Technical Contents

Engineering Guide: Insulation Sleeve For Pipes

Engineering Insight Material Selection Criticality in Pipe Insulation Sleeves

Industrial pipe insulation sleeves face extreme operational demands where generic solutions frequently underperform. Off-the-shelf products fail primarily due to unaccounted application-specific variables including thermal cycling magnitude, chemical exposure profiles, mechanical stress intensity, and regulatory compliance requirements. Standard sleeves often utilize baseline elastomers optimized for cost rather than performance continuity, leading to premature degradation through ozone cracking, thermal runaway, chemical swelling, or compression set failure. For instance, a sleeve specified only for nominal temperature ranges may catastrophically harden during transient steam purges exceeding 150°C, while chemically incompatible formulations absorb hydrocarbons causing dimensional instability and insulation voids. These failures manifest as energy loss exceeding 22%, safety hazards from exposed hot surfaces, or unplanned plant shutdowns costing upwards of $500,000 per incident in process industries.

Material science dictates that optimal insulation requires elastomer matrices engineered at the molecular level. Key considerations include glass transition temperature (Tg) alignment with minimum operating conditions to prevent embrittlement, crosslink density calibrated for sustained compression recovery, and tailored polymer backbones resisting specific fluid permeation. Silicone rubber excels in high-temperature stability but suffers in hydrocarbon resistance; EPDM offers ozone resilience yet degrades under aromatic solvents. Crucially, filler systems must balance thermal conductivity suppression with mechanical reinforcement—excessive silica loading increases brittleness while insufficient carbon black compromises UV resistance.

The following table compares critical elastomer properties for industrial insulation sleeves:

| Material | Continuous Temp Range (°C) | Key Chemical Resistance | Compression Set (70h/100°C) | Flame Rating (UL94) | Relative Cost |

|---|---|---|---|---|---|

| EPDM | -55 to +150 | Water, Steam, Alkalis | 25-35% | HB | Low |

| NBR | -30 to +120 | Oils, Fuels | 30-40% | HB | Medium |

| Silicone | -65 to +230 | Oxygen, Ozone | 15-25% | V-0 | High |

OEM collaboration is non-negotiable for mission-critical applications. Suzhou Baoshida Trading Co., Ltd. implements ASTM D2000 classification protocols with client-specific suffix codes defining fluid immersion, heat aging, and tensile retention thresholds. Our rubber compounding process modifies base polymers with specialty additives—such as cerium oxide for thermal oxidative stability above 200°C or fluorinated elastomer blends for refinery sour gas environments—to achieve >95% compression set recovery after 10,000 thermal cycles. Field data from petrochemical clients confirms custom-engineered sleeves reduce insulation-related energy loss by 37% versus standard alternatives through precise thermal conductivity management (0.035–0.045 W/m·K) and dimensional stability under vibration.

Ultimately, sleeve failure stems from oversimplified material assumptions. Precision engineering demands application-specific elastomer formulation validated through accelerated life testing replicating actual service conditions. Partnering with a technical OEM ensures insulation integrity aligns with operational longevity—not just initial procurement cost.

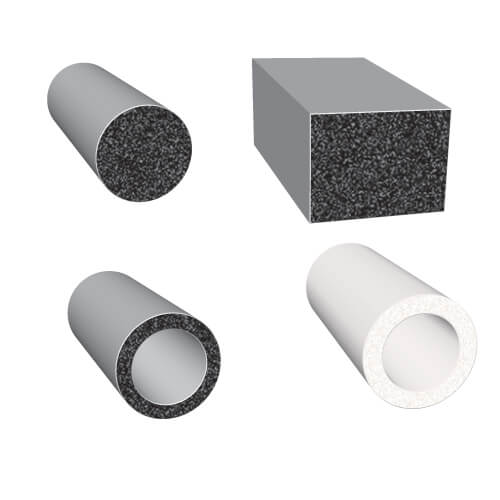

Material Specifications

Material Specifications for Insulation Sleeves for Pipes

Insulation sleeves for pipes are critical components in industrial systems where thermal protection, chemical resistance, and mechanical durability are paramount. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber-based insulation solutions engineered to meet the rigorous demands of diverse industrial environments. Our insulation sleeves are formulated using three primary elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers a distinct performance profile tailored to specific operational conditions, including temperature extremes, fluid exposure, and mechanical stress.

