Technical Contents

Engineering Guide: Interlocking Floor Pads

Engineering Insight: The Critical Role of Material Selection in Interlocking Floor Pads

In industrial environments, interlocking floor pads serve as more than just protective coverings—they are engineered solutions designed to withstand mechanical stress, chemical exposure, temperature fluctuations, and continuous foot or vehicular traffic. At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection is the cornerstone of performance, longevity, and safety in these applications. Off-the-shelf interlocking floor pads frequently fail under real-world conditions due to generic material formulations that prioritize cost over functionality. These pre-manufactured solutions often utilize low-grade recycled rubber or thermoplastics with insufficient resilience, leading to premature degradation, surface cracking, and loss of structural integrity.

The failure of standard pads becomes evident in high-demand sectors such as automotive assembly, warehousing, and heavy machinery operation. In these settings, floors are subjected to dynamic loads, oil and coolant spills, and extreme thermal cycles. Materials lacking appropriate cross-link density or chemical resistance absorb contaminants, swell, or become brittle, compromising both safety and operational efficiency. A pad that deforms under a forklift’s load or delaminates after exposure to hydraulic fluid is not merely an inconvenience—it represents a liability.

At Baoshida, we approach interlocking floor pad design through a precision engineering lens. Our formulations are based on vulcanized synthetic rubbers such as EPDM, Nitrile (NBR), and SBR, selected for their proven performance in targeted industrial environments. These materials offer superior tensile strength, abrasion resistance, and stability across a broad temperature range. Custom compounding allows us to adjust hardness (Shore A), density, and oil resistance to match the client’s operational profile, ensuring that each pad performs reliably under specified service conditions.

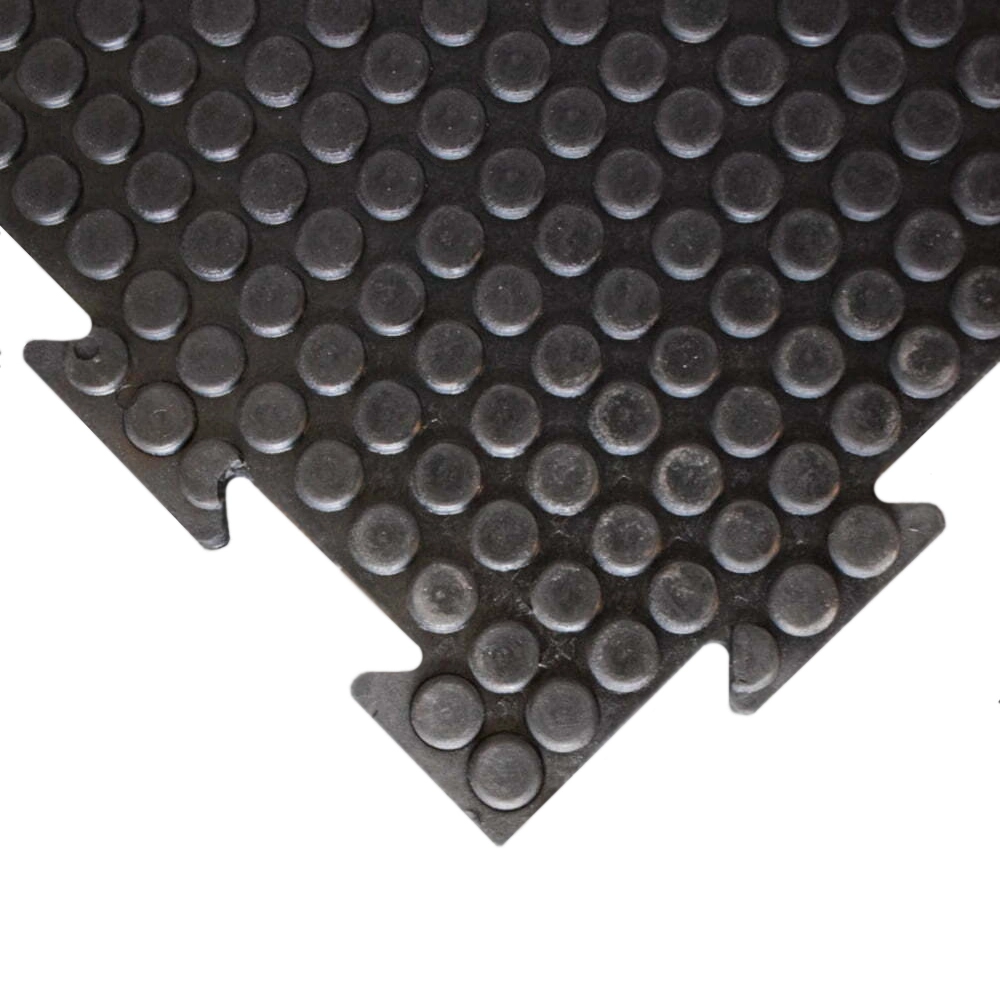

Moreover, the interlocking mechanism itself depends on material elasticity and dimensional stability. Inferior materials deform over time, causing misalignment, tripping hazards, and gaps that trap debris. Our engineered rubber compounds maintain consistent geometry and interlock integrity even after years of compression and shear stress.

