Technical Contents

Engineering Guide: Marsh Industries Ohio

Engineering Insight: Material Selection for Industrial Rubber Applications at Marsh Industries Ohio

In industrial environments such as those operated by Marsh Industries Ohio, the performance and longevity of rubber components are directly tied to precise material selection. Off-the-shelf rubber solutions, while cost-effective in the short term, frequently fail to meet the rigorous demands of continuous operation, extreme temperatures, chemical exposure, and mechanical stress. These failures result in unplanned downtime, increased maintenance costs, and potential safety risks. At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material solutions tailored to the operational parameters of each application.

Generic rubber compounds are formulated for broad compatibility, not specific performance. For example, standard nitrile rubber (NBR) may resist petroleum-based oils but degrades rapidly when exposed to ozone or elevated temperatures above 100°C. In contrast, fluorocarbon (FKM) compounds offer superior resistance to heat and aggressive chemicals but carry a higher cost and reduced flexibility at low temperatures. Selecting the optimal elastomer requires a comprehensive understanding of service conditions, including media exposure, compression set requirements, dynamic loading, and regulatory compliance.

Marsh Industries Ohio operates in sectors where precision and reliability are non-negotiable. Whether in sealing systems, conveyor components, or vibration dampening, the margin for error is minimal. A seal that swells due to incompatible fluid exposure can lead to system leakage, while a misformulated rubber roller may degrade under UV exposure or mechanical fatigue, compromising production quality.

To illustrate the importance of material properties, consider the following comparison of common industrial elastomers used in demanding applications:

| Material | Temperature Range (°C) | Key Chemical Resistances | Typical Applications | Limitations |

|---|---|---|---|---|

| Nitrile (NBR) | -30 to +100 | Petroleum oils, aliphatic hydrocarbons | Seals, gaskets, hoses | Poor ozone and UV resistance |

| EPDM | -50 to +150 | Water, steam, alkalis, brake fluids | HVAC, outdoor seals | Swells in petroleum-based fluids |

| Fluorocarbon (FKM) | -20 to +200 | Acids, fuels, aromatic hydrocarbons | Aerospace, chemical processing | High cost, limited low-temp flexibility |

| Silicone (VMQ) | -60 to +200 | Oxidation, UV, ozone | Electrical insulation, food-grade seals | Low tensile strength, poor abrasion resistance |

| Neoprene (CR) | -40 to +120 | Flame, weather, mild chemicals | Cable jackets, dampers | Moderate fluid resistance |

The data underscores that no single elastomer excels in all conditions. Material selection must be application-driven. At Suzhou Baoshida, we collaborate with partners like Marsh Industries Ohio to conduct failure analysis, environmental assessment, and performance benchmarking. This enables us to recommend or develop custom rubber formulations that align precisely with operational demands.

Ultimately, relying on off-the-shelf rubber components is a false economy. The true cost of failure extends beyond material replacement—it includes lost productivity, safety exposure, and reputational risk. Precision engineering begins with precision materials.

Material Specifications

Industrial Rubber Material Specifications for Critical Applications

Material selection is paramount in industrial sealing and component manufacturing, directly influencing product longevity, safety, and operational efficiency. At Suzhou Baoshida Trading Co., Ltd., we engineer precision rubber compounds to meet the rigorous demands of OEMs like Marsh Industries Ohio. Our formulations undergo stringent ASTM D2000 and ISO 37 testing to ensure compliance with aerospace, automotive, and heavy machinery standards. Below we detail three core elastomers—Viton, Nitrile, and Silicone—highlighting their scientific properties and industrial applicability.

Viton fluoroelastomers (FKM) deliver exceptional resistance to high temperatures, aggressive chemicals, and hydrocarbons. With a continuous service range of -20°C to 230°C and intermittent peaks up to 250°C, Viton excels in fuel systems, chemical processing seals, and aerospace hydraulic applications. Its molecular stability under oxidative stress prevents hardening or cracking, even when exposed to jet fuels, acids, or chlorinated solvents. Compression set values remain below 25% after 70 hours at 200°C, ensuring long-term sealing integrity in dynamic environments.

