Technical Contents

Engineering Guide: O-Rings Lubrication

Engineering Insight: The Critical Role of Material Selection in O-Ring Lubrication

The performance and longevity of an O-ring in dynamic sealing applications are fundamentally influenced by the interaction between the elastomer material and the lubricant used. While lubrication is often viewed as a secondary consideration—applied primarily to reduce friction or aid assembly—its role is far more critical in precision environments. Incompatible material-lubricant pairings can lead to swelling, shrinkage, hardening, or chemical degradation, all of which compromise seal integrity and accelerate failure. This is why off-the-shelf O-ring solutions, while cost-effective and readily available, frequently underperform in demanding industrial applications.

Standard O-rings are typically manufactured from generic elastomers such as NBR (nitrile) or EPDM, designed for broad compatibility rather than optimized performance. When paired with conventional lubricants—especially those containing esters, silicones, or hydrocarbons—these materials may exhibit unpredictable behavior. For example, NBR swells excessively in phosphate ester-based hydraulic fluids, leading to extrusion and increased friction. EPDM, while excellent in water and steam environments, degrades rapidly in contact with mineral oils. These mismatches underscore a fundamental principle: material-lubricant compatibility must be engineered, not assumed.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific formulation. Our precision rubber seals are developed with a systems approach, where the O-ring compound is designed in conjunction with the intended lubricant and operating environment. This includes evaluating base polymer chemistry, filler systems, crosslink density, and additive packages to ensure dimensional stability, consistent modulus, and long-term resilience.

The table below outlines key elastomer-lubricant compatibility characteristics for common industrial pairings:

| Elastomer | Lubricant Type | Swell (%) | Hardness Change (Shore A) | Recommended Use |

|---|---|---|---|---|

| NBR (70 Shore A) | Mineral Oil | +8 to +12 | +3 to +5 | Moderate pressure, general purpose |

| FKM (75 Shore A) | Silicone Oil | +2 to +4 | +1 to +3 | High temperature, aerospace |

| FKM (80 Shore A) | Fluorinated Fluid | -1 to +2 | 0 to +2 | Chemical processing |

| EPDM (70 Shore A) | Water-Glycol | +10 to +15 | -2 to +1 | HVAC, brake systems |

| Silicone (60 Shore A) | Alkylbenzene | +15 to +20 | -5 to -3 | Low-temp, non-pressure |

As illustrated, even within the same elastomer family, responses vary significantly based on formulation and lubricant chemistry. Off-the-shelf O-rings rarely account for these nuances, leading to premature seal failure, unplanned downtime, and increased total cost of ownership.

True reliability in sealing systems is achieved not through component substitution, but through engineered synergy. At Baoshida, we collaborate with OEMs to match compound design with lubrication strategy, ensuring that every O-ring performs as an integrated element of the mechanical system—not merely a replaceable part.

Material Specifications

Material Selection Fundamentals for O-Ring Lubrication Performance

Precision o-ring lubrication efficacy is intrinsically linked to base polymer compatibility with both operating environments and lubricant chemistry. Inadequate material-lubricant pairing induces swelling, hardening, or extraction of plasticizers, directly compromising seal integrity and service life. Suzhou Baoshida Trading Co., Ltd. emphasizes rigorous material validation against application-specific lubricants, particularly for critical static and dynamic sealing scenarios in automotive, aerospace, and industrial hydraulics. The following analysis details three prevalent elastomers—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—focusing on lubrication-critical properties.

Viton fluorocarbon rubber excels in high-temperature and aggressive chemical environments where standard lubricants fail. Its saturated backbone provides exceptional resistance to non-polar lubricants like mineral oils, synthetic hydrocarbons, and phosphate esters. Continuous service up to 230°C necessitates fluorinated or perfluoropolyether (PFPE) greases to prevent degradation. Viton maintains low compression set under thermal stress, ensuring long-term sealing force retention even with intermittent lubricant exposure. However, cost sensitivity and poor compatibility with ketones or low-molecular-weight amines require careful lubricant screening per ASTM D471.

