Technical Contents

Engineering Guide: Manufacturing Rubber Products

Engineering Insight: The Critical Role of Material Selection in Manufacturing Rubber Products

In the precision-driven domain of rubber product manufacturing, material selection is not a secondary consideration—it is the foundational determinant of performance, durability, and reliability. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf rubber components often fail in demanding industrial applications due to a fundamental mismatch between standardized material properties and the specific environmental, mechanical, and chemical conditions of the application.

Generic rubber seals are typically formulated for broad compatibility rather than targeted performance. This one-size-fits-all approach overlooks critical variables such as temperature extremes, fluid exposure, compression set resistance, and dynamic stress. For example, a standard nitrile (NBR) seal may perform adequately in moderate oil environments but rapidly degrade when exposed to high-temperature hydraulic fluids or ozone-rich atmospheres. Similarly, ethylene propylene diene monomer (EPDM), while excellent for weather and steam resistance, swells significantly in hydrocarbon oils, rendering it unsuitable for fuel system applications.

The failure of off-the-shelf solutions often manifests in premature leakage, extrusion, hardening, or cracking—issues that compromise system integrity and result in costly downtime. These failures are not inherent to rubber as a material class but stem from improper material pairing. Precision rubber seals must be engineered at the molecular level to meet application-specific demands. This requires a deep understanding of polymer chemistry, cross-linking mechanisms, additive packages, and curing processes.

At Suzhou Baoshida, we approach material selection as a system-level engineering decision. Our process begins with a comprehensive analysis of operating conditions: temperature range, media compatibility, pressure loads, dynamic movement, and required service life. Based on this data, we select or custom-formulate elastomers that balance resilience, chemical resistance, and dimensional stability.

The following table outlines key elastomer types and their performance characteristics relevant to industrial sealing applications:

| Material | Temperature Range (°C) | Key Strengths | Limitations | Typical Applications |

|---|---|---|---|---|

| Nitrile (NBR) | -30 to +120 | High resistance to oils, fuels, and hydraulic fluids | Poor ozone and weather resistance | Automotive seals, hydraulic systems |

| EPDM | -50 to +150 | Excellent steam, weather, and ozone resistance | Swells in hydrocarbons | HVAC systems, water/glycol lines |

| Fluorocarbon (FKM) | -20 to +200 | Outstanding chemical and heat resistance | High cost, limited low-temperature flexibility | Aerospace, chemical processing |

| Silicone (VMQ) | -60 to +180 | Excellent thermal stability and low-temperature performance | Low tensile strength, poor abrasion resistance | Medical devices, food processing |

| Chloroprene (CR) | -40 to +100 | Good flame and weather resistance | Moderate oil resistance | Electrical enclosures, marine seals |

Material selection is not a compromise—it is a strategic optimization. By moving beyond off-the-shelf solutions and embracing engineered elastomers, manufacturers ensure long-term reliability, reduce maintenance cycles, and enhance overall system efficiency. At Suzhou Baoshida, we specialize in translating application requirements into precise rubber formulations, delivering seals that perform under real-world conditions.

Material Specifications

Material Specifications for Precision Rubber Seals

Material selection fundamentally dictates the performance lifecycle of precision rubber seals in demanding industrial applications. At Suzhou Baoshida Trading Co., Ltd., we prioritize rigorous material science to ensure dimensional stability, chemical compatibility, and longevity under operational stress. Viton, Nitrile, and Silicone represent three critical elastomer families, each engineered for specific environmental challenges. Understanding their intrinsic properties prevents premature seal failure and optimizes total cost of ownership.

Viton fluorocarbon rubber excels in extreme chemical and thermal environments. Its molecular structure provides exceptional resistance to aviation fuels, hydraulic fluids, acids, and aromatic hydrocarbons. Continuous service temperatures range from -20°C to 230°C, with brief excursions up to 300°C. Viton maintains seal integrity in semiconductor manufacturing, aerospace hydraulics, and oilfield equipment where exposure to aggressive media is unavoidable. However, its high fluorine content increases material cost and reduces flexibility at sub-zero temperatures compared to alternatives.

