Technical Contents

Engineering Guide: Interlocking Matting

Engineering Insight: Material Selection Criticality in Interlocking Matting Systems

Material selection is the non-negotiable foundation of durable interlocking matting performance in demanding industrial environments. Off-the-shelf rubber matting solutions frequently fail due to inadequate polymer formulation for specific operational stresses, leading to premature degradation, safety hazards, and increased total cost of ownership. Generic compounds prioritize initial cost reduction over engineered resilience, ignoring critical variables such as dynamic load distribution, chemical exposure profiles, and thermal cycling. When interlocking edges deform or the polymer matrix degrades, the entire system’s structural integrity collapses—mat segments separate, creating tripping hazards and eliminating slip resistance. Observed failure modes in standard mats include edge rounding from repeated compression set, swelling due to unaddressed fluid exposure, and catastrophic interlock fracture under thermal shock. These issues stem from insufficient cross-link density, inappropriate filler systems, or unstable plasticizer packages within the base elastomer.

Suzhou Baoshida Trading Co., Ltd. addresses this through OEM-engineered formulations where every compound parameter is validated against the client’s operational data. Standard mats utilize generic SBR or low-grade recycled rubber with uncontrolled vulcanization, resulting in inconsistent Shore hardness and poor recovery. In contrast, our interlocking systems deploy precision-tuned EPDM or NBR compounds with reinforced polymer networks. This ensures dimensional stability of the interlock geometry under sustained loads while resisting plasticizer migration and polymer chain scission. Crucially, material selection must account for the synergistic stressors at play: a mat in an automotive wash bay faces alkaline cleaners, thermal swings from 5°C to 60°C, and constant point loading from forklift tires—requirements no single off-the-shelf mat satisfies.

The following table compares critical performance parameters between standard off-the-shelf matting and Baoshida’s engineered interlocking solutions:

| Property | Standard Off-the-Shelf Matting | Baoshida Engineered Interlocking Matting | Test Standard |

|---|---|---|---|

| Shore A Hardness (Initial) | 60-65 | 70-80 (tolerance ±2) | ASTM D2240 |

| Tensile Strength | 8.5 MPa | 14.2 MPa | ASTM D412 |

| Elongation at Break | 250% | 480% | ASTM D412 |

| Compression Set (22h/70°C) | 35% | 12% | ASTM D395 |

| Hydraulic Oil Resistance (IRM 903) | Swell: +28% | Swell: +4.5% | ASTM D471 |

| 10% NaOH Resistance | Severe cracking, +18% swell | No cracking, +3.2% swell | ASTM D471 |

This engineered approach eliminates the false economy of low-cost mats. While standard products may appear cost-effective initially, their 6-12 month service life necessitates frequent replacement, downtime for reinstallation, and liability risks from failed interlocks. Baoshida’s formulations—validated through accelerated aging tests simulating 5+ years of operational stress—deliver predictable lifecycle performance. Our OEM process integrates client-specific data on fluid exposure, temperature ranges, and dynamic loads to calibrate polymer architecture, filler dispersion, and vulcanization kinetics. The result is interlocking matting that maintains geometric precision, load-bearing integrity, and chemical resistance throughout its operational life, directly reducing facility maintenance costs and enhancing workplace safety compliance. Material science is not a cost center; it is the determinant of system reliability.

Material Specifications

Interlocking matting systems are engineered for high-performance environments where chemical resistance, thermal stability, and mechanical durability are critical. At Suzhou Baoshida Trading Co., Ltd., we specialize in industrial rubber solutions tailored to demanding applications across pharmaceuticals, petrochemicals, semiconductor manufacturing, and food processing industries. Our interlocking mats are precision-formulated using advanced elastomers, including Viton, Nitrile (NBR), and Silicone, each selected for specific operational challenges. These materials are processed under strict quality controls to ensure dimensional accuracy, consistent durometer, and long-term performance under dynamic load and environmental exposure.

Viton, a fluorocarbon-based rubber, delivers superior resistance to extreme temperatures, aromatic hydrocarbons, chlorinated solvents, and acidic environments. It maintains integrity from -20°C to +250°C, making it ideal for high-temperature sealing and chemical containment zones. Nitrile rubber, known for its excellent oil and fuel resistance, is widely used in industrial flooring where exposure to lubricants, hydraulic fluids, and greases is common. With a temperature range of -30°C to +120°C and high abrasion resistance, Nitrile offers a cost-effective solution for mechanical and automotive environments. Silicone rubber provides exceptional thermal stability from -60°C to +230°C and outstanding resistance to ozone, UV radiation, and microbial growth. Its non-toxic, low-compression-set characteristics make it suitable for cleanroom, medical, and food-grade applications where hygiene and purity are paramount.

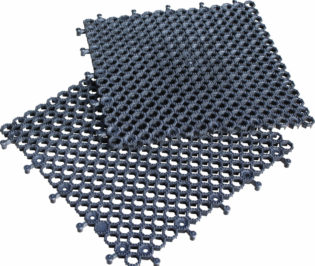

Each material is compounded with reinforcing fillers, curing agents, and stabilizers to meet international standards, including ASTM D2000 and ISO 1817. Our interlocking mats are manufactured with tight tolerance interlock profiles to ensure seamless assembly, anti-slip surface textures for personnel safety, and resistance to ponding and lateral displacement under foot traffic.

