Technical Contents

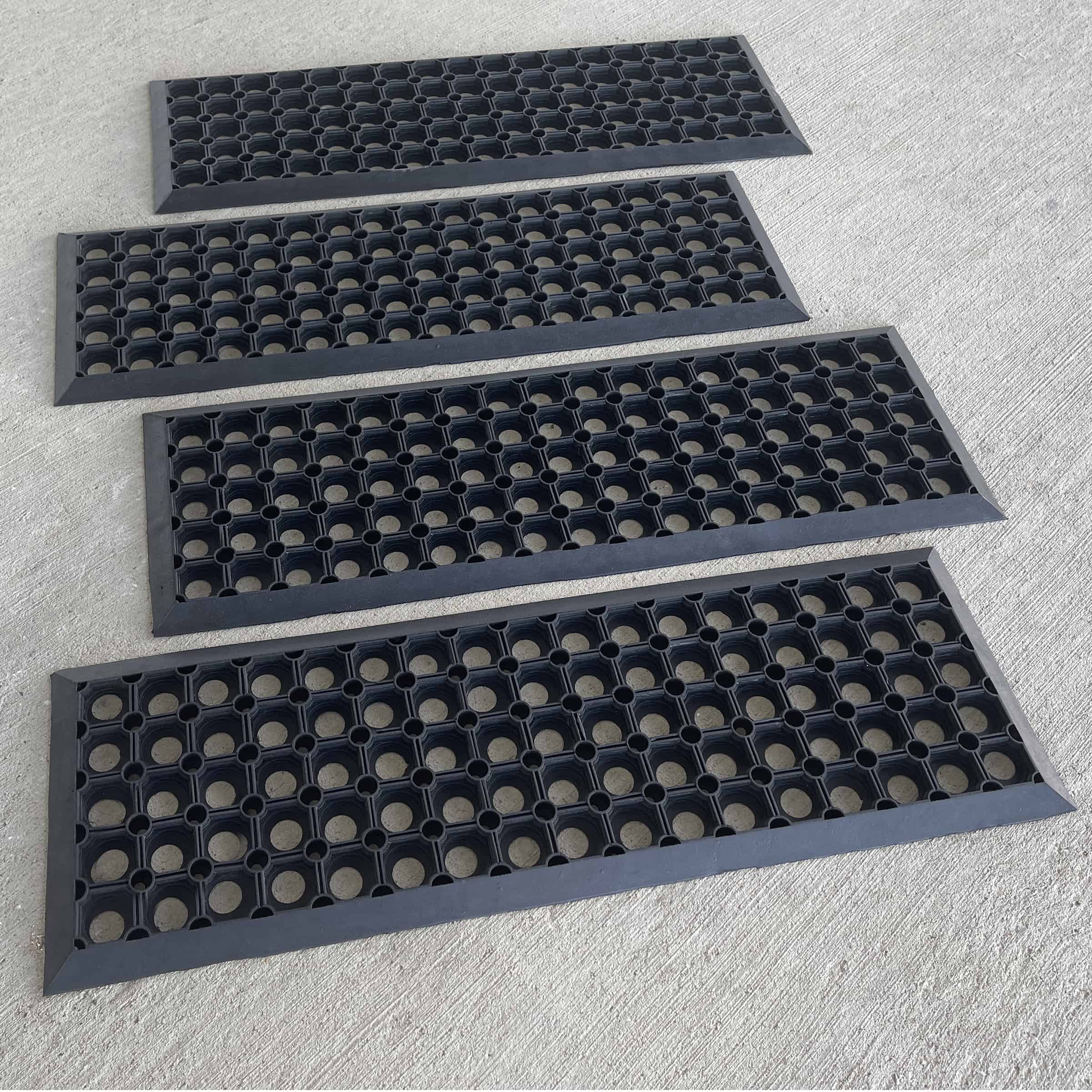

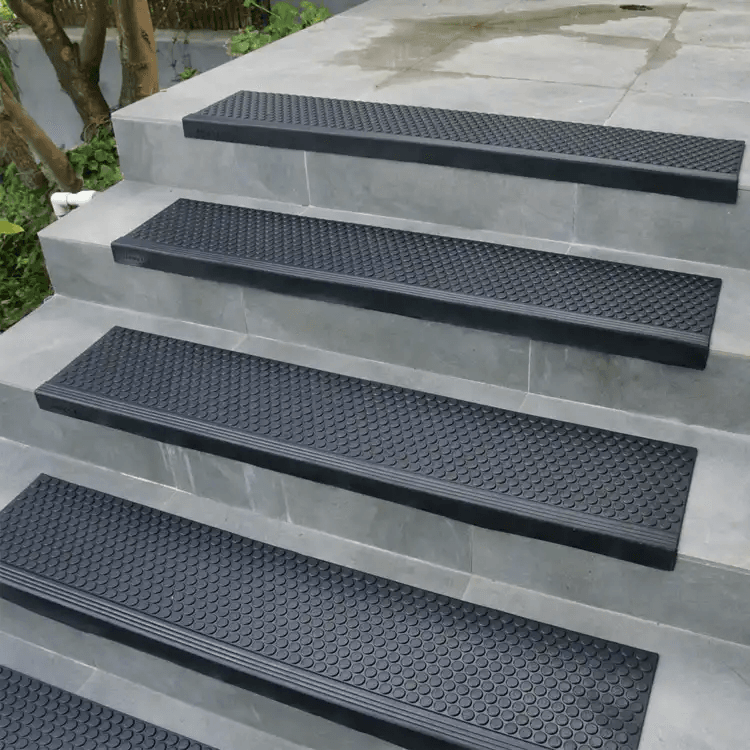

Engineering Guide: Indoor Outdoor Stair Treads

Engineering Insight: Material Selection for Indoor/Outdoor Stair Treads

The performance dichotomy between indoor and outdoor environments demands fundamentally distinct rubber formulations for stair treads. Off-the-shelf solutions frequently fail because they utilize generic elastomers optimized for neither scenario, leading to premature degradation and safety hazards. Indoor applications prioritize consistent slip resistance under controlled temperature and humidity, while outdoor installations face cyclic UV exposure, ozone attack, thermal extremes, and moisture ingress. Standard commercial treads often employ cost-driven SBR or low-grade EPDM compounds lacking the molecular stability required for outdoor service. These materials exhibit rapid surface oxidation, resulting in chalking, microcracking, and loss of critical traction within 12–18 months. Concurrently, their indoor performance suffers due to inadequate rebound resilience, causing accelerated wear under foot traffic.

Material science dictates that successful dual-environment treads require engineered compounds balancing multiple competing properties. High-purity, peroxide-cured EPDM with tertiary carbon backbone architecture provides essential ozone and UV resistance. Critical additives