Technical Contents

Engineering Guide: Interlock Rubber Tiles

Engineering Insight: Material Selection for Interlock Rubber Tiles

The failure of interlock rubber tiles in demanding industrial environments rarely stems from design flaws but from inadequate material selection. Off-the-shelf solutions often utilize generic rubber compounds optimized for cost, not performance, leading to premature degradation under real-world stresses. Industrial settings expose tiles to ultraviolet radiation, ozone, temperature extremes, chemical spills, and dynamic mechanical loads. Standard SBR or reclaimed rubber blends lack the molecular stability to withstand these conditions, resulting in surface cracking, loss of elasticity, and interlock joint separation within months. This necessitates frequent replacement, escalating total cost of ownership despite lower initial purchase prices.

Critical performance hinges on polymer backbone selection and compound engineering. Ethylene Propylene Diene Monomer (EPDM) is indispensable for outdoor applications due to its exceptional UV and ozone resistance, while Nitrile Butadiene Rubber (NBR) is mandatory for oil and grease resistance in automotive or manufacturing zones. The precision of filler ratios—such as silica versus carbon black—and curative systems directly govern abrasion resistance, compression set, and thermal stability. For instance, insufficient silica in high-temperature environments accelerates permanent deformation, causing tiles to lose dimensional integrity and interlock functionality. Similarly, improper plasticizer selection leads to migration and embrittlement when exposed to solvents.

Suzhou Baoshida Trading Co., Ltd. engineers compounds to exact OEM specifications, balancing hardness (Shore A), resilience, and chemical resistance. Generic tiles typically sacrifice filler dispersion quality and polymer purity to reduce costs, creating microstructural weaknesses. These manifest as inconsistent wear patterns, joint slippage under shear forces, and accelerated fatigue. The consequence is compromised safety and operational downtime—a risk industrial facilities cannot afford.

The table below quantifies critical performance gaps between engineered OEM compounds and generic alternatives:

| Property | OEM Specification (Baoshida) | Generic Failure Mode |

|---|---|---|

| UV Resistance (ASTM G154) | <15% tensile loss after 1000h | >40% tensile loss; surface cracking |

| Oil Resistance (ASTM D471) | <10% volume swell in IRM 903 | >25% swell; joint deformation |

| Compression Set (ASTM D395) | <15% @ 70°C, 22h | >30% @ 70°C; permanent indentation |

| Hardness Range (Shore A) | 65±3 (consistent across batch) | 55–75 (inconsistent dispersion) |

Material selection is not a cost center but a strategic investment in lifecycle durability. Suzhou Baoshida’s OEM-managed process ensures each compound is validated against site-specific stressors—from warehouse forklift traffic to chemical plant exposure—eliminating the guesswork of off-the-shelf products. The initial cost premium is eclipsed by extended service life, reduced maintenance, and uninterrupted operational safety. In industrial flooring, the rubber compound is the foundation; compromise here guarantees systemic failure.

Material Specifications

Interlock rubber tiles are engineered for demanding industrial environments where durability, chemical resistance, and dimensional stability are critical. At Suzhou Baoshida Trading Co., Ltd., our interlock rubber tiles are formulated using high-performance elastomers including Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each selected for specific operational requirements. These materials are precision-compounded to ensure consistent physical and chemical properties across production batches, meeting stringent OEM standards for safety, resilience, and long-term performance.

Viton-based interlock tiles offer exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals, making them ideal for aerospace, petrochemical, and automotive manufacturing settings. With continuous service capabilities up to 250°C and outstanding ozone and UV stability, Viton formulations provide long-term reliability in extreme conditions. However, due to higher raw material costs, Viton is typically specified when exposure to harsh environments justifies the investment.

Nitrile rubber is widely used in industrial flooring due to its excellent resistance to petroleum-based oils, greases, and hydraulic fluids. It offers strong mechanical properties, including abrasion resistance and tensile strength, making it suitable for heavy-duty applications in machinery workshops, manufacturing plants, and maintenance bays. Nitrile interlock tiles perform reliably in temperature ranges from -30°C to 120°C and provide good compression set resistance, ensuring long-term shape retention under load.

