Technical Contents

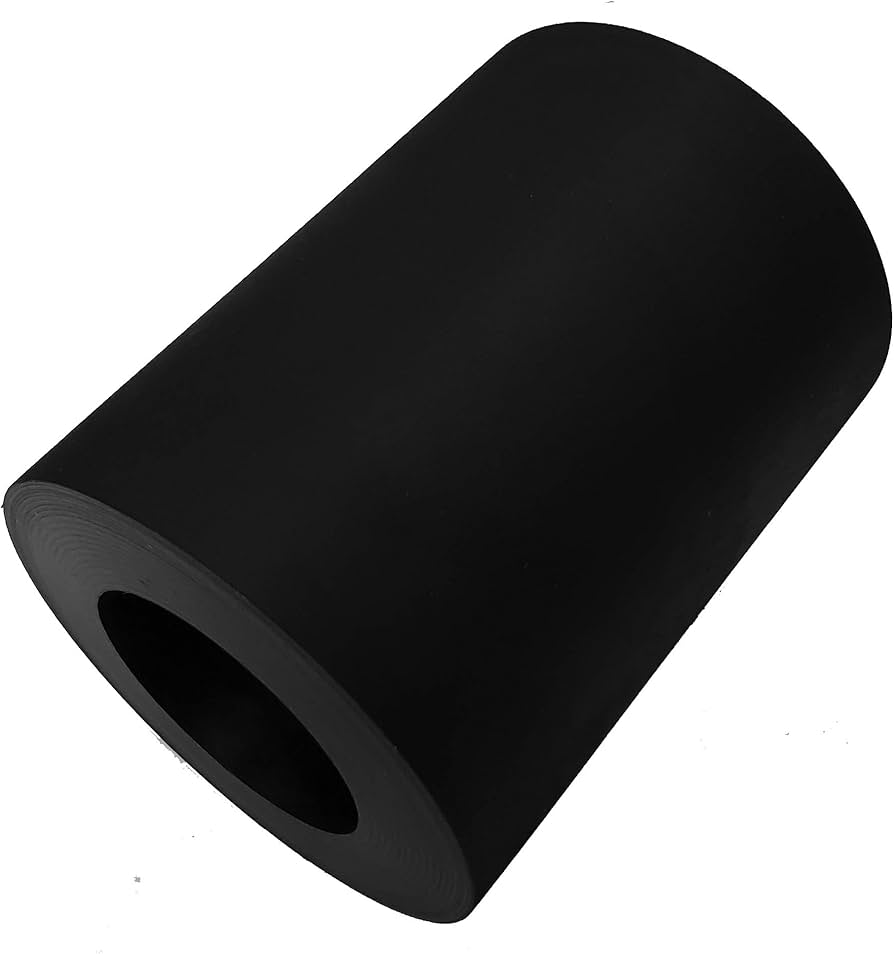

Engineering Guide: Neoprene Roller

Engineering Insight: Neoprene Roller Material Selection Imperatives

Generic neoprene rollers represent a significant risk in demanding industrial applications. Off-the-shelf solutions frequently fail because they utilize standardized compound formulations that ignore the intricate interplay between material properties and specific operational stresses. Neoprene (polychloroprene rubber, CR) possesses inherent advantages like good ozone resistance, flame retardancy, and moderate oil resistance. However, its performance envelope is highly dependent on precise compounding. Variations in polymer grade, plasticizer type and concentration, filler systems, and cure chemistry drastically alter critical characteristics such as compression set, low-temperature flexibility, heat aging resistance, and dynamic fatigue life. A roller specified for a printing press handling solvent-based inks requires fundamentally different resistance profiles than one operating in a high-heat textile calendering line or a cold-chain conveyor system. Standardized compounds cannot simultaneously optimize all these parameters.

The consequence of mismatched material selection is premature field failure. Common failure modes include excessive permanent deformation (compression set) leading to loss of tension control, surface cracking due to inadequate low-temperature flexibility or ozone exposure, hardening from plasticizer migration in solvent environments, or catastrophic fracture under dynamic cyclic loading. These failures result in unplanned downtime, product scrap, and costly emergency replacements – far exceeding the initial savings from a generic roller. Critical parameters must be rigorously defined against the application’s mechanical, thermal, chemical, and environmental profile. Relying on nominal durometer or generic “neoprene” labels is insufficient; the underlying compound formulation dictates real-world performance.

