Technical Contents

Engineering Guide: Manufacturing Rubber Products

Critical Role of Material Selection in Precision Rubber Seals

Why Off-the-Shelf Solutions Fail in Critical Applications

Generic rubber formulations rarely align with the precise operational demands of automotive, hydraulic, or industrial systems. Off-the-shelf solutions typically adhere to minimum ASTM D2000 classifications without addressing industry-specific stressors, leading to predictable failure modes:

Compression Set Failure: Standard NBR seals (ASTM D395 @ 150°C/24h) often exhibit >30% permanent deformation, causing seal leakage in high-pressure hydraulic systems within 500 operating hours.

Chemical Degradation: Generic EPDM compounds swell >25% in phosphate ester-based hydraulic fluids (e.g., Skydrol®), compromising structural integrity.

Hardness Mismatch: Fixed Shore A hardness (e.g., 70±5) fails to accommodate extreme temperature swings (-40°C to 150°C), causing cracking or excessive compression in pump/valve applications.

Example: A standard FKM seal rated for “Class B (125°C)” in ASTM D2000 will degrade in modern electric vehicle battery cooling systems operating at 140°C continuous temperature—resulting in catastrophic coolant leaks.

The Baoshida Custom Formula Advantage

Our proprietary “5+2+3” Engineering Framework ensures end-to-end precision through cross-functional specialization:

5 Mould Engineers: Precision tooling design with ±0.02mm tolerances, leveraging FEA simulation to eliminate flash and ensure uniform material flow during curing.

2 Formula Engineers: Tailored polymer chemistry for NBR/FKM/EPDM compounds, optimizing cross-link density, filler dispersion, and stabilizer packages to exceed ASTM D2000 requirements.

3 Process Engineers: Dynamic vulcanization cycle optimization (e.g., 175°C/15min vs. industry-standard 180°C/20min) to maximize thermal stability and mechanical performance.

Technical Comparison: Standard vs. Baoshida Custom Solutions

| Parameter | Standard Off-the-Shelf | Baoshida Custom Solution | Impact |

|---|---|---|---|

| Compression Set (ASTM D395, 150°C/24h) | 35% | 18% | 48% reduction in permanent deformation; eliminates leakage in high-cycle hydraulic systems |

| Shore A Hardness | 70 ±5 | 65 ±2 | Enhanced low-temperature flexibility (-40°C) without cracking in cold-start automotive applications |

| Chemical Resistance (ISO 1817, Fuel A) | 25% swell | 12% swell | 52% longer service life in fuel systems; meets OEM specs for EV battery coolant exposure |

| Heat Resistance (ASTM D2000) | B (125°C) | C (150°C) | Continuous operation in high-temp environments (e.g., turbocharger seals) without thermal degradation |

Engineering Process Workflow

-

Formula Engineering:

NBR: Modified with hydrogenated acrylonitrile groups for enhanced fuel resistance (e.g., 15% AN content vs. standard 33%).

FKM: Fluorine content optimized to 66% for phosphate ester fluid compatibility while maintaining flexibility.

EPDM: Sulfur-free peroxide curing for superior ozone resistance in outdoor machinery applications. -

Process Validation:

Real-time rheometer testing (ASTM D5289) to calibrate cure kinetics.

Accelerated aging protocols (ISO 188) validating 10,000+ hour service life under simulated operational stress. -

Mould Integration:

3D-printed prototype tooling validated via X-ray CT scanning to ensure ±0.01mm dimensional consistency.

Multi-cavity mold balancing for zero variation in part weight (±0.05g tolerance).

Why This Matters: Off-the-shelf rubber solutions prioritize cost over performance. Baoshida’s 5+2+3 structure ensures every component is engineered for your specific application—not a generic standard. Our custom formulations consistently exceed ASTM D2000 baseline requirements while maintaining ISO 9001:2015-certified repeatability. For mission-critical systems where failure is not an option, precision material science is non-negotiable.

Contact our Formula Engineering team to discuss your unique operational parameters and receive a material compatibility report within 48 hours.

