Technical Contents

Engineering Guide: Monel 400 Bar

Engineering Insight: Monel 400 Bar in Demanding Industrial Applications

Material selection is a foundational decision in the engineering of high-performance industrial components, particularly when operating under extreme conditions such as high pressure, elevated temperatures, and corrosive environments. Monel 400 bar stock represents a critical solution in such contexts, offering a nickel-copper alloy composition that delivers exceptional resistance to seawater, acids, and alkaline environments. Off-the-shelf alternatives, often based on carbon steel or lower-grade stainless alloys, frequently fail prematurely due to localized corrosion, stress cracking, or mechanical degradation. These failures are not merely operational setbacks—they represent safety risks, unplanned downtime, and increased lifecycle costs.

Monel 400 is composed primarily of nickel (63–70%) and copper (29–34%), with trace amounts of iron and manganese. This composition grants it a unique combination of high tensile strength, excellent ductility, and remarkable resistance to chloride-ion stress-corrosion cracking—properties that are indispensable in marine engineering, chemical processing, and oil & gas applications. In bar form, Monel 400 is commonly used for shafts, pump components, valve stems, and fasteners where dimensional stability and long-term reliability are non-negotiable.

Standardized materials often fail because they are not engineered for the specific electrochemical or mechanical environment of the application. For instance, in seawater cooling systems, stainless steels such as 316L may initially appear cost-effective but are prone to pitting and crevice corrosion over time. Monel 400, by contrast, forms a stable, adherent oxide layer that resists biofouling and galvanic attack, ensuring sustained performance even in continuous immersion conditions.

Furthermore, Monel 400 maintains its mechanical integrity across a broad temperature range, from sub-zero to approximately 480°C (900°F), making it suitable for both cryogenic and high-heat applications. Its ability to resist scaling and retain strength at elevated temperatures surpasses that of many common alloys, reducing the need for frequent replacement or maintenance.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material solutions over generic substitutes. Monel 400 bar is not a commodity; it is a precision-engineered material selected for mission-critical applications where failure is not an option. Our technical team works closely with OEMs and end-users to verify compatibility with process media, thermal cycles, and mechanical loads—ensuring that every bar supplied meets stringent performance criteria.

The following table summarizes key mechanical and chemical properties of Monel 400 bar per ASTM B164 specifications:

| Property | Value |

|---|---|

| Nickel Content | 63.0–70.0% |

| Copper Content | 29.0–34.0% |

| Tensile Strength (Annealed) | ≥550 MPa |

| Yield Strength (0.2% Offset) | ≥240 MPa |

| Elongation (in 50 mm) | ≥35% |

| Density | 8.84 g/cm³ |

| Melting Range | 1300–1350°C |

| Corrosion Resistance | Excellent in seawater, hydrofluoric acid, sulfuric acid (reducing conditions), and alkaline media |

Material integrity begins with informed selection. Monel 400 bar is not merely a metal form—it is a performance guarantee in the world’s most challenging industrial environments.