Suzhou Baoshida Trading Co., Ltd. engineers neoprene rollers by deconstructing the application’s core demands. We prioritize compound customization based on measured operational data, not assumptions. The following table illustrates key specification ranges where off-the-shelf solutions often fall short, necessitating tailored engineering:

| Critical Parameter | Typical Off-the-Shelf Range | Engineered Range (Baoshida) | Failure Risk if Mismatched |

|---|---|---|---|

| Hardness (Shore A) | 60-70 | 45-90 | Poor traction or excessive wear |

| Continuous Use Temp (°C) | -20 to +100 | -45 to +135 | Thermal degradation or stiffening |

| Ozone Resistance (pphm) | 50 | 100+ | Surface cracking in outdoor use |

| Compression Set (% @ 70°C) | 25-35 | <15 | Loss of dimensional stability |

| Tensile Strength (MPa) | 15-20 | 22-28 | Reduced fatigue life under load |

Material selection is not a commodity decision but a foundational engineering requirement. Suzhou Baoshida Trading Co., Ltd. partners with OEMs to translate application physics into precise rubber chemistry. We reject the one-size-fits-all approach, instead developing neoprene compounds where every additive serves a defined purpose against the operational reality. This precision engineering eliminates the hidden costs of premature roller failure, ensuring sustained line efficiency and product quality. Contact our technical team with your specific duty cycle parameters for a compound solution engineered to perform.

Material Specifications

Neoprene rollers are widely employed in industrial applications due to their balanced mechanical properties, resistance to environmental degradation, and cost-effectiveness. However, in high-performance environments, alternative elastomeric materials such as Viton, Nitrile, and Silicone are often considered to meet specific operational demands. At Suzhou Baoshida Trading Co., Ltd., we provide engineered rubber solutions tailored to the functional requirements of diverse manufacturing processes. Understanding the material characteristics of these elastomers is critical to selecting the optimal roller composition for applications involving temperature extremes, chemical exposure, abrasion, or dynamic mechanical stress.

Viton, a fluorocarbon-based rubber, exhibits exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With a continuous service temperature range up to 200°C and intermittent exposure capability beyond 250°C, Viton is ideal for sealing and rolling applications in automotive, aerospace, and chemical processing industries. Its low gas permeability and excellent aging resistance ensure long-term performance, though it is typically more expensive than other elastomers and exhibits lower flexibility at low temperatures.

Nitrile rubber (NBR) is one of the most commonly used materials in industrial roller applications due to its excellent resistance to petroleum-based oils and fuels. It offers good abrasion resistance and mechanical strength, making it suitable for printing, textile, and automotive manufacturing lines. Nitrile performs reliably in temperature ranges from -30°C to 120°C, with formulations available to extend low-temperature flexibility. While it lacks the chemical resistance of Viton, its cost-effectiveness and robust mechanical properties make it a preferred choice for general-purpose rollers exposed to lubricants and hydraulic fluids.

Silicone rubber is valued for its extreme temperature stability, functioning effectively from -60°C to 200°C, and in some grades, beyond. It offers excellent resistance to ozone and UV radiation, making it suitable for outdoor or high-heat environments. Silicone is also biocompatible and FDA-compliant in certain formulations, enabling use in food processing and medical device manufacturing. However, it has lower tensile strength and abrasion resistance compared to Nitrile or Viton, necessitating careful evaluation in high-wear applications.

The following table summarizes key physical and chemical properties of these materials for comparative reference in neoprene roller selection.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (+250 intermittent) | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Chemical Resistance | Outstanding | Moderate | Moderate |

| Abrasion Resistance | Good | Excellent | Fair |

| FDA Compliance (typical) | Limited grades | No | Yes (certain grades) |

Material selection for neoprene rollers must balance performance requirements, environmental exposure, and total cost of ownership. At Suzhou Baoshida Trading Co., Ltd., our technical team supports OEMs and industrial clients in matching material properties to application demands, ensuring durability, efficiency, and compliance across operational lifecycles.

