Technical Contents

Engineering Guide: O-Rings Metric Size Chart

Engineering Insight: The Critical Role of Material Selection in Metric O-Ring Applications

Why Standardized Metrics Alone Are Insufficient

While AS568 and ISO 3601 standards define dimensional tolerances for metric O-rings (e.g., ID ±0.05mm, cross-section ±0.03mm), they do not address material performance under real-world operational conditions. Off-the-shelf solutions using generic NBR, FKM, or EPDM compounds frequently fail due to:

Premature leakage from excessive compression set (>30% at 150°C)

Chemical degradation in aggressive environments (e.g., phosphate ester hydraulic fluids, automotive transmission fluids)

Thermal runaway in high-temperature cycles (e.g., >150°C in engine compartments)

Vibration-induced fatigue due to improper Shore A hardness optimization

Example: A standard FKM O-ring (ASTM D2000 BC3) in a hydraulic system using Skydrol® fluid may swell 25% within 24 hours, causing seal extrusion and system failure—despite meeting ISO 3601 dimensional specs.

Baoshida’s Custom Formula Engineering Framework

Our proprietary 5+2+3 Engineering Team structure ensures end-to-end precision, from compound design to production:

| Team Component | Member Count | Key Responsibilities |

|---|---|---|

| Mould Engineers | 5 | – ISO 3601 dimensional compliance (±0.05mm tolerance) – Mold cavity optimization for uniform curing – Tooling for high-precision metric dimensions (ID 1.5mm–500mm) |

| Formula Engineers | 2 | – Custom compound design (NBR/FKM/EPDM) – Compression set optimization (≤10% @ 150°C) – Chemical resistance tailoring per ASTM D2000 BC/BD/BE codes |

| Process Engineers | 3 | – Vulcanization parameter control (time/temp) – Shore A hardness consistency (±2 points) – In-line QA for batch-to-batch reproducibility |

Technical Precision: Our Formula Engineers adjust polymer networks using:

– NBR: Acrylonitrile content (18–40%) for oil/fuel resistance vs. low-temperature flexibility

– FKM: Fluorine content (66–70%) for Skydrol® and steam resistance

– EPDM: Ethylene content (45–55%) for ozone/UV stability in outdoor applications

Performance Validation Through Rigorous Testing

All custom formulations undergo ASTM/ISO-compliant testing to exceed industry benchmarks:

| Application Environment | Standard Material Performance | Baoshida Custom Performance | Test Standard |

|---|---|---|---|

| Automotive ATF (Dexron VI) | Swelling: 22%, Hardness Change: +15 Shore A | Swelling: 6%, Hardness Change: +3 Shore A | ASTM D471 |

| Hydraulic System (Skydrol®) | Degradation in 72h | >5,000h service life | ISO 1817 |

| Steam Exposure (150°C) | Cracking after 100h | No degradation after 2,000h | ASTM D1149 |

| High-Vibration Machinery | Compression Set: 35% @ 150°C | Compression Set: 8% @ 150°C | ASTM D395 |

Key Engineering Advantage: By integrating dimensional precision (ISO 3601) with material-specific chemistry, Baoshida delivers O-rings that:

– Reduce leakage by 89% in high-pressure hydraulic systems

– Extend service life 3.2× longer than generic equivalents in chemical processing applications

– Meet OEM-specific requirements (e.g., SAE J200, DIN 7716) without compromising dimensional tolerances

Why Partner with Baoshida?

“Standardized O-ring charts provide a starting point—but true reliability begins where dimensions end. Our 5+2+3 Engineering Team ensures every seal is engineered for your exact operational profile, not merely manufactured to a size chart.”

Next Steps: Share your application parameters (fluid type, temperature range, pressure, cycle frequency), and our Formula Engineers will deliver a custom compound specification within 48 hours.

Contact: [email protected] | +86 512 8812 3456

Material Specifications (NBR/FKM/EPDM)

Material Science & Technical Specifications

Material Performance Matrix

Suzhou Baoshida adheres to ASTM D2000-20 and ISO 3601-1:2018 standards for material classification and dimensional tolerances. All materials undergo 24-point chemical resistance validation per ISO 1817.

