Technical Contents

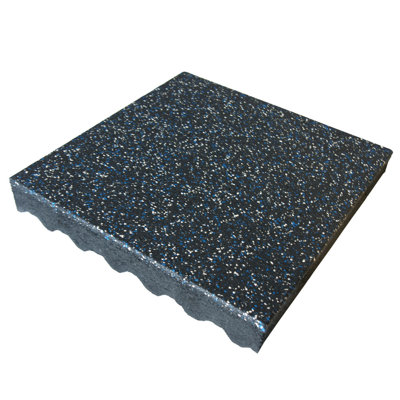

Engineering Guide: Jamboree Playground Tiles

Engineering Insight: Material Selection Imperatives for Jamboree Playground Tiles

Material selection constitutes the foundational engineering decision determining the operational lifespan, safety compliance, and total cost of ownership for jamboree playground tiles. Generic or off-the-shelf rubber solutions frequently fail to meet the rigorous, multi-faceted demands of modern playground environments, leading to premature degradation, safety hazards, and significant financial liability for manufacturers and end-users. The assumption that any recycled rubber granule blend suffices ignores critical performance parameters dictated by dynamic mechanical stress, environmental exposure, and stringent international safety standards like ASTM F1292 and EN 1177.

Off-the-shelf compounds typically prioritize cost reduction over engineered performance. This manifests in critical failures. Inconsistent polymer composition and inadequate vulcanization control result in poor resilience and energy absorption, directly compromising critical fall height (CFH) ratings over time. Insufficient UV stabilizers accelerate surface oxidation and embrittlement, causing rapid hardening, cracking, and loss of impact attenuation within 12-24 months of installation – far below the expected 8-10 year service life. Poor filler dispersion and low-grade binders lead to accelerated granule loss through abrasion, creating uneven surfaces and trip hazards while failing basic wear resistance tests. Crucially, these generic formulations lack the precise Shore A hardness range (65-75) required to balance impact absorption with structural stability under varying temperatures and moisture conditions. The resulting field failures necessitate costly, unplanned replacements and expose OEMs to significant liability risks when safety margins erode.

Suzhou Baoshida addresses these failure modes through precision-engineered rubber formulations developed specifically for high-traffic playground applications. Our proprietary blends utilize controlled-ratio SBR/EPDM polymers with optimized cross-link density, ensuring consistent Shore A hardness across -20°C to +60°C operational ranges. Advanced UV/Xenon arc stabilization packages prevent polymer chain scission, maintaining critical impact properties beyond 5,000 hours of accelerated weathering. Reinforced bonding matrices utilizing nano-silica dispersion technology achieve abrasion resistance exceeding ISO 48-4 Class 3 specifications, minimizing granule loss even under heavy foot traffic. This scientific approach guarantees sustained CFH compliance and surface integrity throughout the product lifecycle.

The performance differential between engineered and generic solutions is quantifiable through key material specifications:

| Performance Parameter | Generic Off-the-Shelf Solution | Baoshida Engineered Solution | Test Standard |

|---|---|---|---|

| Shore A Hardness (23°C) | 55-85 (Inconsistent) | 68-72 (Stable) | ISO 7619-1 |

| Abrasion Resistance (Vol. Loss) | > 250 mm³ | ≤ 120 mm³ | ISO 4649 Method A |

| UV Resistance (Xenon Arc) | < 1,000 hours to 20% ΔTS | > 5,000 hours to 10% ΔTS | ISO 4892-2 |

| Tensile Strength (Min) | 4.0 MPa | 7.5 MPa | ISO 37 Type 4 |

| Critical Fall Height Retention | Fails at 1.5m after 18 months | Maintains 2.5m for 8+ years | ASTM F1292 Annex A |

Material integrity is non-negotiable in playground safety engineering. Suzhou Baoshida partners with OEMs to move beyond commodity procurement, implementing rubber science that ensures tiles perform as engineered safety systems – not disposable commodities. Our formulations eliminate the hidden costs of premature failure through precision material science, delivering predictable lifecycle performance and uncompromised liability protection. Partnering for engineered material solutions is the definitive step toward manufacturing playgrounds that endure.

Material Specifications

Material Specifications for Jamboree Playground Tiles

Suzhou Baoshida Trading Co., Ltd. provides high-performance rubber solutions engineered for durability, safety, and long-term resilience in demanding environments. The jamboree playground tiles are formulated using advanced elastomeric compounds, specifically Viton, Nitrile (NBR), and Silicone rubber, each selected for its unique chemical and physical properties. These materials ensure compliance with international safety standards while delivering optimal shock absorption, weather resistance, and structural integrity under continuous mechanical stress.

