Technical Contents

Engineering Guide: Metal Stair Treads Outdoor

Engineering Insight: Material Selection for Outdoor Metal Stair Treads

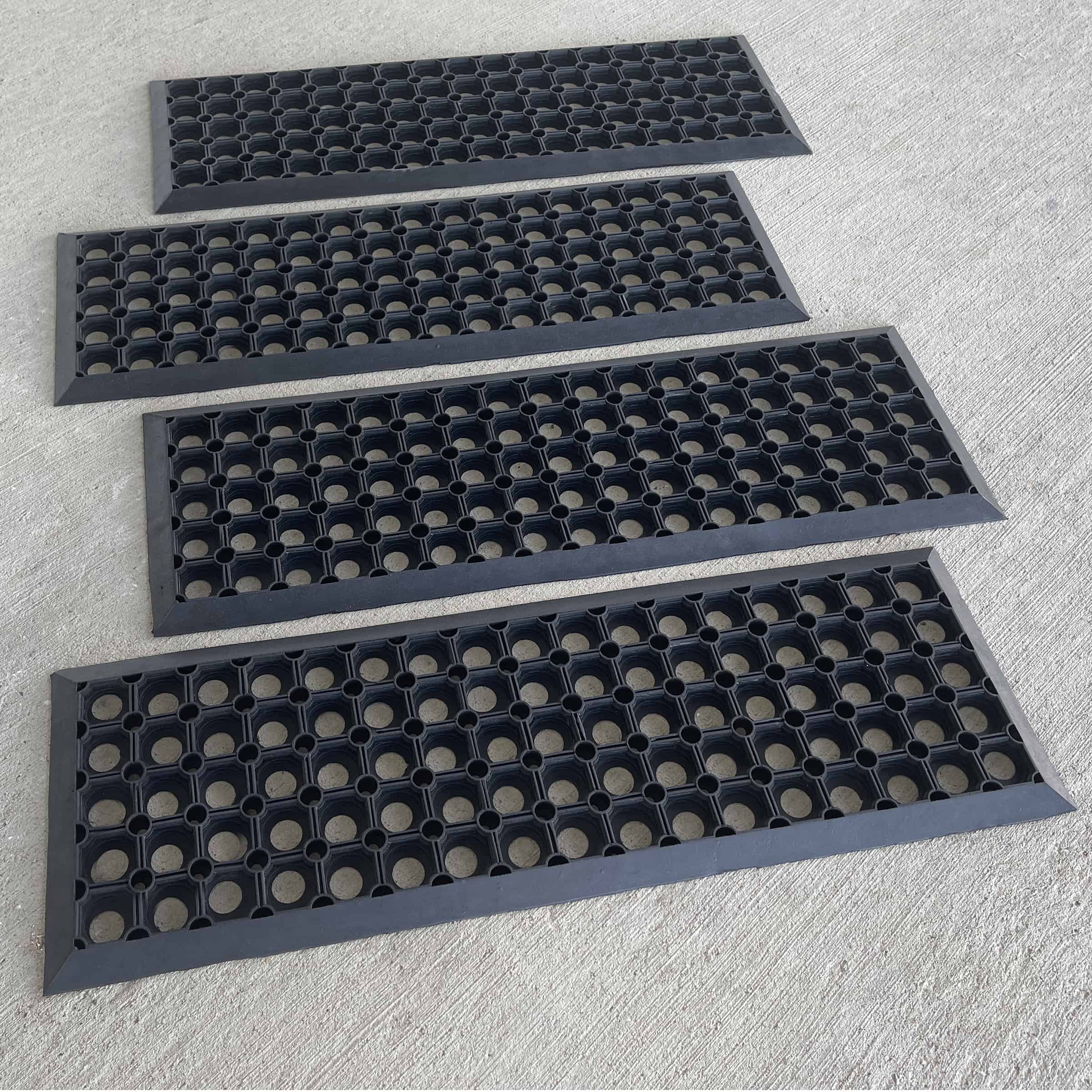

In industrial and commercial environments, outdoor metal stair treads are subjected to relentless mechanical, chemical, and environmental stresses. While standard off-the-shelf solutions may appear cost-effective initially, they frequently fail to meet long-term performance demands. The root cause lies not in design, but in improper material selection. At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered rubber solutions tailored to the operational realities of outdoor applications.