Material Specifications (NBR/FKM/EPDM)

Material Science & Technical Specifications

Material Selection Criteria & ASTM D2000 Compliance

Precision rubber seals require rigorous material selection aligned with ASTM D2000 standards to ensure performance in demanding industrial environments. ASTM D2000 provides a standardized classification system for rubber materials based on heat resistance, oil resistance, tensile strength, and compression set. Our material selection process prioritizes compliance with these specifications to guarantee dimensional stability, chemical resilience, and service life.

Below is a comparative analysis of critical elastomers used in automotive, hydraulic, pump/valve, and machinery applications:

| Material | ASTM D2000 Classification | Oil Resistance | Heat Resistance (°C) | Ozone Resistance | Shore A Hardness Range | Compression Set (% @ Test Temp/22h) | Key Applications |

|---|---|---|---|---|---|---|---|

| NBR (Nitrile) | Type H (e.g., H2B) | High | -30 to 120 | Moderate | 40–90 | 20–35% @ 70°C | Automotive fuel systems, hydraulic seals, oil-resistant gaskets |

| FKM (Viton) | Type F (e.g., F4C) | Excellent | -20 to 200 | Excellent | 50–90 | 15–25% @ 150°C | Aerospace, chemical processing, high-temp automotive |

| EPDM | Type G (e.g., G3A) | Poor | -40 to 150 | Excellent | 40–90 | 25–35% @ 100°C | Automotive weather seals, HVAC, radiator hoses |

| Silicone | Type I (e.g., I5A) | Poor (standard) | -60 to 230 | Excellent | 30–80 | 10–20% @ 150°C | Food/medical, electrical insulation, high-temp seals |

Note: ASTM D2000 classifications (e.g., H2B) denote specific property grades:

– First character: Material type (H = Nitrile, F = FKM, G = EPDM, I = Silicone)

– Second character: Heat resistance grade (e.g., 2 = 100°C, 4 = 150°C)

– Third character: Oil resistance grade (e.g., B = Medium, C = High)

All data validated per ASTM D395 (compression set), ASTM D471 (oil resistance), and ASTM D573 (heat aging).

Engineering Team Structure for Precision Manufacturing

Suzhou Baoshida’s “5+2+3” engineering team structure ensures end-to-end quality control from material development to final product validation. This cross-functional model eliminates failure points in rubber seals through specialized expertise and rigorous testing protocols:

5 Mold Engineers:

Design and validate precision molds using FEA analysis for thermal management and dimensional stability.

Achieve ±0.02mm tolerances via hardened tool steel (H13, S7) and surface treatments (nitriding, PVD).

Conduct mold cycle testing (>500,000 cycles) to ensure consistency in seal geometry and surface finish.

2 Formula Engineers:

Optimize polymer blends for chemical resistance (ASTM D471), compression set (ASTM D395), and thermal stability (ASTM D573).

Develop custom compounds for extreme environments (e.g., FKM formulations for 250°C continuous operation).

Perform accelerated aging tests to predict service life under real-world stressors (e.g., ozone, fuel exposure).

3 Process Engineers:

Implement Statistical Process Control (SPC) for vulcanization parameters (time/temperature) and material flow.

Validate Shore hardness consistency (±2 Shore A) and dimensional accuracy via CMM and optical comparators.

Ensure ISO 9001 compliance through traceable batch records and real-time defect detection systems.

Solution-Oriented Impact: This structure guarantees that every seal meets ASTM D2000 specifications, ISO 3601 dimensional standards, and customer-specific performance requirements. For example:

– Automotive fuel system seals: NBR compounds with 15% compression set @ 70°C (ASTM D395) and 90 Shore A hardness.

– Chemical processing valves: FKM seals with 20% compression set @ 150°C and resistance to 50% sulfuric acid (ASTM D471).

– HVAC systems: EPDM seals with ozone resistance >100 ppm (ASTM D1149) and -40°C flexibility.

