Technical Contents

Engineering Guide: National Seal Size Chart

Engineering Insight: The Critical Role of Material Selection in National Seal Size Charts

When referencing a national seal size chart, engineers often assume dimensional compliance ensures functional reliability. However, at Suzhou Baoshida Trading Co., Ltd., our experience in precision rubber seals reveals a critical oversight: material selection is equally, if not more, important than size. While national standards such as GB/T (China), ISO, or ANSI define dimensional tolerances and geometric profiles, they do not prescribe material properties. This gap leads to frequent field failures when off-the-shelf seals are deployed without considering operational stressors.

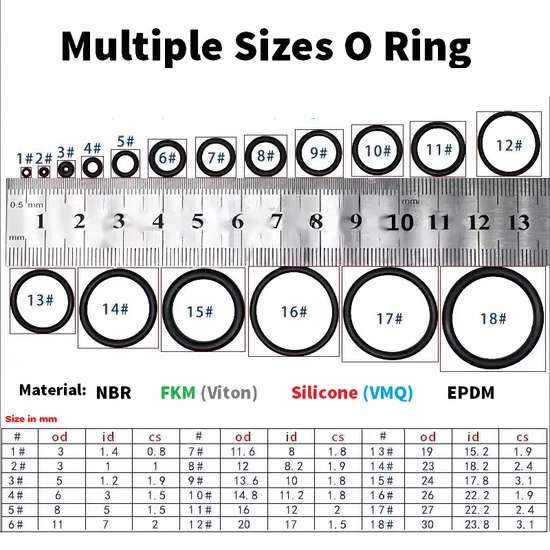

Standardized size charts provide essential guidance for interchangeability and assembly, but they cannot account for dynamic variables such as temperature extremes, chemical exposure, compression set resistance, or cyclic loading. An NBR O-ring that fits perfectly per GB/T 3452.1 may degrade rapidly in a high-temperature hydraulic system where FKM would be more appropriate. Similarly, an EPDM seal compliant with ISO 3601 may swell and lose integrity when exposed to non-polar hydrocarbons, despite correct sizing.

Off-the-shelf solutions often fail because they prioritize dimensional availability over material compatibility. Manufacturers stock common sizes in generic compounds—typically NBR or silicone—optimized for broad market appeal rather than specific application demands. This one-size-fits-all approach neglects the thermodynamic and chemical environment of the sealing interface. For instance, in automotive transmission systems, continuous exposure to automatic transmission fluid (ATF) at elevated temperatures demands superior resistance to swelling and softening. A standard NBR seal may initially install correctly but will degrade within months due to inadequate material resilience.

At Baoshida, we emphasize application-specific formulation. Our engineering team evaluates fluid compatibility, operating temperature range, pressure cycles, and surface finish to recommend or develop custom compounds. This approach ensures that while the seal conforms to national dimensional standards, the material exceeds functional requirements. For example, in oil and gas applications, we substitute standard FKM with high-temperature perfluoroelastomers (FFKM) when H2S and steam exposure exceed conventional limits.

The following table illustrates common elastomers used in precision seals, aligned with national size standards, and their performance under industrial conditions:

| Material | Temp Range (°C) | Fluid Resistance | Compression Set | Typical Application |

|---|---|---|---|---|

| NBR | -30 to +100 | Good (oils, water) | Moderate | Hydraulic systems, pneumatic seals |

| EPDM | -50 to +150 | Excellent (water, steam) | Good | HVAC, brake systems |

| FKM | -20 to +200 | Excellent (fuels, acids) | Excellent | Automotive, chemical processing |

| Silicone | -60 to +200 | Poor (hydrocarbons) | Poor | Medical, food-grade seals |

| ACM | -30 to +170 | Good (heat, oils) | Moderate | Transmission seals |

In conclusion, adherence to a national seal size chart is necessary but insufficient for long-term reliability. Material selection must be engineered in parallel with dimensional compliance. At Suzhou Baoshida Trading Co., Ltd., we integrate material science with precision manufacturing to deliver seals that perform beyond specification.

Material Specifications

Material Specifications for Precision Rubber Seals

Material selection critically determines seal performance under operational stress, dimensional stability, and service longevity. At Suzhou Baoshida Trading Co., Ltd., we prioritize ASTM D2000 and ISO 3601 compliance to ensure seals meet rigorous industrial demands. Viton, Nitrile, and Silicone represent three foundational elastomers, each engineered for distinct environmental challenges. Understanding their molecular properties prevents premature failure in dynamic sealing applications.

Viton (FKM) delivers exceptional resistance to high temperatures, aggressive chemicals, and oxidation. Its fluorocarbon structure withstands continuous exposure to automotive fuels, hydraulic fluids, and acids at temperatures ranging from -20°C to +230°C. This material maintains integrity in aerospace and semiconductor manufacturing where ozone and plasma exposure occur. However, its high fluorine content increases cost and reduces flexibility at sub-zero temperatures compared to hydrocarbon-based elastomers.