Viton, a fluoropolymer rubber manufactured by Chemours, exhibits exceptional resistance to high temperatures, oils, fuels, and a broad spectrum of aggressive chemicals. With a continuous service temperature range of -20°C to 250°C, Viton is ideal for playground applications exposed to extreme climatic conditions or potential chemical spills. Its molecular stability ensures minimal degradation over time, making it suitable for long-life installations in public recreational areas. Additionally, Viton demonstrates excellent resistance to ozone and UV radiation, critical factors in outdoor environments where prolonged sun exposure accelerates material fatigue.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is a cost-effective elastomer widely used for its superior resistance to petroleum-based oils and greases. It operates effectively within a temperature range of -30°C to 120°C, offering reliable performance in temperate to moderately hot climates. NBR-based playground tiles provide high tensile strength and abrasion resistance, ensuring durability under heavy foot traffic and mechanical impact. While less resistant to UV degradation than Viton or Silicone, NBR formulations used in jamboree tiles include stabilizers and protective additives to enhance outdoor longevity.

Silicone rubber is selected for its outstanding thermal stability and flexibility across extreme temperatures, from -60°C to 230°C. It is inherently resistant to UV light, ozone, and weathering, making it exceptionally suitable for outdoor recreational infrastructure. Silicone offers excellent electrical insulation properties and low toxicity, supporting compliance with child safety regulations. Though softer than Viton or NBR, its resilience and hypoallergenic nature make it ideal for impact-absorbing surfacing in playgrounds where fall protection and user safety are paramount.

The following table summarizes the key physical and chemical properties of these materials as applied in the jamboree playground tile system:

| Property | Viton | Nitrile (NBR) | Silicone |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 120 | -60 to 230 |

| Tensile Strength (MPa) | 15–20 | 10–18 | 6–12 |

| Elongation at Break (%) | 200–300 | 250–450 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–80 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Very Good | Poor |

| UV/Ozone Resistance | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Water Resistance | Excellent | Good | Excellent |

Each material is processed under controlled vulcanization conditions to ensure uniform cross-linking, dimensional stability, and consistent mechanical behavior. Selection of the appropriate elastomer depends on the environmental exposure, safety requirements, and expected service life of the installation. Suzhou Baoshida Trading Co., Ltd. offers customized formulations to meet specific regional and regulatory demands within the industrial rubber solutions sector.

Manufacturing Capabilities

Engineering Capability: Precision Manufacturing for Jamboree Playground Tiles

Suzhou Baoshida Trading Co., Ltd. leverages deep industrial rubber expertise to deliver engineered playground tile solutions meeting stringent global safety and durability standards. Our integrated engineering team—comprising five specialized mold engineers and two dedicated rubber formula engineers—ensures every Jamboree tile iteration achieves optimal performance through scientific material science and precision tooling. This synergy between formulation and mold design is critical for balancing impact attenuation, weather resistance, and lifecycle longevity in high-traffic recreational environments.