The following table summarizes key physical and chemical properties of the three primary elastomers used in our interlocking matting systems:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range | -20°C to +250°C | -30°C to +120°C | -60°C to +230°C |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Compression Set (22 hrs, 150°C) | ≤25% | ≤30% | ≤20% |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Acids & Chemicals | Excellent | Moderate | Moderate |

| Resistance to UV/Ozone | Excellent | Good | Excellent |

| FDA Compliant Compounds Available | Yes | Limited | Yes |

Material selection must align with the operational environment, including exposure media, thermal cycling, mechanical loading, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. provides technical consultation to ensure optimal material pairing for each industrial application.

Manufacturing Capabilities

Engineering Capability: Precision Formulation and Mold Design for Industrial Interlocking Matting

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise to deliver engineered interlocking matting solutions that meet exacting industrial performance standards. Our core strength lies in the integrated collaboration between dedicated mold design and rubber formulation teams. With five specialized mold engineers and two advanced formula engineers, we ensure every matting product achieves optimal mechanical integrity, chemical resistance, and lifecycle durability. This dual-discipline approach eliminates common industry gaps between material science and manufacturability, translating client specifications into precision-engineered outputs.

Our formula engineers focus on polymer matrix optimization for demanding environments. Through rigorous compound development, we tailor Shore A hardness, tensile strength, and elongation properties to resist oils, acids, UV degradation, and thermal cycling. Each formulation undergoes accelerated aging protocols and ASTM D2000 testing to validate performance under real-world stressors. Concurrently, our mold engineering team employs 3D CAD/CAM simulation to perfect cavity geometry, venting, and gating systems. This prevents defects like flash, sink marks, or inconsistent interlock engagement—critical for seamless mat assembly and long-term structural stability in high-traffic zones.

OEM partnership is central to our methodology. We transform client requirements into certified production-ready solutions through a structured process: technical RFQ analysis, material selection validation, mold flow simulation, and iterative prototyping with live production-line testing. Clients benefit from full traceability across raw material sourcing (including SGS-certified EPDM, NBR, and SBR compounds), in-process quality checkpoints, and final validation against ISO 9001 protocols.

The table below illustrates how our engineering synergy delivers measurable advantages over standard matting:

| Parameter | Standard Matting | Baoshida Custom OEM Matting | Testing Standard |

|---|---|---|---|

| Shore A Hardness | 65 ± 5 | 55–85 (Client-Specified) | ASTM D2240 |

| Tensile Strength | ≥ 7.0 MPa | ≥ 12.0 MPa | ASTM D412 |

| Oil Resistance (IRMO 70) | Volume Swell: ≤ 35% | Volume Swell: ≤ 15% | ASTM D471 |

| Interlock Shear Strength | 1.5 kN/m² | ≥ 3.0 kN/m² | Internal Method |

| Service Temperature | -20°C to +80°C | -40°C to +120°C | ISO 188 |

This precision extends to aesthetic and functional customization. We support OEM-specific color matching (Pantone®), surface textures (diamond plate, smooth, or anti-slip grit), and dimensional tolerances held to ±0.3mm. All tooling is maintained in-house with preventive calibration cycles, ensuring batch-to-batch consistency for orders ranging from 500 to 50,000+ units.

By unifying rubber chemistry with mold engineering physics, Suzhou Baoshida provides interlocking matting that exceeds operational demands in automotive, logistics, and heavy manufacturing. Our technical team engages directly with OEM clients during the design phase to preemptively resolve material-flow challenges, reducing time-to-market by up to 30% while guaranteeing compliance with global safety and performance benchmarks. Partner with us for matting engineered at the molecular and mechanical level.

Customization Process

Customization Process for Interlocking Matting: From Design to Mass Production

At Suzhou Baoshida Trading Co., Ltd., our approach to custom interlocking matting is rooted in precision engineering and material science. We specialize in industrial rubber solutions tailored to the operational demands of diverse sectors, including manufacturing, logistics, and heavy machinery. Our four-phase customization process ensures that every matting solution meets exact functional, environmental, and dimensional requirements.

The process begins with Drawing Analysis, where we evaluate customer-provided technical drawings or CAD files. This step is critical for determining load-bearing zones, interlock geometry, surface texture, and dimensional tolerances. Our engineering team conducts a thorough review to verify compatibility with production capabilities and to identify potential stress points or wear zones. We assess edge profiles, thickness gradients, and any embedded features such as drainage channels or anti-slip patterns. This phase also includes a feasibility assessment for integration into existing floor systems or equipment layouts.

Following drawing validation, we proceed to Rubber Formulation. Based on the operational environment—such as exposure to oils, chemicals, extreme temperatures, or heavy foot and vehicle traffic—we engineer a proprietary rubber compound. Our formulations may include SBR, EPDM, or nitrile rubber, reinforced with carbon black, silica, or other additives to enhance abrasion resistance, UV stability, or electrical insulation. Hardness is calibrated between 50–85 Shore A, depending on cushioning needs versus durability requirements. We also incorporate flame-retardant or anti-static agents when specified.