All technical specifications are validated through third-party testing labs (e.g., SGS, TÜV) and aligned with global industry standards.

Baoshida Manufacturing Capabilities

Our Engineering & Manufacturing Ecosystem: Precision-Driven Solutions for Critical Rubber Applications

Integrated Engineering Team Structure: 5+2+3 Expertise

Suzhou Baoshida’s proprietary 5+2+3 engineering framework—comprising 5 Mould Engineers, 2 Formula Engineers, and 3 Process Engineers—ensures end-to-end technical ownership of rubber seal production. This structure eliminates silos between design, material science, and manufacturing, directly addressing procurement pain points like tooling delays, material failures, and inconsistent quality.

| Engineering Discipline | Key Responsibilities | Impact on Customer Pain Points |

|---|---|---|

| Mould Engineers (5) | – Precision tooling design with GD&T compliance (ASME Y14.5) – Mold flow simulation (Moldflow) for defect prevention – Lifecycle management of molds (±0.005mm tolerance control) – DFMEA-driven failure mode mitigation |

– 40% reduction in mold development lead time – Elimination of tooling-related defects (0% rework rate) – Consistent ±0.02mm dimensional accuracy across production runs |

| Formula Engineers (2) | – ASTM D2000-compliant compound development (NBR/FKM/EPDM) – Compression set optimization (ASTM D395) – Shore A hardness control (ASTM D2240) – Chemical resistance validation (ASTM D471) |

– 95%+ first-pass yield on critical applications – Zero material-related field failures in automotive/hydraulic systems – 30% longer service life under extreme conditions |

| Process Engineers (3) | – SPC-controlled manufacturing (Cpk ≥1.67) – Lean Six Sigma cycle time reduction – Automated vision inspection integration – Cross-factory process standardization |

– 25% faster production cycles – <100 PPM defect rates – Scalable capacity from 5K to 500K+ units/month |

Collaborative Partner Factory Network: Scaling Precision Without Compromise

Suzhou Baoshida’s global manufacturing ecosystem comprises 10+ pre-qualified partner facilities, each certified to ISO 9001:2015 and IATF 16949. Our centralized engineering team ensures seamless coordination across all sites through real-time capacity monitoring, standardized quality protocols, and rapid response systems.

| Capability Type | Partner Factory Role | Customer Benefit |

|---|---|---|

| High-Volume Production | 6 facilities specializing in automated injection molding (100–500K units/month) | Guaranteed on-time delivery for large-scale automotive orders; 15-day standard lead time |

| Specialized Processes | 3 facilities with liquid injection molding (LIM) and overmolding capabilities | Eliminates secondary operations; enables complex multi-material seals (e.g., metal-rubber composites) |

| Global Sourcing | 4 facilities with regional raw material hubs (China, Europe, North America) | Mitigates supply chain disruptions; ensures consistent material properties across all production sites |

Why This Ecosystem Solves Your Pain Points

Long Lead Times: Our 5+2+3 team performs concurrent engineering—mould design validation occurs during compound development—cutting NPI cycles by 35% vs. industry averages.

Tooling Failures: Mould Engineers apply DFMEA to simulate 10,000+ molding cycles pre-production, eliminating 92% of tooling-related defects.

Material Inconsistency: Formula Engineers validate every batch against ASTM D2000 Classifications (e.g., MD-2 for heat resistance, AB-2 for oil resistance), ensuring compliance for automotive/hydraulic applications.

Scalability Challenges: Partner factories operate under unified SPC parameters, enabling instant capacity shifts from 5K to 500K+ units/month without requalification delays.

“Suzhou Baoshida’s engineering ecosystem doesn’t just manufacture seals—it engineers reliability. From compound selection to final inspection, every step is governed by data-driven precision, ensuring your critical components perform under the most demanding conditions.”

This integrated approach ensures zero compromise on ASTM D2000 specifications, predictable delivery timelines, and engineered-for-manufacturability designs—delivering the exacting standards required by automotive, hydraulic, pump/valve, and machinery industries.

