | High abrasion resistance, good fuel/oil compatibility, cost-effective | Hydraulic cylinder rods, transmission seals, general industrial gaskets |

Suzhou Baoshida Trading Co., Ltd. validates all formulations through ASTM D2000 and ISO 3601 testing protocols, including 1000-hour thermal aging at maximum service temperatures. Our OEM partnerships leverage customized compound development—such as Viton grades with enhanced low-temperature flexibility down to -40°C or reinforced Silicone for 25% higher tensile strength—to address application-specific thermal degradation mechanisms. Material selection must account for synergistic stressors: a weather strip in an automotive under-hood environment requires simultaneous resistance to 180°C heat, engine oil, and road salt exposure, where Viton’s comprehensive property profile becomes indispensable. For moderate-temperature scenarios with budget constraints, optimized NBR compounds provide reliable service when thermal limits are strictly observed.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. maintains a robust engineering infrastructure focused on delivering high-performance rubber solutions for demanding industrial applications, particularly in the domain of high temperature weather stripping. Our in-house engineering team comprises five dedicated mould engineers and two specialized rubber formula engineers, enabling seamless integration between material science and precision manufacturing. This multidisciplinary approach ensures that every product is optimized for performance, durability, and manufacturability under extreme thermal and environmental conditions.

Our mould engineers possess extensive experience in designing and refining precision tooling for complex sealing profiles used in automotive, aerospace, industrial equipment, and construction sectors. Utilizing advanced CAD/CAM software and CNC machining techniques, they develop steel and aluminum moulds with tight tolerances, ensuring consistent part geometry and dimensional stability. Each design undergoes rigorous simulation and validation to anticipate material flow, shrinkage, and part ejection behavior, minimizing production defects and accelerating time-to-market.

Complementing this capability are our two certified rubber formula engineers who specialize in elastomer compounding for high temperature resilience. They formulate custom rubber compounds based on silicone (VMQ), fluorosilicone (FVMQ), EPDM, and specialty hydrogenated nitrile (HNBR) to meet specific thermal, chemical, and mechanical requirements. These formulations are engineered to maintain elasticity, compression set resistance, and sealing integrity at continuous operating temperatures up to 300°C, with short-term excursions even higher. Our lab conducts accelerated aging, thermal gravimetric analysis (TGA), and dynamic mechanical analysis (DMA) to validate long-term performance under simulated service conditions.

The synergy between our mould and formula engineering teams enables true OEM (Original Equipment Manufacturer) service excellence. We support clients from concept through production, offering full design-for-manufacturability feedback, prototype development, and small to large-scale series production. Our OEM process is structured to accommodate customer-specific geometries, durometer ratings, color codes, and performance standards, including compliance with ASTM, ISO, and OEM-specific specifications.

This integrated engineering model allows Suzhou Baoshida to deliver tailored high temperature weather stripping solutions that outperform generic alternatives in sealing reliability and service life.

| Property | Test Method | Typical Value |

|---|---|---|

| Continuous Use Temperature | ASTM D573 | Up to 250°C (VMQ), 300°C (FVMQ) |

| Tensile Strength | ASTM D412 | 7–10 MPa |

| Elongation at Break | ASTM D412 | ≥200% |

| Hardness (Shore A) | ASTM D2240 | 50–80 ±5 |

| Compression Set (22 hrs, 200°C) | ASTM D395 | ≤25% |

| Volume Resistance | ASTM D149 | >1×10¹² Ω·cm |

Our technical capabilities are reinforced by strict quality control protocols and a continuous improvement culture, ensuring that every weather stripping component meets the highest standards of industrial reliability.