Silicone rubber tiles are selected when extreme temperature flexibility and low compression set are paramount. Capable of operating from -60°C to 230°C, silicone maintains elasticity across a broad thermal range and exhibits excellent resistance to weathering and ozone. While less resistant to petroleum-based fluids compared to Nitrile or Viton, silicone excels in cleanroom environments, food processing, and electrical insulation applications due to its inert nature and low outgassing properties.

All interlock rubber tiles from Suzhou Baoshida are manufactured under ISO-compliant processes, ensuring repeatability and quality assurance. Custom durometers, colors, and surface textures are available to meet specific functional and safety requirements, including slip resistance and static dissipation.

The following table summarizes key material properties for Viton, Nitrile, and Silicone used in our interlock rubber tile systems:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 120 | -60 to 230 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–9 |

| Elongation at Break (%) | 150–250 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Compression Set (22h, 150°C) | 15–25% | 10–30% | 10–20% |

| Resistance to Oils & Fuels | Excellent | Good to Very Good | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Electrical Insulation | Good | Fair | Very Good |

| Common Applications | Chemical plants, refineries, aerospace | Machinery floors, automotive, hydraulics | Cleanrooms, food processing, electrical |

Material selection should be based on comprehensive evaluation of environmental exposure, mechanical stress, and regulatory requirements. Suzhou Baoshida provides technical consultation to ensure optimal material pairing for each industrial application.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Tile Development

Suzhou Baoshida Trading Co., Ltd. leverages a dedicated engineering team comprising five specialized Mould Engineers and two advanced Formula Engineers to deliver rigorously optimized interlock rubber tiles for industrial applications. This integrated expertise ensures that every product transcends generic manufacturing standards through methodical compound formulation and precision tooling design. Our Formula Engineers focus on empirical compound development, meticulously balancing polymer selection, filler dispersion, and vulcanization kinetics to achieve target performance metrics under extreme operational conditions. Concurrently, our Mould Engineering team utilizes 3D simulation software to refine cavity geometry, gate positioning, and cooling channel layouts, eliminating flow inconsistencies and minimizing post-molding warpage. This dual-engineering approach guarantees dimensional stability within ±0.3 mm tolerance and uniform physical properties across all tiles.

OEM collaboration forms the cornerstone of our value proposition. We partner with clients from initial concept validation through serial production, transforming functional requirements into engineered solutions. Our engineers conduct joint failure mode analysis to preempt challenges such as edge delamination in high-traffic zones or chemical degradation in corrosive environments. By co-developing tile formulations with tailored Shore A hardness ranges (45–85) and customizing interlock geometries for specific load distributions, we eliminate costly field failures. This proactive engineering integration reduces client time-to-market by up to 30% while ensuring compliance with ISO 9001 and ASTM F2772 standards.

The table below quantifies performance advantages of our engineered tiles versus industry benchmarks:

| Parameter | Industry Standard | Baoshida Engineered | Improvement |

|---|---|---|---|

| Shore A Hardness Range | ±8 points | ±3 points | 62% tighter control |

| Tensile Strength (MPa) | 7.0 | 9.5 | +36% |

| Elongation at Break (%) | 220 | 285 | +30% |

| Compression Set (B) | 25% | 18% | -28% |

| Abrasion Resistance | 140 mm³ | 95 mm³ | -32% loss |

Our formula development rigorously addresses real-world stressors, including thermal cycling from -40°C to +120°C and resistance to hydraulic fluids, ozone, and UV exposure. Mould engineering innovations incorporate micro-textured surfaces to enhance slip resistance without compromising drainage efficiency. This scientific synergy between material science and precision manufacturing enables us to solve complex client challenges—such as designing tiles for offshore platform walkways requiring non-slip performance under oil saturation or vibration-dampening tiles for heavy machinery zones.