Nitrile butadiene rubber (NBR) offers the optimal balance of oil resistance and economic efficiency for general industrial use. With acrylonitrile content typically between 34% and 45%, it withstands petroleum-based oils, greases, and water up to 120°C. Its tensile strength (15–25 MPa) and abrasion resistance suit dynamic sealing applications like automotive fuel systems and hydraulic pumps. Limitations include poor ozone/weathering resistance and embrittlement below -40°C, necessitating protective coatings or alternative materials in outdoor or cryogenic settings.

Silicone rubber delivers unmatched flexibility across extreme temperatures (-60°C to 200°C continuous). Its inorganic backbone resists thermal degradation, making it ideal for aerospace gaskets, medical device seals, and food processing equipment requiring steam sterilization. While exhibiting excellent electrical insulation and low compression set, silicone has inferior tensile strength (6–12 MPa) and tear resistance versus NBR or Viton. It also swells significantly in non-polar solvents like toluene, restricting use in fuel-handling systems.

The following table quantifies critical performance parameters for informed material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -40 to +120 | -60 to +200 |

| Fuel/Oil Resistance | Excellent | Good to Excellent | Poor |

| Acid/Chemical Resistance | Excellent | Fair | Fair |

| Tensile Strength (MPa) | 12–20 | 15–25 | 6–12 |

| Hardness Range (Shore A) | 50–90 | 40–90 | 30–80 |

| Key Limitations | High cost, poor low-temp flexibility | Poor ozone resistance, limited high-temp use | Low tear strength, solvent swelling |

| Typical Applications | Jet engines, chemical valves | Fuel hoses, O-rings | Medical tubing, bakeware seals |

Suzhou Baoshida Trading Co., Ltd. leverages decades of OEM partnership experience to tailor compound formulations within these material families. Our engineering team conducts ASTM D2000-compliant validation testing, including compression set analysis per ISO 815 and fluid immersion studies, to certify material suitability against your exact operational parameters. Precision sealing demands more than generic material data sheets—it requires application-specific compound optimization to mitigate real-world failure modes. Contact our technical division for custom compound development and accelerated lifecycle validation protocols.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our precision rubber seal manufacturing process. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we maintain full technical control from concept to production. Our engineers work in close collaboration to ensure that material science and precision tooling are seamlessly integrated, delivering rubber components that meet exacting OEM specifications.

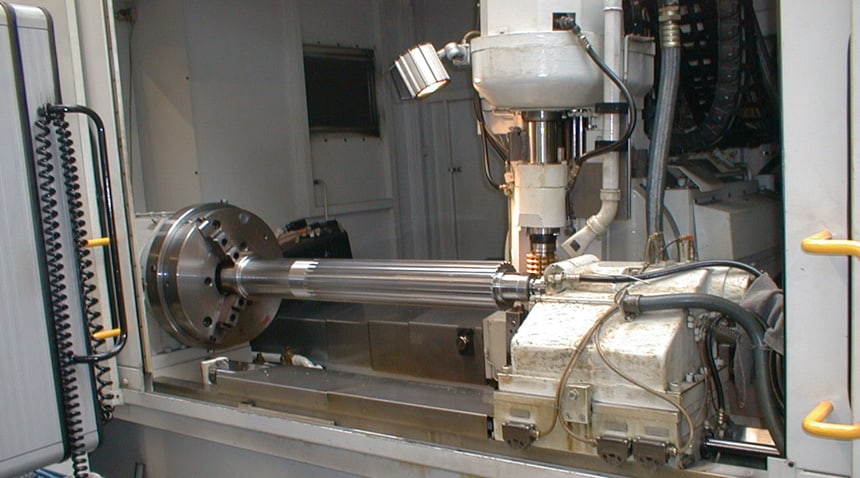

Our mould engineering team possesses extensive expertise in designing and optimizing rubber compression, transfer, and injection moulds. Each engineer applies advanced CAD/CAM tools—SolidWorks, AutoCAD, and UG—to develop high-tolerance tooling solutions tailored to complex sealing applications. We conduct rigorous mould flow analysis and perform dimensional validation using CMM and optical measurement systems, ensuring cycle efficiency, part consistency, and long-term tool durability. All moulds are manufactured in-house or through tightly controlled partner facilities, with full traceability and documented quality checkpoints.

