Technical Contents

Engineering Guide: Horse Stall Matts

Engineering Insight: Material Selection in Horse Stall Mats

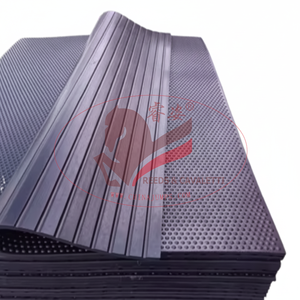

In the industrial design of horse stall mats, material selection is not merely a cost-driven decision—it is a structural and performance imperative. Off-the-shelf rubber mats, often marketed as universal solutions, frequently fail under the dynamic loading, biological exposure, and environmental stressors inherent in equine facilities. These failures manifest as cracking, delamination, microbial degradation, and loss of dimensional stability, ultimately compromising animal safety and facility hygiene.

The root cause lies in the inconsistency of base materials. Many commercial products utilize recycled rubber content with unverified polymer composition, inconsistent vulcanization, and unknown cross-link density. Such variability leads to unpredictable mechanical behavior under sustained compressive loads. Horses exert localized pressures exceeding 150 psi during rest and movement, particularly when lying down or shifting weight. Low-grade rubber compounds lack the elastic recovery and compression set resistance required to maintain surface integrity over time.

At Suzhou Baoshida Trading Co., Ltd., our engineered rubber solutions are formulated with high-density SBR (Styrene-Butadiene Rubber) and EPDM compounds, selected for superior tensile strength, abrasion resistance, and resilience. These polymers undergo controlled vulcanization with sulfur and accelerators to achieve optimal cross-linking, ensuring long-term durability under continuous load. The result is a mat that maintains its thickness, surface texture, and load-bearing capacity for over a decade in high-traffic stables.

Another critical factor is resistance to biological degradation. Conventional mats absorb moisture and organic contaminants, creating an ideal environment for bacterial and fungal growth. This not only accelerates material breakdown but poses health risks to horses, including dermatitis and respiratory issues. Our formulations incorporate antimicrobial additives and closed-cell structures that resist fluid penetration, significantly reducing pathogen retention.

Dimensional stability is equally vital. Thermal expansion and contraction due to seasonal temperature shifts can cause warping or buckling in poorly formulated mats. Our materials are engineered with balanced filler dispersion—using precipitated silica and reinforcing carbon black—to minimize thermal drift while maintaining flexibility in sub-zero conditions.

The following table outlines key performance specifications of our industrial-grade horse stall mats compared to typical off-the-shelf alternatives:

| Property | Baoshida Engineered Mat | Standard Recycled Mat |

|---|---|---|

| Material Composition | High-density SBR/EPDM blend | Mixed recycled rubber (unspecified) |

| Thickness Tolerance | ±0.5 mm | ±2.0 mm |

| Hardness (Shore A) | 75–80 | 60–70 |

| Tensile Strength | ≥12 MPa | ≤7 MPa |

| Elongation at Break | ≥250% | ≤150% |

| Compression Set (22h at 70°C) | ≤15% | ≥30% |

| Water Absorption (24h) | <1.0% | >5.0% |

| Antimicrobial Treatment | Yes (integrated) | No |

| Service Temperature Range | -40°C to +80°C | -10°C to +60°C |

In conclusion, the failure of generic stall mats stems from inadequate material science, not operational misuse. Precision-engineered rubber systems, designed with known polymer matrices and controlled processing, deliver measurable improvements in safety, longevity, and hygiene. For facility operators, the initial investment is offset by reduced replacement frequency, lower maintenance, and enhanced equine welfare.

Material Specifications

Material Specifications for Equine Stall Flooring Systems

Selecting optimal elastomeric compounds is critical for horse stall mats subjected to aggressive biological fluids, mechanical abrasion, and variable thermal cycles. Suzhou Baoshida Trading Co., Ltd. prioritizes formulations balancing resilience, chemical inertness, and lifecycle cost for equestrian infrastructure. Our engineered solutions leverage three primary synthetic rubbers, each validated against ASTM D2000 and ISO 37 standards for industrial performance.

Viton fluoroelastomer (FKM) delivers unparalleled resistance to equine urine ammonia degradation and disinfectant solvents like quaternary ammonium compounds. With a continuous service temperature range of -20°C to +250°C, it maintains structural integrity under steam cleaning protocols exceeding 120°C. Its 18-22 MPa tensile strength and 70-80 Shore A hardness prevent permanent deformation from concentrated hoof impacts. While premium-priced, Viton’s molecular stability ensures >15-year service life in high-turnover training facilities where chemical exposure is chronic.

Nitrile butadiene rubber (NBR) offers the optimal cost-performance ratio for standard stabling environments. Our high-acrylonitrile variants (45% ACN content) achieve 15-20 MPa tensile strength with exceptional resistance to aliphatic hydrocarbons in urine and manure. Operating effectively from -30°C to +100°C, it provides reliable non-slip traction at 65-75 Shore A hardness. NBR’s abrasion resistance index of 120% (vs. natural rubber baseline) minimizes surface wear from shod hooves, making it ideal for boarding operations with moderate chemical exposure.