Material Specifications

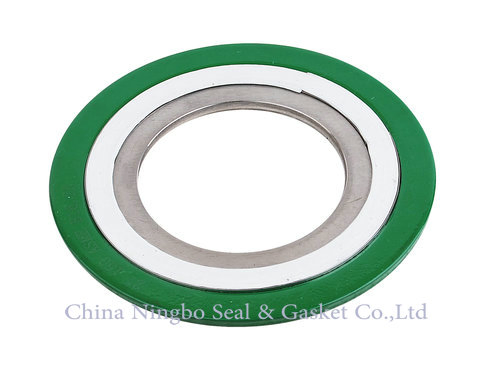

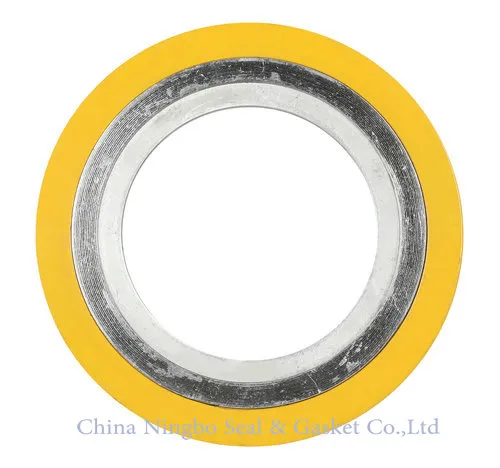

Material Specifications for Sealing Systems with Monel 400 Bar Components

Suzhou Baoshida Trading Co., Ltd. provides precision-engineered rubber solutions designed for critical sealing applications involving Monel 400 bar components. Monel 400, a nickel-copper alloy, is widely used in corrosive environments such as chemical processing, marine engineering, and aerospace due to its exceptional resistance to seawater, acids, and high-pressure conditions. The integrity of systems utilizing Monel 400 bars hinges on compatible elastomeric seals that withstand operational stresses without degradation. Viton, Nitrile, and Silicone rubber compounds are rigorously formulated to meet these demands, with properties validated against ASTM D2000 and ISO 37 standards. Each material offers distinct advantages depending on temperature exposure, chemical compatibility, and mechanical requirements.

Viton fluorocarbon rubber (FKM) delivers superior performance in aggressive chemical environments, including hydrocarbons, acids, and ozone. Its molecular structure ensures stability at temperatures ranging from -20°C to 230°C, making it ideal for high-temperature Monel 400 systems in oil refining or chemical reactors. Compression set resistance remains below 25% after 70 hours at 150°C, per ASTM D395. Nitrile rubber (NBR) provides cost-effective resilience in petroleum-based applications, with a functional range of -40°C to 120°C. It exhibits excellent abrasion resistance and tensile strength up to 25 MPa but is unsuitable for ketones or chlorinated solvents. Silicone rubber (VMQ) excels in extreme temperature flexibility (-60°C to 200°C) and maintains elasticity in cryogenic or steam sterilization processes, though its tensile strength (6–8 MPa) limits use in high-pressure dynamic seals.

Critical selection parameters must align with Monel 400’s operational profile. Viton is optimal for sour gas service per NACE MR0175, while Nitrile suits hydraulic systems with mineral oils. Silicone is preferred for pharmaceutical or food-grade applications requiring biocompatibility. All compounds undergo stringent batch testing for hardness (50–90 Shore A), elongation at break (200–600%), and fluid immersion resistance per ISO 1817.

The following table compares key technical specifications for informed material selection:

| Material | Temperature Range (°C) | Key Fluid Resistances | Key Limitations | Typical Monel 400 Applications |

|---|---|---|---|---|

| Viton (FKM) | -20 to 230 | Hydrocarbons, acids, fuels, ozone | Poor ketone resistance; higher cost | Chemical valves, aerospace actuators, sour gas pipelines |

| Nitrile (NBR) | -40 to 120 | Mineral oils, water, alcohols | Swells in esters; limited high-temp stability | Hydraulic cylinders, pump seals, marine fuel systems |

| Silicone (VMQ) | -60 to 200 | Water, steam, oxygen, mild chemicals | Low tear strength; incompatible with concentrated acids | Sterilization equipment, medical devices, cryogenic seals |

Suzhou Baoshida Trading Co., Ltd. emphasizes empirical validation for Monel 400 integration. Our rubber formulations undergo accelerated aging tests in simulated service conditions, including exposure to Monel 400-induced galvanic corrosion environments. Clients are advised to consult our technical team for application-specific compound customization, ensuring zero leakage and extended service life in demanding industrial ecosystems. Precision in material pairing directly impacts system reliability and operational safety.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in deep technical expertise and a disciplined approach to industrial rubber solutions. With a dedicated team of five mould engineers and two specialized rubber formula engineers, we maintain full in-house control over the design, development, and production processes. This integrated engineering structure enables us to deliver high-performance rubber components compatible with demanding applications involving materials such as Monel 400 bar, where thermal stability, corrosion resistance, and mechanical integrity are critical.

Our mould engineers bring over a decade of cumulative experience in precision tooling design for complex sealing and damping applications. Utilizing advanced CAD/CAM software and CNC machining protocols, they develop robust moulds that ensure dimensional accuracy, repeatable part geometry, and optimal material flow during compression, transfer, and injection moulding. Each design undergoes rigorous simulation and tolerance analysis to prevent defects such as flash, incomplete curing, or stress concentration—common failure points when sealing against high-strength alloys like Monel 400.

