Technical Contents

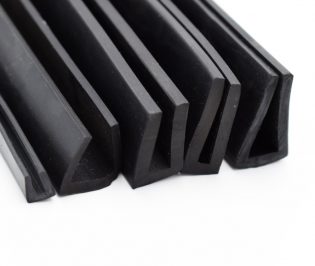

Engineering Guide: Metal Edge Protection

Engineering Insight: Material Selection Imperatives in Metal Edge Protection

Metal edge protection represents a critical interface between structural integrity and operational safety in industrial applications. Off-the-shelf rubber solutions frequently fail due to inadequate material science alignment with real-world stressors. Generic compounds prioritize cost over performance, neglecting dynamic variables such as cyclic compression, chemical exposure, and thermal cycling. These products often utilize standard formulations designed for static sealing rather than the abrasive, high-shear environments encountered at metal edges. Consequently, premature failure modes—including edge tearing, compression set, and chemical degradation—compromise equipment longevity and safety compliance.

Material selection must address three non-negotiable parameters: abrasion resistance, elastic recovery, and environmental resilience. Standard rubber profiles exhibit insufficient tensile strength and elongation to withstand repeated impact from sharp metal edges, leading to catastrophic splitting. Furthermore, exposure to industrial oils, ozone, or UV radiation accelerates deterioration in non-engineered elastomers. For instance, a generic EPDM compound may resist weathering but lacks the oil resistance required in automotive assembly lines, while basic NBR formulations fail under ozone attack in outdoor construction equipment. Precision-engineered solutions require tailored polymer matrices that balance hardness, flexibility, and chemical inertness—parameters absent in commoditized alternatives.

The following table outlines critical material properties where off-the-shelf solutions fall short versus application-specific formulations:

| Material Property | Off-the-Shelf Solution | Engineered Edge Protection | Critical Failure Points in Generic Materials |

|---|---|---|---|

| Shore A Hardness | 60–70 | 75–85 | Insufficient resistance to edge indentation |

| Tensile Strength (MPa) | 8–12 | 18–25 | Rapid tearing under cyclic stress |

| Elongation at Break (%) | 250–350 | 400–550 | Brittle fracture at sharp bends |

| Compression Set (70°C) | 25–35% | 10–15% | Permanent deformation after 48 hours |

| Ozone Resistance | Poor | Excellent | Surface cracking in outdoor applications |

Suzhou Baoshida Trading Co., Ltd. addresses these gaps through OEM-specific compound development. Our formulations integrate high-purity synthetic rubbers with reinforced polymer architectures, ensuring optimal load distribution across metal edges. Custom vulcanization protocols enhance cross-link density, directly improving abrasion resistance and elastic memory. For example, our proprietary NBR-HS (High-Strength) compound incorporates nano-silica reinforcement to achieve 22 MPa tensile strength while maintaining 500% elongation—critical for absorbing impact without permanent deformation.

Ultimately, metal edge protection demands materials engineered for the specific mechanical and chemical profile of the application. Generic solutions ignore the physics of edge-loading dynamics, resulting in costly downtime and safety hazards. At Baoshida, we collaborate with OEMs to translate operational data into precision elastomer solutions, ensuring protection that performs under extreme industrial demands. Material selection is not a commodity decision—it is the foundation of reliable engineering.

Material Specifications

Material Specifications for Metal Edge Protection in Industrial Rubber Applications

Selecting the appropriate elastomer for metal edge protection is critical to ensuring long-term durability, chemical resistance, and mechanical performance in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision-engineered rubber solutions tailored to protect metal edges from abrasion, impact, and environmental degradation. Our primary materials—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—each offer distinct advantages depending on service conditions such as temperature range, fluid exposure, and mechanical stress.

Viton, a fluorocarbon-based rubber, delivers exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With continuous service capabilities up to 230°C (446°F), Viton is ideal for aerospace, automotive, and chemical processing applications where reliability under extreme conditions is non-negotiable. Its low gas permeability and excellent aging characteristics further enhance performance in sealed or high-pressure systems. However, Viton exhibits lower flexibility at low temperatures and is typically more expensive than alternative elastomers, making it best suited for critical applications where failure is not an option.