Manufacturing Capabilities

Engineering Excellence in Neoprene Roller Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the bedrock of precision neoprene roller production for demanding industrial applications. We deploy a specialized team comprising five dedicated mould engineers and two advanced formula engineers, ensuring end-to-end scientific control from molecular design to final tooling. This dual-discipline integration addresses the critical interplay between polymer chemistry and mechanical geometry, which defines roller performance in high-stress environments such as printing presses, conveyor systems, and material handling equipment.

Neoprene (polychloroprene) rollers require exacting formulation to balance resilience, heat resistance, and chemical stability. Our formula engineers optimize molecular crosslink density and additive dispersion to achieve target properties, including controlled compression set below 15% after 22 hours at 70°C and Shore A hardness tolerance of ±3 points. Concurrently, mould engineers translate these material specifications into precision tooling, utilizing CAD/CAM simulations to eliminate flow lines, knit lines, and dimensional drift during vulcanization. This collaborative workflow reduces prototyping cycles by 40% compared to conventional supplier models, directly accelerating time-to-market for client projects.

Our OEM capabilities are engineered for seamless integration with global manufacturing standards. We support clients through a structured four-phase process:

1. Requirement Analysis: Joint review of operational parameters (load, speed, chemical exposure).

2. Material & Tooling Design: Custom neoprene compounds developed against ASTM D2000 or ISO 37 specifications.

3. Validation: Rigorous in-house testing per ISO 48 (hardness), ISO 188 (aging), and ISO 1885 (tear strength).

4. Serial Production: Traceable batch manufacturing with PPAP documentation and SPC-controlled curing profiles.

Critical neoprene roller specifications achievable through our engineering framework include:

| Property | Standard Range | Precision Tolerance | Test Standard |

|---|---|---|---|

| Hardness (Shore A) | 40–90 | ±3 points | ISO 48 |

| Tensile Strength | 10–25 MPa | ±1.5 MPa | ISO 37 |

| Elongation at Break | 200–600% | ±25% | ISO 37 |

| Compression Set (70°C) | ≤15% | ±2% | ISO 815 |

| Operating Temperature | -40°C to +120°C | ±5°C stability | ISO 188 |

This technical rigor enables us to solve complex failure modes—such as surface glazing under UV exposure or hardening in ozone-rich environments—through targeted co-agent modifications and peroxide curing systems. Every roller undergoes 100% dimensional verification via CMM and dynamic balancing to G6.3 quality standards, ensuring vibration-free operation at rotational speeds exceeding 3,000 RPM.

Suzhou Baoshida’s engineering synergy delivers not just components, but validated performance solutions. By anchoring OEM partnerships in material science and precision tooling, we mitigate field failures while extending service life in the most aggressive industrial settings. Collaborate with us to transform your neoprene roller requirements into engineered reality.

Customization Process

Customization Process for Neoprene Rollers at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., the customization of neoprene rollers follows a rigorous, science-driven methodology designed to meet exact industrial performance criteria. Our process ensures dimensional accuracy, material resilience, and long-term operational stability under demanding conditions. The workflow progresses through four critical stages: Drawing Analysis, Formulation Development, Prototyping, and Mass Production.

The process begins with Drawing Analysis, where engineering teams evaluate client-provided technical drawings or CAD models. Key parameters such as outer diameter, core bore size, face width, tolerance class (typically ISO 2768-m), and surface finish requirements are verified. Special attention is given to load-bearing zones, rotational speed compatibility, and environmental exposure zones (e.g., UV, ozone, or chemical contact). This analysis forms the foundation for both mechanical design validation and material selection.

Following drawing validation, the Formulation Development phase commences. Our rubber chemists tailor the neoprene (polychloroprene) compound to meet specific hardness (Shore A), tensile strength, elongation at break, and thermal resistance requirements. Additives such as reinforcing fillers, antidegradants, and processing oils are precisely balanced to enhance abrasion resistance, compression set performance, and low-temperature flexibility. All formulations comply with industrial standards, including ASTM D2000 and ISO 1817, ensuring compatibility with oils, solvents, and weathering conditions typical in printing, textile, and material handling applications.

Once the compound is finalized, we proceed to Prototyping. Using precision rubber molding techniques—compression, transfer, or injection molding—initial samples are produced under controlled conditions. Each prototype undergoes dimensional inspection via coordinate measuring machines (CMM) and performance testing, including durometer measurement, hardness profile mapping, and dynamic balancing. Clients receive test reports and physical samples for field evaluation, enabling iterative refinements if necessary.