Nitrile (NBR) remains the industry standard for cost-effective oil and fuel resistance. With acrylonitrile content dictating performance, standard grades (-40°C to +120°C continuous service) handle petroleum derivatives, aliphatic hydrocarbons, and water-based fluids. Its tensile strength (15–25 MPa) and abrasion resistance suit hydraulic systems and automotive fuel handling. Limitations include poor ozone resistance and degradation above 125°C, necessitating protective additives for outdoor applications.

Silicone (VMQ) excels in extreme temperature variance (-60°C to +200°C) while maintaining elasticity. Its silicon-oxygen backbone provides biocompatibility and resistance to weathering, making it ideal for medical devices and food processing seals. However, low tear strength (4–12 kN/m) and susceptibility to hydraulic fluids limit use in high-pressure industrial systems. Reinforced grades improve mechanical properties but cannot match Nitrile’s oil resistance.

Selection requires balancing chemical exposure, thermal profiles, and mechanical stress. Below is a comparative analysis of critical parameters per ASTM D2000 standards.

| Material Type | Temperature Range (Continuous Service) | Key Chemical Resistances | Primary Limitations | Typical Industrial Applications |

|---|---|---|---|---|

| Viton (FKM) | -20°C to +230°C | Fuels, acids, oils, ozone | Poor ketone/aromatic resistance; high cost | Aerospace hydraulic systems, chemical processing valves |

| Nitrile (NBR) | -40°C to +120°C | Petroleum oils, water, aliphatic hydrocarbons | Degrades in ozone, esters, and strong acids | Automotive fuel lines, hydraulic pumps, industrial machinery |

| Silicone (VMQ) | -60°C to +200°C | Oxygen, weathering, steam, water | Low oil/fuel resistance; poor tensile strength | Medical device seals, food-grade gaskets, electrical insulation |

Suzhou Baoshida emphasizes material certification traceability for all compounds. Each formulation undergoes compression set testing (ASTM D395) at 150°C for 70 hours to validate dimensional recovery. For critical applications, we recommend accelerated aging per ISO 188 alongside fluid immersion testing in end-user media. Consult our engineering team to align material properties with your seal’s operational envelope and national size chart tolerances.

Manufacturing Capabilities

Engineering Excellence in Precision Rubber Seal Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our reputation as a trusted OEM partner in the precision rubber seal industry. With a dedicated team of five certified mould engineers and two advanced rubber formula engineers, we integrate material science with precision tooling to deliver custom sealing solutions that meet exacting international standards. Our engineers work in tandem across the product development lifecycle—from concept and compound formulation to mould design and performance validation—ensuring optimal functionality under real-world operating conditions.

Our mould engineering team specializes in designing high-precision tooling for NBR, EPDM, FKM, silicone, and other elastomers used in automotive, industrial hydraulics, and fluid handling systems. Each design is validated using 3D CAD simulations and tolerance analysis to minimize flash, ensure part consistency, and extend tool life. We maintain strict control over critical dimensions, surface finishes, and gating systems to support repeatable, high-yield production across complex geometries, including O-rings, gaskets, and custom profiles.

Complementing our tooling expertise, our two in-house rubber formula engineers bring deep knowledge of polymer chemistry and compounding. They formulate custom rubber compounds tailored to specific performance requirements such as temperature resistance (-40°C to +250°C), compression set, chemical exposure, and dynamic sealing loads. This vertical integration allows us to optimize both material and mould design in parallel, reducing development time and improving long-term reliability.

As an OEM manufacturer, we support full turnkey solutions—from prototype to mass production—with complete documentation including material certifications (e.g., FDA, ROHS, UL), dimensional reports, and PPAP files. Our facility is equipped with advanced compression, transfer, and injection moulding machines, enabling production scalability from small batches to high-volume runs with consistent quality.

The following table outlines key capabilities and specifications supported by our engineering team:

| Parameter | Specification |

|---|---|

| Mould Design Software | AutoCAD, SolidWorks, UG NX |

| Tolerance Control (O-ring) | ±0.05 mm (per ISO 3601) |

| Standard Compliance | ISO 3601, AS568, JIS B 2401, GB/T 3452.1 |

| Compound Development Range | Hardness: 30–90 Shore A; Temp: -40°C to +250°C |

| Lead Time (Prototype Mould) | 15–20 days |

| Production Capacity (O-rings) | Up to 5 million units/month |

| Testing Equipment | Tensile tester, aging oven, hardness durometer, compression set rig |

Through rigorous engineering discipline and vertical integration, Suzhou Baoshida delivers precision rubber seals that meet the functional and regulatory demands of global markets. Our OEM partnerships are built on technical transparency, continuous improvement, and long-term reliability.