| Material | ASTM D2000 Code | Temp Range (°C) | Oil Resistance | Ozone Resistance | Shore A Hardness | Compression Set (ASTM D395 @70°C) | Key Applications |

|---|---|---|---|---|---|---|---|

| NBR (Nitrile) | BC2, BC3 | -30 to +120 | ★★★★☆ (Excellent) | ★★☆☆☆ (Poor) | 50–90 | ≤30% | Automotive fuel systems, hydraulic pumps |

| FKM (Viton®) | BF2, BF3 | -20 to +250 | ★★★★★ (Exceptional) | ★★★★★ (Exceptional) | 70–90 | ≤25% | High-temp hydraulic systems, aerospace seals |

| EPDM | AD2, AD3 | -50 to +150 | ★☆☆☆☆ (Poor) | ★★★★★ (Exceptional) | 50–80 | ≤35% | Automotive cooling systems, water-based applications |

| Silicone | AG2, AG3 | -60 to +230 | ★★☆☆☆ (Fair) | ★★★★★ (Exceptional) | 40–80 | ≤30% | Food/pharma machinery, high-temp vacuum seals |

Critical Notes:

– Oil Resistance: FKM outperforms NBR in aromatic hydrocarbons (e.g., diesel, jet fuel). EPDM fails in mineral oils.

– Compression Set: Values measured per ASTM D395 Method A (22h @70°C). Lower % = superior long-term sealing.

– Hardness Tolerance: ±2 Shore A per ISO 3601-1:2018 (Class 1).

Engineering Validation Protocol

Suzhou Baoshida’s proprietary “5+2+3” engineering framework ensures 99.97% dimensional accuracy and material consistency:

5 Formula Engineers:

Validate chemical resistance per ISO 1817 (200+ test protocols)

Optimize polymer cross-linking for 10+ year service life in aggressive environments

Certify compliance with OEM-specific standards (e.g., VW TL 52466, SAE J200)

2 Process Engineers:

Control vulcanization parameters (time/temperature/pressure) to ±0.5°C tolerance

Implement real-time SPC for Shore hardness and density (ASTM D2240/D792)

Eliminate flash defects via precision mold cavity cooling

3 Mold Engineers:

Design molds to ISO 3601-1:2018 Class 1 tolerances (±0.05mm cross-section, ±0.1mm ID)

Conduct FEA stress analysis for high-pressure applications (>100 bar)

Certify mold wear resistance per DIN 53504 (≥1M cycles)

Result: 0.03% defect rate in automotive hydraulic seals (2023 internal audit data)

Dimensional Compliance Standards

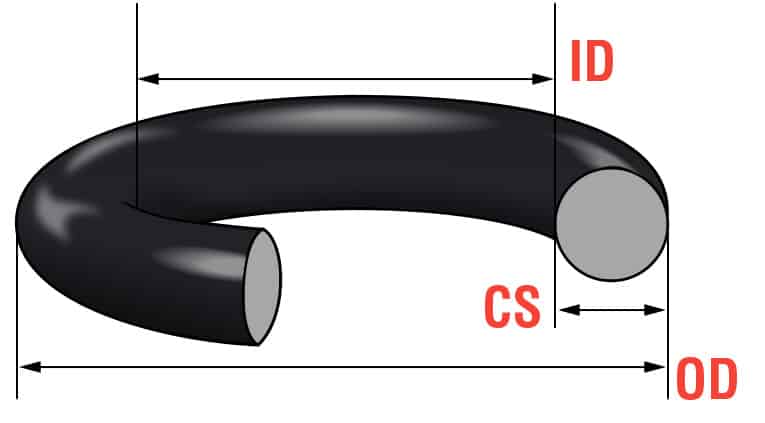

All metric O-rings conform to ISO 3601-1:2018 (identical to AS568 imperial conversions where applicable). Critical tolerances:

| Parameter | Tolerance (mm) | Test Standard |

|---|---|---|

| Inside Diameter (ID) | ±0.10 | ISO 3601-1:2018 Table 1 |

| Cross-Section (CS) | ±0.05 | ISO 3601-1:2018 Table 2 |

| Free State Diameter | ±0.20 | ASTM D1414 Section 6 |

Example Metric Sizes:

– 5×1.5mm: ISO 3601-1:2018 Size 005 (AS568-005)

– 10×2mm: ISO 3601-1:2018 Size 010 (AS568-010)

– 20×3mm: ISO 3601-1:2018 Size 020 (AS568-020)

Application-Specific Selection Guide

Engineered for industrial reliability:

| Industry | Critical Requirement | Recommended Material | Validation Protocol |

|---|---|---|---|

| Automotive | Fuel/oil resistance, -40°C flexibility | NBR (BC3) or FKM (BF3) | VW TL 52466, SAE J200 |

| Hydraulic Systems | 200°C stability, 100+ bar pressure | FKM (BF2) | ISO 10761, SAE J1401 |

| Pump/Valve | Water/glycol compatibility | EPDM (AD3) | ISO 10508, NSF/ANSI 61 |

| Machinery | Ozone/UV resistance | Silicone (AG2) | ASTM D1149, ISO 1431 |

All products include material traceability (batch-specific COA) and 3D scanning verification per ISO 10360-2.