Metal stair treads, typically fabricated from steel or aluminum, require durable anti-slip surfacing to ensure safety and longevity. Most generic products utilize basic rubber compounds such as natural rubber (NR) or low-grade SBR (styrene-butadiene rubber). These materials degrade rapidly when exposed to UV radiation, temperature extremes, moisture, and industrial contaminants like oils, salts, and ozone. Cracking, delamination, and loss of traction are common failure modes observed within 6 to 12 months in harsh outdoor conditions.

The failure of off-the-shelf treads stems from a one-size-fits-all approach. These solutions are often designed for indoor or light-duty use and lack formulation precision. In contrast, high-performance applications demand rubber compounds engineered for specific environmental profiles. For instance, chloroprene rubber (CR), also known as neoprene, offers superior resistance to weathering, ozone, and moderate oil exposure. Ethylene propylene diene monomer (EPDM) excels in UV and thermal stability, making it ideal for prolonged sun exposure. Nitrile rubber (NBR) is preferred in oil-prone environments due to its exceptional oil and fuel resistance.

Beyond compound selection, adhesion technology is critical. Many pre-fabricated treads rely on mechanical fasteners or weak adhesive systems that compromise structural integrity over time. Our engineered solutions utilize high-strength, two-part polyurethane adhesives that chemically bond rubber to metal substrates, ensuring long-term durability even under dynamic loading and thermal cycling.

The following table outlines key rubber compounds and their performance characteristics for outdoor metal stair tread applications:

| Rubber Compound | UV Resistance | Temperature Range (°C) | Oil Resistance | Ozone Resistance | Typical Service Life (Outdoor) |

|---|---|---|---|---|---|

| Natural Rubber (NR) | Low | -30 to +70 | Low | Low | 6–12 months |

| SBR | Low-Moderate | -20 to +80 | Low | Low | 6–15 months |

| Neoprene (CR) | High | -40 to +100 | Moderate | High | 3–5 years |

| EPDM | Very High | -50 to +150 | Low | Very High | 5+ years |

| Nitrile (NBR) | Moderate | -30 to +120 | Very High | Moderate | 3–4 years |

Selecting the appropriate rubber compound is not a secondary consideration—it is a fundamental engineering decision. At Suzhou Baoshida, we collaborate with OEMs and facility managers to analyze site-specific conditions and deploy rubber formulations that deliver sustained performance. By moving beyond generic solutions and embracing material science, outdoor stair treads can achieve safety, compliance, and operational longevity.

Material Specifications

Material Specifications for Outdoor Metal Stair Tread Applications

Selecting the appropriate rubber compound for outdoor metal stair treads is critical for ensuring long-term safety, durability, and performance under harsh environmental conditions. At Suzhou Baoshida Trading Co., Ltd., we rigorously formulate and validate rubber solutions to withstand UV exposure, temperature extremes, moisture, and mechanical stress inherent in exterior architectural applications. Our engineered compounds prioritize slip resistance, adhesion to metal substrates, and resistance to degradation from ozone, oils, and common industrial contaminants. The three primary elastomers deployed in this context—Viton, Nitrile, and Silicone—each offer distinct molecular advantages tailored to specific operational demands. Understanding their intrinsic properties is essential for optimal material selection in stair tread manufacturing.

Viton fluoroelastomers provide unparalleled resistance to extreme temperatures and aggressive chemicals. Their carbon-fluorine backbone delivers exceptional stability against ozone, UV radiation, and oxidation, making them ideal for stair treads in industrial zones exposed to fuels, solvents, or high-heat environments. Viton maintains integrity from -20°C to 250°C, though its higher cost necessitates strategic deployment where chemical exposure is severe. Nitrile rubber (NBR) remains the industry standard for balanced performance in cost-sensitive applications. Its acrylonitrile content directly correlates with oil and fuel resistance, while hydrogenation enhances ozone stability. NBR compounds excel in moderate outdoor settings with incidental exposure to hydraulic fluids or greases but exhibit reduced flexibility below -30°C and moderate UV resistance without protective additives. Silicone rubber dominates scenarios requiring extreme temperature resilience and superior weatherability. With a siloxane backbone, it resists thermal degradation from -60°C to 230°C and maintains elasticity under prolonged UV exposure. However, its lower tensile strength and susceptibility to tearing in high-abrasion zones require careful formulation for stair tread use.