Customization Process

Precision Rubber Seal Customization Process for National Standards Compliance

Suzhou Baoshida Trading Co., Ltd. implements a rigorous, four-phase customization protocol for national seal size chart applications, ensuring dimensional accuracy and material performance meet stringent industrial requirements. This structured approach minimizes iteration cycles and guarantees final products adhere to specified national standards, such as GB/T 3452.1 or ISO 3601.

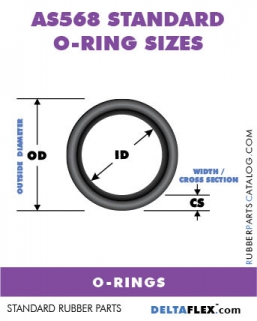

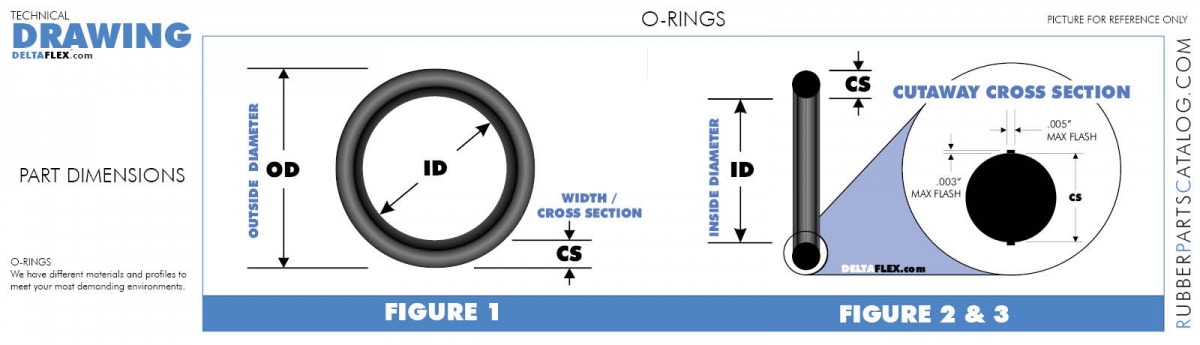

Drawing Analysis initiates the process with comprehensive geometric dimensioning and tolerancing (GD&T) validation against the target national size chart. Our engineering team meticulously cross-references client-provided drawings with standard dimension tables, identifying critical features like inner diameter (ID), outer diameter (OD), cross-section (CS), and tolerance classes. Material compatibility with the intended fluid medium, temperature range, and pressure conditions is concurrently assessed. Any discrepancies between the drawing and standard specifications are flagged immediately for client consultation, preventing downstream rework. This phase establishes the foundational technical parameters governing all subsequent stages.

Formulation leverages our proprietary compound development expertise. Based on the operating environment defined in Drawing Analysis, our rubber chemists select the optimal base polymer (e.g., NBR, FKM, EPDM) and engineer a custom compound. Key properties—compression set resistance per ASTM D395, tensile strength per ASTM D412, fluid resistance per ASTM D471, and low-temperature flexibility per ISO 1817—are precisely targeted. The formulation undergoes computational modeling to predict performance before physical mixing, optimizing filler systems, plasticizers, and cure packages to achieve the exact hardness (Shore A), resilience, and durability required by the application and standard.

Prototyping transforms the validated design and compound into physical samples. Utilizing precision tooling calibrated to the national size chart tolerances, we produce limited batches via injection or compression molding. Each prototype undergoes stringent metrological verification using calibrated CMMs and optical comparators against the dimensional specifications. Simultaneously, accelerated life testing in simulated service conditions validates the formulation’s performance claims. Dimensional and functional test reports are provided to the client for approval prior to tooling sign-off.

Mass Production commences only after formal client acceptance of prototypes. Production occurs in our ISO 9001-certified facility under strict Statistical Process Control (SPC). Real-time monitoring of critical parameters—mold temperature, cure time, and compound viscosity—ensures batch-to-batch consistency. Every production lot undergoes 100% visual inspection and抽样 inspection per AQL 1.0 for dimensional conformance. Comprehensive material traceability, from raw polymer lot to finished seal, is maintained. Final shipment includes certified material test reports (MTRs) and dimensional conformance certificates aligned with the national standard referenced in the original drawing.