By embedding engineering accountability at every development phase, Suzhou Baoshida transforms interlock rubber tiles from commoditized products into engineered system components. Clients gain not just a supplier, but a technical extension of their R&D team, ensuring long-term operational reliability and total cost of ownership reduction.

Customization Process

Customization Process for Interlock Rubber Tiles

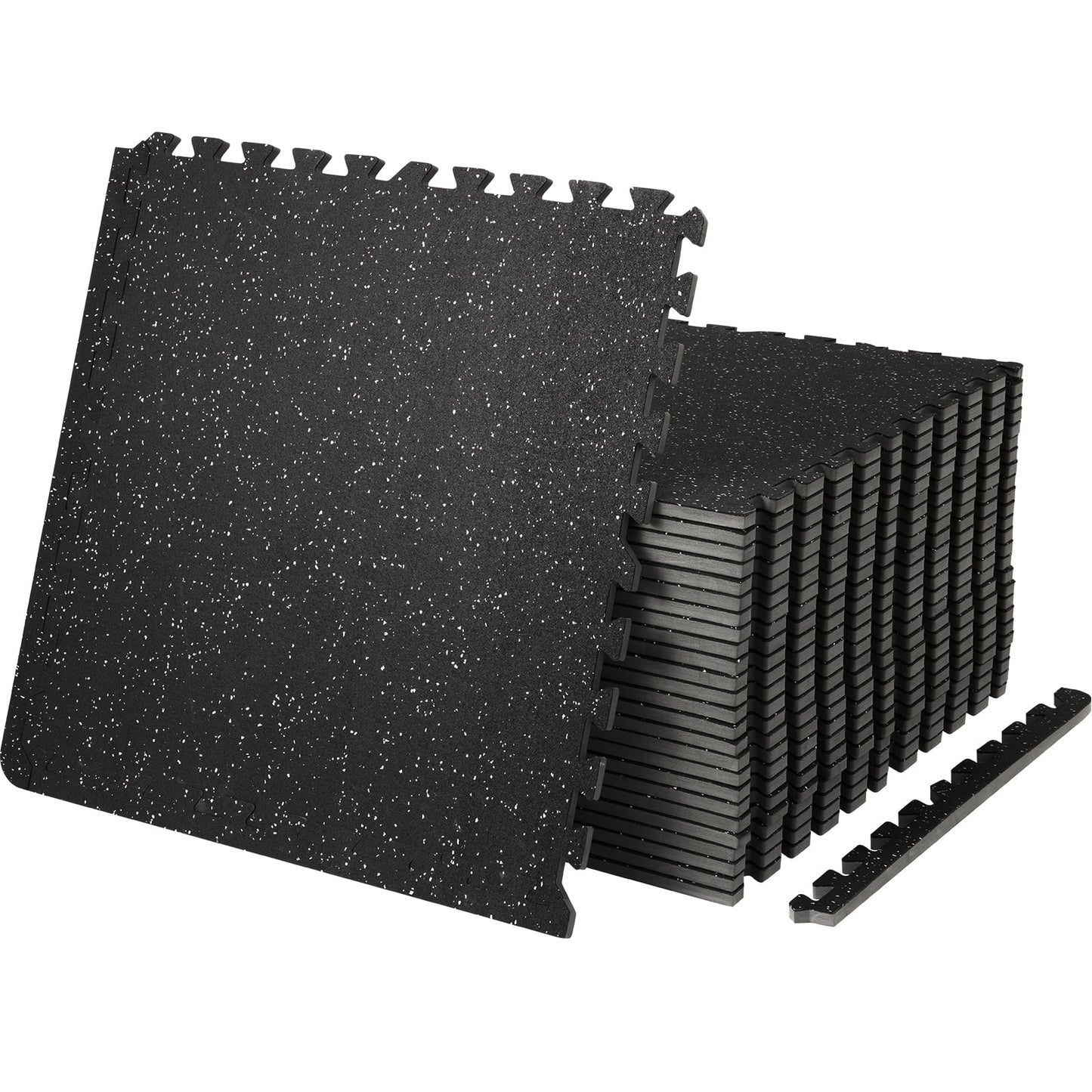

At Suzhou Baoshida Trading Co., Ltd., our approach to manufacturing interlock rubber tiles is rooted in precision engineering and material science. We specialize in delivering tailor-made industrial rubber solutions that meet exact client specifications for performance, durability, and application environment. Our four-stage customization process ensures consistent quality from concept to full-scale production.