Baoshida optimizes each compound with proprietary fillers and curing systems to meet ASTM D2000 and ISO 37 standards for tensile strength, elongation, and compression set. Our NBR formulations incorporate specialty carbon blacks for enhanced abrasion resistance, while Viton grades include peroxide curing for low-temperature flexibility. Silicone compounds are reinforced with fumed silica to improve tear strength without compromising weatherability. All materials undergo accelerated aging tests per ASTM G154 to validate 15+ year service life in outdoor stair applications.

The comparative analysis below details critical performance parameters for informed material selection

| Material | Temperature Range (°C) | Hardness Range (Shore A) | Key Strengths | Primary Limitations | Best For Outdoor Stair Treads In |

|---|---|---|---|---|---|

| Viton | -20 to 250 | 60–90 | Extreme chemical resistance Ozone/UV stability High-temperature resilience | High cost Lower flexibility at low temps | Chemical plants refineries coastal marine facilities |

| Nitrile | -30 to 120 | 50–85 | Cost-effective Oil/fuel resistance Good abrasion resistance | Moderate UV resistance Hardens above 100°C | Warehouses parking structures light industrial sites |

| Silicone | -60 to 230 | 40–70 | Exceptional UV/weather resistance Ultra-low/high-temp stability Biocompatibility | Lower tear strength Higher compression set | Rooftop access points solar farms arctic climates |

Suzhou Baoshida Trading Co., Ltd. provides OEMs with application-specific compound recommendations backed by real-world validation in global infrastructure projects. Our technical team collaborates with stair manufacturers to customize durometer, color stability, and anti-slip profiles—ensuring compliance with ISO 14122 safety standards while maximizing lifecycle value. Material selection must align with site-specific environmental stressors; we recommend Viton for chemical-intensive zones, Nitrile for general industrial use, and Silicone for extreme weather exposure where thermal cycling exceeds 150°C. All formulations include Baoshida’s proprietary anti-microbial agents to prevent organic growth on tread surfaces in humid climates.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. delivers advanced engineering solutions in industrial rubber applications, with a specialized focus on high-performance outdoor metal stair treads. Our in-house engineering team comprises five dedicated mould engineers and two certified rubber formula engineers, enabling full vertical control from concept to production. This integrated technical capability ensures precision, durability, and compliance with rigorous industrial standards.

Our mould engineers specialize in designing complex, high-tolerance tooling systems tailored to the structural and environmental demands of outdoor stair applications. Utilizing advanced CAD/CAM software and CNC prototyping, they develop moulds that ensure consistent part geometry, optimal rubber flow, and long-term wear resistance. Each design undergoes rigorous simulation testing to anticipate thermal expansion, load distribution, and de-moulding efficiency—critical factors in outdoor installations exposed to dynamic weather and heavy foot traffic.

Complementing this is our rubber formulation expertise. Our two formula engineers possess deep knowledge in elastomer chemistry, focusing on compounding materials that enhance slip resistance, UV stability, and temperature resilience. For metal stair treads, we develop custom EPDM, NBR, and SBR-based compounds engineered to bond securely with metal substrates while maintaining flexibility across temperature ranges from -40°C to +120°C. These formulations are tested for abrasion resistance (DIN 53516), anti-slip performance (DIN 51130), and resistance to oils, ozone, and salt spray—essential for industrial, marine, and public infrastructure environments.

As an OEM manufacturer, Suzhou Baoshida provides end-to-end development support. Clients can supply performance requirements or existing designs, and we optimize both material composition and mould architecture to meet functional, cost, and scalability targets. Our facility supports low-volume prototyping and high-volume production, with strict QC protocols including dimensional inspection, adhesion testing, and batch traceability.

We maintain a comprehensive library of certified rubber compounds and mould design templates, reducing development lead time by up to 40%. This technical agility allows us to deliver stair tread solutions that exceed industry benchmarks for safety, longevity, and performance in harsh outdoor conditions.

The following table outlines key technical specifications achievable through our engineering capabilities:

| Property | Test Standard | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 55–75 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Abrasion Loss | DIN 53516 | ≤90 mm³ |

| Anti-slip Rating (R-value) | DIN 51130 | R10–R13 |

| Operating Temperature | — | -40°C to +120°C |

| Adhesion to Metal | ASTM D429 | ≥4.5 kN/m |

This combination of formulation science and precision tooling design positions Suzhou Baoshida as a trusted engineering partner for industrial stair tread systems requiring superior durability and safety.