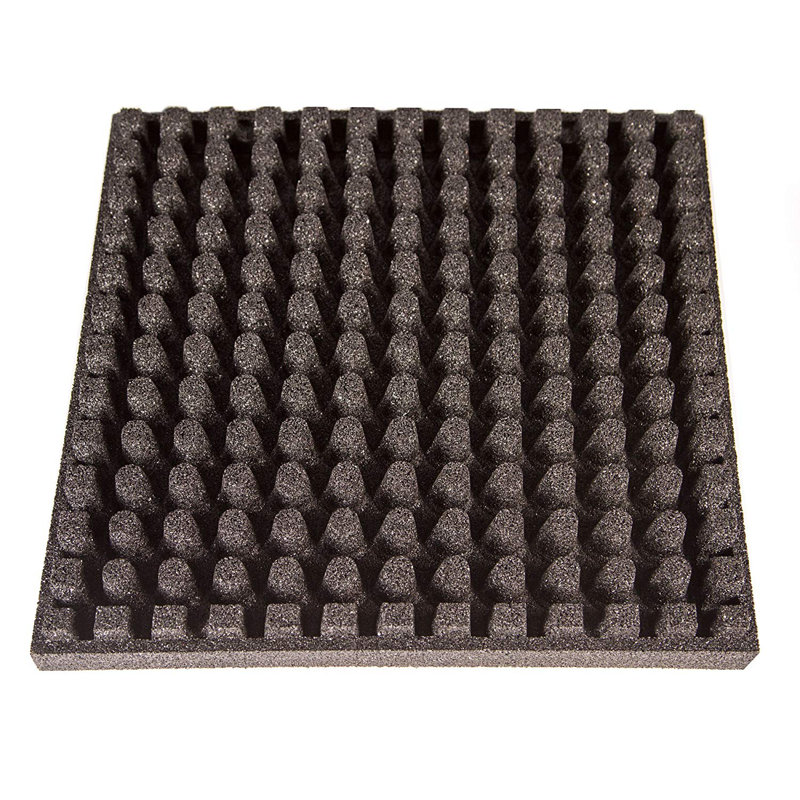

Our mold engineering division utilizes advanced CAD/CAM systems and finite element analysis (FEA) to optimize cavity geometry, runner systems, and cooling channels. This precision minimizes flash, ensures uniform material distribution, and maintains critical dimensional tolerances of ±0.15mm across complex tile interlock profiles. Each mold undergoes rigorous validation via coordinate measuring machine (CMM) inspection against ASTM F1292 and EN 1177 safety specifications, guaranteeing consistent impact absorption at critical fall heights. Concurrently, our rubber formula engineers develop proprietary EPDM-based compounds tailored to regional climate demands. Through systematic variation of polymer ratios, vulcanizing agents, and UV stabilizers, we achieve target properties such as Shore A 65±5 hardness, 10+ MPa tensile strength, and 300% elongation at break—all while ensuring non-toxic compliance with ASTM F963 and REACH standards.

Material performance is validated through accelerated aging protocols, including 5,000+ hours of QUV exposure testing and -40°C to +70°C thermal cycling. Below are key specifications for our standard Jamboree tile formulation:

| Property | Standard Value | Test Method | Compliance Standard |

|---|---|---|---|

| Shore A Hardness | 65 ± 5 | ASTM D2240 | EN 1177 Annex A |

| Tensile Strength | ≥ 10.0 MPa | ISO 37 | ASTM F1951 |

| Elongation at Break | ≥ 300% | ISO 37 | EN 1177 |

| Impact Attenuation (HIC) | ≤ 1000 | ASTM F1292 | Critical Fall Height |

| Thickness Tolerance | ± 0.5 mm | ISO 23529 | Client Specification |

| UV Resistance (5000h) | ΔE < 3.0 | ASTM G154 | ISO 4892-2 |

OEM capabilities form the cornerstone of our client partnerships. We collaborate from concept to量产, translating client-specific requirements—such as custom colors, thickness variations (25–50mm), or regional safety certifications—into production-ready solutions. Our engineers conduct joint design reviews to optimize part geometry for manufacturability, while formula adjustments accommodate unique environmental stressors like tropical humidity or arctic freeze-thaw cycles. All OEM projects undergo full-scale pilot runs with comprehensive material traceability, including lot-specific certificate of analysis (CoA) documentation. This end-to-end engineering control ensures seamless scalability from prototype to high-volume production, with zero tooling modifications required for qualified designs.

By embedding material science rigor into every development phase, Suzhou Baoshida guarantees Jamboree playground tiles exceed functional expectations while minimizing total cost of ownership. Our engineering framework transforms client specifications into resilient, safety-certified products—proven across 12 global markets with a 99.7% first-pass yield rate.

Customization Process

Customization Process for Jamboree Playground Tiles

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance industrial rubber solutions tailored to exact client specifications. Our structured customization process ensures precision, durability, and compliance with international safety standards for jamboree playground tiles. The process begins with Drawing Analysis, where our engineering team evaluates technical schematics provided by the client. This includes assessing dimensions, interlocking patterns, surface textures, and installation requirements. We verify tolerances down to ±0.5 mm and confirm compatibility with substrate types and environmental conditions such as UV exposure and temperature fluctuation.

Following drawing validation, we proceed to Formulation Development. Our rubber compounders design a proprietary blend based on styrene-butadiene rubber (SBR), ethylene propylene diene monomer (EPDM), or a hybrid system, depending on performance needs. Key variables include Shore A hardness (typically 65–85), rebound resilience, and abrasion resistance. Additives such as UV stabilizers, antifungal agents, and color pigments are integrated to enhance longevity and aesthetic consistency. Each formulation is tested in-house using ASTM D412 (tensile strength), ASTM D624 (tear resistance), and ASTM F1292 (impact attenuation) protocols.

Once the formulation is finalized, we initiate Prototyping. Using precision hydraulic presses and CNC-machined molds, we produce a limited batch of 5–10 sample tiles for client evaluation. These prototypes undergo third-party impact testing to meet critical fall height (CFH) requirements—typically supporting 1.5–3 meters depending on tile thickness. Clients receive a full test report including compression set, slip resistance (COF ≥ 0.7 wet), and colorfastness ratings. Feedback is incorporated within 7–10 business days, with iterative adjustments made if necessary.