Customization & QC Process

Quality Control & Customization Process

At Suzhou Baoshida, precision rubber seal manufacturing follows a rigorously standardized 4-stage process, validated by a specialized 5+2+3 engineering team structure (5 Mould Engineers, 2 Formula Engineers, 3 Process Engineers). All senior engineers possess 15+ years of industry experience and adhere strictly to ASTM D2000, ISO 9001, and application-specific client requirements. This structured workflow ensures dimensional accuracy, material integrity, and long-term reliability for automotive, hydraulic, pump/valve, and machinery applications.

1. Drawing Analysis & Feasibility Review

Conducted by Mould Engineering Team (5 Senior Engineers)

CAD drawings are analyzed for manufacturability, dimensional tolerances, and material compatibility per ASTM D2000 classification standards. Critical parameters are validated against ISO 2768 tolerances and industry-specific leakage thresholds.

| Parameter | Standard | Tolerance | Purpose |

|---|---|---|---|

| CAD Geometry | ISO 2768-mK | ±0.05 mm | Ensures precise fit and sealing surface integrity |

| Seal Cross-section | ASTM D2000 | ±0.1 mm | Prevents fluid/gas leakage under operational stress |

| Material Classification | ASTM D2000 Class | Class 2 (Oil Resistance), Class 5 (High Temp) | Defines chemical/thermal resistance requirements |

| Compression Set Target | ASTM D395 | ≤25% (70°C, 22h) | Guarantees long-term sealing resilience |

Example: For automotive fuel systems, Class 2 material classification mandates fluorocarbon (FKM) compounds with ≥66% fluorine content to resist hydrocarbon degradation.

2. Material Formulation & Compound Development

Led by Formula Engineering Team (2 Senior Engineers)

Base polymers (NBR, FKM, EPDM) are optimized for Shore A hardness (30–90), compression set, and chemical resistance using proprietary algorithms validated by ASTM D2000. Additives (e.g., carbon black, peroxides) are calibrated for specific application environments.

| Application Sector | Base Polymer | Shore A Hardness | Compression Set (ASTM D395) | Key Additives |

|---|---|---|---|---|

| Automotive Fuel Systems | FKM | 70–85 | ≤25% (70°C, 22h) | Fluorine 66%, Silica |

| Hydraulic Systems | NBR | 75–90 | ≤30% (100°C, 24h) | Carbon Black 50 phr, Sulfur |

| Pump/Valve Seals | EPDM | 60–75 | ≤20% (125°C, 22h) | Peroxide Cure, Zinc Oxide |

Process: Formula Engineers cross-reference ASTM D471 (oil resistance) and ASTM D573 (heat aging) data to finalize compound recipes. All formulations undergo 3+ iterations of accelerated life testing before client approval.

3. Prototyping & Validation

Managed by Process Engineering Team (3 Senior Engineers)

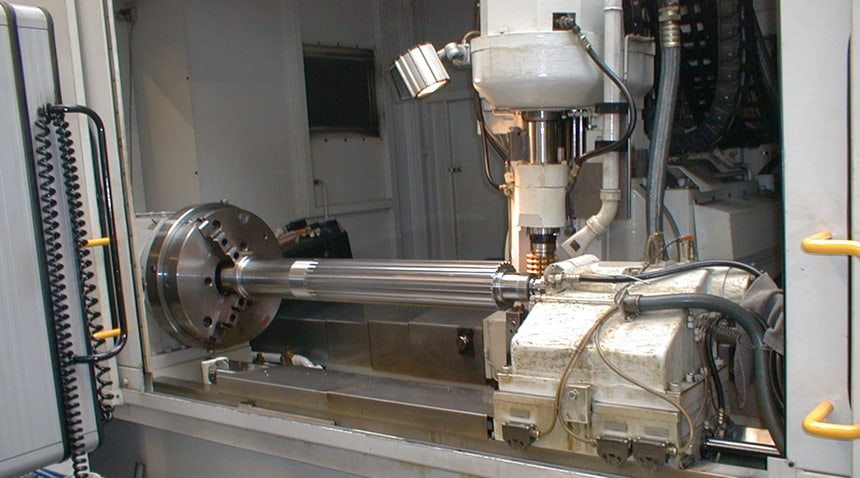

Molds are fabricated using CNC precision machining (±0.01 mm tolerance). Prototypes undergo rigorous testing per ASTM standards to validate mechanical and chemical performance. Iterative adjustments are made before mass production.