Nitrile butadiene rubber remains the cost-optimized solution for general-purpose hydraulic and pneumatic systems using petroleum-based lubricants. Its acrylonitrile content (typically 34-45%) dictates balance between fuel/oil resistance and low-temperature flexibility. NBR effectively swells 5-15% in ISO VG 32 hydraulic oils, enhancing sealing without excessive deformation. Yet, its limited thermal stability (max 120°C continuous) and susceptibility to oxidation mandate antioxidant-infused lubricants. Avoid silicone-based greases with NBR, as incompatible additives accelerate hardening per SAE AS568 standards.

Silicone rubber offers unparalleled low-temperature performance (-60°C) and biocompatibility but presents unique lubrication challenges. Its polar structure absorbs polar lubricants like silicone oils excessively, causing dimensional instability. Non-polar hydrocarbon greases yield insufficient wetting, increasing friction in dynamic seals. Silicone o-rings require specially formulated methyl-phenyl silicone lubricants to minimize swelling while maintaining lubricity. Critical limitations include poor tear strength and vulnerability to compressed air injection in pneumatic systems, demanding strict lubricant viscosity control.

Comparative Material Specifications for Lubricated O-Ring Applications

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -40 to +120 | -60 to +200 |

| Lubricant Compatibility | PFPE, Fluorinated | Petroleum, Synthetic | Methyl-Phenyl Silicone |

| Swelling in ISO VG 32 Oil | < 5% | 5-15% | > 30% (Unacceptable) |

| Critical Limitation | Amines, Ketones | Ozone, High Temp | Compressed Air, Non-polar Greases |

| ASTM D2000 Reference | FC 7474 | NBR 7074 | VMQ 7070 |

Material selection must integrate lubricant chemistry, dynamic motion parameters, and regulatory constraints. Suzhou Baoshida Trading Co., Ltd. provides OEMs with application-specific lubrication compatibility matrices and accelerated aging protocols per ISO 1817. Partner with qualified seal manufacturers to validate material-lubricant pairs through immersion testing and dynamic seal trials, ensuring zero leakage in mission-critical systems. Precise elastomer formulation remains non-negotiable for achieving optimal lubrication performance and extended service intervals.

Manufacturing Capabilities

Engineering Excellence in Precision Rubber Seal Development

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our reputation in the precision rubber seals industry. With a dedicated team of five certified mould engineers and two specialized rubber formula engineers, we maintain full in-house control over the entire development cycle—from concept and material formulation to tooling design and final product validation. This integrated technical structure enables us to deliver high-performance o-rings tailored precisely to the operational demands of diverse industrial environments.

Our formula engineers possess deep expertise in polymer chemistry and elastomer compounding, allowing for the precise customization of rubber materials to meet specific performance criteria such as temperature resistance, chemical compatibility, compression set, and dynamic sealing behavior. Whether the application calls for Nitrile (NBR), Fluorocarbon (FKM), Silicone (VMQ), Ethylene Propylene (EPDM), or specialty compounds like FFKM or ACM, our team formulates proprietary blends optimized for longevity and reliability under extreme conditions. This scientific approach to material development ensures that every o-ring we produce is not only compliant with international standards (such as ASTM D2000 and ISO 3601) but also engineered for functional superiority in its intended environment.