Customization Process

Customization Process for Outdoor Metal Stair Tread Rubber Components

Suzhou Baoshida Trading Co., Ltd. implements a rigorous, science-driven customization pathway for industrial rubber components applied to outdoor metal stair treads. This process ensures optimal performance under demanding environmental and mechanical stressors while meeting precise OEM specifications. Our methodology progresses sequentially through four critical engineering phases, guaranteeing material integrity and functional reliability.

Drawing Analysis initiates the project. Our engineering team conducts a meticulous review of client-provided CAD drawings and technical specifications. Key parameters scrutinized include dimensional tolerances, substrate geometry (e.g., expanded metal mesh type, perforation pattern), load-bearing requirements, and installation methodology. We assess critical interfaces between the rubber compound and the metal substrate, focusing on adhesion mechanics, thermal expansion differentials, and stress concentration points. Environmental exposure factors such as UV intensity, temperature extremes, moisture levels, and potential chemical contact are quantified to inform subsequent material selection. This phase culminates in a formal engineering sign-off confirming feasibility and identifying any necessary design modifications for manufacturability.

Formulation leverages Suzhou Baoshida’s proprietary compound database and accelerated aging protocols. Based on the environmental and mechanical requirements defined in Drawing Analysis, our rubber chemists develop a tailored elastomer recipe. Primary considerations include selecting the optimal base polymer—typically peroxide-cured EPDM or specialized nitrile blends for superior ozone and UV resistance—and incorporating critical additives. These include high-efficiency UV stabilizers, anti-oxidants, reinforcing fillers for abrasion resistance, and specialized pigments for color stability. The target Shore A hardness (usually 60-75) is precisely calibrated to balance slip resistance with impact absorption and fatigue life. Key physical properties are predetermined to meet or exceed ASTM D2000 standards for outdoor industrial applications.

Prototyping validates the formulated compound. Using precision tooling, we produce functional samples under controlled production conditions. These prototypes undergo comprehensive laboratory testing per ASTM standards, including tensile strength, elongation at break, compression set, Shore hardness verification, and critical slip resistance measurement (ASTM F2913). Accelerated weathering tests (QUV, Xenon arc) simulate years of outdoor exposure within weeks. Adhesion strength between the rubber and the specific client-supplied metal substrate is rigorously measured. Client feedback on prototype fit, function, and aesthetics is integrated, with compound adjustments made if necessary before final approval.

Mass Production commences only after prototype validation and client sign-off. Our ISO-certified facility employs automated mixing, precision extrusion or molding, and vulcanization systems with real-time process monitoring. Every production batch undergoes stringent in-process quality control checks against the approved formulation and dimensional specifications. Final inspection includes 100% visual examination for defects and statistical sampling for critical physical properties. Comprehensive traceability documentation accompanies each shipment, ensuring full compliance with the client’s OEM requirements and enabling rapid root-cause analysis if required.

The following table summarizes critical rubber compound specifications targeted for standard outdoor metal stair tread applications:

| Property | Test Method | Target Value Range | Significance for Outdoor Stair Treads |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 65 – 75 | Optimal slip resistance & impact absorption |

| Tensile Strength (MPa) | ASTM D412 | ≥ 12.0 | Resistance to tearing under foot traffic |

| Elongation at Break (%) | ASTM D412 | ≥ 300 | Flexibility to accommodate substrate movement |

| Compression Set (B) (%) | ASTM D395 | ≤ 25 (70°C, 22h) | Long-term recovery, maintains grip profile |

| Abrasion Loss (mm³) | ASTM D5963 | ≤ 120 | Durability against wear from foot traffic |

| UV Resistance (QUV) | ASTM G154 | Pass 1500h | Prevents cracking/chalking from sun exposure |

| Slip Resistance (Dry/Wet) | ASTM F2913 | ≥ 0.60 / ≥ 0.45 | Critical safety performance metric |

This structured engineering approach ensures Suzhou Baoshida delivers rubber stair tread components that provide exceptional longevity, safety, and performance in the harshest outdoor environments, fully aligned with OEM manufacturing standards.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Metal Stair Treads for Outdoor Applications