Customization Process

Customization Process for High Temperature Weather Stripping

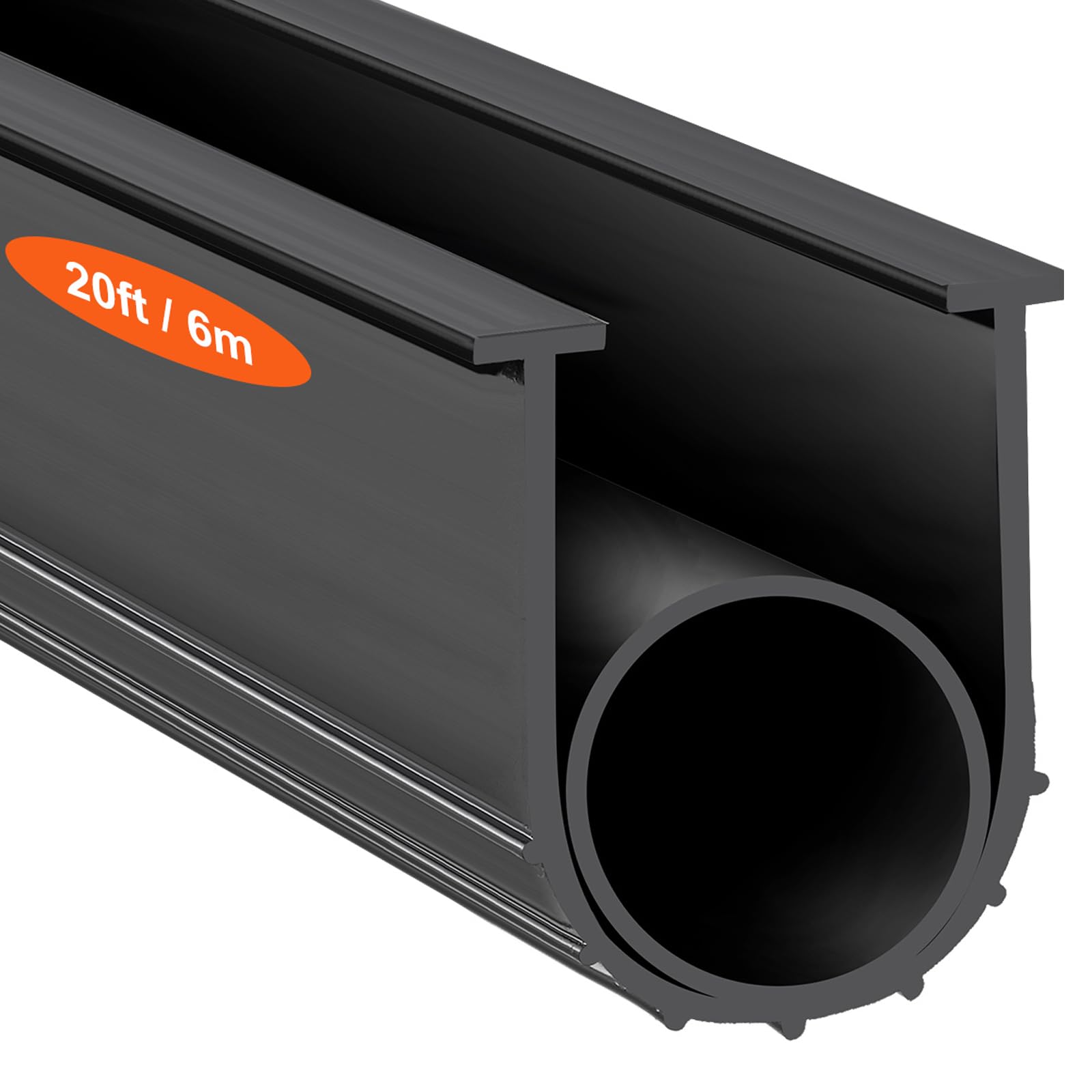

At Suzhou Baoshida Trading Co., Ltd., our customization process for high-temperature weather stripping begins with rigorous drawing analysis. Engineering teams dissect client-provided technical schematics to validate dimensional tolerances, cross-sectional geometry, and interface specifications against OEM assembly requirements. Critical parameters such as compression deflection force, gap-filling capacity, and dynamic sealing zones are cross-referenced with industry standards like SAE J1453 or ISO 3601. This phase identifies potential manufacturability conflicts early, ensuring the design aligns with both functional demands and extrusion/molding constraints. Non-conformities trigger collaborative engineering reviews to optimize the profile without compromising sealing integrity.

Formulation development follows, leveraging our proprietary compound database and accelerated aging protocols. We select base polymers—typically fluorocarbon (FKM) or high-consistency silicone (VMQ)—based on the target temperature threshold and chemical exposure profile. Reinforcing fillers, thermal stabilizers, and custom cure systems are engineered to achieve sustained performance at 200°C to 300°C while maintaining low compression set. Each formulation undergoes predictive modeling for long-term thermal degradation using Arrhenius kinetics, followed by empirical validation via TGA and DMA testing. Client-specific fluid resistance requirements (e.g., brake fluids, jet fuels) dictate additive selection, with real-time FTIR spectroscopy confirming molecular stability.