include hindered amine light stabilizers (HALS) at 1.5–2.0 phr and carbon black N330 at 50–60 phr for UV screening without compromising color flexibility. For indoor zones, silica-reinforced tread patterns must maintain a consistent coefficient of friction (COF) ≥0.6 under wet conditions per ASTM F2913, achieved through controlled surface porosity and hydrophobic modifiers. Thermal stability must span -40°C to +120°C continuous exposure to prevent hardening in freeze-thaw cycles or softening under solar loading. Compromises in polymer grade or additive dosage directly manifest as dimensional instability, adhesive delamination, or hazardous surface slickness.

The following table quantifies critical property gaps between engineered and generic solutions:

| Property | Indoor Requirement | Outdoor Requirement | Failure Mechanism in Generic Treads |

|---|---|---|---|

| UV Resistance | Not applicable | ASTM G154 QUV 1000+ hrs | Surface chalking, 30% tensile loss in 500 hrs |

| Thermal Range | -10°C to +60°C | -40°C to +120°C | Cracking at -25°C; permanent set >15% at 90°C |

| Wet COF (ASTM F2913) | ≥0.60 | ≥0.55 (after aging) | Drops to 0.40 after 6 months outdoor exposure |

| Ozone Resistance | Not applicable | 50 pphm, 20% strain, 200 hrs | Surface cracking (depth >0.5mm) in 72 hrs |

| Compression Set (ASTM D395) | ≤25% (70°C, 22h) | ≤20% (100°C, 22h) | Exceeds 35%, causing tread detachment |