Silicone rubber (VMQ) excels in extreme temperature zones and low-compression-set applications. Its -60°C to +200°C operational envelope prevents winter embrittlement while resisting thermal shock during pressure washing. With 6.0-8.5 MPa tensile strength and 45-60 Shore A flexibility, it accommodates subfloor irregularities without fatigue cracking. Though vulnerable to concentrated acids in some cleaning agents, food-grade silicone variants meet FDA 21 CFR 177.2600 for direct animal contact, suiting therapeutic rehabilitation stalls requiring hypoallergenic surfaces.

The following comparative analysis summarizes critical parameters for OEM specification:

| Material Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Tensile Strength (MPa) | 18-22 | 15-20 | 6.0-8.5 |

| Hardness (Shore A) | 70-80 | 65-75 | 45-60 |

| Temp Range (°C) | -20 to +250 | -30 to +100 | -60 to +200 |

| Ammonia Resistance | Excellent | Good | Fair |

| Hydrocarbon Resistance | Excellent | Excellent | Poor |

| Compression Set (%) | ≤15 (24h @ 150°C) | ≤25 (24h @ 70°C) | ≤20 (24h @ 200°C) |

| Relative Cost Factor | 3.5x | 1.0x | 2.8x |

Suzhou Baoshida’s OEM engineering team customizes durometer tolerances within ±3 Shore A and incorporates anti-microbial additives per ISO 22196 without compromising mechanical properties. Material selection must align with facility-specific exposure profiles—NBR for general use, Viton for intensive sanitation regimes, or Silicone for climate-extreme regions. All compounds undergo 500-hour accelerated aging tests per ASTM D573 prior to batch release.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Industrial Rubber Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in specialized applications such as horse stall mats. With a dedicated team comprising five experienced mould engineers and two advanced formula engineers, we deliver technically robust, application-specific products that meet the demanding requirements of agricultural, equestrian, and industrial environments. Our integrated engineering approach ensures seamless development from concept to final production, with precision at every stage.

Our mould engineering team specializes in designing high-tolerance, durable steel and aluminum tooling optimized for long production cycles and consistent part quality. Each mould is engineered using CAD/CAM software, enabling precise control over geometry, venting, and cooling channels to minimize cycle time and eliminate defects such as warping or incomplete curing. This expertise ensures that every horse stall mat produced maintains uniform thickness, surface texture, and dimensional accuracy across large batch runs.

Complementing our mould design capability is our in-house rubber formulation expertise. Our two formula engineers possess deep knowledge of elastomer chemistry, focusing on optimizing compound performance for impact absorption, slip resistance, UV stability, and long-term compression set resistance—critical factors in equestrian flooring. We formulate using SBR, EPDM, and recycled rubber compounds, tailoring each recipe to balance cost, durability, and environmental resilience. This allows us to produce mats that withstand heavy loads, frequent cleaning, and outdoor exposure without degradation.

Our OEM service model is built around technical collaboration. Clients provide performance targets or application parameters, and our engineering team responds with customized solutions—whether adjusting durometer (typically 60–80 Shore A), integrating interlocking profiles, or enhancing edge durability. We support low-volume prototyping and rapid tooling iterations, ensuring design validation before full-scale production.

All formulations and mould designs undergo rigorous in-house testing, including tensile strength, elongation at break, and abrasion resistance, following ISO 37 and ASTM D412 standards. This data-driven development process ensures compliance with international quality benchmarks and consistent performance in real-world conditions.

Below is a summary of typical technical specifications for our standard horse stall mat product line, reflecting our engineering precision and material optimization.

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 65–75 |

| Tensile Strength | ASTM D412 | ≥7.5 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤20% |

| Tear Resistance | ASTM D624 | ≥25 kN/m |

| Specific Gravity | ASTM D297 | 1.15–1.25 |

| Operating Temperature Range | — | -40°C to +80°C |

Through the synergy of advanced mould design and scientific rubber formulation, Suzhou Baoshida delivers engineered reliability in every horse stall mat. Our OEM framework empowers partners to co-develop solutions that meet exact functional and commercial objectives, reinforcing our role as a trusted technical manufacturer in the global industrial rubber market.

Customization Process

Customization Process for Industrial-Grade Horse Stall Mats

Suzhou Baoshida Trading Co., Ltd. executes a rigorous four-phase customization protocol for OEM horse stall mats, ensuring alignment with equestrian facility durability requirements and animal safety standards. Our process begins with Drawing Analysis Phase, where engineering teams deconstruct client-provided CAD schematics to assess dimensional tolerances, load-bearing zones, and surface texture specifications. Critical parameters include stall layout integration, drainage channel geometry, and edge sealing requirements. Non-conformities in draft angles or undercuts are flagged for immediate client consultation to prevent production defects. This phase mandates ISO 10287 compliance verification for agricultural rubber products.