Critical Dimensional Specifications per National Seal Size Chart (Example)

| Parameter | Symbol | Standard Tolerance (mm) | Critical Control Limit (mm) | Measurement Method |

|---|---|---|---|---|

| Inner Diameter | ID | ±0.15 | ±0.10 | Optical Comparator |

| Outer Diameter | OD | ±0.20 | ±0.15 | Calibrated Micrometer |

| Cross-Section | CS | ±0.10 | ±0.07 | Laser Micrometer |

| Eccentricity | – | ≤ 0.25 | ≤ 0.20 | CMM Scan |

| Flash Thickness | – | ≤ 0.10 | ≤ 0.07 | Optical Profilometer |

Contact Engineering Team

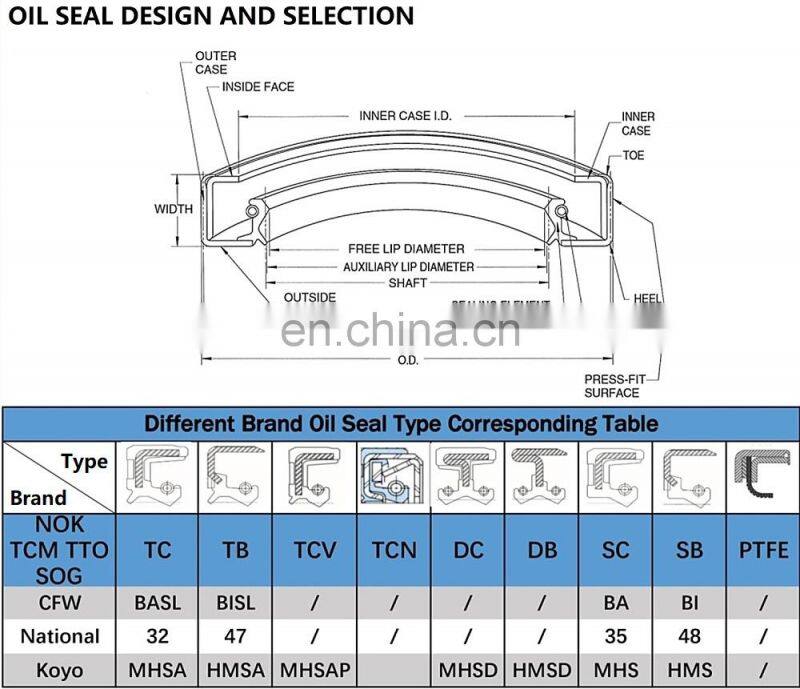

For precision rubber seals in industrial applications, dimensional accuracy and material compatibility are non-negotiable. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered sealing solutions that meet strict international standards, including the widely referenced National Seal Size Chart. Our expertise lies in translating standardized dimensions into high-performance elastomeric components tailored to dynamic and static sealing environments. Whether you are working with hydraulic systems, pneumatic actuators, or rotary shaft applications, our team ensures that every seal meets the exact specifications required for optimal performance and longevity.

Understanding the National Seal Size Chart is critical for maintaining interchangeability, reducing downtime, and ensuring system reliability. Our technical team has extensive experience in cross-referencing these standardized dimensions with OEM requirements, material performance data, and application-specific conditions such as temperature, pressure, and fluid media. We support clients in selecting the correct seal profile, inner diameter, cross-section, and durometer based on operational demands.

We manufacture and supply a full range of precision rubber seals compliant with national and international size standards. Our production processes are governed by ISO 9001-certified quality systems, ensuring consistency, traceability, and performance. From NBR and FKM to EPDM and silicone, we offer material formulations engineered for resistance to oils, fuels, water, steam, and aggressive chemicals.

To support seamless integration into your supply chain, we provide technical documentation, dimensional validation reports, and material certification upon request. Our engineering team is available for direct consultation to assist in seal selection, failure analysis, or custom design development.

Below is a representative sample of standard seal dimensions aligned with the National Seal Size Chart for common O-ring profiles:

| Dash Number | Inside Diameter (inch) | Cross Section (inch) | Inside Diameter (mm) | Cross Section (mm) | Standard Material |

|---|---|---|---|---|---|

| -012 | 0.250 | 0.040 | 6.35 | 1.02 | NBR 70 Shore A |

| -014 | 0.375 | 0.040 | 9.53 | 1.02 | FKM 75 Shore A |

| -022 | 0.500 | 0.070 | 12.70 | 1.78 | EPDM 60 Shore A |

| -030 | 1.000 | 0.104 | 25.40 | 2.64 | Silicone 50 Shore A |

| -137 | 3.500 | 0.139 | 88.90 | 3.53 | NBR 80 Shore A |

For technical inquiries, custom specifications, or volume procurement, contact Mr. Boyce, OEM Manager at Suzhou Baoshida Trading Co., Ltd. Direct correspondence ensures prompt access to engineering support, sample provisioning, and competitive pricing structures. Reach out via email at [email protected] to initiate a technical review of your sealing requirements. Our team responds within 24 business hours to all qualified industrial inquiries. Partner with us for precision, reliability, and expert-driven rubber sealing solutions.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).