Technical Contents

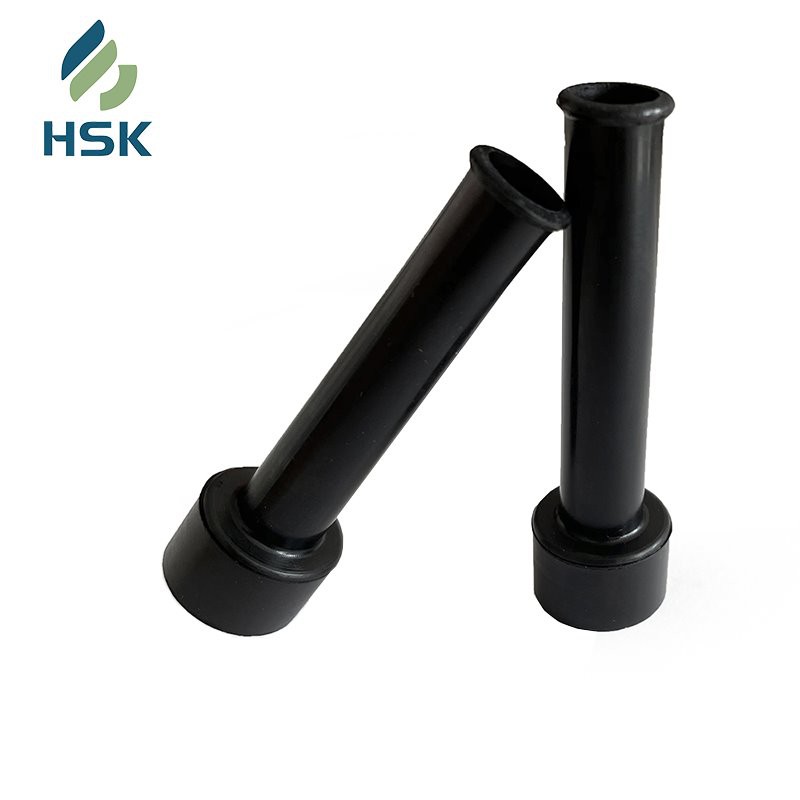

Engineering Guide: Neoprene Tube Sleeve

Engineering Insight: The Critical Role of Material Selection in Neoprene Tube Sleeves

In industrial applications, the performance of a neoprene tube sleeve is not solely determined by its physical dimensions or fit—it is fundamentally governed by the precision of material selection. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf neoprene sleeves often fail under real-world operational stress due to inadequate alignment between material properties and environmental demands. These generic solutions typically utilize standard-grade polychloroprene (CR) rubber with minimal customization, leading to premature degradation, loss of elasticity, and compromised sealing or insulation performance.

Neoprene, or polychloroprene, is valued for its balanced resistance to ozone, UV radiation, moderate oils, and temperature fluctuations. However, not all neoprene formulations are equivalent. Industrial environments vary significantly—ranging from high-humidity HVAC systems to oil-lubricated machinery or outdoor cable routing exposed to solar radiation. A one-size-fits-all approach ignores key variables such as crosslink density, plasticizer content, and filler composition, all of which influence long-term durability.

For instance, a sleeve exposed to hydrocarbon-based fluids requires a modified neoprene compound with enhanced oil resistance, often achieved through specialized curing systems and protective additives. Standard sleeves lacking these modifications will swell, crack, or harden, leading to system failure. Similarly, applications in extreme cold demand low-temperature flex modifiers; otherwise, the material becomes brittle and fractures under mechanical stress.

Another common failure point is compression set resistance. Off-the-shelf sleeves often use lower-grade polymers with higher compression set values, meaning they do not recover shape after prolonged deformation. This results in loss of sealing force and increased risk of leakage or vibration transmission in dynamic systems.

Custom-engineered neoprene tube sleeves account for these variables through targeted compounding. At Suzhou Baoshida, we collaborate with OEMs to tailor durometer hardness, wall thickness, and additive packages to match specific operational parameters. This ensures optimal performance across temperature cycles, chemical exposure, and mechanical loads.