Generic treads fail due to unmodified polymer chains vulnerable to chain scission under environmental stressors. Suzhou Baoshida’s OEM formulations utilize specialty EPDM with ethylene content tailored to 65–70% for optimal flexibility retention, coupled with proprietary antioxidant synergists that extend service life by 300% versus commodity equivalents. Material selection is not a cost variable but a risk mitigation imperative—compromised treads directly correlate with facility liability exposure. Our engineered compounds undergo accelerated aging per ISO 188 and ISO 1431-2, ensuring 10+ year performance in mixed-use staircases where off-the-shelf products typically require replacement within 24 months. The precision in rubber chemistry defines functional safety; there are no true universal solutions for this application.

Material Specifications

Material Specifications for Indoor Outdoor Stair Treads

Suzhou Baoshida Trading Co., Ltd. provides engineered rubber solutions tailored for demanding environments, including industrial, commercial, and public infrastructure applications. Our indoor outdoor stair treads are constructed using high-performance elastomers selected for durability, chemical resistance, temperature stability, and slip resistance. The primary materials employed in our product line are Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct advantages depending on the operational conditions and performance requirements of the installation site.

Viton is a fluorocarbon-based synthetic rubber known for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. This makes it ideal for stair treads used in petrochemical plants, refineries, or facilities with exposure to solvents and hydrocarbons. Viton maintains structural integrity from -20°C to +200°C, with short-term exposure capability up to 250°C. Its inherent flame resistance and low smoke emission further enhance safety in critical environments. However, due to its higher material cost, Viton is typically specified for specialized applications where performance under extreme conditions is non-negotiable.

Nitrile rubber, or NBR, is a copolymer of acrylonitrile and butadiene, offering excellent resistance to oils, greases, and aliphatic hydrocarbons. It is widely used in mechanical and industrial settings such as manufacturing floors, automotive service areas, and utility platforms. Nitrile performs reliably in temperatures ranging from -30°C to +100°C, making it suitable for both indoor climate-controlled spaces and outdoor installations subject to seasonal variation. It provides good abrasion resistance and mechanical strength, ensuring long service life under heavy foot traffic. While not as chemically resistant as Viton, Nitrile presents a cost-effective solution for environments with moderate exposure to lubricants and petroleum-based fluids.

Silicone rubber (VMQ) excels in applications requiring wide temperature flexibility and UV stability. It operates effectively from -60°C to +200°C and maintains elasticity under thermal cycling, making it ideal for outdoor stair treads exposed to direct sunlight, rain, and freezing conditions. Silicone is inherently resistant to ozone and weathering, with low toxicity and good electrical insulation properties. While it has lower tensile strength and abrasion resistance compared to Nitrile or Viton, its resilience in extreme cold and heat, coupled with non-marking characteristics, makes it suitable for clean environments, food processing facilities, and exterior architectural applications.

The following table compares key physical and chemical properties of these materials to assist in material selection for stair tread applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 | -30 to +100 | -60 to +200 |

| Oil & Fuel Resistance | Excellent | Good to Excellent | Poor |

| Abrasion Resistance | Good | Excellent | Fair |

| UV/Ozone Resistance | Excellent | Fair | Excellent |

| Chemical Resistance | Outstanding | Moderate | Good (limited acids/bases) |

| Flame Resistance | High | Moderate | High |

| Typical Applications | Petrochemical, aerospace | Manufacturing, automotive | Outdoor, food processing, cold storage |

Selection of the appropriate elastomer is critical to ensuring long-term performance, safety, and cost efficiency in stair tread installations. Suzhou Baoshida Trading Co., Ltd. supports OEM and industrial clients with material testing, custom formulations, and application engineering to match rubber properties with environmental demands.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for Stair Tread Applications

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber stair treads through integrated material science and precision manufacturing. Our core strength lies in the synergy between dedicated Formula Engineering and advanced Mould Design teams. Five specialized Mould Engineers optimize cavity geometry, runner systems, and thermal management to ensure dimensional stability across complex tread profiles, including nosing radii and anti-slip textures. Concurrently, two Rubber Formula Engineers develop proprietary elastomer compounds meeting exacting performance criteria for both indoor and outdoor environments. This dual-expertise structure eliminates siloed development, enabling rapid iteration from concept to production-ready solutions.