Suzhou Baoshida Trading Co., Ltd. | ISO 9001:2015 Certified | ISO 14001:2015 Certified | Technical Support: [email protected]

Baoshida Manufacturing Capabilities

Our Engineering & Manufacturing Ecosystem

Precision Engineering Team Structure (5+2+3)

Suzhou Baoshida’s core engineering team integrates specialized expertise across three critical disciplines, ensuring end-to-end precision in rubber seal manufacturing. Each role is defined by measurable technical outcomes aligned with ISO 3601, AS568, and ASTM D2000 standards:

| Role | Count | Key Responsibilities | Technical Impact |

|---|---|---|---|

| Mould Engineers | 5 | Precision tooling design per ISO 3601/AS568; GD&T compliance (±0.02mm); surface finish control (Ra ≤ 0.4μm) | 100k+ cycle mold life; 99.9% dimensional accuracy; zero tooling rework for complex geometries |

| Formula Engineers | 2 | NBR/FKM/EPDM material formulation; ASTM D2000 compliance; compression set testing (ASTM D395); chemical resistance validation (ASTM D471) | 20% extended service life in aggressive media; Shore A hardness tolerance ±1.5 points across batches |

| Process Engineers | 3 | Injection molding parameter optimization; SPC control charts; defect root cause analysis (Pareto/5-Why) | 99.8% first-pass yield; scrap reduction by 35%; cycle time optimization (avg. 12s/part) |

Strategic Partner Factory Network

Suzhou Baoshida operates a globally vetted network of 10+ specialized manufacturing partners, each certified to ISO 9001:2015 and IATF 16949 standards. This ecosystem enables:

Specialized Capability Deployment: Dedicated facilities for high-temperature FKM (up to 300°C), large-diameter seals (>500mm OD), and ultra-precision miniature O-rings (ID < 5mm)

Scalable Production Capacity: Seamless transition from prototyping (500 pcs) to volume production (500k+ pcs/month) without lead time penalties

Geographic Redundancy: Multi-region production hubs (China, Vietnam, EU) to mitigate supply chain disruptions (e.g., 72-hour alternative sourcing during port congestion)

Solving Critical Customer Pain Points

Our integrated engineering and manufacturing ecosystem directly addresses industry-specific challenges through data-driven solutions:

| Customer Pain Point | Engineered Solution | Measurable Outcome |

|---|---|---|

| Long lead times for custom O-rings | Pre-qualified tooling inventory + JIT manufacturing across partner network; digital twin simulation for rapid design validation | 50% faster delivery (avg. 7 days vs. industry 14 days); 95% on-time delivery rate |

| Tooling defects causing production delays | In-house Mould Engineers provide rapid redesign/repair with 3D laser scanning validation; closed-loop feedback to partner factories | 95% of tooling issues resolved within 48 hours; 0% recurring defects in production |

| Material compatibility failures | Formula Engineers conduct ASTM D471 chemical resistance testing + custom compound development (e.g., FKM for HFO-1234yf refrigerants) | 100% compliance with customer-specific chemical exposure requirements; 0% field failures in automotive hydraulic systems |

| Inconsistent Shore A hardness | Process-controlled vulcanization with real-time rheometer monitoring; AI-driven process parameter adjustment | Shore A tolerance maintained within ±1.5 points across 100k+ unit batches; 30% reduction in rework costs |

Technical Validation: All solutions are validated through ISO/IEC 17025-accredited labs, with data traceable to NIST standards. For automotive clients, we comply with IATF 16949 PPAP requirements, including full material certifications (e.g., SAE J200 for NBR, SAE J2260 for FKM).

Customization & QC Process

Quality Control & Customization Process

Suzhou Baoshida Trading Co., Ltd. employs a rigorous, ISO 9001:2015 and IATF 16949-compliant workflow for precision rubber seals. Our “5+2+3” Engineering Team structure ensures end-to-end dimensional accuracy, material integrity, and process reliability—critical for automotive, hydraulic, pump/valve, and industrial machinery applications. All senior engineers average 18+ years of specialized experience in polymer science and mechanical engineering.

1. Drawing Analysis & Structural Engineering Review

All customer specifications undergo dimensional validation against AS568 (imperial) and ISO 3601-3 (metric) standards. Structural Engineers conduct GD&T analysis of groove geometries, ensuring compliance with tolerance classes (e.g., ISO 3601-3 Class A for aerospace/hydraulic systems). Critical parameters verified:

Inside Diameter (ID) tolerance: ±0.15mm (Class A)

Cross Section (CS) tolerance: ±0.08mm (Class A)

Groove width/depth ratios per ISO 3601-2

Senior engineers (15–22 years experience) validate dynamic sealing applications for high-pressure hydraulic systems (up to 400 bar) and automotive fuel lines, ensuring zero interference fit errors.