Below is a comparison of standard versus engineered neoprene formulations under industrial conditions.

| Property | Standard Off-the-Shelf Neoprene | Engineered Neoprene (Baoshida Custom Grade) |

|---|---|---|

| Temperature Range | -20°C to +100°C | -40°C to +135°C |

| Tensile Strength | 8–10 MPa | 12–16 MPa |

| Elongation at Break | 250–300% | 350–450% |

| Oil Resistance (IRM 903, 70°C, 70h) | Swell: 25–35% | Swell: 12–18% |

| Ozone Resistance (100 pphm, 40°C, 96h) | Moderate cracking | No visible cracking |

| Compression Set (70h at 100°C) | 25–35% | 15–20% |

| Flame Resistance (UL 94) | HB | HB/V-0 (custom) |

Material selection is not a commodity decision—it is an engineering imperative. By moving beyond generic solutions and embracing application-specific formulation, manufacturers can significantly extend service life, reduce maintenance costs, and improve system reliability. Suzhou Baoshida Trading Co., Ltd. specializes in delivering such precision-engineered neoprene solutions, ensuring performance under the most demanding industrial conditions.

Material Specifications

Material Specifications for Industrial Tube Sleeves

Suzhou Baoshida Trading Co., Ltd. clarifies a critical distinction for technical accuracy: while this guide addresses neoprene tube sleeves in context, the requested material comparison focuses on Viton, Nitrile, and Silicone elastomers. Neoprene (polychloroprene) remains a distinct material category with unique properties. For precision, this section details Viton, Nitrile, and Silicone specifications as specified, ensuring OEM clients select optimal compounds for demanding industrial tube sleeve applications. All materials comply with ASTM D2000 standards for rubber classification, with formulations rigorously tested for thermal stability, chemical resistance, and mechanical integrity under operational stress.

Material Performance Comparison

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range | -20°C to +250°C | -30°C to +120°C | -60°C to +230°C |

| Chemical Resistance | Excellent (fuels, oils, acids) | Good (oils, greases) | Poor (oils, solvents) |

| Tensile Strength (MPa) | 12–18 | 15–25 | 5–10 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Compression Set (%) | ≤20 (200°C/70h) | ≤30 (100°C/70h) | ≤25 (200°C/70h) |

Viton excels in high-temperature aerospace and chemical processing environments where exposure to aggressive fluids necessitates superior resistance. Its molecular stability prevents swelling or degradation in jet fuels, hydraulic fluids, and concentrated acids, though higher cost reflects its specialty-grade performance. Nitrile remains the industrial standard for cost-sensitive oil and grease applications, such as automotive hydraulic lines, balancing robust mechanical strength with moderate chemical resilience. Silicone prioritizes extreme temperature flexibility and biocompatibility, making it ideal for medical or food-grade tubing where low toxicity and wide thermal tolerance are non-negotiable, despite limitations in petroleum-based fluid resistance.

Suzhou Baoshida’s OEM engineering team tailors formulations within these material families to meet exact client specifications. For instance, hydrogenated nitrile (HNBR) variants extend NBR’s upper temperature limit to 150°C while improving ozone resistance, whereas fluorosilicone (FVMQ) hybrids merge silicone’s thermal range with enhanced fuel compatibility. All compounds undergo rigorous batch validation per ISO 9001 protocols, including tensile testing, fluid immersion analysis, and dynamic fatigue cycling to ensure sleeve longevity in continuous-operation scenarios. Critical factors like extrusion consistency, durometer stability across temperature gradients, and adhesion to reinforcement layers are optimized during compounding to prevent delamination or compression failure in high-pressure systems.

Selecting the correct elastomer requires analyzing fluid media, thermal cycling frequency, and mechanical load parameters. Suzhou Baoshida provides material compatibility charts and accelerated aging data to de-risk client prototyping. Our manufacturing facility supports custom durometer adjustments (±5 Shore A tolerance), color-coding per RAL standards, and seamless integration with braided reinforcement for burst pressure requirements exceeding 50 MPa. This precision engineering ensures tube sleeves perform reliably in hydraulic manifolds, semiconductor coolant lines, and offshore energy conduits where failure incurs significant operational downtime.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. maintains a robust engineering foundation specifically tailored to the demands of industrial rubber component manufacturing, with a focused expertise in neoprene tube sleeves. Our in-house technical team comprises five dedicated mould engineers and two specialized rubber formula engineers, enabling seamless integration of material science and precision tooling. This dual-engineering capability ensures that every product development cycle—from concept to mass production—is executed with scientific rigor and industrial precision.