Complementing this capability are our two rubber formula engineers, who specialize in compounding elastomers for extreme environments. Monel 400, a nickel-copper alloy known for its resistance to seawater, hydrofluoric acid, and high-pressure steam, often operates at elevated temperatures and corrosive interfaces. To match these conditions, our formula engineers develop custom rubber compounds—primarily based on FKM, EPDM, and peroxide-cured silicone—that exhibit long-term resilience against swelling, compression set, and chemical degradation. Every formulation is validated through accelerated aging tests, Shore hardness tracking, and dynamic mechanical analysis (DMA) to ensure performance parity with the metal components they interface with.

Our OEM capabilities are built on this dual-engineering foundation. We support customers from concept to mass production, offering design for manufacturability (DFM) feedback, rapid prototyping, and full documentation packages including material certifications (e.g., ASTM D2000, ROHS, REACH). Whether the application involves static sealing in offshore valves or dynamic gasketing in chemical processing equipment, our team ensures that every rubber component is engineered to perform reliably in conjunction with Monel 400 bar stock components.

The following table outlines key rubber material specifications developed for compatibility with Monel 400-based systems:

| Property | FKM (26 Type) | EPDM | Silicone (Peroxide Cured) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 | -50 to +150 | -60 to +200 |

| Hardness Range (Shore A) | 60–90 | 50–80 | 40–80 |

| Tensile Strength (MPa) | ≥12 | ≥10 | ≥7 |

| Elongation at Break (%) | ≥200 | ≥250 | ≥200 |

| Compression Set (22h at 150°C) | ≤25% | ≤30% | ≤20% |

| Key Resistance | Acids, oils, steam | Water, steam, alkalis | Extreme temp, ozone |

| Typical Use with Monel 400 | High-pressure valves, pumps | Heat exchangers, marine seals | Instrumentation seals, aerospace |

This technical synergy between mould design and material science positions Suzhou Baoshida as a trusted OEM partner in advanced industrial sectors including oil & gas, marine engineering, and chemical processing.

Customization Process

Monel 400 Bar Customization Process: Precision Rubber Integration

Suzhou Baoshida Trading Co., Ltd. executes a rigorous, science-driven customization workflow for Monel 400 bar components requiring industrial rubber integration. This process ensures optimal performance under demanding conditions where Monel 400’s exceptional corrosion resistance and mechanical properties must interface flawlessly with elastomeric elements. Our methodology eliminates guesswork through sequential, data-anchored phases.

Initial Drawing Analysis constitutes a critical metallurgical and dimensional review. We meticulously evaluate client CAD models or engineering prints, focusing on Monel 400 bar geometry, surface finish requirements (Ra values), tolerance bands per ASME Y14.5, and critical bonding zones. This phase identifies potential stress concentrations, verifies material grade compliance to ASTM B164, and assesses compatibility with intended service media. Concurrently, we define rubber contact surfaces and establish baseline parameters for adhesion strength and environmental resistance.

Formulation Development leverages our proprietary compound database and Monel 400-specific interfacial chemistry knowledge. Monel’s nickel-copper matrix presents unique adhesion challenges requiring tailored cure systems. We select base polymers (typically HNBR or EPDM for high-temperature stability) and engineer curative packages to mitigate Monel-induced scorch risks while maximizing bond durability. Critical adjustments include optimizing silane coupling agents for metal oxide layer interaction and fine-tuning filler systems to match Monel’s thermal expansion coefficient. Every formulation undergoes predictive modeling for compression set and fluid resistance before lab synthesis.

Prototyping & Validation employs controlled laboratory vulcanization to produce bonded assemblies. We conduct stringent destructive and non-destructive testing per ASTM/ISO standards. Peel strength (ASTM D429 Method B), compression set (ASTM D395), and accelerated aging in client-specified media are mandatory. Dimensional verification via CMM confirms conformance to the original drawing tolerances. Client feedback on prototype performance directly informs final compound adjustments, ensuring the rubber formulation compensates for Monel 400’s specific thermal and chemical behavior.