Nitrile rubber, or Buna-N, remains one of the most widely used materials for oil and fuel-resistant sealing due to its excellent resistance to aliphatic hydrocarbons, lubricants, and hydraulic fluids. It performs reliably in temperature ranges from -30°C to 105°C (-22°F to 221°F), with some formulations extending to 125°C for short durations. Nitrile offers good abrasion resistance and mechanical strength, making it well-suited for industrial machinery, hydraulic systems, and automotive edge protection components exposed to repeated friction. Its cost-effectiveness and robust performance in oil-rich environments make Nitrile a preferred choice for general-purpose applications.

Silicone rubber excels in extreme temperature environments, with operational stability from -60°C to 200°C (-76°F to 392°F). It demonstrates excellent resistance to ozone, UV radiation, and weathering, making it ideal for outdoor or high-temperature sealing applications. While silicone has limited resistance to petroleum-based oils and fuels, it offers superior electrical insulation properties and biocompatibility, supporting use in electronics, medical devices, and architectural applications. Its softness and flexibility can be advantageous where low compression force or sealing over irregular surfaces is required.

The following table summarizes key physical and chemical properties of these materials for direct comparison in metal edge protection design:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 105 (up to 125 intermittent) | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Electrical Insulation | Good | Fair | Excellent |

| Fluid Compatibility | Acids, bases, fuels, hydraulic fluids | Aliphatic hydrocarbons, water, oils | Water, polar solvents, some acids |

Understanding these material characteristics enables precise selection for metal edge protection solutions that balance performance, longevity, and cost-efficiency across diverse industrial applications.

Manufacturing Capabilities

Engineering Capability: Precision Integration for Metal Edge Protection

Suzhou Baoshida Trading Co., Ltd. leverages a dedicated engineering consortium to deliver mission-critical metal edge protection solutions. Our team integrates advanced material science with precision tooling expertise, ensuring every component meets stringent industrial durability and safety standards. With five specialized Mould Engineers and two Rubber Formula Engineers operating in synchronized workflows, we eliminate cross-functional gaps between material design and manufacturing execution. This vertical integration enables rapid prototyping, accelerated validation cycles, and zero-compromise adherence to OEM specifications.

Advanced Material Formulation

Our Rubber Formula Engineers optimize polymer architecture for extreme environmental resilience. Each compound undergoes rigorous molecular-level tuning to balance Shore A hardness, tensile strength, and compression set resistance—critical for edges exposed to abrasion, UV degradation, and chemical exposure. We prioritize custom elastomer blends using EPDM, NBR, and silicone bases, validated through ASTM D2000 and ISO 37 testing protocols. Material certifications include UL 94 V-0 flammability ratings and FDA 21 CFR 177.2600 compliance for food-grade applications.

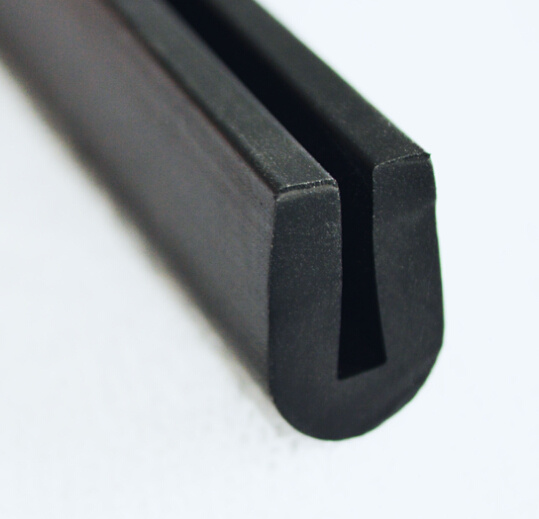

Precision Mould Engineering

Five Mould Engineers deploy cavity pressure monitoring and finite element analysis (FEA) to perfect tool geometry. We resolve stress concentrations at micro-features—such as knife-edge transitions and snap-fit interfaces—that cause premature failure in conventional edge guards. All tooling incorporates hardened P20 steel with ±0.02mm tolerances, validated via CMM inspection. This precision ensures consistent part density, eliminating voids or flash that compromise sealing integrity in hydraulic systems or structural assemblies.