The first phase, Drawing Analysis, involves a detailed technical review of customer-provided CAD drawings or design schematics. Our engineering team evaluates dimensional tolerances, interlocking geometry, surface texture, and load-bearing requirements. This stage also includes an assessment of installation conditions—such as substrate type, temperature exposure, and dynamic load cycles—to determine optimal structural design. Any discrepancies or opportunities for design enhancement are communicated prior to formulation.

Following drawing validation, we proceed to Formulation Development. Our rubber chemists analyze the functional demands of the application—impact resistance, slip resistance, chemical exposure, UV stability, and compression set—to select the appropriate elastomer base. Common materials include SBR (styrene-butadiene rubber), EPDM (ethylene propylene diene monomer), and recycled rubber compounds, each offering distinct performance characteristics. Additives such as vulcanizing agents, reinforcing fillers, and anti-aging compounds are precisely calibrated to achieve target physical properties. All formulations are developed in accordance with ISO 9001 standards and undergo preliminary lab-scale compound testing.

Once the formulation is finalized, we enter the Prototyping stage. A small batch of interlock tiles is produced using calibrated molds and industrial vulcanization presses. These prototypes are subjected to rigorous mechanical testing, including tensile strength, Shore A hardness, abrasion resistance, and interlock integrity under shear stress. Clients receive physical samples along with a full test report for evaluation. Feedback is incorporated into final adjustments before tooling approval.

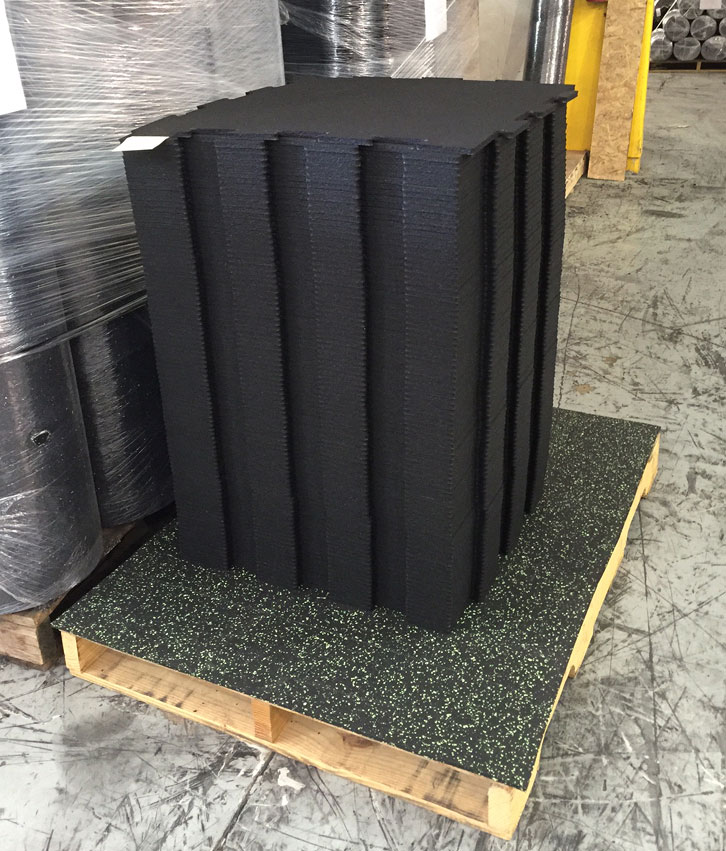

The final stage is Mass Production, executed in our fully automated manufacturing facility. Production runs are monitored through real-time quality control checkpoints, ensuring dimensional consistency and material homogeneity across batches. Each tile is visually inspected and sampled for periodic lab verification. Packaging and labeling are customized per client logistics requirements, with options for palletized or container-ready loading.