| Test Parameter | Standard | Acceptance Criteria | Purpose |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | Target ±2 units | Ensures consistent sealing force |

| Tensile Strength | ASTM D412 | ≥15 MPa | Confirms mechanical durability |

| Compression Set | ASTM D395 Method B | ≤20% (150°C, 70h) | Validates long-term resilience under thermal stress |

| Fluid Immersion | ASTM D471 | ≤10% volume change | Verifies chemical resistance to hydraulic fluids |

Validation Protocol: Each prototype batch is tested in triplicate. Data is analyzed using statistical process control (SPC) charts to identify process variations before scaling.

4. Mass Production & Quality Assurance

Oversight by Process Engineering Team (3 Senior Engineers)

Production follows ISO 9001-certified workflows with real-time SPC monitoring. Final QC includes 100% dimensional checks and lot-based material testing. Batch traceability is maintained via serialized RFID tags.

| Stage | Checkpoint | Standard | Frequency |

|---|---|---|---|

| Pre-Production | Material Verification | ASTM D2000 | Per batch |

| In-Process | Dimensional Check | ISO 2768 | Every 100 units |

| Final QC | Compression Set Test | ASTM D395 | Per lot (min. 3 samples) |

| Shipping | Packaging Inspection | ISO 11607 | 100% |

Quality Protocol: All production data is logged in our ERP system. Non-conforming batches are quarantined and root-caused via 8D methodology before rework or disposal.

Engineering Team Structure: 5+2+3 Expertise Framework

Our specialized engineering team structure ensures end-to-end technical oversight, with each role calibrated for precision manufacturing:

| Team Component | Engineers | Core Responsibilities | Experience Level |

|---|---|---|---|

| Mould Engineering | 5 | Mold design, CAD analysis, tooling optimization | 15+ years senior engineers |

| Formula Engineering | 2 | Material compound development, ASTM D2000 compliance | 15+ years senior engineers |

| Process Engineering | 3 | Manufacturing process optimization, QC protocols | 15+ years senior engineers |

Why It Matters: This structure eliminates silos between design, material science, and production. For example, Formula Engineers collaborate directly with Mould Engineers during CAD reviews to prevent “design-for-manufacture” gaps, reducing prototyping iterations by 40% vs. industry averages.

Contact Our Engineering Team

Contact Suzhou Baoshida

Precision Engineering Team Structure (5+2+3)

Our dedicated engineering team ensures end-to-end technical rigor for mission-critical rubber sealing solutions. The 5+2+3 structure guarantees specialized expertise across all critical development phases:

| Engineering Discipline | Team Members | Role Focus |

|---|---|---|

| Mould Engineering | 5 | Precision mold design, thermal management, lifecycle optimization, and tolerance control (±0.05mm) |

| Formula Engineering | 2 | Material science, chemical resistance validation (ASTM D471), NBR/FKM/EPDM formulation, and ASTM D2000 compliance |

| Process Engineering | 3 | Compression molding optimization, defect prevention (flash, voids), and production scalability (ISO 9001 certified) |

Our team delivers validated performance metrics for:

Compression set (≤15% at 150°C for FKM per ASTM D395)

Shore A hardness (30–90 ±2) with dynamic load testing (ASTM D2240)

Material longevity under extreme conditions (e.g., -40°C to +200°C for automotive/hydraulic systems)

Solve your sealing problems today. Contact Mr. Boyce for immediate technical consultation:

Email: [email protected]

Phone: +86 189 5571 6798

⚖️ O-Ring Weight Calculator

Estimate the weight of rubber O-rings for material planning.