Technical Contents

Engineering Guide: Non-Asbestos Compressed Fiber Gasket

Engineering Insight: The Critical Role of Material Selection in Non-Asbestos Compressed Fiber Gaskets

In industrial sealing applications, the shift from asbestos-based to non-asbestos compressed fiber gaskets has been driven by health regulations and environmental responsibility. While this transition is necessary, it introduces new engineering challenges, particularly in material selection. A common misconception is that non-asbestos gaskets are direct drop-in replacements for their predecessors. This assumption frequently leads to premature seal failure, unplanned downtime, and increased maintenance costs. The reality is that non-asbestos compressed fiber gaskets require precise material engineering tailored to specific operational conditions.

Material selection is not a one-size-fits-all proposition. Off-the-shelf gasket solutions often fail because they are formulated for generalized service environments, not the unique combination of temperature, pressure, chemical exposure, and flange dynamics present in real-world applications. For example, a gasket rated for high temperature may degrade rapidly when exposed to certain organic solvents, even if the thermal load is within specification. Similarly, compressibility and recovery characteristics must align with flange type and bolt loading to maintain sealing integrity under cyclic conditions.

Non-asbestos gaskets typically consist of reinforcing fibers—such as aramid, cellulose, or synthetic blends—bound by elastomeric or resin-based matrices. The performance of these composites depends on the synergy between fiber architecture and binder chemistry. Inadequate formulation can result in fiber shedding, chemical attack on the binder, or irreversible compression set. These failure modes are rarely apparent during initial installation but manifest under sustained operational stress.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific engineering over commoditized supply. Our non-asbestos gasket materials are developed through rigorous testing protocols that simulate actual service environments. This ensures compatibility with media such as steam, acids, oils, and hydraulic fluids across a broad temperature spectrum.

The following table outlines key performance specifications of our engineered non-asbestos compressed fiber gasket materials:

| Property | Test Method | Value Range |

|---|---|---|

| Maximum Continuous Temperature | ASTM D149 | 300–550°F (150–288°C) |

| Compressibility (%) | ASTM F36 | 8–18% |

| Recovery (%) | ASTM F36 | 40–60% |

| Tensile Strength | ASTM D412 | 800–1,600 psi |

| Fluid Resistance | ASTM D471 | Excellent to oils, water, mild acids |

| Density | ASTM D2240 | 1.6–1.8 g/cm³ |

These values are not static; they are optimized based on customer application data. Standard gaskets may meet nominal industry benchmarks, but they lack the tailored formulation required for mission-critical sealing. By prioritizing material science and application intelligence, Suzhou Baoshida ensures gasket reliability, longevity, and operational safety in demanding industrial environments.

Material Specifications

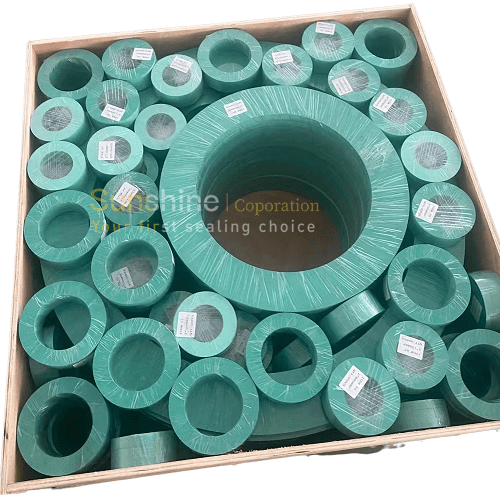

Material Specifications for Non-Asbestos Compressed Fiber Gaskets

Suzhou Baoshida Trading Co., Ltd. delivers engineered non-asbestos compressed fiber gasket materials meeting stringent industrial sealing demands. These formulations eliminate health hazards associated with asbestos while maintaining superior mechanical integrity, thermal stability, and chemical resistance across critical applications. Material selection is paramount for operational reliability, directly influencing service life, leak prevention, and system safety. Our precision-engineered compounds—Viton, Nitrile, and Silicone—are rigorously tested to ASTM F104 standards, ensuring consistency in density, compressibility, and recovery. Each material addresses distinct operational environments, requiring careful evaluation of temperature extremes, fluid compatibility, and pressure dynamics.

Viton fluorocarbon rubber excels in aggressive chemical environments, particularly where exposure to aromatic hydrocarbons, chlorinated solvents, or strong acids is prevalent. Its molecular structure provides exceptional resistance to degradation at continuous service temperatures up to 230°C, with intermittent peaks reaching 260°C. Viton maintains sealing force under high pressure without significant extrusion, making it ideal for aerospace fuel systems, chemical processing reactors, and semiconductor manufacturing tooling. However, its cost profile necessitates justification through critical fluid compatibility requirements.

Nitrile butadiene rubber (NBR) offers optimal balance for petroleum-based applications, including hydraulic oils, greases, and aliphatic hydrocarbons. With a standard continuous service range of -30°C to 120°C (extendable to 150°C with peroxide curing), Nitrile provides robust abrasion resistance and cost efficiency. Its formulation versatility allows customization for enhanced ozone resistance or low-temperature flexibility. Primary use cases span automotive engine gaskets, hydraulic equipment seals, and general industrial machinery where fuel and oil exposure dominate. Limitations include vulnerability to ketones, esters, and phosphate ester hydraulic fluids.