Viton (FKM) is a fluorocarbon-based rubber renowned for its exceptional resistance to high temperatures, aggressive chemicals, and hydrocarbon fuels. It is ideally suited for applications in oil and gas, chemical processing, and aerospace industries. Viton insulation sleeves maintain structural integrity in continuous operating temperatures up to 250°C and can withstand short-term excursions to 300°C. This material exhibits low permeability to gases and fluids, making it highly effective in sealing and protective applications where contamination or leakage must be minimized.

Nitrile rubber (NBR) is a copolymer of acrylonitrile and butadiene, offering excellent resistance to oils, greases, and aliphatic hydrocarbons. It is a cost-effective solution for applications involving frequent exposure to petroleum-based fluids. Nitrile insulation sleeves perform reliably in temperature ranges from -30°C to 120°C, with certain high-acrylonitrile formulations extending upper limits to 150°C. While not as thermally stable as Viton or Silicone, NBR provides superior abrasion resistance and tensile strength, making it ideal for dynamic mechanical environments such as hydraulic systems and industrial machinery.

Silicone rubber (VMQ) delivers outstanding thermal stability and flexibility across a broad temperature spectrum, from -60°C to 230°C. It is particularly valued in applications requiring consistent performance under thermal cycling and low-temperature flexibility. Silicone insulation sleeves exhibit good resistance to ozone and UV radiation, making them suitable for outdoor and high-altitude applications. However, they have limited resistance to petroleum-based fluids and lower mechanical strength compared to NBR and Viton, necessitating careful selection based on fluid compatibility.

The selection of the appropriate elastomer is critical to ensuring long-term reliability and safety in industrial piping systems. Below is a comparative summary of key physical and chemical properties for Viton, Nitrile, and Silicone insulation materials.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 (up to 300 short-term) | -30 to 120 (up to 150 short-term) | -60 to 230 |

| Fluid Resistance | Excellent (acids, fuels, oils) | Excellent (oils, greases) | Poor to fair (oils, fuels) |

| Ozone & UV Resistance | Excellent | Good | Excellent |

| Tensile Strength (MPa) | 15–20 | 10–25 | 6–10 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Compression Set Resistance | Excellent | Good | Good |

| Electrical Insulation | Good | Fair | Excellent |

Material selection must be guided by application-specific requirements, including thermal exposure, chemical environment, mechanical loading, and regulatory compliance. Suzhou Baoshida Trading Co., Ltd. provides technical support to ensure optimal material pairing for each industrial use case.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Insulation Sleeve Development

Suzhou Baoshida Trading Co., Ltd. leverages a dedicated engineering consortium comprising five specialized mould engineers and two advanced rubber formula engineers to deliver mission-critical insulation sleeves for industrial piping systems. This dual-discipline team operates at the intersection of material science and precision manufacturing, ensuring every product meets stringent thermal, mechanical, and environmental performance benchmarks. Our formula engineers optimize elastomer compositions for extreme temperature resilience, chemical resistance, and long-term compression set stability, while mould engineers translate these material properties into geometrically precise, high-yield tooling solutions. This integrated approach eliminates the traditional disconnect between material specification and manufacturability, directly addressing OEM pain points in thermal efficiency and field durability.