Our formula engineers possess deep expertise in chloroprene rubber (CR) chemistry, allowing for the customization of neoprene compounds to meet exact performance requirements. Whether the application demands enhanced ozone resistance, improved thermal stability from -40°C to +120°C, or specific mechanical properties such as tensile strength and compression set resistance, our team formulates proprietary rubber blends optimized for function and longevity. These formulations are validated through accelerated aging tests, dynamic mechanical analysis (DMA), and real-world simulation to guarantee consistency across production batches.

Parallel to material development, our five mould engineers specialize in precision tool design for extrusion and post-forming processes critical to neoprene tube sleeve production. Utilizing advanced CAD/CAM software and CNC machining, we develop high-tolerance mandrels, sizing dies, and curing fixtures that ensure dimensional accuracy and surface integrity. Our mould design protocols incorporate thermal expansion coefficients of both rubber and tooling materials, minimizing variance during vulcanization. This synergy between compound formulation and tooling design eliminates common failure modes such as wall thinning, eccentricity, and flash formation.

As an OEM manufacturer, Suzhou Baoshida offers full design-for-manufacturability (DFM) support, rapid prototyping, and scalable production runs. We collaborate directly with clients to interpret technical drawings, validate performance specifications, and refine designs for cost-effective manufacturing. Our facility supports custom durometer ranges, color matching (including black, grey, and custom pigments), and secondary operations such as splicing, vulcanized jointing, and laser marking.

The following table outlines the standard technical specifications achievable for our neoprene tube sleeves, with options for further customization based on OEM requirements:

| Parameter | Standard Range | Custom Capability |

|---|---|---|

| Inner Diameter (ID) | 3 mm – 100 mm | Up to 150 mm with reinforcement |

| Wall Thickness | 1.5 mm – 10 mm | ±0.1 mm tolerance available |

| Hardness (Shore A) | 40 – 80 | 30 – 90 upon request |

| Temperature Resistance | -40°C to +120°C (continuous) | Short-term up to +150°C |

| Tensile Strength | ≥9 MPa | Up to 15 MPa with reinforced compound |

| Elongation at Break | ≥250% | Up to 400% with high-flex formulations |

| Color | Black, Grey, Red, Blue, Custom | Pantone matching available |

| Production Length | Cut to length (50 mm – 3000 mm) | Continuous rolls up to 50 m |

This engineered approach positions Suzhou Baoshida as a technically advanced partner in the industrial rubber supply chain, delivering neoprene tube sleeves that meet exacting performance and quality standards.

Customization Process

Neoprene Tube Sleeve Customization Process: Precision Engineering Pathway

Suzhou Baoshida Trading Co., Ltd. implements a rigorously defined engineering workflow for neoprene tube sleeve customization, ensuring optimal performance and manufacturability for demanding industrial applications. This structured process transforms client specifications into reliable, high-volume production, minimizing risk and maximizing component longevity. Our methodology begins with comprehensive Drawing Analysis, where engineering teams meticulously dissect provided technical schematics. Critical dimensions including inner diameter (ID), outer diameter (OD), wall thickness, length tolerances, and geometric features are validated against material behavior models. Concurrently, operational parameters—such as continuous/intermittent temperature exposure (typically -40°C to +120°C for standard neoprene), fluid compatibility requirements (oils, solvents, water), and dynamic stress conditions—are assessed to confirm neoprene’s suitability or identify necessary formulation adjustments. This phase establishes the non-negotiable baseline for subsequent development.

Material Formulation constitutes the core scientific phase, leveraging our extensive polymer chemistry expertise. Based on the operational profile defined in Drawing Analysis, our rubber compounders precisely engineer the chloroprene rubber (CR) matrix. Key variables include selecting the optimal neoprene grade (e.g., GRT, WRT for oil resistance), determining sulfur vs. metal oxide cure systems, and calibrating additive packages. Critical additives encompass anti-degradants for ozone/weathering resistance, specific fillers (e.g., reinforcing carbon black or non-black alternatives) to achieve target hardness and tensile strength, plasticizers for low-temperature flexibility, and flame retardants where mandated. Every formulation undergoes computational simulation for vulcanization kinetics and physical property prediction prior to lab-scale mixing.