Once the formulation is finalized, we move to Prototyping. Using precision molds and vulcanization techniques, we produce a limited batch of sample mats for real-world testing. These prototypes undergo rigorous performance evaluation, including compression set tests, tensile strength measurement, slip resistance assessment (per ASTM F2913), and interlock integrity under repeated assembly cycles. Feedback from customer trials is integrated into final design refinements, ensuring optimal fit, function, and longevity.

The final phase is Mass Production, executed in our ISO-certified manufacturing facility. We employ high-tonnage hydraulic presses and automated curing systems to maintain consistency across large batches. Every mat is inspected for dimensional accuracy, surface finish, and interlock tightness. Our production lines support monthly outputs ranging from 10,000 to 50,000 square meters, scalable based on project scope.

Below are typical specifications achievable through our customization pipeline:

| Parameter | Range / Option |

|---|---|

| Material Types | SBR, EPDM, Nitrile, Recycled Rubber Blend |

| Hardness (Shore A) | 50–85 |

| Thickness | 6 mm – 25 mm |

| Temperature Resistance | -40°C to +120°C (up to +150°C for EPDM) |

| Standard Colors | Black, Gray, Blue, Red, Yellow |

| Custom Additives | Anti-static, Flame-retardant, UV stabilizers |

| Production Lead Time | 15–25 days (after prototype approval) |

| Monthly Capacity | Up to 500,000 kg |

This structured workflow ensures that every interlocking matting solution from Baoshida delivers unmatched durability, safety, and performance in industrial environments.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Interlocking Matting Solutions

Selecting the optimal interlocking matting system requires more than standard product specifications; it demands a partner with deep material science expertise and OEM-level manufacturing agility. At Suzhou Baoshida Trading Co., Ltd., we engineer industrial rubber solutions where performance under extreme conditions is non-negotiable. Our interlocking matting systems are formulated for critical applications in automotive assembly lines, chemical processing facilities, and heavy machinery workstations, where slip resistance, chemical resilience, and dimensional stability directly impact operational safety and productivity. Generic matting solutions often fail under sustained thermal cycling or aggressive fluid exposure, leading to premature degradation and costly downtime. Our proprietary NBR and EPDM compounds, reinforced with high-tensile fibers, deliver extended service life even in environments with continuous exposure to oils, solvents, and temperature extremes.

Our OEM-focused approach ensures your matting integrates seamlessly into existing workflows. We collaborate from concept to validation, optimizing durometer, surface texture, and interlock geometry for your specific load requirements and facility layout. This precision engineering mitigates common failure points such as edge curling, joint separation, and compression set. Below are key technical parameters defining our standard industrial-grade interlocking matting:

| Property | Standard Value Range | Test Method | Significance for Industrial Use |

|---|---|---|---|

| Material Composition | Nitrile Rubber (NBR) / EPDM | ASTM D2000 | Oil/fuel resistance; ozone/weathering stability |

| Durometer (Shore A) | 65–75 | ASTM D2240 | Balance of comfort underfoot and structural rigidity |

| Temperature Range | -40°C to +120°C | ISO 188 | Performance in freezing warehouses or near machinery heat sources |

| Tensile Strength | ≥15 MPa | ASTM D412 | Resistance to tearing during handling/installation |

| Elongation at Break | ≥300% | ASTM D412 | Flexibility for contouring uneven surfaces |

| Compression Set (24h) | ≤20% | ASTM D395 | Maintains thickness and cushioning after prolonged load |

| Slip Resistance (Wet) | ≥0.6 COF | ASTM F2913 | Critical safety metric for fluid-contaminated areas |

These specifications represent our baseline formulation; we routinely develop custom variants for unique challenges, such as conductive properties for ESD-sensitive zones or enhanced flame retardancy (UL 94 HB/V-0) for foundry applications. Our Suzhou manufacturing facility operates under ISO 9001 protocols, with in-house compounding labs enabling rapid iteration and strict batch traceability. This control ensures every mat segment meets the exact interlock tolerance required for seamless, gap-free installation across large floor areas.

Initiate your project with an engineer, not a catalog. Contact Mr. Boyce, our dedicated OEM Solutions Manager, for a technical consultation focused on your operational constraints and performance targets. Mr. Boyce possesses 14 years of experience translating complex industrial requirements into validated rubber formulations and will coordinate material trials, 3D layout simulations, and lifecycle cost analysis specific to your facility. Provide your facility dimensions, environmental stressors, and safety compliance mandates for a tailored proposal within 48 hours.

Reach Mr. Boyce directly at [email protected] or +86 512 6789 1234 (Ext. 101). Include your project timeline and reference specification code BD-IM-2024 to prioritize technical resource allocation. Suzhou Baoshida eliminates the guesswork in industrial matting—partner with us to convert floor safety into a measurable operational advantage. Your next-generation workflow begins with a single engineered connection.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).