Silicone rubber delivers unparalleled temperature resilience from -60°C to 200°C continuous operation, with brief excursions to 230°C. Its inert composition ensures biocompatibility and resistance to water, steam, and oxidizing chemicals, though mechanical strength is lower than Viton or Nitrile. Silicone is the material of choice for food and beverage processing, pharmaceutical equipment, and electrical insulation where thermal cycling and purity are critical. Avoid use in applications involving concentrated acids, alkalis, or non-polar solvents like toluene.

The following table summarizes key comparative specifications for precision engineering reference

| Material Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Continuous Temp Range | -20°C to +230°C | -30°C to +120°C | -60°C to +200°C |

| Max Intermittent Temp | 260°C | 150°C | 230°C |

| Pressure Rating (Static) | Up to 25 MPa | Up to 20 MPa | Up to 15 MPa |

| Key Chemical Resistances | Aromatics, Acids, Chlorinated Solvents | Aliphatic Hydrocarbons, Water, Hydraulic Oils | Water, Steam, Alcohols, Ozone |

| Primary Industrial Applications | Chemical Processing, Aerospace, Semiconductor | Automotive, Hydraulics, General Machinery | Food/Beverage, Pharma, Electrical |

Material selection must align with fluid compatibility charts and operational stress profiles. Suzhou Baoshida Trading Co., Ltd. provides comprehensive technical datasheets and OEM consultation to validate gasket performance against specific application parameters. Always conduct application-specific testing under actual service conditions prior to full deployment.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability in the field of non-asbestos compressed fiber gasket manufacturing is anchored in deep technical expertise and a disciplined approach to material science and tooling design. Our team comprises five dedicated mould engineers and two specialized rubber formula engineers, all operating within a tightly integrated development environment. This structure ensures that every gasket solution we produce is optimized for performance, durability, and application-specific demands.

Our formula engineers focus on the precise development of composite fiber-reinforced materials that meet stringent industry standards for thermal resistance, chemical compatibility, and mechanical strength. Leveraging advanced testing methodologies and raw material screening, they formulate non-asbestos compounds that deliver consistent sealing performance under extreme operating conditions. These formulations are engineered to replace traditional asbestos-based materials without compromising on resilience or longevity, aligning with global environmental and safety regulations.

Complementing this material expertise, our five mould engineers bring precision to the manufacturing process. They are responsible for the design, validation, and continuous improvement of compression moulding tooling. Utilizing CAD/CAM systems and finite element analysis (FEA), they ensure dimensional accuracy, uniform material flow, and minimal flash formation during production. This synergy between material formulation and mould design enables us to produce gaskets with tight tolerances and repeatable quality across batch cycles.

As an OEM manufacturing partner, we offer full technical collaboration from concept to量产 (mass production). Our engineers work directly with client specifications to customize gasket dimensions, hardness, density, and performance parameters. Whether supporting prototyping for new equipment platforms or scaling production for established supply chains, our engineering team ensures seamless integration with customer requirements.

We maintain strict process controls and conduct comprehensive validation testing, including compression recovery, creep relaxation, and fluid resistance assessments. This data-driven approach allows us to certify performance against international standards such as ASTM F104, EN 13555, and ISO 2768.

The following table outlines key technical specifications achievable with our non-asbestos compressed fiber gasket materials:

| Property | Test Method | Typical Value |

|---|---|---|

| Density | ASTM D2240 | 1.6 – 2.0 g/cm³ |

| Hardness (Shore A) | ASTM D2240 | 70 – 90 |

| Maximum Continuous Temperature | ASTM D1418 | 300°C |

| Tensile Strength | ASTM D412 | ≥ 8 MPa |

| Compression Set (22 hrs, 200°C) | ASTM D395 | ≤ 25% |

| Fluid Resistance | ASTM D471 | Excellent in oils, water, mild acids |

Our engineering team’s combined experience spans over two decades in industrial sealing applications, serving sectors including automotive, petrochemical, marine, and power generation. This depth of knowledge positions Suzhou Baoshida as a technically robust OEM partner for mission-critical gasket solutions.

Customization Process

Customization Process for Non-Asbestos Compressed Fiber Gaskets

Suzhou Baoshida Trading Co., Ltd. executes a stringent four-phase customization protocol for non-asbestos compressed fiber gaskets, ensuring dimensional accuracy, material integrity, and operational reliability for critical industrial sealing applications. This methodology eliminates asbestos-related health hazards while meeting rigorous OEM performance demands.

Drawing Analysis

Initial engagement requires comprehensive review of the client’s technical drawings and operational parameters. Our engineering team scrutinizes dimensional tolerances per ISO 3601, surface finish requirements (Ra ≤ 3.2 µm), flange geometry, and assembly constraints. Critical factors include groove compatibility, bolt load distribution, and potential misalignment scenarios. Any ambiguities in ASME Y14.5 annotations or material callouts trigger immediate client consultation to prevent downstream deviations. This phase establishes the foundation for material selection and process validation.