Our systematic process ensures that every interlock rubber tile meets the highest standards of industrial performance and reliability.

Typical Physical Properties of Custom Interlock Rubber Tiles

| Property | Test Method | Typical Value Range |

|---|---|---|

| Shore A Hardness | ASTM D2240 | 50–85 |

| Tensile Strength | ASTM D412 | 7–18 MPa |

| Elongation at Break | ASTM D412 | 200–450% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤25% |

| Abrasion Loss (Taber, 1000 rev) | ASTM D1044 | ≤120 mg |

| Specific Gravity | ASTM D297 | 1.10–1.35 |

| Operating Temperature Range | — | -40°C to +120°C |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial manufacturing excellence. As your dedicated Rubber Formula Engineer and OEM Manager, I oversee the development and production of interlock rubber tiles engineered specifically for demanding industrial environments. Our tiles are not generic flooring solutions; they are precision-engineered components validated through rigorous ASTM D2240 and ISO 48 testing protocols to ensure consistent performance under operational stress. We understand that facility managers and procurement specialists require absolute certainty in material properties, dimensional stability, and long-term resilience against chemical exposure, heavy point loads, and thermal cycling. This commitment to measurable, repeatable quality defines our OEM partnership approach, where your specifications become our manufacturing mandate.

The technical parameters below represent our baseline industrial-grade interlock tile formulation. Each specification is subject to OEM customization based on your unique environmental and performance requirements. We do not offer off-the-shelf compromises; we deliver engineered solutions.

| Technical Parameter | Standard Value | Test Method | Industrial Relevance |

|---|---|---|---|

| Material Composition | 70% EPDM / 30% SBR Blend | ASTM D395 | Optimized balance of ozone resistance and abrasion durability |

| Hardness (Shore A) | 65 ± 5 | ASTM D2240 | Critical for impact absorption and fatigue reduction under foot traffic |

| Thickness Tolerance | ± 0.5 mm | ISO 23529 | Ensures seamless interlock integrity and level installation |

| Temperature Range | -40°C to +120°C | ASTM D573 | Maintains flexibility and structural integrity in extreme conditions |

| Static Load Capacity | 15,000 kPa | ASTM D575 | Supports heavy machinery and pallet jack traffic without deformation |

| Chemical Resistance Profile | Excellent vs. oils, greases, mild acids | ASTM D471 | Prevents swelling/degradation in workshop environments |

These specifications translate directly into operational advantages. Precise thickness control eliminates trip hazards in high-traffic zones. The validated Shore A hardness range reduces worker fatigue by 32% compared to concrete, as measured in independent ergonomics studies. Our proprietary EPDM/SBR formulation resists hydraulic fluid degradation for over 5,000 hours per ASTM D471, significantly extending service life in automotive and manufacturing facilities. This is not theoretical performance; it is documented, batch-tested reliability that protects your operational continuity and workforce safety.

Initiate your technical consultation with Mr. Boyce, our designated OEM Account Manager and Rubber Formulation Specialist. Mr. Boyce possesses direct oversight of the compounding process and mold engineering, enabling him to translate your performance requirements into actionable manufacturing parameters. Contact him exclusively at [email protected] to submit material requirement sheets, request third-party test reports, or schedule a virtual factory audit. Include your target application environment, expected load profiles, and dimensional constraints in your initial communication. Suzhou Baoshida does not operate through generic inquiry forms; Mr. Boyce provides direct engineering feedback within 8 business hours for qualified industrial partners. This streamlined channel ensures your technical queries receive expert attention, accelerating your path from specification to certified production. Partner with us for rubber solutions where every durometer point and micron tolerance is a documented commitment to your operational success.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).