Nitrile rubber (NBR) remains the industry benchmark for oil and fuel resistance in cost-sensitive applications. Operating effectively from -40°C to 120°C, standard NBR grades withstand hydraulic fluids, lubricants, and aliphatic hydrocarbons. High-acrylonitrile variants (45-50% ACN) enhance fuel resistance but reduce low-temperature flexibility. NBR’s tensile strength (15-25 MPa) and abrasion resistance make it ideal for O-rings, gaskets, and fuel hoses in automotive transmissions and industrial hydraulics. However, it degrades rapidly under ozone, ketones, or phosphate ester fluids.

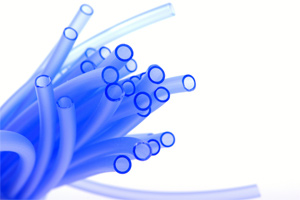

Silicone rubber (VMQ) provides unmatched thermal stability across extreme ranges (-60°C to 200°C continuous, 230°C intermittent) and superior electrical insulation. Its inert, biocompatible structure resists UV, ozone, and microbial growth, making it indispensable for medical devices, food processing seals, and outdoor electrical insulation. While tensile strength is moderate (6-10 MPa), silicone’s flexibility retention at cryogenic temperatures and non-toxic combustion byproducts meet stringent FDA and USP Class VI requirements. Limitations include poor tear strength and susceptibility to concentrated acids.

The comparative analysis below summarizes critical performance metrics for informed material selection:

| Material | Temperature Range (°C) | Key Resistance Properties | Primary Industrial Applications |

|---|---|---|---|

| Viton (FKM) | -20 to 230 | Hydrocarbons, acids, jet fuels, high-temp oxidation | Aerospace seals, chemical pump diaphragms, automotive fuel systems |

| Nitrile (NBR) | -40 to 120 | Aliphatic hydrocarbons, hydraulic fluids, lubricants | Transmission seals, fuel hoses, industrial O-rings |

| Silicone (VMQ) | -60 to 200 | UV, ozone, extreme cold, steam, biological fluids | Medical tubing, food-grade gaskets, electrical insulation |

Selection must balance chemical exposure, thermal cycles, mechanical stress, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. provides OEM-tailored compounding services, including custom durometer adjustments (40-90 Shore A), conductive or flame-retardant additives, and accelerated aging validation per SAE AS568 standards. Partner with our engineering team to optimize material performance for Marsh Industries Ohio’s specific manufacturing challenges, ensuring reduced downtime and extended component service life. All formulations include full traceability documentation and batch-specific certificates of conformance.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. delivers advanced engineering support for industrial rubber manufacturing, tailored to meet the rigorous demands of global OEMs, including strategic partners such as Marsh Industries Ohio. Our engineering capability is anchored in a specialized team of 5 dedicated mould engineers and 2 certified rubber formulation scientists, enabling end-to-end product development from concept to mass production. This integrated technical team ensures precision, material performance, and manufacturability across complex rubber components used in automotive, industrial machinery, and fluid handling systems.

Our mould engineering team applies finite element analysis (FEA), 3D CAD modeling (SolidWorks, AutoCAD), and mold flow simulation to optimize cavity design, gating systems, and ejection mechanisms. This proactive design validation reduces prototyping cycles and accelerates time-to-market. All moulds are fabricated using hardened tool steel with tight tolerances (±0.05 mm), ensuring dimensional stability and extended service life under high-volume production. We support both cold-runner and hot-runner systems, with multi-cavity configurations scalable to customer volume requirements.