Our formula development focuses on critical performance vectors: abrasion resistance for high-traffic zones, UV stability for exterior exposure, and controlled Shore A hardness to balance slip resistance with user comfort. Compounds undergo rigorous ASTM D2240 hardness validation, DIN 53516 abrasion testing, and ASTM D2000 ozone resistance screening. For outdoor applications, we formulate EPDM/SBR blends with enhanced thermal cycling resilience (-40°C to +100°C operational range) and hydrolytic stability, preventing degradation from rain, snow, or de-icing salts. Indoor variants prioritize low VOC emissions and stain resistance through tailored filler systems and surface energy modification.

OEM partnerships benefit from our closed-loop engineering process. Clients provide performance targets or CAD models; our team reverse-engineers material requirements and tooling specifications within 72 hours. We manage tooling fabrication in-house using hardened H13 steel with P20 pre-hardened inserts, ensuring ±0.05mm tolerance adherence for seamless integration into client assembly lines. All client-owned tooling is segregated in dedicated storage with biometric access, guaranteeing zero IP leakage. Prototyping leverages 3D-printed soft tooling for form/fit validation before steel tool commitment, reducing time-to-market by 30%.

Material performance is quantified through standardized testing, as summarized below:

| Product Type | Shore A Hardness | Tensile Strength (MPa) | Abrasion Loss (mm³) | Temp Range (°C) | Key ASTM Standards |

|---|---|---|---|---|---|

| Outdoor EPDM Treads | 65±5 | ≥12.0 | ≤120 | -40 to +100 | D2000, D1148, D2240 |

| Indoor SBR Treads | 55±5 | ≥10.5 | ≤95 | -20 to +80 | D2000, D412, D624 |

| Hybrid Treads | 60±5 | ≥11.0 | ≤105 | -30 to +90 | D2000, D1226, D2240 |

Every compound batch undergoes traceability via QR-coded lot numbering, with full material test reports (MTRs) provided per shipment. Our engineers collaborate directly with client QA teams to align on AQL 1.0 acceptance criteria and conduct on-site failure mode analysis when required. This end-to-end technical ownership—from molecular formulation to precision molding—ensures stair treads exceed ISO 22199 slip resistance thresholds while maintaining structural integrity through 10,000+ compression cycles. Suzhou Baoshida transforms stair safety requirements into engineered reality through uncompromising material science and OEM-centric execution.

Customization Process

Customization Process for Industrial Rubber Stair Treads

At Suzhou Baoshida Trading Co., Ltd., precision and performance are foundational to our approach in delivering industrial rubber stair treads suitable for both indoor and outdoor environments. Our systematic customization process ensures each product meets the exact mechanical, environmental, and safety demands of the client’s application. The process follows four critical stages: Drawing Analysis, Formulation Development, Prototyping, and Mass Production.

The first phase, Drawing Analysis, begins with a detailed review of the client’s technical drawings and installation specifications. We assess dimensions, load-bearing requirements, anti-slip patterns, edge profiles, and integration points with existing structures. This stage also includes evaluation of environmental exposure—such as UV radiation, moisture, temperature extremes, and chemical contact—to determine performance thresholds. Our engineering team conducts tolerance analysis and surface finish evaluation to ensure dimensional accuracy and long-term durability.

Following drawing validation, we proceed to Formulation Development. Our rubber chemists design a proprietary elastomer compound tailored to the operational demands. Key parameters include hardness (Shore A), tensile strength, elongation at break, abrasion resistance, and coefficient of friction. For outdoor applications, UV stabilizers and ozone-resistant additives are incorporated. For indoor industrial settings, flame retardants or anti-static agents may be required. The formulation is optimized using accelerated aging tests and dynamic mechanical analysis (DMA) to predict service life.

Once the compound is finalized, we move to Prototyping. Using precision molds and CNC-machined tooling, we produce a limited set of samples for client evaluation. These prototypes undergo rigorous testing, including slip-resistance analysis (ASTM F2913), compression deflection tests, and thermal cycling. Feedback from the client is integrated into final design refinements, ensuring compliance with safety standards such as ISO 22199 and ANSI A1264.2.