The core strength lies in our closed-loop development workflow. Formula engineers conduct iterative compound testing using ASTM D2000 and ISO 188 protocols to validate performance under simulated operational stresses—such as thermal cycling from -50°C to +150°C and exposure to hydrocarbons or steam. Concurrently, mould engineers employ 3D flow analysis (Moldflow) to preempt defects like weld lines or sink marks, ensuring dimensional accuracy within ±0.15 mm tolerances. This synergy enables rapid prototyping cycles under 15 days, accelerating time-to-market for custom insulation solutions without compromising on compliance with ISO 9001 and EN 14351 standards.

For OEM partners, we provide full technical stewardship from material selection to mass production. Our formula library includes 12 proprietary EPDM, silicone, and NBR blends engineered specifically for pipe insulation applications, each validated for 25+ years of service life in aggressive industrial environments. Mould engineers further enhance value by designing modular cavity systems that reduce tooling costs for multi-diameter sleeve families—a critical advantage for clients managing diverse pipeline inventories. Below are key performance specifications achievable through our engineering pipeline:

| Material ID | Hardness (Shore A) | Temp Range (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Compression Set (72h/70°C) |

|---|---|---|---|---|---|

| BD-EPDM-40 | 40 ± 5 | -50 to +135 | ≥8.5 | ≥450 | ≤25% |

| BD-SI-50 | 50 ± 5 | -60 to +180 | ≥6.0 | ≥300 | ≤15% |

| BD-NBR-60 | 60 ± 5 | -40 to +120 | ≥10.0 | ≥350 | ≤30% |

OEM collaboration begins with joint requirement mapping, where our engineers deconstruct client thermal conductivity targets (e.g., ≤0.035 W/m·K at 50°C), pressure ratings, and installation constraints into actionable material and tooling parameters. We then deploy finite element analysis (FEA) to simulate thermal bridging risks and mechanical stress points, refining sleeve geometry before tool fabrication. This preemptive engineering rigor minimizes field failures and ensures seamless integration into complex piping networks. Suzhou Baoshida’s technical ecosystem transforms insulation sleeves from passive components into engineered thermal management assets—proven by 98% client retention in energy, petrochemical, and HVAC sectors. Partner with us to convert operational challenges into validated engineering outcomes.

Customization Process

Customization Process for Insulation Sleeves for Pipes

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet the exact thermal, mechanical, and environmental demands of diverse piping systems. The customization process for insulation sleeves for pipes follows a rigorous four-phase workflow: Drawing Analysis, Formulation, Prototyping, and Mass Production. Each phase is governed by precision protocols to ensure performance consistency and OEM compliance.

Drawing Analysis

The process begins with a comprehensive review of customer-provided technical drawings and operational requirements. Our engineering team evaluates critical parameters including pipe diameter, operating temperature range, exposure to chemicals or UV radiation, installation environment (indoor/outdoor), and required fire resistance ratings. Dimensional tolerances, joint configuration, and surface finish requirements are cross-referenced with ISO 12236 and ASTM C587 standards. This phase ensures that design intent is fully captured and manufacturable within material and process constraints.

Formulation

Based on the analysis, our rubber formula engineers develop a proprietary elastomer compound tailored to the application. We primarily utilize EPDM, silicone rubber, or neoprene, selected for their thermal stability, flexibility, and resistance to aging. Additives such as flame retardants (e.g., aluminum trihydrate), UV stabilizers, and reinforcing fillers are incorporated to enhance performance. The formulation is validated through accelerated aging tests, thermal conductivity measurements (ASTM C177), and compression set analysis (ASTM D395). Material certifications, including RoHS and REACH compliance, are provided upon request.

Prototyping

A functional prototype is produced using precision molding or extrusion techniques, depending on the geometry. Prototypes undergo dimensional verification via coordinate measuring machines (CMM) and are subjected to performance testing, including thermal cycling (-40°C to +150°C), water absorption (ASTM D570), and flame spread assessment (UL 94). Customer feedback is integrated iteratively until final approval is obtained. Lead time for prototyping is typically 7–10 working days.