Complementing our mould expertise, our two in-house rubber formulation engineers possess extensive experience in elastomer chemistry, including NBR, EPDM, FKM, silicone, and specialty compounds. They develop custom formulations to meet specific performance criteria such as oil resistance, ozone stability, low-temperature flexibility, and compression set. Each formulation undergoes rigorous laboratory testing for tensile strength, elongation, hardness (Shore A), and aging per ASTM and ISO standards. This control over material science ensures consistent performance in demanding environments and full compliance with OEM technical data sheets.

We operate as a certified OEM partner, providing private-label manufacturing with strict IP protection and traceability. Our production lines support compression, transfer, and injection molding processes, with annual capacity exceeding 1,500 tons of rubber goods. All processes are governed by IATF 16949 and ISO 9001 quality management systems, ensuring repeatability and defect prevention.

The following table summarizes our core engineering and production specifications:

| Parameter | Specification |

|---|---|

| Mould Engineers | 5 (CAD/CAM, FEA, Mold Flow Simulation) |

| Formula Engineers | 2 (Elastomer Chemistry, ASTM Testing) |

| Compound Types | NBR, EPDM, FKM, Silicone, CR, NR, SBR |

| Hardness Range (Shore A) | 30–90 ±5 |

| Tensile Strength | Up to 25 MPa (compound-dependent) |

| Operating Temperature Range | -60°C to +300°C (FKM) |

| Molding Processes | Compression, Transfer, Injection |

| Tolerance Control | ±0.05 mm (critical dimensions) |

| Annual Production Capacity | >1,500 metric tons |

| Quality Standards | IATF 16949, ISO 9001, ASTM D2000, ROHS, REACH |

Suzhou Baoshida Trading Co., Ltd. combines deep materials science with precision tooling to deliver reliable, high-performance rubber solutions. Our engineering team collaborates directly with OEM design departments to resolve sealing, damping, and durability challenges, ensuring optimal function in final assembly.

Customization Process

Customization Process for Industrial Rubber Components

Suzhou Baoshida Trading Co., Ltd. implements a rigorously controlled four-phase customization workflow for Marsh Industries Ohio, ensuring technical alignment with operational demands. This methodology eliminates design-to-production gaps while adhering to ASTM D2000 and ISO 37 standards for industrial rubber applications.

Drawing Analysis

Engineering teams commence with dimensional and geometric validation of client-provided CAD models or technical drawings. Critical features—including tolerance stacks, draft angles, and parting line feasibility—are assessed against material flow dynamics in compression, transfer, or injection molding processes. Non-conformities such as undercuts exceeding 0.5mm or wall thickness variations >15% trigger immediate cross-functional review with Marsh Industries’ design engineers. Finite element analysis (FEA) simulates compression set behavior under dynamic loads, preempting in-service failure modes. All measurements are verified per ASME Y14.5-2018 standards before progression.

Formulation Development

Material science protocols dictate compound design based on operational parameters: temperature range (-55°C to +250°C), fluid exposure (e.g., hydraulic oils, ozone), and mechanical stress profiles. Our laboratory synthesizes bespoke elastomer blends using EPDM, FKM, or HNBR base polymers, incorporating proprietary filler systems for enhanced abrasion resistance. Accelerated aging tests (70 hours at 150°C per ASTM D573) validate thermal stability, while Shore A hardness and tensile strength are fine-tuned within ±3% of target values. Formulation certificates detail peroxide vs. sulfur cure systems, critical for Marsh Industries’ high-cycle pneumatic seal requirements.

Prototyping and Validation

Low-volume prototype runs (50–200 units) utilize production-intent tooling to assess manufacturability. Each batch undergoes:

Dimensional inspection via CMM (tolerance ±0.05mm)

Dynamic sealing performance testing at 10,000 cycles

Compression set evaluation per ASTM D395 Method B

Discrepancies trigger Design for Manufacturing (DFM) iterations, typically reducing cavity pressure by 15–20% through gate optimization. Client approval requires ≤0.5% defect rate in critical characteristics.