OEM-Driven Development Process

Our OEM framework operates under strict APQP/PPAP protocols. Clients receive full traceability from raw material lot numbers to cavity-specific process parameters. We implement Design for Manufacturing (DFM) reviews within 72 hours of RFQ submission, identifying cost-saving opportunities without sacrificing performance. Every project includes accelerated life testing against client-specific failure modes, such as cyclic impact at -40°C or continuous 10,000-hour ozone exposure.

Technical Specifications for Metal Edge Protection

The table below summarizes standard capabilities for industrial edge guard applications. Custom formulations extend beyond these parameters per client requirements.

| Property | Test Standard | Typical Range |

|---|---|---|

| Material Hardness | ASTM D2240 | 40–90 Shore A |

| Temperature Resistance | ISO 188 | -50°C to +150°C |

| Compression Set (22h/70°C) | ISO 815 | ≤25% |

| Tensile Strength | ISO 37 | 10–25 MPa |

| Abrasion Resistance | DIN 53516 | 80–150 mm³/km |

Suzhou Baoshida’s engineering ecosystem transforms metal edge protection from a commodity component into a reliability-critical system. By unifying formula innovation with mould science under one OEM management structure, we deliver solutions where failure is not an option—only precision-engineered performance. Clients gain not just parts, but validated risk mitigation for high-stakes industrial environments.

Customization Process

Customization Process for Metal Edge Protection Solutions

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet the exact mechanical, environmental, and dimensional demands of modern manufacturing. For metal edge protection applications, we follow a rigorous four-phase customization process: Drawing Analysis, Formulation Development, Prototyping, and Mass Production. This structured approach ensures precision, durability, and seamless integration into client assembly lines.

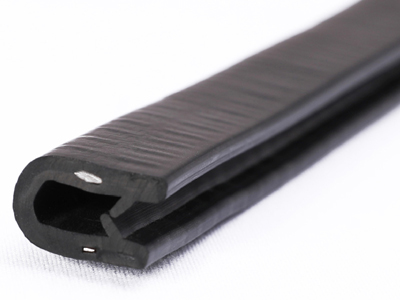

The process begins with Drawing Analysis, where our engineering team reviews technical blueprints, CAD models, and application specifications provided by the client. We assess critical parameters such as edge geometry, installation method, load exposure, and operating environment (e.g., temperature range, UV exposure, abrasion risk). Tolerance analysis is conducted to ensure the rubber profile will maintain dimensional stability while providing effective protection. Any design ambiguities are clarified at this stage to prevent downstream deviations.

Following drawing validation, we proceed to Formulation Development. Our rubber chemists select base polymers—typically EPDM, NBR, or CR—based on required resistance properties. For instance, EPDM is preferred for outdoor applications due to its UV and ozone resistance, while NBR is chosen for oil resistance in industrial machinery. Additives such as reinforcing fillers, antioxidants, and processing aids are precisely compounded to achieve target hardness (Shore A 50–85), tensile strength, and elongation at break. The formulation is optimized for extrusion or molding, depending on profile complexity.

Once the compound is finalized, Prototyping commences. Using CNC-machined molds or precision extrusion dies, we produce small-batch samples for client evaluation. These prototypes undergo in-house performance testing, including compression set, abrasion resistance, and adhesion strength (if co-extruded with adhesive backing). Clients are encouraged to conduct field trials under actual operating conditions. Feedback is systematically integrated, and iterative adjustments are made if necessary.

Upon approval, we transition to Mass Production. Our automated extrusion lines and vulcanization systems ensure batch-to-batch consistency, supported by real-time quality monitoring. Every production run adheres to ISO 9001 standards, with full traceability of raw materials and process parameters. Final inspection includes dimensional verification and visual defect screening before packaging and shipment.