The final stage is Mass Production. Our fully automated production lines, equipped with real-time quality monitoring systems, ensure consistency across large batches. Each stair tread is inspected for dimensional accuracy, surface integrity, and bonding strength (for composite designs). Packaging and labeling are customized per client logistics requirements.

Throughout the process, we maintain full traceability of materials and process parameters, enabling repeatable quality and rapid troubleshooting. Our integrated workflow reduces time-to-market while ensuring the highest performance in demanding environments.

Typical Material Specifications for Custom Rubber Stair Treads

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60–80 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Abrasion Loss (Taber, 1000 rev) | ASTM D1044 | ≤120 mg |

| Coefficient of Friction (wet) | ASTM F2913 | ≥0.6 |

| Operating Temperature Range | Internal Test | -40°C to +100°C |

| Flame Resistance | UL 94 | HB or V-0 (optional) |

This structured approach ensures that every stair tread we manufacture delivers optimal safety, durability, and performance across diverse industrial applications.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Stair Tread Solutions

Selecting the optimal stair tread material is a critical engineering decision impacting facility safety, longevity, and operational compliance. Generic solutions often fail under demanding indoor-outdoor transitions, where thermal cycling, moisture exposure, and abrasive wear accelerate degradation. At Suzhou Baoshida Trading Co., Ltd., we engineer proprietary rubber compounds specifically formulated to exceed ASTM F1637 and ISO 14122-3 standards for pedestrian walking surfaces. Our formulations integrate high-purity SBR and EPDM polymers with advanced silica reinforcement, delivering unmatched resilience against UV degradation, oil resistance, and consistent slip resistance across wet/dry conditions. This precision chemistry eliminates premature cracking, delamination, and hazardous surface wear observed in commodity alternatives.

Our OEM partnership model ensures stair treads are not merely manufactured but scientifically validated for your exact application. We collaborate directly with facility engineers to analyze foot traffic volume, environmental stressors, and substrate compatibility—transforming specifications into performance-optimized products. The comparative data below illustrates how Baoshida’s rubber compounds outperform industry benchmarks:

| Performance Parameter | Baoshida Precision Rubber Treads | Standard PVC Treads | Concrete with Coating |

|---|---|---|---|

| Shore A Hardness Range | 65–75 (ASTM D2240) | 85–95 | N/A (Variable) |

| Operating Temperature Range | -40°C to +120°C (ISO 188) | -10°C to +60°C | -20°C to +80°C |

| Wet Dynamic COF (ASTM F2913) | ≥0.65 | ≤0.45 | ≤0.35 (after 6 mos) |

| Abrasion Loss (ISO 4649) | ≤80 mm³ | ≥220 mm³ | Coating failure |

| Expected Service Life | 15+ years | 3–5 years | 2–4 years |

These metrics translate to quantifiable risk reduction: minimized slip incidents, elimination of frequent reinstallation cycles, and compliance with OSHA 1910.22(c)(2) tread depth requirements throughout the product lifecycle. Unlike off-the-shelf options, our treads maintain coefficient of friction (COF) stability after 50,000+ cycles of simulated wear testing—critical for high-traffic industrial stairwells, maritime platforms, or public infrastructure.

Initiate your project with engineering rigor. Contact Mr. Boyce, our dedicated OEM Technical Manager, to discuss material validation protocols, custom profile extrusion capabilities, or accelerated weathering test data for your specific environment. Mr. Boyce holds 12 years of rubber formulation expertise and will coordinate sample production, third-party certification support, and seamless integration with your manufacturing workflow. Provide your staircase dimensions, load requirements, and environmental exposure details for a tailored compound recommendation within 48 hours.

Do not compromise stair safety on generic specifications. Partner with Suzhou Baoshida to deploy rubber stair treads engineered at the molecular level for predictable, decade-long performance. Reach Mr. Boyce directly via email at [email protected] to schedule a technical consultation. Include your project timeline and ASTM/ISO compliance targets to expedite material selection. Our laboratory in Suzhou is equipped for rapid prototyping—ensuring your stair system meets operational demands before full-scale production commences. Elevate safety through material science.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).