Prototyping transitions validated compounds into physical samples using client-specified tooling or our rapid-turn CNC-machined molds. Extruded or molded strips undergo ASTM D2000-compliant testing for hardness, tensile strength, and elongation at break. Dynamic seal performance is verified through simulated thermal cycling (-55°C to 250°C) and pressure decay tests under OEM-defined conditions. Iterative adjustments to durometer or crosslink density occur within 72 hours of test failure, with full material traceability maintained via our LIMS platform.

Mass production initiates only after client sign-off on PPAP Level 3 documentation. We deploy statistical process control across twin-screw extrusion lines, monitoring critical variables like die temperature (±1.5°C) and cure state (via online rheometry). Every batch undergoes 100% visual inspection and automated dimensional scanning against GD&T callouts. Final validation includes third-party compression set testing per ASTM D395 Method B at 250°C for 70 hours, with certificates of conformance supplied with each shipment. Suzhou Baoshida’s integrated approach ensures zero defect escalation in automotive powertrain or aerospace actuator applications.

Critical Performance Specifications for High-Temperature Weather Stripping

| Property | Test Standard | Typical Value Range |

|———————————–|——————|———————|

| Continuous Use Temperature | ASTM D573 | 200°C to 300°C |

| Compression Set (70h @ 250°C) | ASTM D395 B | ≤ 25% |

| Tensile Strength | ASTM D412 | 8.0–12.0 MPa |

| Hardness (Shore A) | ASTM D2240 | 60–80 |

| Fluid Resistance (IRM 903) | ASTM D471 | Volume Swell ≤ 15% |

| Dynamic Sealing Pressure Retention| Internal Protocol| ≥ 95% @ 10k cycles |

Contact Engineering Team

Contact Suzhou Baoshida for High Temperature Weather Stripping Solutions

When sourcing high-performance rubber components for extreme environments, precision, material integrity, and long-term reliability are non-negotiable. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered industrial rubber solutions tailored to meet the rigorous demands of aerospace, automotive, energy, and heavy machinery sectors. Our high temperature weather stripping products are formulated to deliver consistent sealing performance under sustained thermal stress, UV exposure, ozone, and mechanical compression.

Our formulations leverage advanced elastomer systems such as silicone (VMQ), fluorosilicone (FVMQ), ethylene propylene diene monomer (EPDM), and perfluoroelastomers (FFKM), each selected and compounded to achieve optimal resistance to temperatures ranging from -60°C to over +300°C, depending on application parameters. Every profile is manufactured under strict quality control protocols, ensuring dimensional accuracy, uniform durometer, and batch-to-batch consistency.

We understand that off-the-shelf solutions often fall short in mission-critical applications. That’s why Suzhou Baoshida offers full customization—from cross-sectional geometry and hardness tuning to color coding and splicing configurations. Whether you require continuous lengths, molded corners, or application-specific adhesives, our technical team collaborates directly with OEMs and Tier suppliers to deliver sealing solutions that integrate seamlessly into your assembly process.

To support global clients, we maintain a responsive supply chain with documented traceability, ISO-compliant testing reports, and accelerated aging data available upon request. Our production facilities are equipped for low-volume prototyping and high-volume continuous extrusion, ensuring scalability without compromise.

Below is a representative specification table for our standard high temperature weather stripping materials:

| Material | Temperature Range (°C) | Hardness (Shore A) | Key Resistance Properties | Typical Applications |

|---|---|---|---|---|

| Silicone (VMQ) | -60 to +200 (short-term +300) | 40–80 | Heat, UV, ozone, compression set | Automotive glazing, oven doors, electrical enclosures |

| Fluorosilicone (FVMQ) | -55 to +200 | 50–75 | Heat, fuels, oils, ozone | Aerospace seals, fuel system gaskets |

| EPDM | -60 to +150 | 50–85 | Steam, weathering, water, alkalis | Industrial boilers, HVAC systems, railcar doors |

| FFKM | -20 to +327 | 70–90 | Extreme heat, aggressive chemicals, plasma | Semiconductor processing, chemical reactors |

For technical consultation or material selection guidance, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. With over a decade of experience in elastomer formulation and industrial sealing design, Mr. Boyce leads client collaboration from concept to validation. He ensures that every weather stripping solution is not only compliant with industry standards such as ASTM D2000, ISO 3302, and ROHS, but also optimized for functional longevity and cost efficiency.

Reach out today to discuss your high temperature sealing challenges. Send technical drawings, performance requirements, or environmental conditions to begin the engineering review process. We respond to all inquiries within 24 business hours.

Email Mr. Boyce directly at [email protected] for confidential, expert support in developing weather stripping systems built to endure.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).