Below is a comparison of typical material properties used in industrial interlocking floor pads:

| Material | Hardness (Shore A) | Tensile Strength (MPa) | Elongation at Break (%) | Oil Resistance | Temperature Range (°C) |

|---|---|---|---|---|---|

| Recycled Rubber | 50–60 | 5–7 | 150–200 | Low | -10 to +70 |

| SBR | 60–70 | 10–14 | 250–350 | Moderate | -30 to +80 |

| Nitrile (NBR) | 65–75 | 12–16 | 200–300 | High | -30 to +100 |

| EPDM | 60–70 | 11–15 | 250–350 | Moderate | -50 to +130 |

As demonstrated, high-performance elastomers significantly outperform generic alternatives. The data underscores why customized material selection is not optional—it is a technical necessity. At Suzhou Baoshida, we reject one-size-fits-all solutions, focusing instead on engineered rubber systems that deliver durability, safety, and total cost of ownership advantages.

Material Specifications

Material Specifications for Industrial Interlocking Floor Pads

Material selection critically determines the operational lifespan and functional efficacy of interlocking floor pads in demanding industrial environments. Suzhou Baoshida Trading Co., Ltd. prioritizes precision-engineered rubber compounds tailored to specific chemical, thermal, and mechanical stressors encountered in manufacturing, automotive, and aerospace facilities. Our formulations undergo rigorous ASTM D2000 and ISO 37 testing to ensure compliance with OEM durability standards. The three primary elastomers—Viton, Nitrile, and Silicone—offer distinct performance profiles essential for optimizing pad resilience against oils, solvents, extreme temperatures, and physical abrasion. Understanding these material properties enables strategic deployment where failure is not an option.

Viton fluoroelastomers deliver unparalleled resistance to aggressive chemicals, including halogenated solvents, jet fuels, and concentrated acids. With a continuous service temperature range up to 230°C and exceptional resistance to compression set, Viton pads maintain structural integrity in high-heat processing lines or chemical handling zones. Its molecular stability prevents swelling or degradation when exposed to aromatic hydrocarbons, making it indispensable for semiconductor fabrication and petrochemical applications. However, Viton’s higher cost necessitates targeted use where lesser elastomers would rapidly fail.

Nitrile butadiene rubber (NBR) remains the industry benchmark for oil and grease resistance at cost-effective performance levels. Optimized for Shore A hardness between 60–90, NBR pads withstand prolonged exposure to hydraulic fluids, lubricants, and aliphatic hydrocarbons common in automotive assembly and machinery maintenance areas. Operating effectively from -30°C to 120°C, NBR balances tensile strength (15–25 MPa) with abrasion resistance, ensuring longevity under heavy foot and forklift traffic. Its moderate resistance to ozone and weathering suits indoor industrial settings but limits outdoor applicability.

Silicone rubber excels in extreme temperature versatility (-60°C to 230°C continuous) and maintains flexibility in cryogenic or high-heat sterilization environments. Its inherent electrical insulation properties and non-marking surface make it ideal for cleanrooms, pharmaceutical facilities, and electronics manufacturing. While silicone demonstrates good resistance to water, ozone, and UV radiation, it exhibits lower tensile strength (6–12 MPa) and higher susceptibility to tearing under sharp impacts compared to NBR or Viton. Compression set performance is moderate, requiring careful design for sustained-load applications.