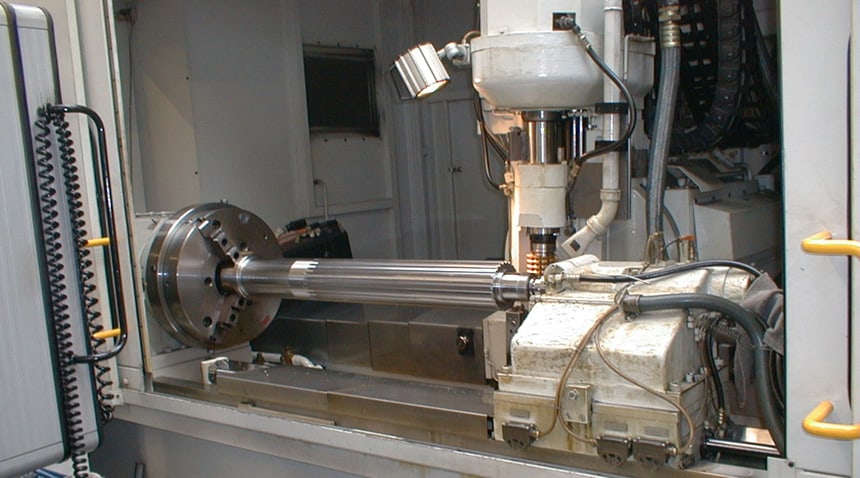

Complementing our material science capability is a robust mould engineering division. Our five experienced mould engineers specialize in precision tooling for o-ring production, utilizing advanced CAD/CAM software and CNC machining to achieve tight tolerances and consistent part geometry. We design and manufacture multi-cavity, cold-runner, and stack moulds optimized for high-volume production efficiency and minimal flash formation. This in-house tooling capacity allows rapid prototyping, faster time-to-market, and full traceability across production batches—critical advantages for OEM partners requiring scalable, repeatable quality.

We support comprehensive OEM services, including custom compound development, technical drawings, 3D modelling, and full documentation packages (DFMEA, PPAP, IMDS, etc.). Our collaborative engineering model ensures seamless integration with client design teams, enabling co-development of sealing solutions that meet exact mechanical, thermal, and regulatory requirements.

The following table summarizes our core technical capabilities and material performance specifications:

| Parameter | Specification / Capability |

|---|---|

| Material Types | NBR, FKM, EPDM, VMQ, ACM, FFKM, CR, IIR, Specialty Blends |

| Hardness Range (Shore A) | 40 to 90 ±5 |

| Temperature Resistance | -60°C to +320°C (depending on compound) |

| Tolerance Compliance | ISO 3601, AS568, JIS B 2401, custom tolerances |

| Mould Design Software | UG, AutoCAD, Moldflow, SolidWorks |

| Production Capacity | 50+ mould sets per month; 10 million+ units monthly |

| Testing Equipment | Tensile tester, aging oven, hardness durometer, compression set apparatus, FTIR analyzer |

Through the synergy of advanced material science and precision tooling engineering, Suzhou Baoshida delivers o-rings that exceed performance expectations in automotive, aerospace, medical, and industrial automation sectors. Our commitment to technical rigor ensures every product is a benchmark in sealing reliability.

Customization Process

Precision O-Ring Lubrication Customization Process: Engineering for Sealing Integrity

At Suzhou Baoshida Trading Co., Ltd., our OEM-driven customization process for lubricated o-rings begins with rigorous drawing analysis. We dissect client-provided technical schematics to identify critical parameters including groove geometry, surface finish tolerances, and dynamic motion profiles. This phase leverages CAD cross-referencing and finite element analysis (FEA) to predict compression set behavior under operational loads. We specifically evaluate lubrication retention requirements against media exposure—whether hydraulic fluids, refrigerants, or aggressive chemicals—to determine optimal lubricant distribution channels within the seal cross-section. Misalignment here risks extrusion or accelerated wear; thus, we validate all dimensional interactions against ISO 3601 standards before progression.

Formulation engineering follows, where our rubber chemists select base polymers (FKM, EPDM, or custom HNBR blends) compatible with both the operating environment and lubricant chemistry. Key considerations include lubricant solubility parameters to prevent swelling-induced seal distortion and thermal stability thresholds to avoid lubricant degradation at peak temperatures. We prioritize low-volatility synthetic esters or perfluoropolyethers (PFPEs) for aerospace applications, while automotive clients receive NSF H1-compliant silicone oils for food-contact safety. Each compound undergoes dynamic mechanical analysis (DMA) to confirm storage modulus retention across -55°C to +230°C ranges, ensuring lubricant remains effective during thermal cycling.

Prototyping employs iterative molding trials using client-specified cavity tools. We measure lubricant migration rates via gravimetric analysis after 72-hour immersion in target media, adjusting formulation viscosity to achieve equilibrium within 48 hours. Prototype validation includes ASTM D1414 compression set testing at 100% squeeze and ISO 2230 rotary shaft testing at 2 m/s surface velocity. Clients receive detailed tribological reports quantifying friction coefficients and wear rates—critical for applications demanding low breakaway torque in precision hydraulics.

Mass production integrates statistical process control (SPC) at every stage. O-rings are lubricated via automated dip-spin systems calibrated to ±0.5% weight consistency, with inline infrared spectroscopy verifying uniform coating thickness. Final inspection uses vision systems to detect lubricant pooling or voids, while batch traceability links each part to its formulation certificate and accelerated aging data. All lubricated seals undergo 100% dimensional verification per AS568C and functional pressure testing to 1.5× rated system pressure.