Complementing our mould expertise, our two rubber formula engineers specialize in compound development for demanding industrial environments. They formulate custom elastomer blends based on NBR, EPDM, FKM, silicone, and other specialty polymers, adjusting hardness, compression set, temperature resistance, and fluid compatibility to meet specific application requirements. Each formulation undergoes accelerated aging, dynamic testing, and chemical exposure analysis to validate performance under real-world conditions. This scientific approach ensures that every seal not only fits precisely but also performs reliably across its intended service life.

We are fully equipped to support OEM partners through all stages of product development. From initial technical consultation and 3D design validation to prototype production and PPAP documentation, our engineering team provides end-to-end technical support. We routinely collaborate with customers on DFMEA reviews, tolerance stack-up analysis, and process optimization to reduce total cost of ownership while enhancing product reliability.

Our OEM capabilities extend to exclusive compound development, IP-protected tooling, and serialized production with full lot traceability. We maintain strict confidentiality agreements and support dual-sourcing strategies where required. With certified quality management systems aligned with IATF 16949 standards, we ensure compliance across automotive, industrial machinery, medical, and energy sectors.

The integration of advanced tooling design and precision material science enables Suzhou Baoshida to deliver engineered rubber solutions that exceed industry benchmarks. This technical synergy positions us as a trusted engineering partner—not just a manufacturer.

Material and Performance Specifications

| Property | NBR | EPDM | FKM | Silicone |

|---|---|---|---|---|

| Hardness Range (Shore A) | 40–90 | 45–85 | 50–90 | 30–80 |

| Temperature Range (°C) | -30 to +120 | -50 to +150 | -20 to +200 | -60 to +230 |

| Fluid Resistance | Oil, fuel, hydraulic fluids | Water, steam, polar solvents | Broad chemical, oil, fuel | Moderate, limited oils |

| Compression Set (22 hrs, 100°C) | ≤25% | ≤20% | ≤15% | ≤20% |

| Typical Applications | Automotive seals, O-rings | HVAC, outdoor gaskets | Aerospace, chemical seals | Medical, food-grade seals |

Customization Process

Precision Rubber Seal Customization Process: From Concept to Volume Production

At Suzhou Baoshida Trading Co., Ltd., our OEM customization process for precision rubber seals rigorously transforms client specifications into reliable, high-performance components. This structured methodology ensures dimensional accuracy, material integrity, and functional longevity under demanding operational conditions. The sequence begins with comprehensive Drawing Analysis. Engineering teams meticulously review submitted CAD files or technical drawings against ISO 3601 and AS568 standards, verifying critical dimensions, tolerances (typically ±0.05mm for critical sealing surfaces), surface finish requirements (Ra ≤ 0.8µm), and geometric dimensioning and tolerancing (GD&T) callouts. Concurrently, we assess material compatibility with specified media (fuels, hydraulic fluids, acids) and operating temperatures, identifying potential design risks such as insufficient land width or inadequate compression set allowances before progression.

Following drawing validation, the Formulation phase commences. Our rubber chemists develop proprietary compound recipes tailored to the application’s mechanical, thermal, and chemical demands. This involves selecting the optimal base polymer (e.g., FKM for high-temperature aerospace seals, EPDM for coolant resistance) and precisely balancing curatives, fillers, plasticizers, and stabilizers. Key properties like tensile strength, elongation at break, and compression set are engineered to meet or exceed ASTM D2000 classification requirements. Material selection is validated through predictive modeling of fluid swell and thermal aging behavior, ensuring long-term seal integrity.

The formulated compound undergoes Prototyping using production-intent tooling. Initial samples are manufactured via precision compression or injection molding, followed by rigorous metrological inspection using CMM and optical comparators to confirm dimensional conformance. Functional validation includes pressure decay testing, compression set measurement per ASTM D395, and accelerated aging in simulated service environments. Client feedback on prototype performance drives iterative refinements to both material formulation and tooling geometry, typically within 10-15 business days per iteration cycle.