The comparative specifications below detail critical parameters for informed material selection. All values represent typical production batch averages per ASTM testing protocols.

| Material | Hardness Range (Shore A) | Continuous Temp Range (°C) | Tensile Strength (MPa) | Key Resistance Properties | Primary Industrial Applications |

|---|---|---|---|---|---|

| Viton (FKM) | 70–90 | -20 to 230 | 10–18 | Aromatic fuels, acids, solvents, heat | Chemical processing, aerospace, refineries |

| Nitrile (NBR) | 50–90 | -30 to 120 | 15–25 | Oils, greases, aliphatic hydrocarbons | Automotive workshops, machinery plants |

| Silicone (VMQ) | 30–80 | -60 to 230 | 6–12 | Extreme temps, ozone, UV, water, electricity | Cleanrooms, medical, food processing |

Suzhou Baoshida’s engineering team collaborates with OEM partners to validate material suitability against site-specific stressors, ensuring interlocking floor pads perform reliably under real-world operational loads. Custom compound adjustments—including filler reinforcement and polymer blending—are available to address unique client requirements beyond standard specifications. Material datasheets with full test reports accompany all production batches.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber engineering, delivering precision-engineered interlocking floor pads tailored to the functional demands of industrial, commercial, and automotive environments. Our engineering capability is anchored in a dedicated team of five specialized mould engineers and two advanced rubber formulation scientists, enabling seamless integration of design, material science, and manufacturing efficiency.

Our mould engineering team possesses extensive experience in the design and optimization of high-tolerance rubber moulds used in compression, transfer, and injection moulding processes. Each engineer applies finite element analysis (FEA) and CAD/CAM simulation tools to validate structural integrity, flow dynamics, and cycle efficiency prior to production. This proactive approach minimizes trial iterations, reduces time-to-market, and ensures dimensional consistency across high-volume runs. The interlocking geometry of our floor pads—characterized by precise tongue-and-groove interfaces and load-bearing ribs—is engineered for rapid assembly, long-term durability, and resistance to lateral displacement under dynamic loads.

Complementing our mould expertise, our two in-house rubber formula engineers specialize in custom elastomer development, focusing on performance attributes such as abrasion resistance, compression set, slip resistance, and temperature stability. Utilizing advanced compounding techniques, they formulate proprietary blends primarily based on SBR, NBR, EPDM, and recycled rubber matrices, tailored to meet specific OEM requirements. These formulations are validated through accelerated aging tests, Shore A hardness profiling, and dynamic mechanical analysis (DMA) to ensure reliability in demanding operational environments.

Our OEM service model is built on collaborative engineering. Clients provide performance parameters or application constraints, and our team co-develops both the rubber compound and the mould design to achieve optimal functional synergy. This vertical integration of material and mechanical engineering eliminates dependency on third-party suppliers and ensures full traceability from raw material to finished product.

We support low-volume prototyping and scalable mass production, maintaining ISO-compliant process controls throughout. All interlocking floor pad solutions undergo rigorous quality validation, including tensile strength, elongation at break, and anti-slip coefficient testing, to meet international safety and durability standards.

Below is a representative specification profile for a standard industrial interlocking floor pad manufactured using our engineered rubber compound:

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 10 MPa |

| Elongation at Break | ASTM D412 | ≥ 250% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤ 20% |

| Abrasion Loss (Taber, 1000 rev) | ASTM D1044 | ≤ 120 mg |

| Operating Temperature Range | — | -30°C to +80°C |

| Coefficient of Friction (wet) | ASTM F2913 | ≥ 0.65 |

This technical foundation enables Suzhou Baoshida to deliver interlocking floor pad systems that meet exacting performance standards, ensuring safety, longevity, and operational efficiency for global OEM partners.

Customization Process

Customization Process for Industrial Interlocking Floor Pads

At Suzhou Baoshida Trading Co., Ltd., our customization process for interlocking floor pads begins with rigorous drawing analysis. Engineering teams meticulously review client-provided CAD files and technical specifications to verify dimensional tolerances, interlock geometry, and surface texture requirements. Critical parameters such as pad thickness (±0.5 mm), interlock depth (±0.3 mm), and edge radii are cross-referenced against ISO 2768-mK machining standards. Any deviations from manufacturable design principles—such as undercuts or non-uniform wall thickness—are flagged for collaborative redesign with the client. This phase ensures geometric feasibility while optimizing material flow during compression molding.

Following drawing validation, rubber formulation is engineered to match performance criteria. Our laboratory develops proprietary compounds using SBR, EPDM, or nitrile rubber bases, tailored to client demands for oil resistance, static dissipation, or extreme-temperature resilience. Key variables include polymer blending ratios, carbon black reinforcement levels (N330/N550), and curative systems (sulfur vs. peroxide). For instance, a pad requiring Shore A 70 hardness with 300% elongation at break necessitates precise phthalate-free plasticizer dosing and silica filler integration to balance flexibility and abrasion resistance. All formulations undergo predictive modeling via Mooney Viscometer ML(1+4) 100°C analysis to confirm scorch safety and cure kinetics.