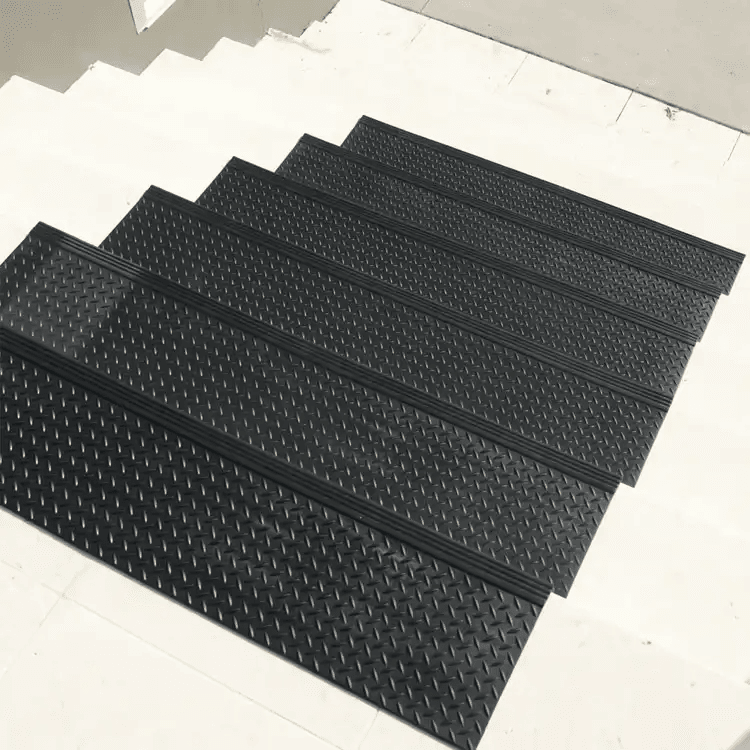

For industrial and commercial projects requiring durable, weather-resistant metal stair treads designed for outdoor use, Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber solutions that meet the highest performance standards. As a specialized provider in industrial rubber applications, we integrate advanced material science with precision manufacturing to produce anti-slip stair treads that enhance safety, extend service life, and withstand harsh environmental conditions. Our rubber-coated metal stair treads are optimized for outdoor infrastructure, including marine docks, industrial walkways, utility platforms, and public access systems where corrosion resistance, impact durability, and reliable traction are critical.

Our manufacturing process leverages high-strength steel substrates bonded with vulcanized rubber compounds formulated for UV stability, ozone resistance, and extreme temperature performance. This ensures long-term integrity under continuous exposure to rain, snow, salt spray, and thermal cycling. Each tread is designed to meet or exceed international safety standards for slip resistance, including DIN 51130 and BS 7976, providing secure footing even in wet or oily environments. The integration of drainage channels and raised cleats enhances surface evacuation and grip, minimizing slip hazards in challenging outdoor conditions.

Suzhou Baoshida operates under strict quality control protocols, with in-house testing facilities that validate adhesion strength, wear resistance, and dimensional accuracy. We support custom engineering to meet project-specific load requirements, tread profiles, mounting configurations, and coating specifications. Whether you require standard grating overlays or fully customized tread assemblies with non-marking rubber compounds, our team ensures compatibility with structural design and environmental demands.

For technical collaboration or procurement inquiries, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce specializes in material formulation, performance validation, and industrial application integration, ensuring that every solution is scientifically optimized for real-world performance. He is available to discuss material certifications, sample testing, lifecycle analysis, and volume production scheduling.

Below are key technical specifications for our standard outdoor metal stair tread series:

| Parameter | Specification |

|---|---|

| Substrate Material | Q235 Carbon Steel, Hot-Dip Galvanized |

| Rubber Hardness (Shore A) | 60 ± 5 |

| Temperature Range | -40°C to +120°C |

| Slip Resistance (Wet, BS 7976) | R11–R13 (Pendulum Test Value > 54) |

| Adhesion Strength | ≥ 8 kN/m (Peel Resistance) |

| UV and Ozone Resistance | ASTM D1149, No Cracking After 720h |

| Fire Rating | UL 94 HF-1 (Optional Flame-Retardant Grade) |

| Standard Sizes | Customizable (Typical: 600–1200 mm length) |

To initiate a technical consultation, request material samples, or submit a project specification, contact Mr. Boyce directly at [email protected]. We respond to all inquiries within 12 business hours and support global OEM partnerships with scalable production capacity and logistics coordination. Trust Suzhou Baoshida for engineered rubber solutions that deliver safety, longevity, and industrial reliability in outdoor stair applications.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).