Critical Lubrication Performance Specifications

| Parameter | Target Range | Test Method | Industrial Relevance |

|---|---|---|---|

| Kinematic Viscosity (40°C) | 50–200 cSt | ASTM D445 | Ensures film stability under shear |

| Pour Point | ≤ -45°C | ASTM D97 | Prevents cold-start seizure |

| Volatility (200°C/1hr) | ≤ 5% mass loss | ASTM D972 | Minimizes long-term lubricant depletion |

| Base Polymer Compatibility | Zero swelling | ISO 1817 | Maintains seal dimensional integrity |

| Friction Coefficient | 0.08–0.15 (vs. steel) | ISO 8295 | Reduces energy loss in dynamic systems |

This end-to-end workflow—grounded in material science and validated through application-specific testing—guarantees lubricated o-rings that extend service life while meeting OEM assembly and performance mandates. Suzhou Baoshida’s engineering rigor transforms sealing challenges into reliability benchmarks.

Contact Engineering Team

For precision-critical applications in aerospace, automotive, medical devices, and industrial automation, the performance of rubber o-rings is not solely determined by material or geometry—lubrication plays a decisive role in longevity, sealing integrity, and operational efficiency. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber sealing solutions where every detail, from compound formulation to surface interaction, is optimized for real-world performance. Our expertise extends beyond manufacturing to include technical guidance on proper lubrication protocols tailored to specific elastomers, operating environments, and media exposure.

O-ring lubrication reduces friction during installation and operation, prevents extrusion and wear, enhances sealing under dynamic conditions, and mitigates the risk of premature failure due to stick-slip phenomena. However, selecting the correct lubricant is not a one-size-fits-all process. Compatibility between the lubricant base (silicone, PAG, perfluoropolyether, etc.) and the elastomer (NBR, FKM, EPDM, etc.) is critical. Incompatible combinations can lead to swelling, softening, hardening, or cracking—compromising the entire sealing system. Additionally, temperature range, pressure cycles, exposure to fluids or gases, and cleanliness requirements (e.g., FDA, USP Class VI) must all be evaluated before specifying a lubricant.

At Suzhou Baoshida, we support our clients with data-driven recommendations backed by material testing, OEM specifications, and field validation. Whether you are sealing hydraulic systems in heavy machinery or designing life-support equipment requiring biocompatible materials, our engineering team ensures that lubrication strategies are fully integrated into the seal design process.

To assist in selection, the following table outlines common elastomer-lubricant pairings and their performance characteristics under typical industrial conditions:

| Elastomer | Recommended Lubricant Type | Temperature Range (°C) | Key Applications | Notes |

|---|---|---|---|---|

| NBR (Nitrile) | PAG-based, Silicone | -30 to +120 | Hydraulics, Pneumatics | Good resistance to oils; avoid chlorinated hydrocarbons |

| FKM (Viton®) | PFPE-based, Silicone | -20 to +200 | Aerospace, Chemical Processing | Excellent chemical and heat resistance |

| EPDM | Silicone, Soap-based | -50 to +150 | Water, Steam Systems | Not suitable for mineral oils |

| Silicone (VMQ) | Silicone Grease | -60 to +180 | Medical, Food Processing | Biocompatible options available |

| FFKM (Perfluoroelastomer) | PFPE-based | -15 to +300 | Semiconductor, Ultra-High Purity | Highest chemical resistance; high cost |

These recommendations serve as a starting point. Final validation must consider system-specific variables.

For technical support in o-ring lubrication strategy, material selection, or custom formulation development, contact Mr. Boyce at Suzhou Baoshida Trading Co., Ltd. With over 15 years of experience in precision rubber seals and OEM collaboration, we provide responsive, expert consultation to ensure your sealing systems perform reliably under demanding conditions.

Reach out directly via email at [email protected] to initiate a technical discussion, request sample data, or submit an application-specific inquiry. Our team responds within 24 business hours. Partner with Suzhou Baoshida for engineering-grade solutions where performance, consistency, and precision matter.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).