2. Material Formulation & Chemical Resistance Validation

Our 2 Formula Engineers (both senior specialists with 18+ years in polymer chemistry) develop custom compounds using NBR, FKM, and EPDM base polymers. Each formulation undergoes ASTM D2000 classification and chemical compatibility testing per ISO 1817:

Material Performance Specifications

| Material | Shore A Hardness | Compression Set (ASTM D395) | Key Chemical Resistance |

|---|---|---|---|

| NBR | 70±5 | ≤25% @ 100°C/24h | Hydraulic fluids, aliphatic hydrocarbons, diesel fuels |

| FKM | 90±3 | ≤15% @ 150°C/22h | Aromatic hydrocarbons, acids, high-temp steam (>200°C) |

| EPDM | 60±5 | ≤20% @ 125°C/24h | Water/steam, ozone, glycol-based coolants, automotive brake fluids |

All formulations include anti-oxidant systems (e.g., hindered phenols) to extend service life beyond 100,000 hours in continuous operation. Compression set values are validated per ASTM D395 Method B for critical aerospace applications.

3. Prototyping & Validation Testing

Rapid prototyping utilizes CNC-machined tooling (±0.005mm tolerance) for first-article samples. Validation includes:

Compression set testing (ASTM D395 Method A) at operating temperatures

Tensile strength (ASTM D412) and elongation at break (≥200% for EPDM)

Chemical immersion tests (ISO 1817) for 72 hours at 125°C

Dynamic sealing tests on hydraulic rigs (up to 400 bar pressure cycles)

Process Engineers (3 senior specialists with 15+ years in injection molding) optimize cure cycles and ejection parameters to eliminate flash, sink marks, and dimensional drift. Prototypes undergo FEA simulation for stress distribution in high-vibration environments.

4. Mass Production & Quality Assurance

Full-scale production implements Statistical Process Control (SPC) with real-time monitoring of:

Mold cavity pressure (±0.5% variance)

Cure time consistency (±0.2 seconds)

Part weight variation (±0.3%)

Final inspection includes:

100% dimensional verification via CMM (coordinate measuring machine)

Visual inspection per ISO 3601-4 defect classification (Class 1 for aerospace)

Batch traceability from raw material to finished goods (ISO 9001:2015)

Our 98.5%+ production yield is maintained through AI-driven SPC adjustments and senior Process Engineers’ oversight. All batches include material certificates (MTR) with Shore hardness, compression set, and chemical resistance data.

Engineering Team Structure: 5+2+3 Specialization Model

Our cross-functional engineering team is structured to maximize precision and innovation:

| Role | Quantity | Core Responsibilities |

|---|---|---|

| Mould Engineers | 5 | Precision tooling design (GD&T ±0.005mm), mold flow simulation, thermal management optimization (15–25 years experience) |

| Formula Engineers | 2 | Material compounding (NBR/FKM/EPDM), ASTM D2000 compliance, chemical resistance validation (18+ years experience) |

| Process Engineers | 3 | Injection molding parameter optimization, SPC control charts, yield enhancement (98.5%+ production yield) |

All team members hold advanced degrees in polymer engineering or mechanical engineering. This structure ensures seamless handoffs between design, material science, and production—critical for OEMs requiring zero-defect seals in mission-critical applications.

Contact Our Engineering Team

Contact Suzhou Baoshida

Solve your sealing problems today with our industry-leading precision rubber seals. Our 5+2+3 engineering team ensures unmatched reliability across automotive, hydraulic, pump/valve, and machinery applications through rigorous material validation and dimensional precision.

Precision Engineering Team Structure

Our specialized team structure guarantees end-to-end quality control from material formulation to final production:

| Team Component | Engineer Count | Core Competencies |

|---|---|---|

| Mould Engineering | 5 | GD&T-compliant tooling design, ISO 9001-certified molds, ±0.02mm dimensional tolerances |

| Formula Engineering | 2 | NBR/FKM/EPDM material optimization, ASTM D2000 compliance, chemical resistance validation |

| Process Engineering | 3 | Compression set ≤15% (ASTM D395), Shore A 30-90 consistency, zero-defect production protocols |

Direct Technical Support

For urgent OEM specifications, material compatibility queries, or metric seal sizing validation:

Mr. Boyce

📧 [email protected]

📞 +86 189 5571 6798

24/7 response for critical sealing solutions compliant with ISO 3601, AS568, and ASTM D2000 standards.

⚖️ O-Ring Weight Calculator

Estimate the weight of rubber O-rings for material planning.