Formulation Development Phase follows, translating geometric data into material science solutions. Our rubber compounders prioritize Shore A hardness 65–75 for optimal shock absorption under equine weight loads while maintaining slip resistance per DIN 51130 R11 standards. Key formulation variables are optimized:

| Property | Target Range | Test Standard | Functional Impact |

|---|---|---|---|

| Tensile Strength | 12–15 MPa | ASTM D412 | Resists tearing during hoof impact |

| Compression Set (70°C) | ≤ 22% after 24h | ASTM D395 | Prevents permanent deformation |

| Abrasion Loss | ≤ 120 mm³ | ASTM D5963 | Extends service life in high-traffic zones |

| Hardness (Shore A) | 65–75 | ASTM D2240 | Balances comfort and structural integrity |

Natural rubber (NR) dominates base polymers for resilience, reinforced with N330 carbon black for UV stability. Antioxidant packages mitigate ozone cracking in ventilated barn environments.

Prototyping Phase validates formulation efficacy through physical trials. Mats undergo accelerated aging (72h @ 70°C), dynamic load testing simulating 700kg equine pressure cycles, and microbial resistance screening against common barn pathogens. Client feedback on prototype texture, odor, and installation compatibility triggers iterative compound adjustments. A minimum 95% pass rate in ASTM F2950 equine safety tests is mandatory before progression.

Mass Production Phase initiates only after formal client sign-off on prototypes. We deploy precision hydraulic presses (2000T capacity) with temperature-controlled platens (±1.5°C stability) to ensure uniform vulcanization. In-line infrared spectrometry monitors cure state in real-time, while automated vision systems inspect surface defects at 0.1mm resolution. Each batch undergoes third-party certification for heavy metal content (RoHS compliant) and formaldehyde emissions (<0.05ppm). Final packaging includes serialized traceability tags linking mats to specific compound batches and QC records.

This closed-loop methodology guarantees stall mats deliver 15+ years of service life under intensive equestrian use while meeting global agricultural safety mandates. Suzhou Baoshida’s OEM partnership model transforms facility-specific requirements into engineered rubber solutions with zero compromise on performance integrity.

Contact Engineering Team

For industrial-grade rubber solutions tailored to demanding applications such as equine facilities, agricultural flooring, and commercial livestock environments, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of precision engineering and material science. Our expertise in manufacturing high-performance horse stall mats is rooted in over a decade of collaboration with OEM partners, equestrian centers, and industrial flooring contractors across Europe, North America, and Asia. Each mat is formulated using advanced rubber compounding techniques to deliver optimal shock absorption, slip resistance, and long-term dimensional stability under continuous load and variable climatic conditions.

Our proprietary rubber formulations utilize a blend of reclaimed and virgin SBR (Styrene-Butadiene Rubber), ensuring consistent physical properties while maintaining environmental responsibility. Every production batch undergoes rigorous quality control testing for tensile strength, elongation at break, compression set, and abrasion resistance—parameters critical for durability in high-traffic and moisture-prone environments. We specialize in custom durometer ratings (ranging from 60 to 85 Shore A), thickness customization (from 10 mm to 20 mm), and color-matching capabilities to meet specific project requirements.

Suzhou Baoshida operates a fully integrated supply chain, from raw material sourcing to final packaging, enabling us to maintain strict process control and on-time delivery performance exceeding 98%. Our facility is ISO 9001-certified, with in-house tooling and mold-making capabilities that allow rapid prototyping and low minimum order quantities (MOQs) for trial installations or private-label development.

Below are standard technical specifications for our most widely deployed horse stall mat configuration:

| Property | Test Method | Value |

|---|---|---|

| Material Composition | ASTM D395 | 70% Virgin SBR, 30% Recycled EPDM |

| Thickness | ISO 2768 | 17.5 mm ± 0.5 mm |

| Density | ASTM D297 | 1.15 g/cm³ |

| Hardness (Shore A) | ASTM D2240 | 75 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 7.5 MPa |

| Elongation at Break | ASTM D412 | ≥ 250% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤ 20% |

| Slip Resistance (R10) | DIN 51130 | Confirmed |

| Temperature Range | — | -40°C to +80°C |

| Fire Rating | UL 94 | HB |

All products are packaged in UV-resistant polywrap, stacked on standard EUR/ISO pallets, and shipped via FCL or LCL depending on order volume. We support OEM labeling, custom branding, and technical documentation packages including MSDS, certificates of conformance, and test reports.

To discuss your specific application requirements, request samples, or initiate a private-label partnership, contact Mr. Boyce directly at [email protected]. As the lead OEM Manager and Rubber Formula Engineer at Suzhou Baoshida, Mr. Boyce oversees material formulation, production optimization, and client technical integration. He is available for virtual consultations, factory audits, and on-site technical support for large-scale installations. Response time is typically within 4 business hours during China Standard Time working hours. For urgent inquiries, include “Priority – Horse Stall Project” in the subject line to ensure immediate routing.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).