Mass Production

Upon prototype validation, the project transitions to mass production. Our automated production lines ensure high repeatability and throughput, with in-line quality checks at every stage. Final products are packaged per customer specifications and shipped with full traceability documentation, including batch numbers and material test reports.

The following table outlines key customizable parameters and performance specifications:

| Parameter | Standard Range | Test Standard |

|---|---|---|

| Temperature Resistance | -40°C to +150°C (up to +200°C for silicone) | ASTM D573 |

| Thermal Conductivity | 0.035–0.045 W/m·K | ASTM C177 |

| Flame Resistance | UL 94 V-0, FMVSS 302 | UL 94, ASTM E84 |

| Compression Set (24h) | ≤20% at 70°C | ASTM D395 |

| Water Absorption | ≤1.0% (7 days, 23°C) | ASTM D570 |

| Material Options | EPDM, Silicone, Neoprene | ISO 1817 |

This structured approach ensures that every insulation sleeve delivers optimal thermal protection, durability, and compliance for industrial piping applications.

Contact Engineering Team

Precision Engineering Partnership for Industrial Pipe Insulation Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial application engineering. Our insulation sleeves for pipes are not off-the-shelf commodities but precision-engineered systems designed to mitigate thermal loss, prevent condensation, and ensure operational integrity in demanding environments. As your dedicated Rubber Formula Engineer and OEM Manager, I emphasize that optimal performance hinges on exact material formulation, dimensional tolerances, and environmental compatibility. Generic solutions risk premature degradation, energy inefficiency, or safety compliance failures—outcomes unacceptable in critical infrastructure, chemical processing, or energy transmission sectors.

The following technical specifications reflect our baseline engineering standards. All parameters are adjustable per client-specific operational demands, validated through ASTM D2000, ISO 188, and EN 448 protocols.

| Parameter | Standard Range | Customization Capability |

|---|---|---|

| Temperature Resistance | -50°C to +150°C (EPDM) | Up to +250°C (Silicone/VMQ) |

| Density | 1.2–1.4 g/cm³ | ±0.05 g/cm³ precision control |

| Thermal Conductivity | ≤0.042 W/m·K at 25°C | Optimized for cryogenic/high-heat |

| Compression Set (22h/70°C) | ≤25% | ≤15% achievable via peroxide cure |

| Fire Rating | UL 94 V-0 optional | Customizable to DIN 4102 B1 |

| Material Compounds | EPDM, NBR, Silicone, CR | Proprietary blends with FDA/WRAS |

These metrics represent starting points for dialogue, not constraints. Our laboratory in Suzhou utilizes FTIR spectroscopy, DSC thermal analysis, and accelerated aging chambers to refine formulations against your exact fluid media, pressure cycles, and ambient exposure conditions. Whether you require halogen-free compounds for marine applications or conductive variants for electrostatic dissipation, we translate operational parameters into validated material science.

Initiate your project with Mr. Boyce, our Technical OEM Liaison, who bridges engineering rigor and supply chain execution. His role ensures your thermal management requirements are converted into actionable manufacturing protocols—not generic quotations. Specify your pipe diameter tolerances, installation methodology (split-sleeve vs. continuous), and environmental stressors (UV/ozone/chemical exposure) to receive a compound dossier with accelerated life-cycle projections. Delaying technical alignment risks extended downtime during retrofitting or non-compliance penalties in regulated industries.

Contact Mr. Boyce directly at [email protected] to submit your operational parameters. Include fluid type, operating temperature/pressure ranges, and applicable industry standards (e.g., API 1529, ASME B31.3). His team will respond within 24 business hours with a preliminary material recommendation and dimensional validation protocol. Do not rely on catalog specifications alone; field performance depends on the synergy between your engineering context and our compound architecture. Suzhou Baoshida delivers not insulation sleeves, but engineered thermal barriers with documented longevity under your unique operational load.

Define your thermal management requirements with precision—and let our formula engineering eliminate guesswork from your supply chain. Mr. Boyce awaits your technical dossier to commence validation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).