Prototyping executes the validated design using client-specified compounds. Small-batch samples (typically 50–100 units) are produced on hydraulic presses with temperature-controlled platens (±2°C stability). Each prototype undergoes three-phase validation:

First, dimensional inspection via CMM against original drawings.

Second, mechanical testing per ASTM D2240 (hardness), D412 (tensile), and D624 (tear strength).

Third, functional trials simulating real-world load conditions (e.g., 5,000 kg/m² static load for 72 hours). Client feedback on slip resistance, noise dampening, and interlock integrity triggers iterative refinements until all KPIs are met.

Upon prototype approval, mass production commences under ISO 9001-certified protocols. Raw materials are traceable via batch-coded inventory systems, with in-process checks at every stage:

Compound homogeneity verified through rheometer scans every 2 hours.

Mold cavity pressure monitored to prevent flash or voids.

Final pads undergo 100% visual inspection and random sampling for density (ASTM D297) and compression set (ASTM D395). All production lots include certified test reports aligned to client specifications, ensuring repeatability across volumes exceeding 10,000 units.

Key Performance Specifications for Custom Interlocking Pads

| Property | Test Standard | Standard Range | Custom Range | Notes |

|---|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 50–80 | 35–90 | Lower values enhance shock absorption |

| Tensile Strength | ASTM D412 | 10–18 MPa | 7–22 MPa | EPDM formulations achieve upper range |

| Density (g/cm³) | ASTM D297 | 1.15–1.25 | 0.95–1.35 | Controlled via filler concentration |

| Compression Set (22h) | ASTM D395 | ≤25% | ≤18% | Critical for long-term load recovery |

| Operating Temp Range | ISO 188 | -40°C to +100°C | -55°C to +130°C | Nitrile variants enable extended range |

Contact Engineering Team

Contact Suzhou Baoshida for Premium Interlocking Floor Pad Solutions

When it comes to industrial flooring systems that deliver durability, safety, and long-term performance, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of engineered rubber solutions. As a trusted OEM manufacturer and supplier specializing in interlocking floor pads, we combine advanced material science with precision manufacturing to meet the rigorous demands of automotive workshops, manufacturing facilities, logistics centers, and fitness environments. Our products are not just floor coverings—they are engineered systems designed to endure heavy loads, resist oil and chemical exposure, and provide slip-resistant surfaces under dynamic operational conditions.

We invite technical buyers, procurement managers, and engineering teams to contact Mr. Boyce, our dedicated OEM Manager, to discuss custom specifications, volume production capabilities, and technical integration support. Whether you require pads tailored to specific load-bearing requirements, custom color coding for zone identification, or enhanced acoustic dampening properties, our R&D team collaborates directly with clients to deliver optimized solutions. With full control over raw material sourcing, vulcanization processes, and dimensional tolerances, Suzhou Baoshida ensures consistency across production batches and adherence to international quality standards.

Our interlocking floor pads are manufactured using high-density recycled rubber compounds, reinforced with proprietary polymer blends to enhance resilience and reduce compression set. Each pad is precision-molded to ensure seamless interlock alignment, minimizing lateral movement and edge uplift during service. In addition to standard configurations, we offer customization in thickness, surface texture (e.g., diamond plate, smooth, or anti-static), and edge profile to suit modular assembly requirements.

For technical documentation, sample requests, or direct consultation on integration into your facility or product line, reaching out to Mr. Boyce is the first step toward a reliable, scalable supply partnership. We support global logistics with containerized shipping, full traceability, and compliance documentation including RoHS, REACH, and ISO 9001:2015 certification.

Below are the standard technical specifications for our most widely deployed interlocking floor pad series:

| Property | Specification |

|---|---|

| Material Composition | Recycled SBR/NR blend with reinforcing fillers |

| Density | 1.25 ± 0.05 g/cm³ |

| Hardness (Shore A) | 65–75 |

| Tensile Strength | ≥ 8.5 MPa |

| Elongation at Break | ≥ 250% |

| Compression Set (22 hrs at 70°C) | ≤ 20% |

| Thickness Options | 10 mm, 12.5 mm, 15 mm |

| Standard Tile Size | 500 mm × 500 mm |

| Interlock Type | Four-way male-female |

| Operating Temperature Range | -30°C to +80°C |

| Fire Rating | UL 94 HF-1 (optional) |

Partner with Suzhou Baoshida to ensure your flooring infrastructure meets the highest benchmarks in safety, performance, and lifecycle value. Contact Mr. Boyce directly at [email protected] to initiate technical discussions, request material test reports, or schedule a factory audit. We are committed to delivering engineered rubber solutions that align precisely with your operational and commercial objectives.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).