Upon client sign-off, Mass Production initiates under strict statistical process control. Each production batch undergoes 100% visual inspection and automated dimensional verification. Critical lots include destructive testing for physical properties and compression set. Our ISO 9001-certified facility maintains CPK >1.67 for critical dimensions, with traceability from raw material lot to finished seal. Production scalability ranges from pilot batches of 500 units to annual volumes exceeding 5 million pieces, with consistent adherence to delivery schedules through optimized scheduling and inventory management.

Material performance specifications for common seal compounds are summarized below:

| Material Type | Temperature Range (°C) | Key Fluid Resistance | Compression Set (70h/100°C) | Typical Applications |

|---|---|---|---|---|

| FKM (Viton®) | -20 to +230 | Fuels, Oils, Acids | ≤ 25% | Aerospace, Automotive Fuel Systems |

| EPDM | -50 to +150 | Water, Glycols, Steam | ≤ 30% | HVAC, Automotive Coolant Systems |

| NBR | -30 to +100 | Oils, Hydraulic Fluids | ≤ 35% | Industrial Hydraulics, General Sealing |

| Silicone | -60 to +200 | Limited Chemicals | ≤ 20% | Medical, Food Processing, High-Purity |

This end-to-end process, governed by stringent quality protocols and deep materials science expertise, guarantees that every Suzhou Baoshida precision rubber seal delivers flawless performance in critical OEM applications.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Seals Engineered to Perform

When it comes to the manufacturing of high-performance rubber products, especially precision seals for industrial applications, material integrity, dimensional accuracy, and long-term reliability are non-negotiable. At Suzhou Baoshida Trading Co., Ltd., we specialize in the development and supply of custom-engineered rubber seals that meet exacting OEM specifications and perform consistently under extreme operational conditions. Our expertise spans material formulation, mold design, vulcanization control, and final product validation—ensuring every seal we produce delivers optimal sealing performance, longevity, and resistance to environmental stressors such as temperature, pressure, and chemical exposure.

Our precision rubber seals are widely used in automotive systems, hydraulic equipment, aerospace components, medical devices, and industrial automation. Whether you require Nitrile (NBR), Ethylene Propylene Diene Monomer (EPDM), Silicone (VMQ), Fluorocarbon (FKM), or specialty compounds like ACM or AEM, our in-house material science team formulates rubber compounds tailored to your application’s thermal, mechanical, and chemical requirements. We support low-volume prototyping and high-volume production runs with strict adherence to ISO 9001 quality management standards and full traceability across batches.

We understand that every industrial sealing challenge is unique. That’s why we collaborate directly with engineering teams to optimize seal geometry, select the most suitable elastomer, and validate performance through rigorous testing protocols—including compression set analysis, tensile strength measurement, and accelerated aging tests.

To ensure seamless integration into your manufacturing workflow, we provide comprehensive technical documentation, including material certifications (e.g., RoHS, REACH, FDA), dimensional inspection reports, and mold flow analysis upon request.

For immediate technical consultation or to initiate a custom seal development project, contact Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer. Mr. Boyce brings over 15 years of experience in elastomer formulation and industrial sealing solutions, offering expert guidance from concept to mass production. He is available to review your application requirements, recommend optimal materials, and support rapid prototyping with fast turnaround times.

Below are typical material properties for commonly used rubber compounds in precision seal manufacturing:

| Material | Hardness (Shore A) | Temp Range (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Key Resistance Properties |

|---|---|---|---|---|---|

| NBR | 50–90 | -30 to +120 | 10–20 | 200–400 | Oil, fuel, abrasion |

| EPDM | 50–80 | -50 to +150 | 8–18 | 250–450 | Ozone, UV, steam, water |

| FKM | 60–90 | -20 to +230 | 12–22 | 150–300 | High heat, chemicals, oil |

| VMQ | 30–80 | -60 to +200 | 6–10 | 200–600 | Extreme cold, high heat |

To discuss your next rubber seal project, request samples, or receive a technical quote, reach out to Mr. Boyce directly at [email protected]. We respond to all inquiries within 24 business hours and offer multilingual support for global OEM partners. Let Suzhou Baoshida be your trusted partner in precision rubber manufacturing.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).