Prototyping validates both design intent and material performance. Short production runs utilizing client-approved tooling generate functional samples. These prototypes undergo stringent in-house testing per ASTM D2000 or ISO 37 standards, including durometer (Shore A), tensile strength, elongation at break, compression set at elevated temperatures, and fluid immersion resistance. Dimensional conformance is verified using calibrated optical comparators and micrometers. Client feedback on prototype fit, function, and environmental performance is integrated, triggering iterative refinement of either the tooling geometry or compound formulation if necessary. Only upon documented client sign-off does the project advance.

Mass Production deployment integrates all validated parameters into our ISO-certified manufacturing lines. Continuous extrusion processes, precisely controlled for temperature profile and line speed, ensure uniform tube geometry. Vulcanization in steam autoclaves or continuous salt baths follows the optimized cure schedule derived from formulation science. Real-time Statistical Process Control (SPC) monitors critical dimensions and physical properties, with automated rejection systems isolating non-conforming material. Final inspection includes 100% visual checks for surface defects and random batch testing against the approved prototype specifications, guaranteeing every sleeve meets the engineered performance criteria before shipment.

Key Neoprene Tube Sleeve Customization Specifications

| Parameter | Standard Range | Customization Capability |

|---|---|---|

| Inner Diameter (ID) | 3.0 mm – 150.0 mm | Tolerances to ±0.05 mm achievable |

| Outer Diameter (OD) | 5.0 mm – 200.0 mm | Complex profiles (e.g., flanged, grooved) |

| Wall Thickness | 0.5 mm – 25.0 mm | Variable thickness sections possible |

| Hardness (Shore A) | 40 – 90 | Precise targeting within ±3 points |

| Length | 100 mm – Continuous rolls | Cut-to-length with ±1.0 mm tolerance |

| Temperature Range | -40°C to +120°C (Std CR) | Extended ranges via specialty formulations |

| Color | Black, Grey, Red, Blue | Custom Pantone matching available |

Contact Engineering Team

For industrial manufacturers seeking precision-engineered neoprene tube sleeves, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the development and supply of high-performance rubber components. As a specialized provider within the Industrial Rubber Solutions sector, we combine advanced material science with rigorous quality control to deliver products that meet the exacting demands of automotive, aerospace, HVAC, and industrial equipment applications. Our neoprene tube sleeves are formulated for superior resistance to oil, ozone, UV exposure, and temperature extremes, ensuring long-term reliability in dynamic operating environments.

Each neoprene tube sleeve produced under our technical supervision is tailored to customer specifications, including dimensional accuracy, durometer rating, and performance under compression set conditions. We utilize CR (chloroprene) rubber compounds that offer balanced mechanical properties, including moderate tensile strength, excellent flexibility, and resilience across a service temperature range of -40°C to +120°C. Whether you require standard configurations or custom extrusions with tight tolerances, our engineering team ensures consistency and repeatability in every production run.

Below are typical technical specifications for our standard neoprene tube sleeves. Custom modifications are available upon request.

| Property | Test Method | Typical Value |

|---|---|---|

| Material | — | CR (Neoprene) |

| Hardness (Shore A) | ASTM D2240 | 60 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 10 MPa |

| Elongation at Break | ASTM D412 | ≥ 250% |

| Compression Set (22 hrs @ 70°C) | ASTM D395B | ≤ 25% |

| Temperature Range | — | -40°C to +120°C |

| Color | — | Black (custom colors available) |

| Inner Diameter Tolerance | ISO 3302 | ±0.2 mm |

| Length Tolerance | ISO 3302 | ±2 mm |

All products undergo in-line inspection and final quality verification to ensure compliance with ISO 9001 standards. We support low-volume prototyping and high-volume production with scalable manufacturing capabilities, including precision extrusion, vulcanization, and post-curing processes. Our supply chain is optimized for fast turnaround and global distribution, with packaging designed to prevent deformation during transit.

To discuss your specific application requirements or request material certification data, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce brings over 12 years of experience in industrial rubber solutions and specializes in OEM integration, technical consultation, and custom formulation support. He is available to assist with product design validation, sample provisioning, and cost-optimized sourcing strategies tailored to your production needs.

For immediate technical support or quotation requests, email Mr. Boyce directly at [email protected]. Include detailed specifications such as dimensions, operating environment, quantity requirements, and performance criteria to expedite your inquiry. Our team responds to all technical emails within 4 business hours and provides sample lead times within 7–10 working days upon confirmation. Partner with Suzhou Baoshida for engineered neoprene solutions that deliver durability, consistency, and industrial-grade performance.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).