Mass Production Execution

Approved formulations transition to automated production lines with real-time Statistical Process Control (SPC). Key parameters monitored include:

| Parameter | Control Limit | Test Standard | Frequency |

|---|---|---|---|

| Hardness (Shore A) | Target ±2 | ASTM D2240 | Per batch |

| Tensile Strength | Min. 18 MPa | ASTM D412 | Hourly |

| Elongation at Break | Min. 350% | ASTM D412 | Per shift |

| Compression Set | Max. 25% @ 70°C/22h | ASTM D395 | Daily |

Full traceability is maintained via lot-specific material certificates and mold cavity serialization. Final shipment includes First Article Inspection (FAI) reports with PPAP Level 3 documentation, ensuring seamless integration into Marsh Industries’ assembly lines. This closed-loop process reduces time-to-market by 30% while guaranteeing <50 PPM defect rates in serial production.

Contact Engineering Team

For industrial partners seeking high-performance rubber solutions tailored to exacting manufacturing standards, Suzhou Baoshida Trading Co., Ltd. stands as a trusted global supplier with deep expertise in engineered elastomers and custom rubber compounding. Our collaboration with precision-driven industries, including automotive, aerospace, and heavy equipment manufacturers, ensures that every product delivered meets rigorous performance benchmarks. As a dedicated OEM manager and rubber formula engineer, I oversee the technical alignment between client specifications and our production capabilities, ensuring seamless integration of our materials into your manufacturing workflows.

We understand that consistency, durability, and material compatibility are non-negotiable in industrial applications. Whether you require high-temperature resistant EPDM for sealing systems, oil-resistant NBR for hydraulic components, or custom silicone formulations for specialty environments, our team develops rubber compounds that perform under real-world operational stress. Our formulations are validated through accelerated aging tests, compression set analysis, and dynamic mechanical testing to guarantee long-term reliability.

Our facility in Suzhou operates under ISO 9001-certified quality management protocols, with full traceability from raw material sourcing to final batch release. We support low-volume prototyping and high-volume production runs, offering rapid turnaround without compromising on quality. In addition, our technical team provides full documentation packages, including material data sheets, RoHS compliance reports, and FDA certifications where applicable.

To ensure optimal performance, we recommend early-stage collaboration during the design phase. By engaging with our engineering team upfront, clients can avoid costly rework, optimize part geometry for molding efficiency, and select the most cost-effective compound for the intended service environment. This proactive approach has been instrumental in supporting OEMs across North America and Europe in reducing total cost of ownership while improving product lifecycle.

For Marsh Industries Ohio and other precision manufacturers, we offer dedicated account support, technical consultation, and sample provisioning to validate material performance prior to full-scale implementation. Our goal is to become an extension of your engineering team, providing not just materials, but engineered solutions.

Contact Mr. Boyce directly at [email protected] to initiate a technical discussion, request material samples, or submit a quotation inquiry. Please include your application requirements, performance specifications, and desired delivery timelines to expedite the evaluation process.

The following table outlines key rubber compounds we routinely supply, along with standard physical properties for reference:

| Material Type | Hardness (Shore A) | Tensile Strength (MPa) | Elongation at Break (%) | Temperature Range (°C) | Common Applications |

|---|---|---|---|---|---|

| NBR | 50–90 | 10–25 | 200–400 | -30 to +100 | Seals, hoses, O-rings |

| EPDM | 50–80 | 8–20 | 250–450 | -50 to +150 | Gaskets, weatherstripping |

| Silicone | 30–80 | 5–12 | 200–600 | -60 to +230 | Electrical insulation, medical |

| Neoprene | 50–85 | 12–22 | 250–400 | -40 to +120 | Vibration mounts, belts |

| FKM | 60–90 | 15–25 | 150–300 | -20 to +250 | High-performance seals |

Initiate your project with precision-engineered rubber materials backed by technical rigor and global supply chain reliability. Reach out to Mr. Boyce today.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).