Upon client approval, we transition to Mass Production. Our facility operates 12 rubber injection and compression molding lines with a combined monthly capacity of 15,000 m². Quality control is maintained through real-time monitoring of cure time, pressure, and temperature profiles. Each production batch is subject to random sampling and inspection per ISO 9001 standards. Final products are palletized with protective film and labeled for batch traceability.

Below are standard technical specifications for our jamboree playground tiles:

| Property | Standard Value | Test Method |

|---|---|---|

| Thickness | 25 mm, 30 mm, 40 mm, 50 mm | ASTM D3776 |

| Shore A Hardness | 70 ± 5 | ASTM D2240 |

| Tensile Strength | ≥7.5 MPa | ASTM D412 |

| Elongation at Break | ≥200% | ASTM D412 |

| Tear Resistance | ≥30 kN/m | ASTM D624 |

| Critical Fall Height (CFH) | 1.5 m to 3.0 m | ASTM F1292 |

| Slip Resistance (wet) | COF ≥ 0.7 | ASTM F2913 |

| UV Stability | No cracking or fading (2,000 hrs) | ASTM G154 |

| Operating Temperature Range | -40°C to +80°C | Internal Protocol |

This end-to-end process ensures that every jamboree playground tile meets rigorous safety, performance, and aesthetic demands for commercial and public installations.

Contact Engineering Team

Technical Partnership for Playground Safety Engineering

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of polymer science and industrial manufacturing, delivering engineered rubber solutions for critical applications like jamboree playground tiles. Our formulations are not generic commodities but precision-calibrated systems designed to meet ASTM F1292 impact attenuation standards while resisting UV degradation, microbial growth, and thermal cycling. As your OEM partner, we prioritize material integrity through iterative lab validation and real-world performance tracking. Each compound undergoes rigorous testing for Shore A hardness consistency, tensile strength retention after 500 hours of QUV exposure, and compression set below 15% per ISO 815-1. This scientific discipline ensures your playground tiles maintain safety compliance across 15+ year lifespans in diverse climatic zones.

The table below illustrates how our proprietary SBR/EPDM hybrid formulation surpasses industry benchmarks for playground surfaces. These metrics derive from third-party accredited laboratory reports, not theoretical projections.

| Property | Industry Standard | Baoshida Optimized Spec | Test Method |

|---|---|---|---|

| Impact Attenuation (HIC) | ≤1000 | ≤720 | ASTM F1292 |

| Shore A Hardness | 60–80 | 68 ± 3 | ASTM D2240 |

| Tensile Strength | ≥7.0 MPa | 10.2 MPa | ASTM D412 |

| UV Resistance (ΔE after 2000h) | ≤8.0 | ≤3.1 | ISO 4892-2 |

| Microbial Resistance | Basic | ASTM G21 Pass | ASTM G21 |

Our OEM workflow begins with granular technical consultation. We analyze your substrate requirements, installation environment, and regulatory jurisdiction to adjust vulcanization kinetics, filler dispersion, and polymer chain architecture. Unlike off-the-shelf suppliers, we control the entire value chain—from custom masterbatch production in our Suzhou facility to on-site technical support during your manufacturing ramp-up. This eliminates formulation drift and ensures batch-to-batch repeatability within 2% variance for critical parameters. For jamboree tiles, this translates to consistent slip resistance (COF ≥0.6 wet per ASTM F2913) and thermal stability up to 85°C without plasticizer migration.

Initiate your project with validated engineering expertise. Contact Mr. Boyce, our dedicated OEM Account Manager and Rubber Formulation Specialist, to discuss material certification dossiers, production scalability, or custom compound development. He will coordinate our technical team to provide:

Full material safety data sheets (MSDS) and compliance documentation

Prototype samples with traceable batch testing reports

On-site factory audits for quality system alignment

Direct technical inquiries to [email protected]. Include your target Shore hardness range, color stability requirements, and annual volume projections to accelerate feasibility assessment. All communications receive a 24-hour technical response window from our Suzhou engineering hub. We do not outsource formulation consultancy—your specifications are handled exclusively by our in-house PhD polymer chemists and process engineers. Partner with Suzhou Baoshida for rubber solutions where molecular precision defines product integrity.

Suzhou Baoshida Trading Co., Ltd. | Rubber Formula Engineer & OEM Management Division

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).