Controlled Mass Production initiates only after formal client approval of validation data. Our ISO 9001-certified facility implements Statistical Process Control (SPC) for both Monel bar machining and rubber molding. Monel surfaces undergo validated cleaning and priming protocols immediately pre-bonding. Real-time monitoring tracks cure temperature profiles, press time, and bonding pressure. Each production lot includes traceable material certifications for Monel 400 (mill test reports) and rubber compounds (full QC test reports), with periodic re-validation of adhesion strength and critical dimensions.

Key performance specifications for Monel 400-rubber bonded components are maintained within these engineered limits:

| Parameter | Standard Test Method | Typical Performance Range |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60 – 90 |

| Operating Temperature | ISO 188 | -50°C to +150°C |

| Adhesion Strength | ASTM D429 B | ≥ 8 kN/m |

| Compression Set (70h/100°C) | ASTM D395 B | ≤ 25% |

| Fluid Resistance (IRMOG) | ASTM D471 | Volume Swell < 15% |

This systematic approach guarantees that every Monel 400 bar assembly delivered meets the exacting functional and reliability demands of industrial OEM applications, minimizing field failure risks through material science precision.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Monel 400 Bar Solutions in Industrial Rubber Applications

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial material supply, delivering high-performance alloy components tailored for demanding environments. As a trusted partner in the field of industrial rubber solutions, we specialize in integrating advanced metallic elements—such as Monel 400 bar—into sealing, reinforcement, and structural systems where corrosion resistance, mechanical strength, and thermal stability are non-negotiable. Our engineering team ensures seamless compatibility between elastomeric compounds and high-integrity alloys, enabling optimized performance in oil & gas, chemical processing, marine engineering, and aerospace sectors.

Monel 400 bar, a solid-solution alloy composed primarily of nickel and copper, offers exceptional resistance to a wide range of corrosive media, including seawater, hydrofluoric acid, and alkaline environments. Its high tensile strength, excellent weldability, and low thermal expansion characteristics make it an ideal candidate for precision components used in dynamic rubber-metal assemblies. Whether employed as shafts, pins, or sealing elements, Monel 400 bars supplied by Suzhou Baoshida meet stringent international standards, including ASTM B164 and ASME SB164, ensuring consistency and reliability across production batches.

We provide Monel 400 bars in multiple diameters, lengths, and surface finishes, customizable to meet OEM specifications. Our supply chain guarantees material traceability, with full certification (MTR 3.1) available upon request. In addition to raw material supply, our technical division supports clients with metallurgical consultation, failure analysis, and integration guidance for hybrid rubber-alloy systems.

Below are the key technical specifications of the Monel 400 bar stock we supply:

| Property | Specification |

|---|---|

| Alloy Designation | ASTM B164 Monel 400, UNS N04400 |

| Composition (Nominal) | 67% Ni, 30% Cu, <2% Fe + Mn |

| Tensile Strength (Annealed) | ≥550 MPa |

| Yield Strength (0.2% Offset) | ≥240 MPa |

| Elongation at Break | ≥35% |

| Density | 8.84 g/cm³ |

| Melting Range | 1300–1350°C |

| Hardness (Brinell, 3000 kg) | ≤110 HB |

| Magnetic Permeability | ~1.02 (non-magnetic) |

| Corrosion Resistance | Excellent in reducing and mild oxidizing environments, seawater, alkalis |

For engineering inquiries, volume procurement, or technical collaboration involving Monel 400 bar integration in industrial rubber systems, we invite you to contact Mr. Boyce, our dedicated OEM Manager. With over 15 years of experience in advanced material sourcing and rubber-metal bonding technologies, Mr. Boyce provides strategic support from prototype development to mass production. He ensures competitive pricing, on-time delivery, and technical alignment with your manufacturing requirements.

Reach out via email at [email protected] to request material data sheets, initiate a quotation, or schedule a technical consultation. At Suzhou Baoshida Trading Co., Ltd., we are committed to advancing industrial performance through precision materials and expert-driven service. Partner with us to enhance the durability and efficiency of your next-generation rubber-based systems.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).