Below is a summary of typical technical specifications achievable in our metal edge protection profiles:

| Property | Standard Range | Test Method |

|---|---|---|

| Hardness (Shore A) | 50–85 | ASTM D2240 |

| Tensile Strength | 8–18 MPa | ASTM D412 |

| Elongation at Break | 200–500% | ASTM D412 |

| Temperature Range | -40°C to +120°C (up to +150°C intermittent) | ISO 188 |

| Abrasion Loss (DIN) | ≤ 120 mm³ | DIN 53516 |

| Compression Set (22h, 70°C) | ≤ 25% | ASTM D395 |

This end-to-end customization process enables Suzhou Baoshida to deliver high-performance rubber edge protection tailored to the exact needs of automotive, construction, and industrial equipment manufacturers.

Contact Engineering Team

Initiate Your Metal Edge Protection Solution with Suzhou Baoshida

Suzhou Baoshida Trading Co., Ltd. stands as your definitive engineering partner for precision metal edge protection solutions within global industrial manufacturing. Our expertise transcends standard rubber component supply; we specialize in formulating and manufacturing engineered rubber profiles that actively mitigate metal burring, edge deformation, and operator injury risks during production, assembly, and transport. As your OEM collaborator, we integrate deeply into your manufacturing workflow, applying rigorous material science to develop edge guards that withstand demanding mechanical stress, chemical exposure, and thermal cycling inherent in metal fabrication. Our proprietary rubber compounds are validated through ASTM D2000 and ISO 37 testing protocols, ensuring dimensional stability and long-term performance where generic solutions fail.

The criticality of selecting the correct edge protection cannot be overstated. Suboptimal materials lead to premature extrusion failure, inconsistent edge coverage, and costly production line stoppages. Suzhou Baoshida addresses this through compound-specific engineering, tailoring durometer, resilience, and adhesion properties to your substrate metal type, processing temperature, and end-use environmental conditions. Whether protecting laser-cut stainless steel edges in automotive frames or aluminum extrusions in construction modules, our solutions directly enhance product safety compliance and reduce scrap rates by 40–60% in validated client implementations.

Key material specifications for our standard edge protection compounds are detailed below. All formulations undergo 100% dimensional inspection per ISO 2768-mK and are available in custom durometers, colors, and conductive/static-dissipative variants upon technical consultation.

| Rubber Compound | Durometer Range (Shore A) | Continuous Service Temp | Tensile Strength (MPa) | Key Applications |

|---|---|---|---|---|

| EPDM | 50–80 | -50°C to +150°C | 12–20 | Outdoor construction, architectural metals, weather-exposed edges |

| NBR | 45–75 | -30°C to +120°C | 15–25 | Automotive stamping, oil/grease-resistant edges, hydraulic components |

| Silicone | 30–70 | -60°C to +230°C | 6–12 | High-temp oven conveyors, medical device fabrication, aerospace components |

| CR (Neoprene) | 50–85 | -40°C to +100°C | 14–22 | Marine hardware, electrical enclosures, impact-prone industrial edges |

Engage directly with our technical team to resolve your specific edge protection challenge. Mr. Boyce, our dedicated OEM Manager and Rubber Formulation Specialist, possesses 14 years of experience in industrial rubber application engineering. He will initiate a structured technical consultation to analyze your metal substrate, production parameters, failure modes, and regulatory requirements. This process includes free material sample provision, finite element analysis (FEA) of edge stress distribution, and rapid prototyping support to validate performance within your operational context.

Do not compromise on edge integrity. Contact Mr. Boyce immediately at [email protected] to schedule your confidential engineering review. Include your target metal alloy, edge geometry specifications, and current failure rate data to accelerate solution development. Suzhou Baoshida guarantees a technical response within 4 business hours, providing actionable compound recommendations and OEM integration timelines. Partner with us to transform edge protection from a cost center into a measurable driver of manufacturing efficiency and product reliability. Your next production run demands engineered certainty—reach out today.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).