Upon approval, the project transitions into Mass Production. Our manufacturing lines operate under strict ISO 9001 protocols, with real-time process monitoring and batch traceability. Final rollers are subjected to 100% visual inspection, hardness testing, and rotational uniformity checks. Packaging is customized to prevent deformation during transit, especially for large-diameter or soft-hardness rollers.

The following table outlines typical specification ranges available for customized neoprene rollers:

| Parameter | Standard Range | Custom Capability |

|---|---|---|

| Hardness (Shore A) | 50–90 | 40–95 (±5) |

| Outer Diameter | 50–500 mm | Up to 800 mm |

| Core Bore | 10–100 mm | Keyed, splined, or custom hubs |

| Tolerance | ±0.1 mm (standard) | ±0.05 mm (precision grade) |

| Temperature Resistance | -40°C to +120°C (continuous) | Up to +150°C (intermittent) |

| Surface Finish | Smooth, textured, or grooved | CNC-machined profiles available |

| Color | Black, grey, green, or custom | Pantone-matched options |

This systematic approach ensures that every neoprene roller delivered by Suzhou Baoshida meets the highest benchmarks in performance, durability, and technical fidelity.

Contact Engineering Team

Strategic Partnership for Precision Neoprene Roller Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber compounding, specializing in engineered neoprene rollers that meet the exacting demands of modern manufacturing. Our technical team leverages decades of compound formulation expertise to address critical performance variables including abrasion resistance, oil swell mitigation, and thermal stability across diverse operational environments. Unlike generic suppliers, we prioritize material science-driven customization, ensuring each roller specification aligns precisely with your machinery’s load dynamics, surface finish requirements, and lifecycle expectations. This approach minimizes downtime, reduces total cost of ownership, and enhances process consistency in applications ranging from printing presses to textile calendering and metal finishing lines.

The core advantage of our neoprene compounds lies in proprietary additive integration and vulcanization control. Below is a technical benchmark of our standard CR (Chloroprene) roller formulation, validated through ASTM D2000 and ISO 37 testing protocols. These values represent baseline performance; all parameters are adjustable per OEM specifications.

| Property | Test Method | Standard Value | Baoshida Performance Enhancement |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60–85 | ±2 tolerance control |

| Tensile Strength (MPa) | ASTM D412 | ≥17.0 | 20.5–24.0 (reinforced grade) |

| Elongation at Break (%) | ASTM D412 | ≥300 | 350–420 (optimized flexibility) |

| Compression Set (24h/70°C) | ASTM D395 | ≤30% | ≤18% (low-recovery compounds) |

| Temperature Range (°C) | ISO 188 | -40 to +100 | Extended to +120 (specialized) |

| Oil Resistance (IRMOG) | ASTM D471 | Volume swell ≤30% | ≤12% (nitrile-modified CR) |

These metrics reflect our commitment to empirical validation over theoretical claims. Each batch undergoes rigorous in-house QC using Mooney viscometers, rheometers, and accelerated aging chambers to guarantee repeatability. For mission-critical applications, we implement lot-specific traceability and provide full material test reports (MTRs) compliant with IATF 16949 standards. Our Suzhou-based production facility integrates German-engineered mixing and curing systems, enabling tight control over molecular cross-link density—a decisive factor in roller longevity under high-speed or high-load conditions.

Initiate a technical collaboration by contacting Mr. Boyce, our dedicated OEM Relationship Manager. Submit your operational parameters—including line speed, substrate composition, chemical exposure profiles, and dimensional tolerances—to receive a compound recommendation backed by finite element analysis (FEA) simulations. Mr. Boyce will coordinate a confidential review of your application requirements, followed by a prototype proposal with accelerated life-cycle testing data. Do not settle for off-the-shelf rollers that compromise throughput; leverage our formulation agility to solve specific friction, static dissipation, or surface adhesion challenges.

Direct all technical inquiries and RFQs to [email protected]. Specify your industry sector and critical performance thresholds in the subject line to expedite engineering resource allocation. Suzhou Baoshida operates as a true strategic partner, not merely a vendor—our success is measured by the sustained operational efficiency of your equipment. Engage our team to transform neoprene roller performance from a maintenance concern into a competitive advantage. Response time for technical queries is guaranteed within 4 business hours.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).