Formulation

Material science drives the next stage. Based on the validated drawing data and client-specified media (e.g., hydraulic fluids, steam, acids), our rubber formula engineers develop bespoke elastomer compounds. Key considerations include temperature extremes, chemical exposure, and pressure cycles. We prioritize aramid, cellulose, and synthetic fiber reinforcements bonded with nitrile (NBR), EPDM, or PTFE-modified binders. Each formulation targets optimal compression set resistance (< 25% per ASTM F36), tensile strength, and thermal stability. The table below outlines standard performance benchmarks achievable through this phase.

| Specification Category | Standard Value Range | Test Method |

|---|---|---|

| MAX TEMP (Continuous) | -40°C to +300°C | ASTM D2240 |

| MAX PRESSURE | 25 MPa | ASTM F38 |

| MEDIA RESISTANCE | Oils, Steam, Water, Mild Acids | ASTM D471 |

| COMPRESSION SET (22h/150°C) | ≤ 25% | ASTM F36 |

| DENSITY | 1.6–1.9 g/cm³ | ASTM D2240 |

Prototyping

Precision-cut prototypes are manufactured using hydraulic presses at 150–200 MPa pressure and controlled vulcanization cycles. Each sample undergoes rigorous in-house validation: dimensional inspection via CMM (accuracy ±0.05 mm), simulated service testing under actual pressure/temperature profiles, and chemical immersion trials per client media specifications. Failure analysis employs FTIR spectroscopy to identify compound degradation mechanisms. Client approval of functional prototypes is mandatory before tooling release, typically requiring ≤ 3 iterative cycles.

Mass Production

Approved formulations transition to ISO 9001-certified production lines. Raw materials undergo batch traceability via RFID tagging, with real-time monitoring of mixing homogeneity (Mooney viscosity ±2 units) and curing kinetics. Final gaskets are 100% visually inspected for surface defects and sampled per ANSI Z1.4 for dimensional conformance. Every shipment includes a material test report (MTR) validating compression set, tensile properties, and media resistance against the agreed ASTM standards. Suzhou Baoshida maintains ±0.1 mm thickness tolerances and 99.8% on-time delivery for volume orders exceeding 50,000 units.

This closed-loop process ensures non-asbestos gaskets deliver leak-free performance in demanding OEM environments, from automotive turbochargers to chemical processing plants, while adhering to global environmental safety mandates.

Contact Engineering Team

For industrial manufacturers seeking high-performance, reliable sealing solutions, Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered non-asbestos compressed fiber gaskets designed for demanding applications across oil & gas, chemical processing, power generation, and heavy machinery sectors. As a trusted OEM partner in the precision rubber seals category, we combine advanced material science with rigorous quality control to produce gaskets that ensure leak-free performance under extreme temperatures, pressures, and chemical exposures.

Our non-asbestos compressed fiber gasket materials are formulated to meet modern environmental and safety standards, eliminating health risks associated with traditional asbestos-based products while maintaining superior mechanical integrity. These gaskets exhibit excellent resistance to thermal degradation, oil, steam, and a broad range of industrial fluids, making them ideal for flange sealing in pipelines, pumps, valves, and heat exchangers. Each product is manufactured under ISO-certified processes, ensuring dimensional accuracy, consistent density, and long service life in critical operations.

Technical performance is at the core of our engineering approach. Below are key specifications for our standard non-asbestos compressed fiber gasket material:

| Property | Test Method | Value |

|---|---|---|

| Density (g/cm³) | ASTM F1414 | 1.7 – 2.0 |

| Compressibility (%) | ASTM F36 | 12 – 18 |

| Recovery (%) | ASTM F36 | ≥ 45 |

| Tensile Strength (MPa) | ASTM D412 | ≥ 8.0 |

| Fluid Resistance (Oil, Water, Steam) | ASTM D471 | Excellent |

| Maximum Continuous Service Temperature | — | 550°F (288°C) |

| Pressure Rating (Cold) | — | Up to 3,000 psi |

| Asbestos-Free | EN 12764 / ISO 21083 | Yes |

Custom formulations and die-cut geometries are available to meet OEM-specific requirements, including non-standard thicknesses, specialty binders, and enhanced chemical resistance profiles. Our technical team supports clients from prototyping through full-scale production, ensuring seamless integration into existing manufacturing workflows.

To discuss your gasketing needs with our lead engineer and OEM account manager, Mr. Boyce, we invite you to reach out directly. Mr. Boyce brings over 15 years of experience in industrial sealing solutions and is positioned to provide technical consultation, material selection guidance, and sample coordination for qualification testing. Whether you are replacing legacy asbestos gaskets or developing a new sealing specification, Suzhou Baoshida ensures a precision-engineered, compliant, and cost-effective solution.

Contact Mr. Boyce at [email protected] to initiate a technical review, request product data sheets, or arrange sample submissions. We respond to all inquiries within 24 business hours and support global logistics with DDP and JIT delivery options for long-term supply contracts. Partner with Suzhou Baoshida for engineered sealing performance you can trust.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).